Sound Skulptor Switcher-2 User manual

www.soundskulptor.com

Document revision 1.3 – Last modification : 09/10/14

Switc er-2 Assembly guide

Safety warning

T e kits are main powered and use potentially let al voltages. Under no circumstance s ould someone undertake t e

realisation of a kit unless e as full knowledge about safely andling main powered devices.

Please read t e “DIY guide” before beginning.

Print or open t e following documents :

• Switc er-2 Sc ematics

• Switc er-2 Components layout

• Switc er-2 Parts list

Follow t is guide from item number 1 till t e end, in t is order. T e assembly order is based on components eig t, from

low to ig profile, in order to ease t e soldering process : T e component you are soldering is always taller t an t e

previously assembled ones and it is pressing nicely against t e work area foam.

Switc er-2 Assembly guide – Main PCB

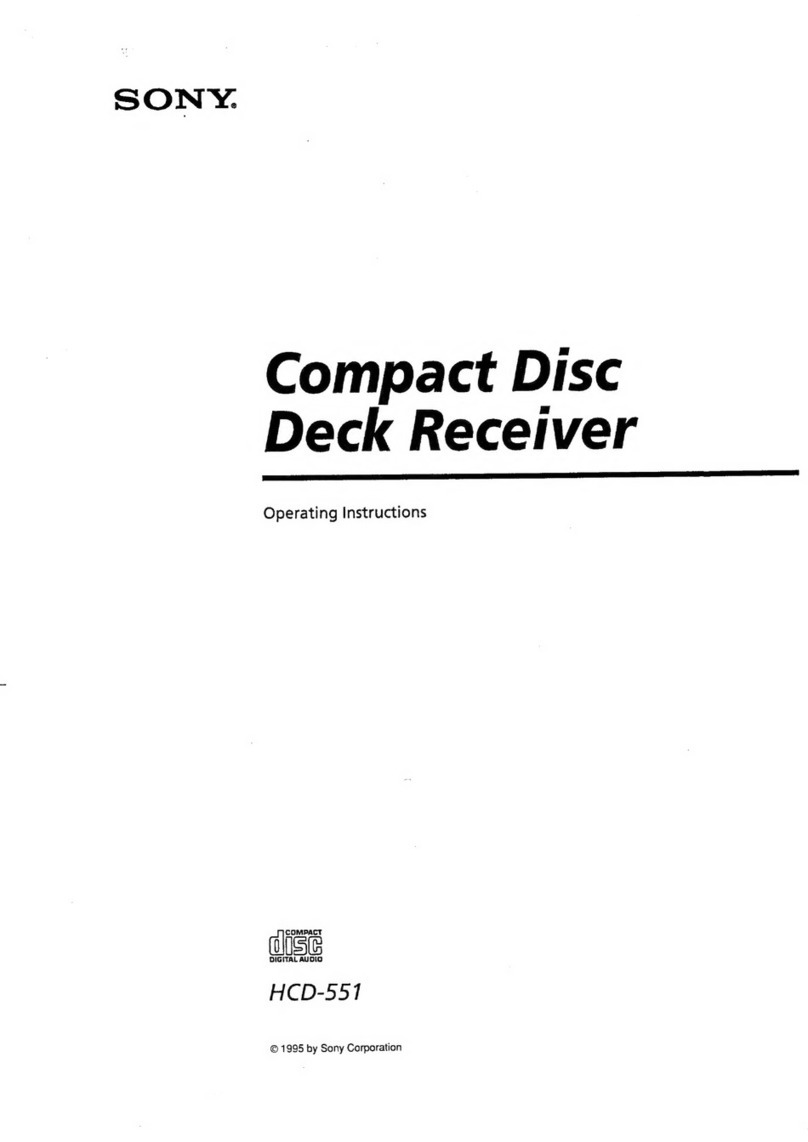

1. Ceramic capacitors

Add C4, C5, C7, C8.

C3 w ic is placed

under

t e PCB will be installed later.

2. Resistors

Add R1 to R5 and R8. R7 will be installed later in order to leave an easy access for soldering t e

transformer.

T e resistors are installed vertically.

Warning : It is very important to c eck t e resistors value wit a DMM because t e colour code can be

ambiguous. For example 1K (brown-black-black-brown-brown) can be confused wit 110R (brown-brewn-

black-black-brown).

