EM-10 E-Keeper latch System

Operating Instructions

Applicable models

EM-10-1X-410 Series front mount latch bolt

EM-10-2X-410 Series side mount latch bolt

EM-10-3X-410 Series side mount latch bolt

EM-10-4X-410 Series dead bolt latch bolt

Electrical specifications and requirements:

To operate the latch, it must be properly connected or wired for

power, control, and optional feedback signal. An external 12VDC

power supply is required to power the latch. The power supply should

be sized to provide sufficient current for your application or a

minimum of 1.5 Amps per latch.

Power:

Voltage required: 12-24 VDC (9 to 26V)

Typical Operating current: 200mA

Typical Operating transit time: less than 1 second

Max current (stalled latch): 1A Max @12VDC

Standby current: less than 200µA, plus output signal current if

applicable. Power must be present during transit times. The latch will

maintain either position if power is removed (fails neutral)

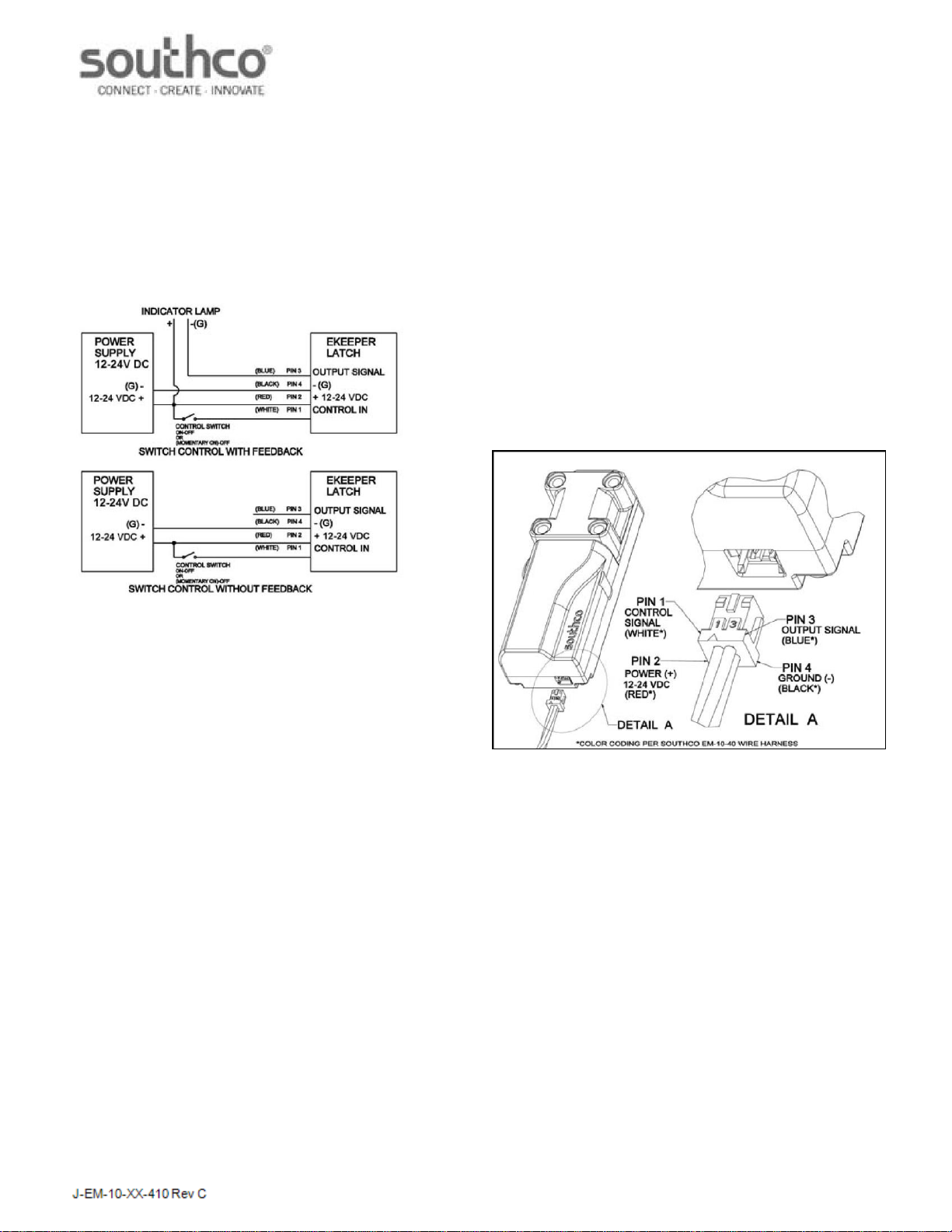

Control Input Signal: is required to control the latch bolt position

either extended or retracted. The control signal can be changed

simply by using a low current switch as wired in the diagram above.

The control signal current draw is less than 1mA.

- For RETRACTED position: supply 12-24 VDC (9 to 26V) for a

minimum of 50 Milliseconds. The latch bolt will remain retracted

for as long as the signal is present or a minimum programmed

time of 1 second.

- For EXTENDED position: supply open contact or 0VDC(0 to .5V)

Note:

1. On power up, there is a 870mS delay before the control signal is active.

2. Once the latch bolt extends, there is an 85mS delay before the

control signal is active again.

Output signal: is a signal that can be used if desired as feedback to

monitor the position of the latch or error mode.

- The output is an open collector output. The maximum load

applied must be less than 450mA.

CAUTION! To avoid damage to the product do not exceed the

maximum output signal load of 450mA and carefully use the correct

polarity shown.

-Output will turn ON when latch bolt is in retracted position. NOTE:

External compression of the latch bolt will not produce any output signal.

-Output will slowly flash ON/OFF when a latch error occurs.

The latch error function is a timer that monitors the transit time of the

latch when traveling between the EXTENDED or RETRACTED

position. The latch will try to reach the new position for two attempts. If

the latch does not reach the new position the latch will enter error

mode and flash the output to indicate that there is a problem. The error

mode is a passive error indicator only and will reset when a new

change in position is commanded.

The latch will go into error mode:

-if there is too much load, or there is an obstruction preventing

the retracting movement of the latch bolt.

-if the output gear is missing or if there is internal damage to the latch.

