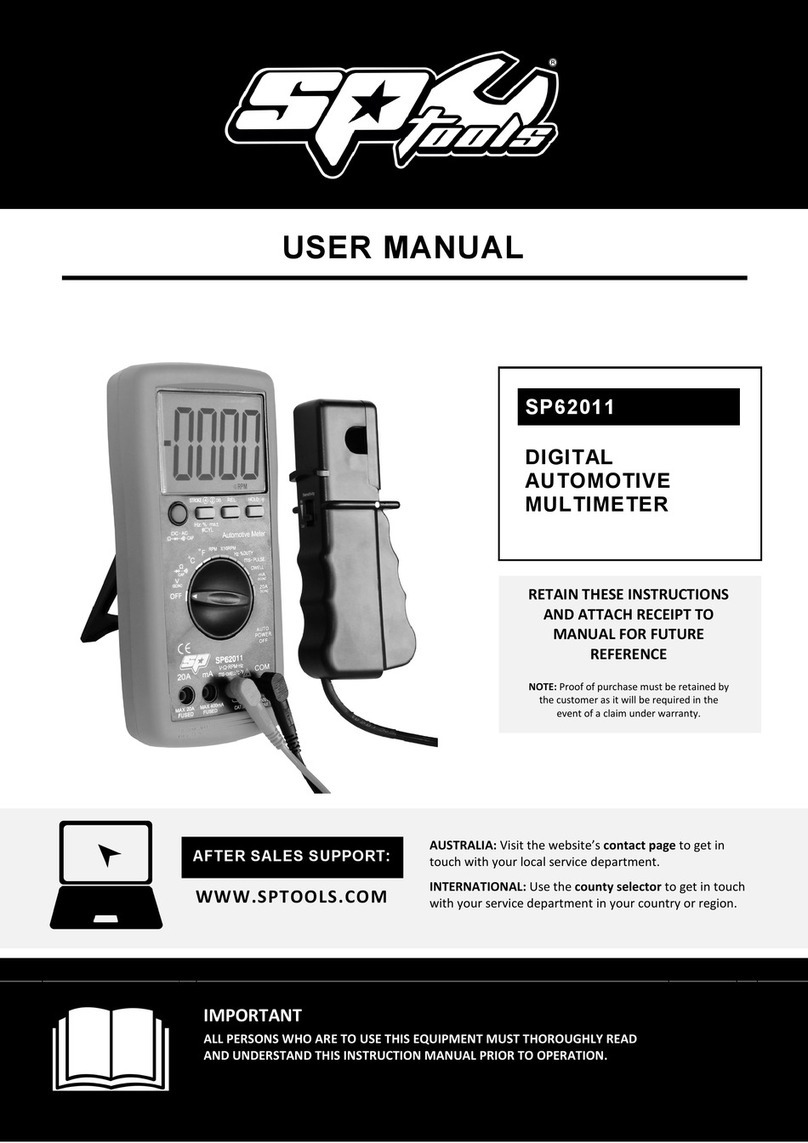

SP tools SP62015 User manual

USER MANUAL

IMPORTANT

ALL PERSONS WHO ARE TO USE THIS EQUIPMENT MUST THOROUGHLY READ

AND UNDERSTAND THIS INSTRUCTION MANUAL PRIOR TO OPERATION.

SP62015

DIGITAL

MULTIMETER

WITH

TEMPERATURE

GAUGE

RETAIN THESE INSTRUCTIONS

AND ATTACH RECEIPT TO

MANUAL FOR FUTURE

REFERENCE

NOTE: Proof of purchase must be retained by

the customer as it will be required in the

event of a claim under warranty.

AFTER SALES SUPPORT:

AUSTRALIA: Visit the website’s contact page to get in

touch with your local service department.

WWW.SPTOOLS.COM

INTERNATIONAL: Use the county selector to get in touch

with your service department in your country or region.