Copyrig t ©2013 to Today SoundSkulptor

www.soundskulptor.com

Document revision 1.3 – Last modification : 09/10/14

Switc er-2 Assembly guide – Main PCB

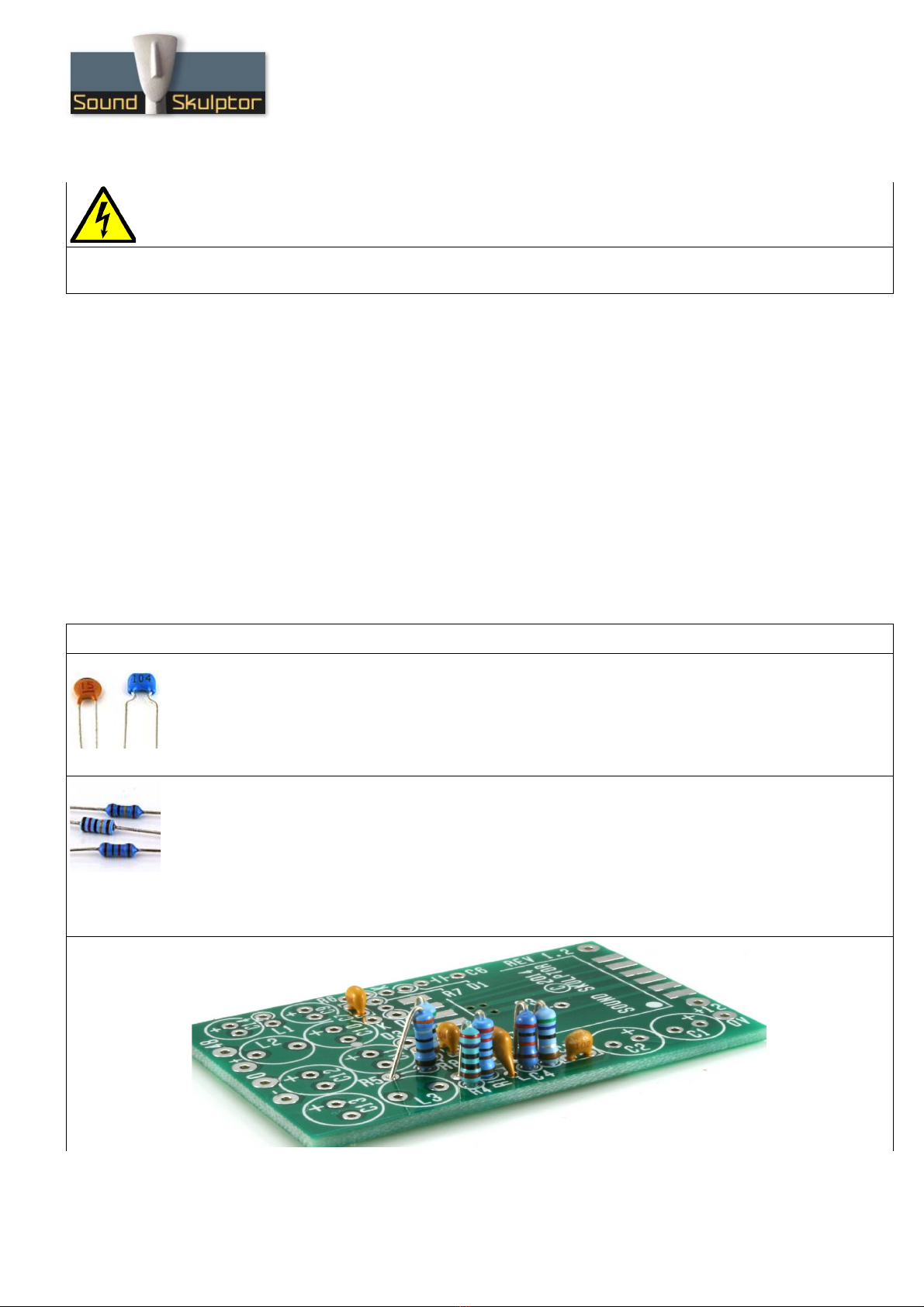

3. Ceramic capacitor C3

Add C3

under

t e PCB.

Cut t e leads ultra s ort.

4. Copper s orted turn

In order to reduce t e transformer radiations we will add a

copper foil turn around t e outside of t e transformer.