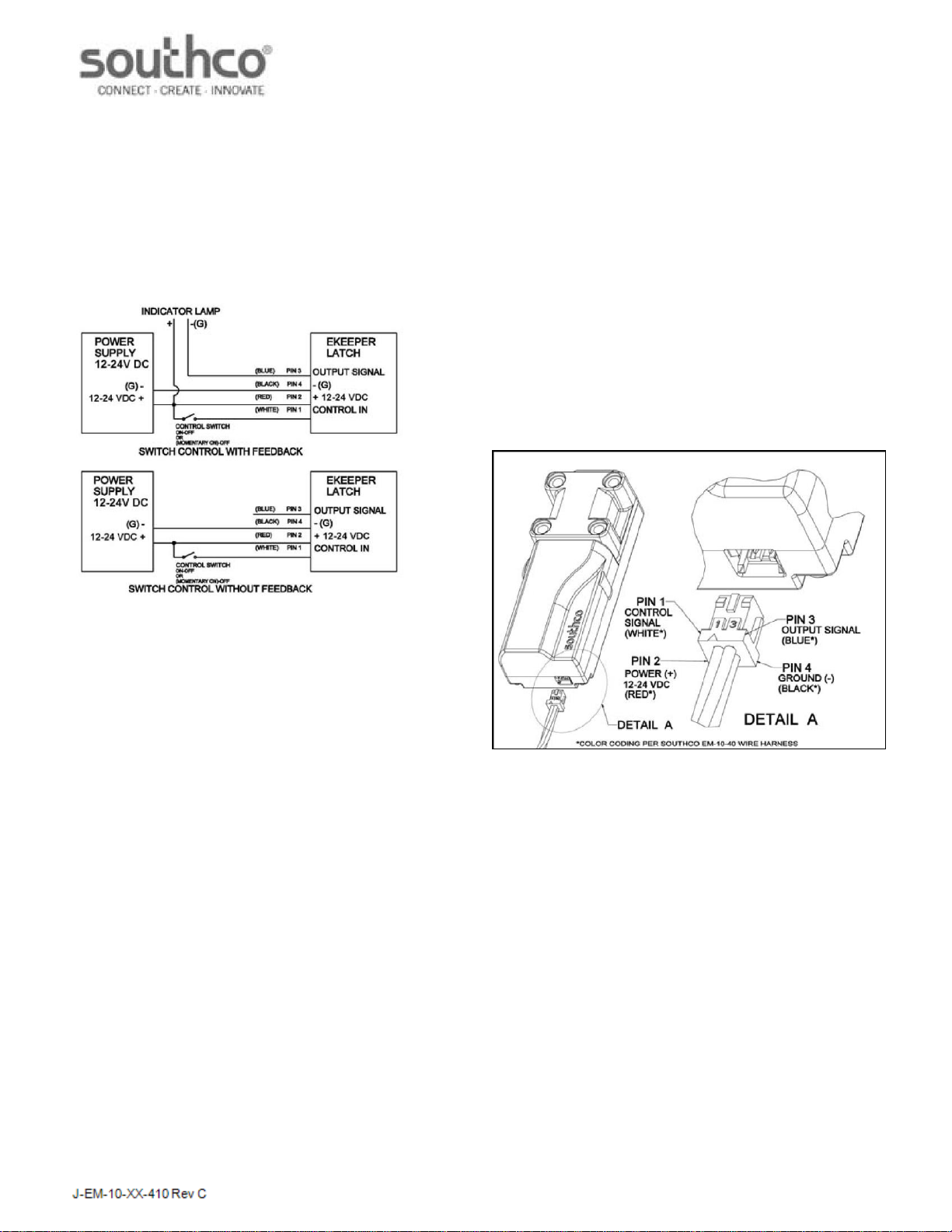

Electrical connections:

The latch is equipped with the following four position connector:

Hirose Electric Co. Ltd Part Number: DF11-4DP-2DS

Pin 1: Control Input signal

Pin 2: Power (+)

Pin 3: Output signal

Pin 4: Ground (-)

Mate connector required (Not Included)

Hirose Electric Co. Ltd

Part Number: DF11-4DS-2C crimp socket

Part Number:DF11-series crimping contact for

socket 24 AWG wire minimum recommended.

OR

Order Southco part Number: EM-10-4X for mate connector with

three wire length options. The Mate connector is polarized and

should be inserted as shown. Note the markings to indicate the

positions.