2

CONTENTS

Safety Information 3

Safety Symbols 3

Controls and Jacks 4

Symbols and Annunciators 4

Specifications 5

DC Voltage (Auto-ranging) 5

AC Voltage (Auto-ranging) 6

DC Current (Auto-ranging for uA and mA) 6

Resistance (Auto-ranging) 6

Diode Test 7

Temperature 7

Audible continuity 7

0peration 7

DC Voltage Measurements 8

AC Voltage Measurements 8

DC Current Measurements 8

AC Current Measurements 9

Resistance Measurements 10

Continuity Check 10

Diode Test 10

Temperature Measurements 11

Non-contact Voltage (NCV) 11

Replacing the Battery 11

Battery Installation 12

Replacing the Fuses 12

Warranty Details 13

3

SAFETY INFORMATION

The following safety information must be observed to insure maximum

personal safety during

the operation at this meter:

•Do not use the meter if the unit or test leads look damaged, or if you suspect that the

meter is not operating properly

.

•Never ground yourself when taking electrical measurements. Do not touch exposed metal

pipes, outlets, fixtures, etc. Keep your body isolated from ground by using dry clothing,

rubber shoes, rubber mats or any approved insulating material.

•

Turn the power to off before testing circuit, cutting, unsoldering or breaking the

circuit. Small amounts of current can be dangerous.

•Use caution when working above 60V de or 30V ac rms. Such voltages pose a shock hazard.

•

When using the probes, keep your fingers behind the finger guards on the probes.

•

Measuring voltage which exceeds the limits of the multimeter maydamage the meter

and expose the operator to a shock hazard.Always recognize the meter voltage limit

as stated on the front of the meter.

•Never apply voltage or current to the meter that exceeds the specified

maximum.

SAFETY INFORMATION

This symbol adjacent to another symbol, terminalor operating

device indicates that the operator must refer to an explanation in

the Operating

Instructions to avoid personal injury or damage to

the

meter.

This

WARNING

symbol indicates a potentially hazardous situation,

which if not avoided, could result in death or serious injury.

This

CAUTION

symbol indicates a potentially hazardous situation,

which if not avoided, may result damage to the product.

This symbol advises that the terminal(s) so marked must not be

connected to a circuit point

at which the voltage with respect to

earth ground exceeds (in this case) 600 VAC or VDC.

This symbol adjacent to one or more terminals identifies them as being

associated with ranges that may, in normal use, be subjected to

particularly hazardous voltages. For maximum safety, the meter and its

test leads should not be handled when these terminals are energised.