Start by redrawing t e dot on t e top of t e transformer, a

little furt er in t e corner because t e original will be idden

by t e foil.

Partially remove t e backing tape from t e ad esive copper

foil and place it on t e top of t e transformer, as s own on

t e picture. Make a full w ile removing t e backing tape.

Solder t e two ends to electrically close t e loop.

5. Transformer soldering

Apply a small quantity of solder on one of t e transformer PCB

pads.

Position t e transformer, making sure t e dot is in t e correct

place and reflow t e pad solder to lock t e transformer. Adjust

until all t e transformer pins are all well centred on t eir respective

pad. Solder one pin on t e opposite row. W en t e position is

correct, solder all t e pins.

6. Resistor R7 & diodes D2, D3

Add R7 and diodes D2, D3.

T e R7 silk-screen writing is idden by t e transformer. It is

adjacent to C7 and D2.

T e diodes are also placed vertically, cat ode on top. Bend t e

cat ode lead (marked by a ring on t e diode body).

Warning : Make sure to respect t e direction of t e diodes. T e

cat ode side is marked by a K on t e PCB.

7. Radial inductors

Add L2, L3.

8. Electrolytic capacitors

Add C1, C2, C10 to C13.

Solder one lead first, adjust verticality t en solder t e second lead.

Warning : T e +lead must go into t e + ole. Do not reverse (t ey may explode !)

Warning : Make sure t e caps are inserted as low as possible because t ey define t e eig t of t e

module.