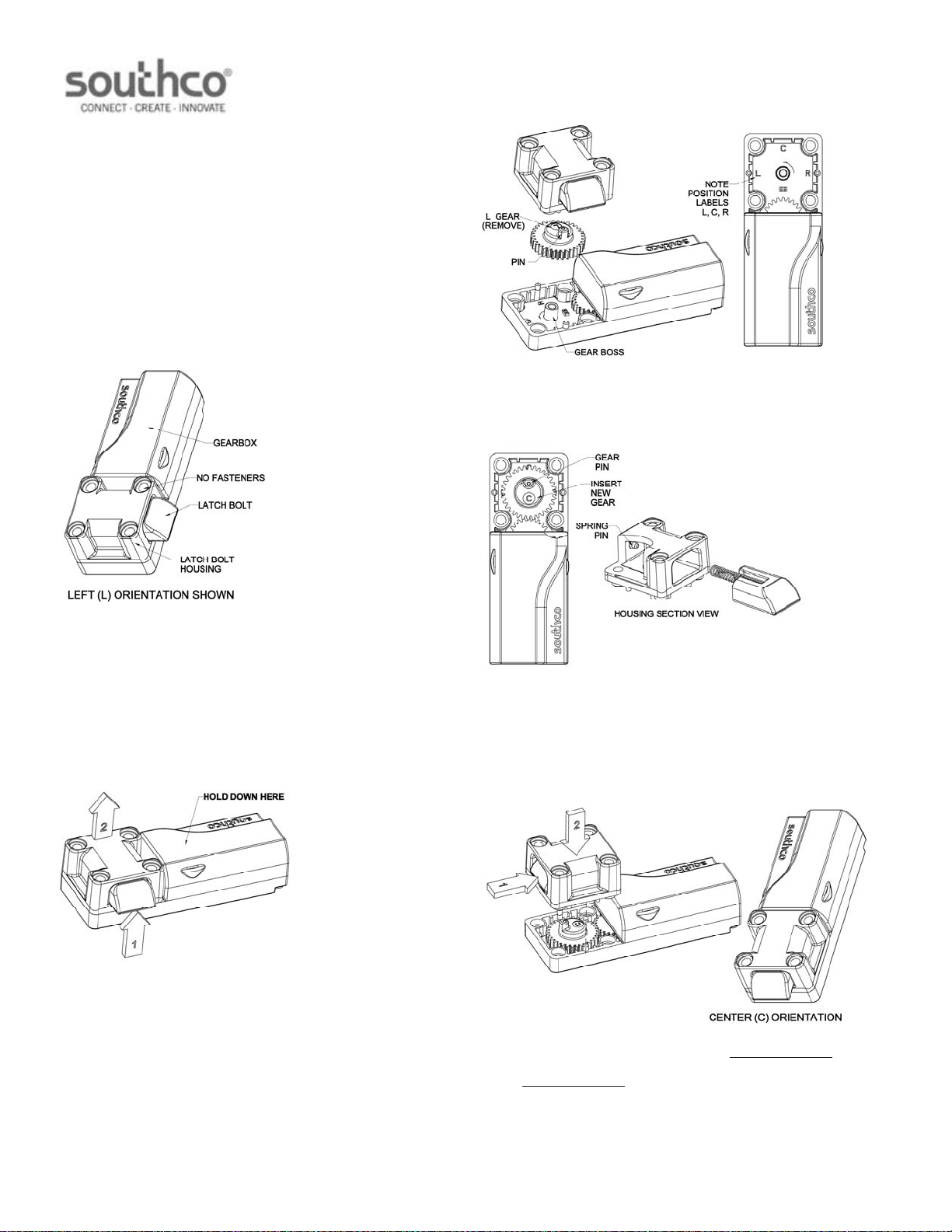

Mounting:

The latch should be mounted to a rigid and flat surface using four #6 or

M4 machine screws of appropriate length for your application (screws

not supplied). For additional product dimension see the customer

drawing specific to your model available from www.southco.com

CAUTION! The mounting fasteners also serve to permanently secure

the latch bolt housing to the base. Do not operate the latch without

mounting fasteners to secure the latch housing. The latch bolt has

approximately 8mm of travel and will fully retract into the latch bolt

housing.

For EM-10-1X-410, EM-10-2X-410 AND EM-10-3X-410 ONLY

When in the EXTENDED position the latch bolt is spring loaded and

can be retracted manually by applying an external force. This

functionality allows it to be used as a "push-to-close" latch.

For EM-10-4X-410 ONLY

Do not obstruct the motion of the dead bolt. Ensure that the dead bolt

is free to travel to its fully extended position. The dead bolt is not

spring loaded. Blocking the dead bolt will stall the drive motor and

may reduce the life of the product.

The E-keeper product is intended to be used with either a fixed strike

or a secondary mechanical latch. For installation recommendations

or support please contact customer service. The orientation of the

latch bolt can be changed from the factory position to Left, Center or,

Right positions, but does require additional parts to do so. Order

latch bolt rotation kit Southco part number EM-10-32-85 to change to

left center or right orientation.