4

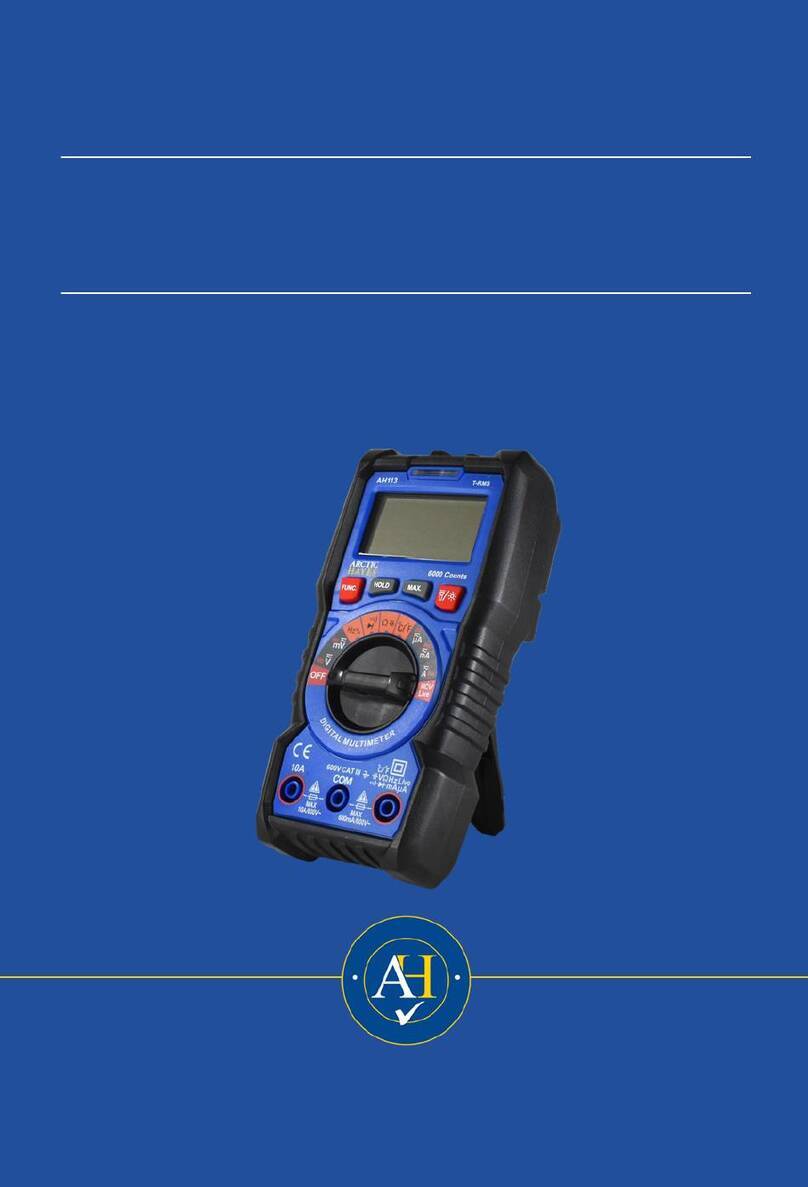

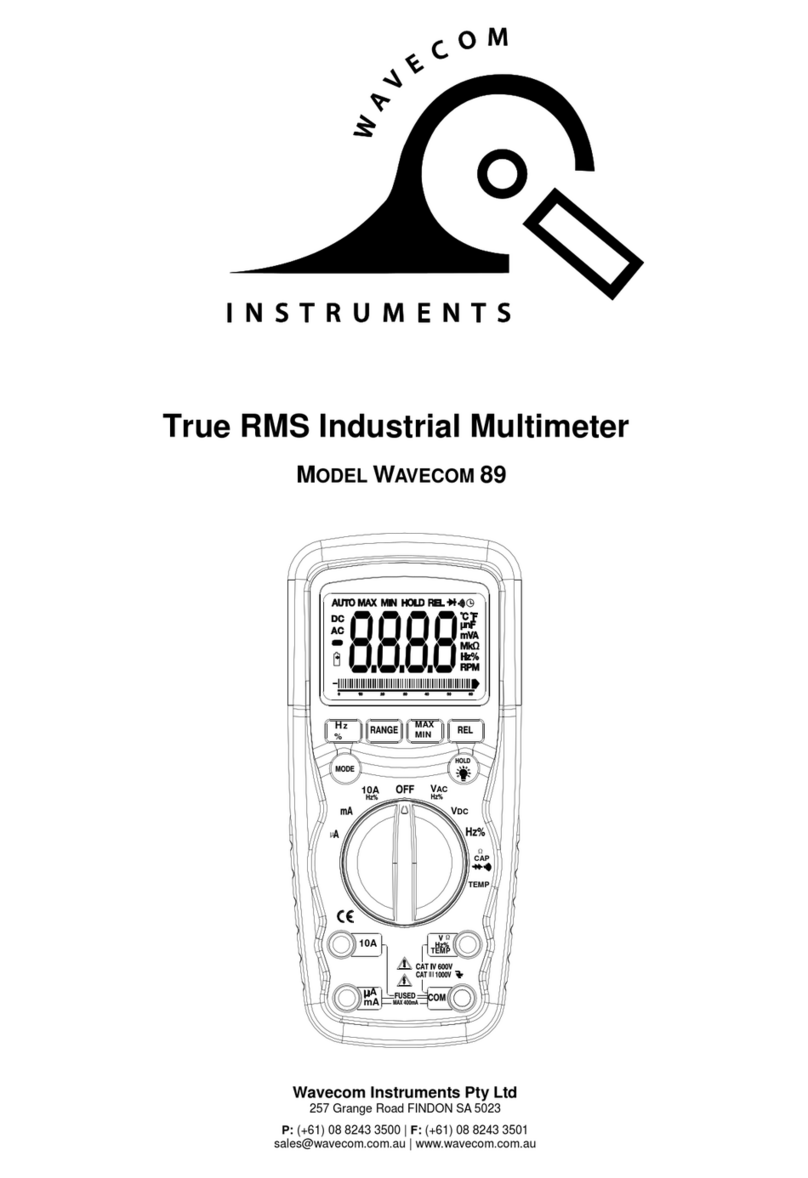

CONTROLS AND JACKS

1)

