Sovereign AJ65A User guide

2

CONTENTS

CONTENTS 2

GENERAL SAFETY WARNINGS 3

WARNING SYMBOLS 9

IN THE BOX 10

OPERATION 11

MAINTENANCE AND STORAGE 18

TECHNICAL DATA 19

RECYCLING AND DISPOSAL 21

UK PLUG 21

GETTING HELP 22

WARRANTY 23

3

GENERAL SAFETY WARNINGS

WARNING! Read all safety warnings,

instructions, illustrations and specifications

provided with this power tool. Failure to

follow all instructions listed below may result

in electric shock, fire and/or serious injury.

Save all warnings and instructions for

future reference. The term ‘power tool’ in

the warnings refers to your mains-operated

(corded) power tool or battery-operated

(cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools

create sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adaptor plugs with earthed (grounded) power

tools. Unmodified plugs and matching outlets will

reduce risk of electric shock.

b) Avoid body contact with earthed or grounded

4

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep the cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords

increase the risk of electric shock.

e) When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk of

electric shock.

f) If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD reduces

the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and

use common sense when operating a power

tool. Do not use a power tool while you are

tired or under the influence of drugs, alcohol

or medication. A moment of inattention while

operating power tools may result in serious

personal injury.

b) Use personal protective equipment (PPE).

Always wear eye protection. Protective

5

equipment such as a dust mask, non-skid safety

shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal

injuries.

c) Prevent unintentional starting. Ensure the

switch is in the 'off' position before connecting

to a power source and/or battery pack, picking

up or carrying the tool. Carrying power tools

with your finger on the switch or energising power

tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewellery

or long hair can be caught in moving parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

these devices can reduce dust-related hazards.

h) Do not let familiarity gained from frequent use

of tools allow you to become complacent and

ignore tool safety principles. A careless action

can cause severe injury within a fraction of a

second.

6

4) Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the

rate for which it was designed.

b) Do not use the power tool if the switch does

not turn it on and off. Any power tool that cannot

be controlled with the switch is dangerous and

must be repaired.

c) Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of

children, and do not allow persons unfamiliar

with the power tool or these instructions

to operate the power tool. Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may affect the

power tools operation. If damaged, have the

power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits,

7

etc., in accordance with these instructions,

taking into account the working conditions and

the work to be performed. Use of the power tool

for operations different from those intended could

result in a hazardous situation.

h) Keep handles and gripping surfaces dry, clean

and free from oil and grease. Slippery handles

and gripping surfaces do not allow for safe

handling and control of the tool in unexpected

situations.

Service

a) Have your power tool serviced by a qualified

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

ADDITIONAL SAFETY WARNINGS FOR SANDERS

a. Harmful/toxic dusts will arise from sanding,

e.g. lead painted surfaces, woods and metals.

Contact with or inhalation of these dusts

can endanger the health of the operator and

bystanders. Always use eye goggles and a dust

mask.

b. Hearing protection should be worn when using

the sander.

c. Always wear safety glasses or eye shields

when using the sander. Everyday spectacles

have only impact-resistant lenses; they are not

8

safety glasses. Following this rule will reduce the

risk of serious personal injury.

d. After long working periods, external metal

parts and accessories could be hot.

e. If possible, ensure the work-piece is firmly

clamped to prevent movement.

f. Your sander is a hand held tool; do not clamp

your sander.

g. Before sanding, check the area is free of nails,

screws, etc.

h. Never stop the sander by applying a force to

the base plate.

i. Only use sand paper in good condition. Do not

use torn or worn paper.

j. Do not sand material containing asbestos, due

to a health risk.

k. Do not sand lead-based paint due to the risk of

lead poisoning.

l. Do not eat or drink in the working area of the

sander.

m. Do not allow people to enter the working area

without wearing a dust mask.

n. Where possible, seal off the working area to

contain the dust for later removal.

o. Your tool is designed for dry sanding only, not

wet sanding.

p. Do not sand magnesium material due to the

risk of fire.

9

WARNING SYMBOLS

Warning

Read the instructions

Wear ear protection

Wear eye protection

Wear a dust mask

Class II tool

The product complies with the applicable

European directives, and an evaluation method

of conformity for these directives was done.

Recycle unwanted materials instead of

disposing of them as household waste. All tools,

hoses and packaging should be sorted, taken to

the local recycling centre and disposed of in an

environmentally safe way.

The product complies with the applicable UK

directives, and an evaluation method of conformity

for these directives was followed.

10

IN THE BOX

Description

1. Speed selection

2. On/off switch

3. Dust outlet

4. Fasten clip

5. Sanding base

6. Dust collection box

7. Soft grip

Accessories

1pc 80# sanding paper

11

OPERATION

NOTE: Before using your sander, be sure to read the

instruction manual carefully.

INTENDED USE

This tool is intended for dry sanding of wood, plastic, filler and

coated surfaces.