Copyrig t ©2013 to Today SoundSkulptor

www.soundskulptor.com

Document revision 1.3 – Last modification : 09/10/14

Switc er-2 Assembly guide – Main PCB

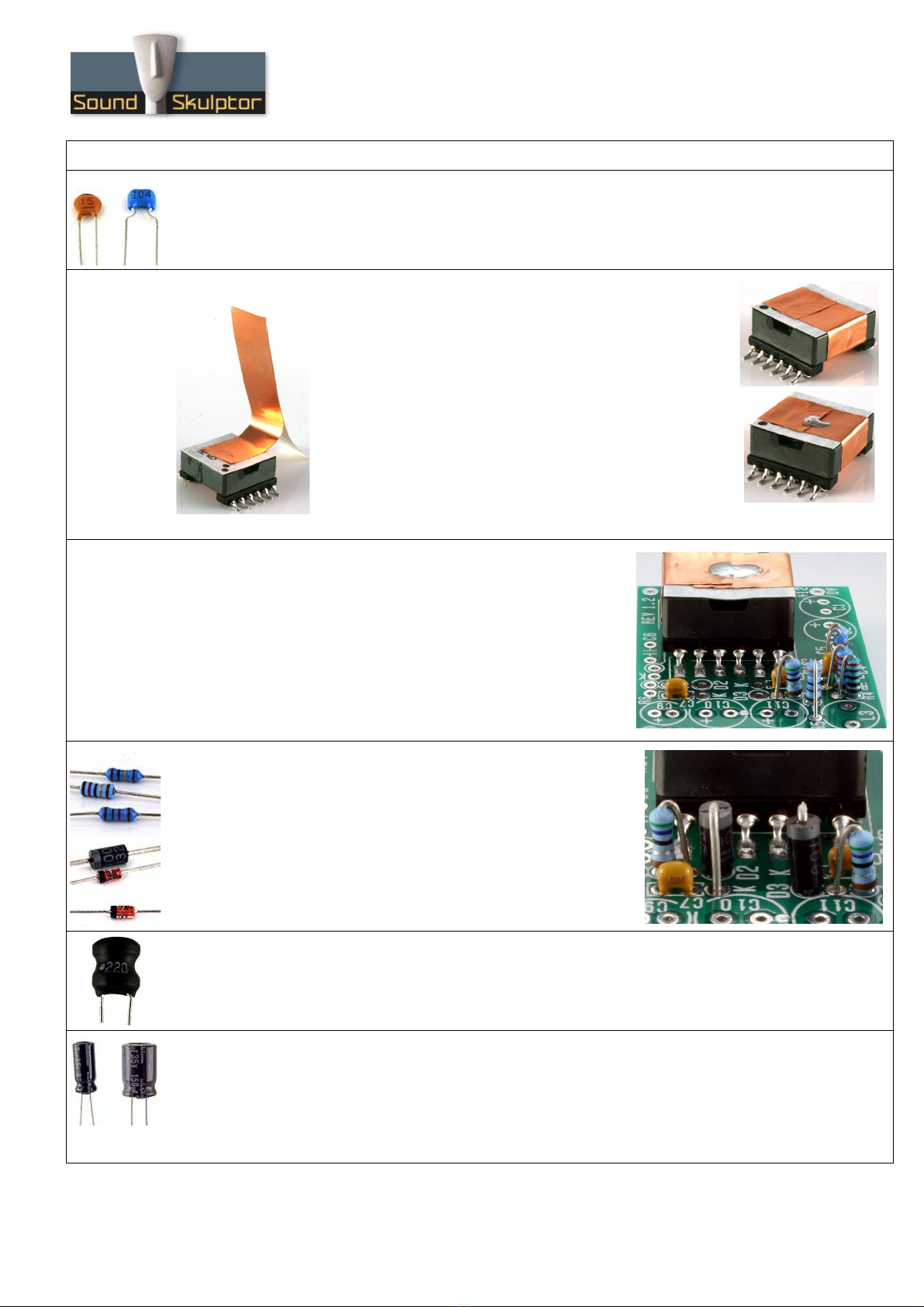

9. LM2586

T e LM2586 is soldered on t e back side of t e PCB.

It is a surface mount component wit relatively close pins. In order to make

t e soldering process easier, we are going to c eat a little:

Lift pins 4 and 6 (counting from t e left) and cut t em off.

And gently bend pin 1 towards t e left.

T is gives us a good iron access to eac pin.

10. Soldering t e LM2586

Put a small quantity of solder on t e rig tmost pad. Place t e IC and

reflow t e solder, adjusting t e position until all t e pins are centred on

t eir respective pad.

Once in position, solder t e ot er pins.

Do not forget t at a bad solder joint is almost always caused by too

muc solder.

Last t ing is to solder t e IC top tab to t e PCB. Start by eating t e

metal tab until t e solder flows and goes down to t e PCB.

11. Connecting pins

Insert t e 7 long pins from t e solder side and solder. It is

necessary to put a little pressure on t e pins to insert t em all

t e way down.