2000 count Liquid Crystal Display with symbolic signs

2)

MAX. Hold push button

3)

Function switch

4)

COM (negative) input jack

5)

Positive input jack

6)

Mode push button: selection Continuity /Diode, AC/DC, Temperature(C/F)

7)

Non-contact voltage

SYMBOLS AND ANNUNCIATIONS

•Continuity •BAT Low Battery

•Diode • AUTO Auto Ranging

• AC Alternating Current or Voltage •DC Direct Current or Voltage

Input Limits

Function

Maximum Input

V DC or V AC

600V DC /AC

mA DCJAC

200mA DCJAC

Resistance, Diode test, Continuity Temperature

250V DCJAC

1

3

2

7

6

5

4

5

SPECIFICATIONS

The instrument complies with: EN61010-1 .

Insulation: Class2, Double insulation.

Overvoltage category: CATIII 300V CATII 600V

Display: 2000 counts LCD display with function indication.

Polarity: Automatic, (-) negative polarity indication.

Over range: "OL" mark indication.

Low battery indication: The "BAT" is displayed when the battery voltage drops

below the operating level.

Measurement rate: 2 times per second, nominal.

Auto power off: Meter automatically shuts down after approx. 15

minutes of inactivity.

Operating environment: 0°C to S0 °C (32 °F to 122 °F) at < 70% relative

humidity.

Storage temperature: -20 °C to 60°C (-4°F to 140 °F) at < 80% relative

humidity.

For inside use, max height: 2000m

Pollution degree: 2

Power: One12V battery

Dimensions: 108(H) x 53(W) x 32(D) mm

Weight: Approx.: 102g.

Accuracy is given at 18° to 28° - 65°F to 83°F, less than 70% RH.