1. FITTING THE SANDING PAPER

SANDING PAPER WITH CLIP SYSTEM (SEE FIG. A, B, C, D)

FIT THE SANDING PAPER

Fit the sanding paper over the base. Make sure the sanding

paper is even with the edges, and that the dust collection

holes in the base and sanding paper is aligned, and that the

sanding paper is taut on the base.

Lift the sanding paper retaining clips to the open position and

insert one end of the sanding paper under the retaining clip.

Push the clip back into the retaining position. Lightly stretch

the paper over the base plate ensuring that it is not folded

or wrinkled, then position under the other retaining clip back

into the retaining position. Check that the paper is flat to the

base plate, if not, release either clip and reposition the paper

before resetting the clip. Switch on momentarily to check that

the sander is functioning correctly. If there is undue vibration,

repeat the paper positioning procedure.

REMOVE THE SANDING PAPER

To remove the sanding paper, liftup the clamp lever and move

away from the clamp lever lock. The sanding paper clamp is

now loose. Repeat with the other clamp on the opposite side

of your sander.

12

13

14

B C2. USING THE DUST COLLECTION BOX (SEE FIG. E)

A) ATTACH THE DUST BOX

Your sander is equipped with a dust collection box (6), which

is designed for collect dust. Insert the dust collection box into

the rear dust outlet the sander. Then pull the dust collection

box and make sure it is tightened securely on the dust outlet.

CAUTION: To prevent the possibility of sanding dust

or foreign objects being thrown into your face or

eyes, never attempt to use your sander without the

collection box properly installed.

B) EMPTY DUST BOX

For more efficient operation, empty the dust box every

5-10mins. This will permit the air to flow through the box

efficiently.

To empty the dust box, pull off the from out of the dust

extraction outlet directly and shake out the dust.

3. USING THE DUST OUTLET (SEE FIG. F)

Your sander is equipped with a 35mm dust outlet, which is

designed for connecting the hose of a vacuum cleaner.

If the vacuum hose is 35mm, insert the hose directly into the

rear dust outlet of the sander.

15

First, turn on the vacuum cleaner, and then turn on the

sander. If you stop sanding, first turn off the sander and then

turn off your vacuum cleaner.

NOTE: Please pull the dust adaptor to make sure it is

tightened securely to the dust outlet.

4. OPERATING THE ON/OFF SWITCH (SEE FIG. G)

Slide the on/off switch to the position marked 'I' to start the

tool. Slide it to the position marked '0' to stop it.

16

5. USING THE SANDER

The workpiece to be sanded must be secured. If it is small or it

may move during sanding, it must be held in a vice or suitably

clamped.

Be sure to hold the sander firmly whilst it is on and apply

it gently to the work, it may 'kick' on first contact. Hold

the sander so that it is flat on the work and move slowly,

preferably with a smooth, circular motion. Regularly check the

condition of the sanding paper and replace when worn for

best results.

6. FLUSH SANDING FACILITY

Your sander can sand flush on three sides of the baseplate,

which allows easy access to corners and edges of moldings.

7. ORBITAL SANDING

Your sander operates in small a circular rotation which

allows efficient material removal. Operate your sander in

long sweeping movements across your workpiece and even

across the grain. For a finer finish, always use a fine grain

sanding paper, and only move the sander in the direction of

the grit and never across the grain. Do not allow your sander

to remain in the same position otherwise you will remove

material and create an uneven surface.

8. SELECT THE RIGHT SAND PAPER

Selecting the correct grit of sandpaper is an extremely

important decision that will allow you to achieve the best

quality sanding finish.

Coarse grit will remove the most material and finer grit

will give you the best finish in all sanding operations. The

condition of the surface to be sanded will determine which grit

will do the job.

17

If the surface is rough:

Start with coarse grit (sold separately) and sand until the

surface is uniform. Then use medium to remove any scratches

left by the coarse grit. Then use finer grit (sold separately) for

finishing the surface.

NOTE:Always continue sanding with each grit until the surface

is uniform.

18

MAINTENANCE AND STORAGE

IMPORTANT!

Make sure that the tool has been thoroughly cleaned

before storing it in a clean, dry and safe place, out of

the reach of children.

1. Switch the product 'OFF' and disconnect it from the power

supply before transporting it anywhere.

2. Always carry the product on its gripping surfaces.

3. Protect the product from any heavy impact or strong

vibrations which may occur during transportation in

vehicles.

4. Secure the product to prevent it from slipping or falling

over.

If the supply cord is damaged, it must be replaced by the

manufacturer, its service agent or similarly qualified persons

in order to avoid a hazard.