Copyrig t ©2013 to Today SoundSkulptor

www.soundskulptor.com

Document revision 1.3 – Last modification : 09/10/14

Switc er-2 Assembly guide – Main PCB

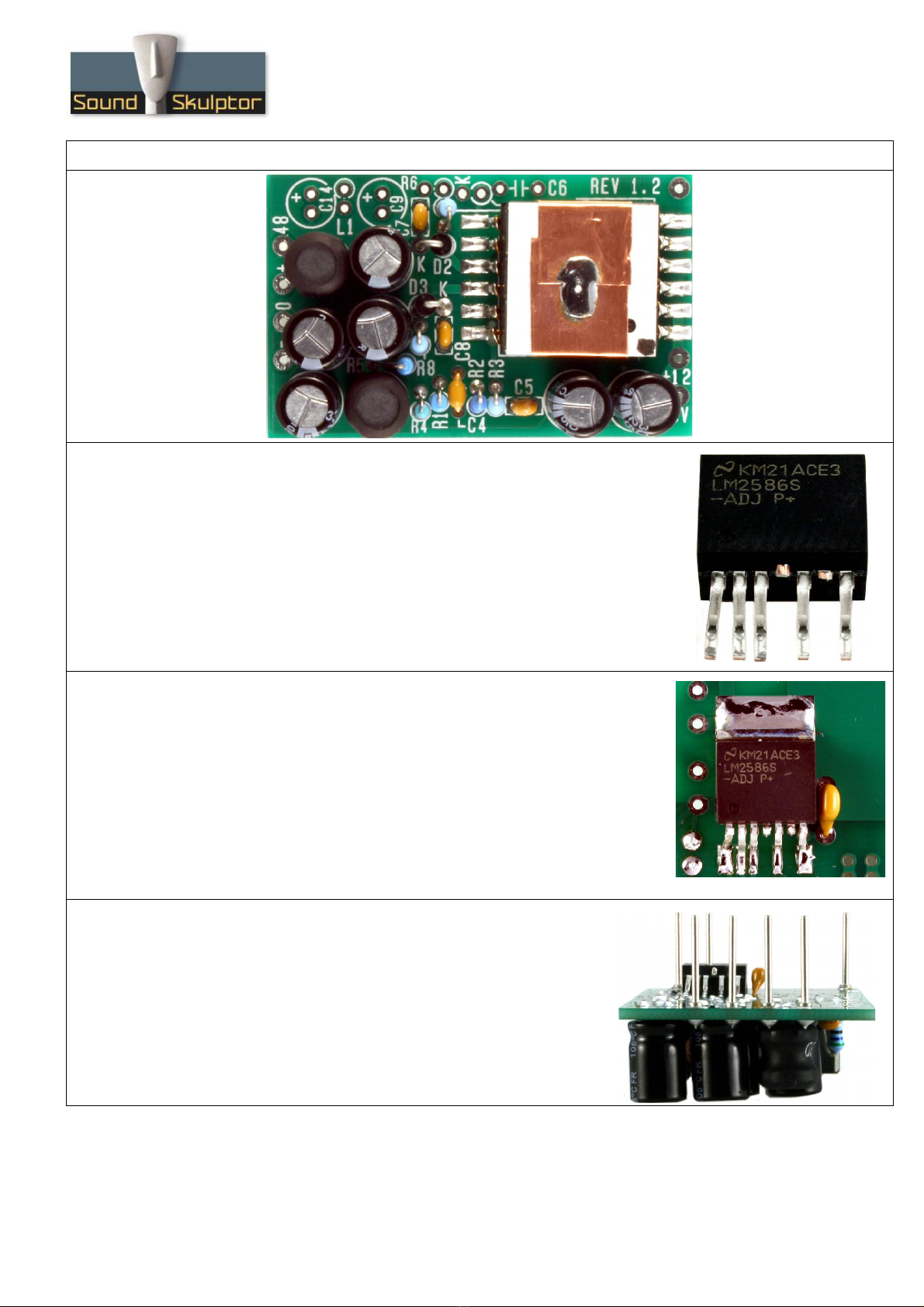

12. Spacer

Stick t e rubber spacer on t e Switc er3 PCB,

at t e position s own on t e picture, between

t e solder pads.

Switc er-2 Quick testing

T e switc er can be tested directly in t e SK501 module but it is a good idea to c eck it alone if you can. W at you

need is a 12V DC source and a voltmeter.

Connect t e 12V source between t e (+12)

and (0V) supply pins (near transformer) and

connect t e voltmeter between t e (0) and

(+) pins on t e output side.

After powering, you s ould read

+19 to 20Volts on t e (+) pin,

-19 to -20Volts on t e (-) pin,

T e full test requires pulling current and will be

done in t e MC624.

Switc er-2 Assembly guide – S ield

1. PCB split

Split t e s ield PCB into 6 pieces.

2. PCB split

Break t e 2 sides along t e ole line and smoot out t e jagged side by rubbing it on

a piece of sand paper.

Copyrig t ©2013 to Today SoundSkulptor

www.soundskulptor.com

Document revision 1.3 – Last modification : 09/10/14

Switc er-2 Assembly guide – S ield

3. Soldering side A

Use a tool wit a s arp rig t angle, like a ruler or an aluminium profile to elp

position t e sides. Place t e top side flat on t e table (“Sound Skulptor”

facing down) and t e (A) labelled side at a 90° angle. (A) edge against (A)

edge. T e vertical panel rests on t e table, not on t e top panel. Solder t e

centre pad. Reflow t e solder until t e 2 panels are perfectly lined and at 90°

t en solder t e next 2 pads.

4. Soldering side B

Repeat t e same operation for side B

5. Soldering sides C and D

Position t e C side against t e assembly and

solder t e centre pad.

Next solder t e 2 low corners. Do not solder t e

top angles yet.

Repeat for t e D side.

Copyrig t ©2013 to Today SoundSkulptor

www.soundskulptor.com

Document revision 1.3 – Last modification : 09/10/14

Switc er-2 Assembly guide – S ield

6. Switc er-S ield assembly

Warning: T is must be done after t e switc er as been fully tested in t e

MC624.

Insert t e switc er PCB into t e s ield, making sure t e pins position

follows t e s ield top writing.

C eck t at t e PCB is orizontal and solder t e connecting pad on t e

side.

7. Closing t e s ield

Place t e closing side over t e switc er PCB. C eck t at it is

orizontal and regularly recessed t en solder t e pads.

Copyrig t ©2013 to Today SoundSkulptor

Table of contents

Other Sound Skulptor Stereo System manuals