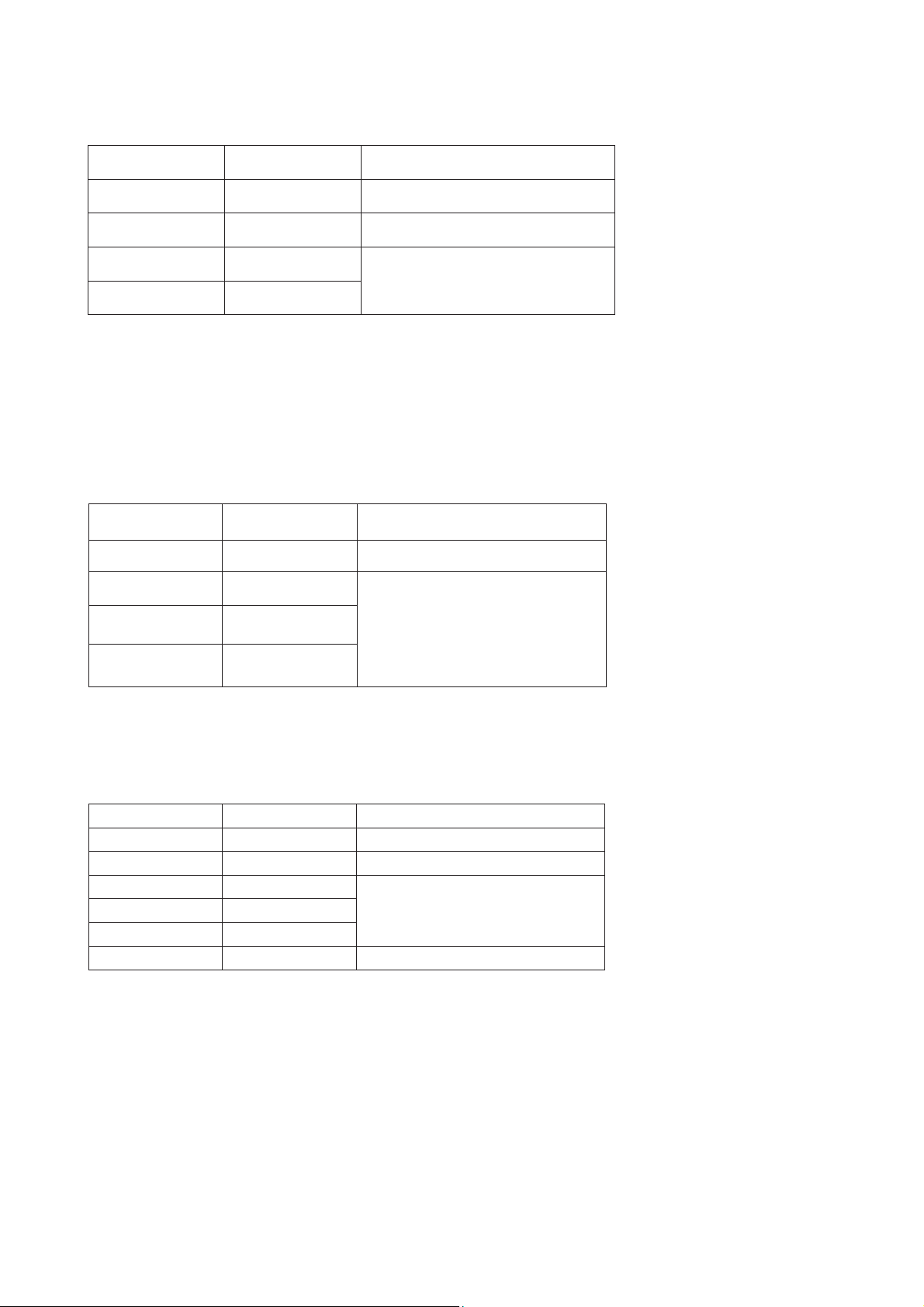

DC Voltage (Auto-ranging)

Input Impedance: 10M

Ω

.

Maximum Input: 600V AC/DC rms

Range

Resolution

Accuracy

200.0mV

0.1mV

±0.5% of rdg ±4 dgts

2.000V

1mV

± 1.2% of rdg ± 2 dgts

20.00V

10mV

200.0V

100mV

600V

1V

±1.5% of rdg ± 2 dgts

6

AC Voltage (Auto-ranging)

Range

Resolution

Accuracy

2.000V

1mV

±1.2% of rdg ± 4 dgts

20.00V

10mV

±1.5% of rdg ± 3 dgts

200.0V

100mV

± 2.0% of rdg ± 4 dgts

600V

1V

Input Impedance: 10MΩ

Frequency Range: 50 to 60Hz

Maximum Input: 600V AC/DC rms.

DC Current (Auto-ranging for uA and mA)

Overload Protection: 0.2A/600V

Maximum Input: 200mA DC or 200mA AC rms on µA/mA ranges

Resistance (Auto-ranging)

Input Protection: 250V DC or 500V AC rms

Range

Resolution

Accuracy

200 .0µA

0.1µA

± 1.0% of rdg ± 3 dgts

2000µA

1µA

± 1.5% of rdg ± 3 dgts

20.00mA

10µA

200 .0mA

100µA

Range

Resolution

Accuracy

200.0

Ω

0.1

Ω

±1.5% of rdg ± 4 dgts

2.000k

Ω

1

Ω

±1.2% of rdg ± 2 dgts

20.00k

Ω

10

Ω

±1.5% of rdg ± 2 dgts

200.0kΩ

100

Ω

2.000 MΩ

1k

Ω

20.00M

Ω

10k

Ω

±2.0% of rdg ± 3 dgts

7

Diode Test

Open circuit voltage: 1.5V DC typical

Overload protection: 250V AC/DC rms.