19

TECHNICAL DATA

Model AJ65A

Voltage/power 230-240V~ 50Hz/200W

No-load speed 6000-12000/min

Sanding pad size 90x187mm

Protection class / II

Weight 1.9kg

NOISE AND VIBRATION DATA

A weighted sound pressure (LpA) 80.6 dB(A), k=3dB(A)

A weighted sound power (LwA) 91.6 dB(A), k=3dB(A)

Vibrations ah=8.106 m/s2 , K=1,5 m/s2

The sound intensity level for the operator may exceed 80

dB(A) and ear protection measures are necessary.

The declared vibration value has been measured in

accordance with a standard test method (according to EN

62841) and may be used for comparing one product with

another. The declared vibration value may also be used in a

preliminary assessment of exposure.

WARNING!

The vibration emission value during actual use of

the power tool can differ from the declared value

depending on the ways in which the tool is used and

dependant on the following examples and other

variations on how the tool is used:

How the tool is used and the materials being cut or

drilled.

The tool being in good condition and well maintained.

Using the correct accessory for the tool and ensuring it

is sharp and in good condition.

The tightness of the grip on the handles and if any

anti-vibration accessories are used.

And the tool is being used as intended by its design

and these instructions.

20

This tool may cause hand-arm vibration syndrome if its

use is not adequately managed.

WARNING! To be accurate, an estimation of exposure

level in the actual conditions of use should also take

account of all parts of the operating cycle, such as

the times when the tool is switched off and when it is

running idle but not actually doing the job. This may

significantly reduce the exposure level over the total

working period.

Helping to minimise your vibration exposure risk.

ALWAYS use sharp chisels, drills and blades.

Maintain this tool in accordance with these instructions

and keep well lubricated (where appropriate).

If the tool is to be used regularly then invest in anti-

vibration accessories.

Plan your work schedule to spread any high vibration

tool use across a number of days.

This manual suits for next models

1

Table of contents

Popular Sander manuals by other brands

Metabo

Metabo BAE 75 Original instructions

Bosch

Bosch Professional GWX 180-LI Original instructions

Neilsen

Neilsen CT1912 Original instructions

Autz + Herrmann

Autz + Herrmann RotoClear S2 A-P 10850 500 operating manual

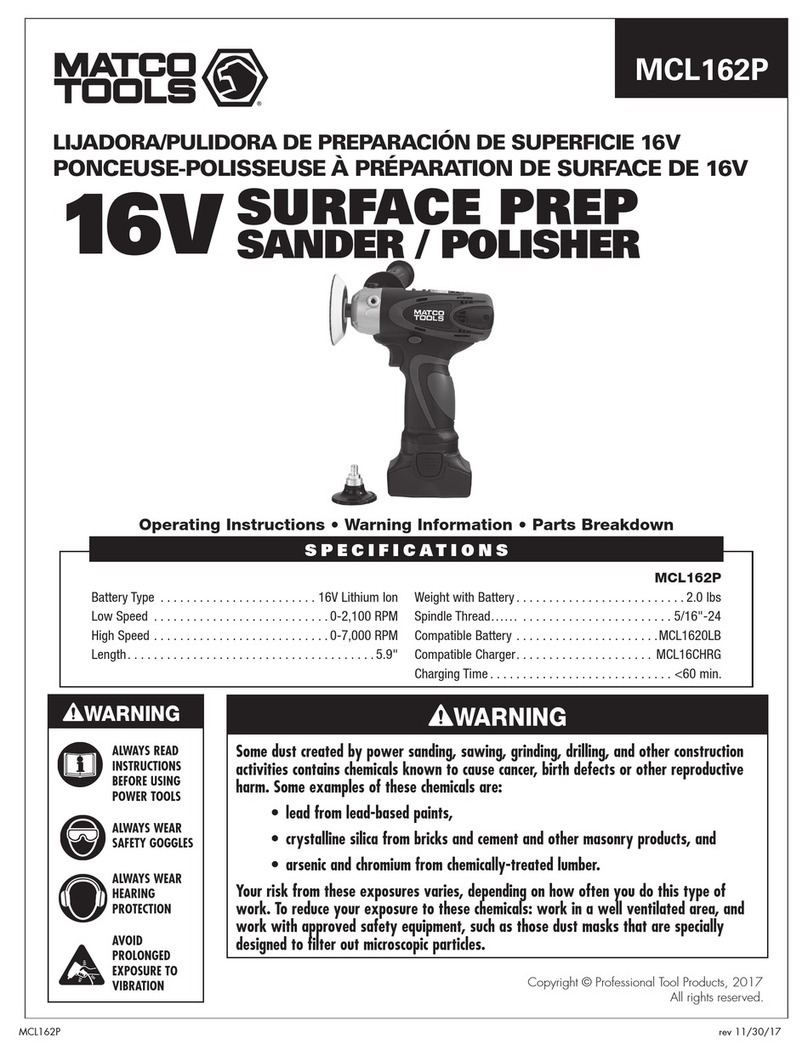

Matco Tools

Matco Tools MCL162P operating instructions

Parkside

Parkside PHS 160 B3 Operation manual