Temperature

Sensor: K Thermocouple

Audible continuity

Audible threshold: Less than 100 Test current: <0.3mA

Overload protection: 250V AC/DC rms

OPERTATION

RISK OF ELECTRICAL SHOCK

Could result in fatal electrical shock

Risk of electrocution. High-voltage circuits, both AC and DC, are very dangerous and should

be measured with great care.

•

ALWAYS

turn the function switch to the OFF position when the meter is not in use.

This meter has Auto OFF that automatically shuts the meter OFF if 15 minutes elapse

between uses.

• If "OL" appears in the display during a measurement, the value

exceeds the

range you have selected. Change to a higher range.

Note:

On some low AC and DC voltage ranges, with the test leads not connected to a

device, the display may show a random, changing

reading. This is normal and is caused by

the high-input sensitivity. The reading will stabilize and give a proper measurement

when connected to a circuit.

Test current

Resolution

Accuracy

0.3mA typical

1 mV

±10% of rdg ± 5 dgts

Range

Resolution

Accuracy

-50°C- + 760 °C

1°c

±3% of rdg ± 5°C

-58°F- + 140

0°F

1°F

±3%

of

rdg

± 9°F

8

Mode Button

To select Diode/Continuity or DC/AC current, Temperature (C/ F).

Max Hold Button

The max Hold position is used to measure the maximum value.

The maximum measured value is up dated continuously. Press onceagain the button, will release

the hold and allow a further measurement.

DC Voltage Measurements

CAUTION

Do not measure DC voltages if a motor on the circuit is being switched ON or OFF.

Large voltage surges may occur that candamage the meter.

•

Set the function switch to the V DC position ("mV" will appear in the display).

•

Insert the black test lead, banana plug into the negative (COM) jack and the red test

lead, banana plug into the positive (V) jack.

•

Touch the test probe tips to the circuit under test. Be sure to observethe correct

polarity (red lead to positive, black lead to negative).

•

Read the voltage in the display. The display will indicate the properdecimal point

and value. If the polarity is reversed, the display will show (-) minus before the

value.

AC Voltage Measurements

RISK OF ELECTRICAL SHOCK

Could result in fatal electrical shock

•

Risk of Electrocution. The probe tips may not be long enough to contact the live parts

inside some 240V outlets for appliances because the contacts are recessed deep in the

outlets.As a result, the reading may show 0 volts when the outlet actually has voltage

on it. Make sure the probe tips are touching the metal contacts inside the outlet

before assuming that no voltage is present.

CAUTION

Do not measure AC voltages if a motor on the circuit is being switched ON or

OFF.

Large voltage surges may occur that candamage the meter.

•

Set the function switch to the V AC position.

•

Insert the black test lead, banana plug into the negative (COM) jack and the red test

lead, banana plug into the positive (V) jack.

•

Touch the test probe tips to the circuit under test.

Read the voltage in the display.

The display will indicate the properdecimal point, value and symbol (AC, V, etc).

9

DC Current Measurements

For current measurements up to 2000uA DC, set the function switchto the uA position and

insert the red test lead, banana plug into the(µA) jack.

•

For current measurements up to 200mA DC, set the function switch to the mA range

and insert the red test lead, banana plug into the (mA) jack.

•

Press the MODE button until "DC" appears in the display.

•

Remove power from the circuit under test, then open up the circuit

at the point

where you wish to measure current.

•

Touch the black test probe tip to the negative side of the circuit.Touch the red test

probe tip to the positive side of the circuit.

•

Apply power to the circuit.

•

Read the current in the display. The display will indicate the proper decimal point,

value and symbol.

AC Current Measurements

RISK OF ELECTRICAL SHOCK

To avoid electric shock, do not measure AC current on anycircuit whose

voltage exceeds 250V AC.

•

Insert the black test lead banana plug into the negative (COM) jack.

•

For current measurements up to 2000µA AC, set the function switchto the µA position

and insert the red test lead, banana plug into the (µA) jack.

•

For current measurements up to 200mA AC, set the function switchto the mA range

and insert the red test lead, banana plug into the (mA) jack.

•

Press the MODE button until "AC" appears in the display.

•

Remove power from the circuit under test, then open up the circuitat the point

where you wish to measure current.

•

Touch the black test probe tip to the negative side of the circuit. And touch the red

test probe tip to the positive side of the circuit.

•

Apply power to the circuit.

•

Read the current in the display. The display will indicate the properdecimal point,

value and symbol.

10

Resistance Measurements

RISK OF ELECTRICAL SHOCK

To avoid electric shock, disconnect power to the unit under test and discharge all

capacitors before taking any resistance measurements.

Remove the batteries and unplug the line cords.

•

Set the function switch to the position.

•

Insert the black test lead, banana plug into the negative (COM) jack

and the red test

lead, banana plug into the positive jack.

•

Touch the test probe tips across the circuit or part under test. It isbest to disconnect

one side of the part under test so the rest of thecircuit will not interfere with the

resistance reading.

•Read the resistance in the display. The display will indicate the proper

decimal point,

value and symbol.

Continuity Check

RISK OF ELECTRICAL SHOCK

To avoid electric shock, never measure continuity on circuitsor wires that have

voltage in them.

•

Set the function switch to the. position.

•

Insert the black lead, banana plug into the negative (-) jack (COM)

and the red test

lead, banana plug into the positive (+) jack

•

Press

the MODE button until the

symbol appears in the display.

•

Touch the test probe tips to the circuit or wire you wish to check.

•

If the resistance is less than approximately 30

Ω

, the audible signal will sound. The

display will also show the actual resistance.

Diode Test

RISK OF ELECTRICAL SHOCK

To avoid electric shock, do not test any diode that hasvoltage in it.

•

Set the function switch to

position

.

•Press the MODE button until the symbol appears in the display.

I

nsert the black test lead, banana plug into the negative (-) jack (COM) and the red

test lead, banana plug into the positive (+) jack.

•

Touch the test probe tips to the diode or semiconductor junctionyou wish to test.

Note

the meter reading.

•

Reverse the probe polarity by switching probe position.

Note

this

reading.

•

The

diode or junction can be evaluated as follows:

11

1.

If one reading shows a value and the other reading shows OL,the diode is good.

2.

If both readings show OL, the device is open.

3.

If both readings are very small or 0, the device is shorted.

Note

: The value indicated in the display during the diode check isthe forward voltage.

Temperature Measurements

RISK OF ELECTRICAL SHOCK

To avoid electric shock, disconnect both test probes from any source of voltage before

making a temperature measurement.

•If you wish to measure temperature in °F, set the function switch to the °F range. If you

wish to measure temperature in °C, set the function switch to the 0c range.

•Insert the black test lead, banana plug into the negative (COM) jack and the red test lead,

banana plug into the positive (V) jack, making sure to observe the correct polarity.

•Touch the Temperature Probe head to the part whose temperature you wish to measure.

Keep the probe touching the part under test until the reading stabilizes (about 30 seconds).

•Read the temperature in the display. The digital reading will indicate the proper decimal

point and value.

Warning: To avoid electric shock, be sure the thermocouple has been removed before

changing to another measurement function.

Non-contact Voltage (NCV)

The NCV function works on any rotary switch position.

•Test the detector on a known live circuit before use.

•Hold the top of the meter very close to the voltage source as shown.

•If voltage is present, the rim of the LCD display will flash a bright red.

Replacing the Battery

Warning: To avoid electric shock, disconnect the test leads from any source of voltage

before removing the battery door.

•When the batteries become exhausted or drop below the operating voltage, "BAT" will

appear in the right-hand side of the LCD display. The battery should be replaced.

•Follow instructions for installing battery

Dispose of the old battery properly.

Warning: To avoid electric shock, do not operate your meter until the battery door is in

place and fastened securely.

12

BATTERY INSTALLATION

RISK OF ELECTRICAL SHOCK

To avoid electric shock, disconnect the test leads from any source of voltage

before removing the battery door.

•Disconnect the test leads from the meter.

•Open the battery door by loosening the screw using a Phillips head screwdriver.

•Insert the battery into battery holder, observing the correct polarity.

•Put the battery door back in place. Secure with the two screws.

Warning: To avoid electric shock, do not operate the meter until the battery door is

in place and fastened securely.

Note: If your meter does not work properly, check the fuses and battery to make sure that

they are still good and that they are properly inserted.

REPLACING THE FUSES

RISK OF ELECTRICAL SHOCK

To avoid electric shock, disconnect the test leads from any source of voltage before

removing the fuse door.

•Disconnect the test leads from the meter and any item under test.

•Open the fuse door by loosening the screw on the door using a Phillips head screwdriver.

•Remove the old fuse from its holder by gently pulling it out.

•Install the new fuse into the holder.

•Always use a fuse of the proper size and value (0.2N 250V fast blow for the 200mA range),

•Put the fuse door back in place. Insert the screw and tighten it securely.

Warning: To avoid electric shock, do not operate your meter until the fuse door is in place

and fastened securely.

13

LIMITED WARRANTY

This Limited Warranty applies only to new products* distributed by SP Tools Pty Ltd (“SP Tools”). It is a condition of this Limited

Warranty Policy that the purchaser read the owner’s manual for the product and only use the product to the extent or for the

purposes stated therein. The purchaser must also ensure that all servicing requirements are completed as listed in the owner’s

manual (said servicing is at the owner’s expense). We recommend that all servicing is completed by an authorised service agent and

that records of said servicing are retained by the purchaser as proof in the event of a warranty claim.

Whilst the owner’s manual, packaging, and/or other documentation supplied with SP Tools’ products may provide details in respect

of a Limited Warranty, the terms set out herein supersede these matters, and this Limited Warranty applies in their place. This

warranty is no less advantageous than otherwise described in such other documentation.

SP Tools agrees, subject to the terms and conditions specified below, to repair or replace at SP Tools’ cost, the product purchased by

you when the product does not perform in accordance with its specifications during the limited warranty period, due to any fault in

manufacturing, materials and/or workmanship. SP Tools is not liable to repair or replace products that the purchaser uses in a

manner that is inconsistent with the owner’s manual or in the circumstances set out in paragraphs 1.1 – 1.7 below.

The benefits to the purchaser under this warranty are in addition to other rights and remedies under the Competition and Consumer

Act 2010 (Cth). The limited warranty period, within which a defect in the product must appear, commences from the date of

purchase and ceases on expiration of the specified term below.

THE LIMITED WARRANTY PERIOD

• SP Speciality Tools –12 Months

THE PURCHASERS ATTENTION IS DRAWN TO THE FOLLOWING

To the extent permitted by law and subject to this Limited Warranty, and as part of the terms of the sale of the equipment or part

thereof: SP Tools shall not be liable for any form of loss, damage, cost, injury or harm of any kind (whether direct, indirect, special

or consequential) howsoever arising from the use or supply of the equipment to the purchaser.

EXCLUSIONS TO LIMITED WARRANTY POILICY

This Limited Warranty will not apply where the equipment or any part thereof:

1.1 Fails due to an accident (including liquid spillage), abuse, misuse, neglect or normal wear and tear;

1.2 Has been used in a manner other than for which it was originally designed;

1.3 Has been tampered with or is otherwise than as supplied by SP Tools;

1.4 Where any damage, malfunction or other failure of the equipment or any part thereof resulted directly or indirectly from

unauthorized persons, adjusting or failing to adjust any part requiring normal maintenance and service (examples include

adjustment of tappets, air filter maintenance, lubrication and tightening of screws nuts and bolts);

1.5 Malfunctions due to the use of defective or incompatible accessories;

1.6 Is damaged by lightning or thunderstorm activity; or

1.7 Has been transported to a country where no authorised Service Agents exist.

CLAIMING WARRANTY

This Limited Warranty may be claimed on in the following manner:

2.1 In order to make a claim under this Limited Warranty, the purchaser must deliver the equipment or any part thereof to an

SP Tools authorised repair agent and pay all costs of transportation and all costs incidental to making a claim under

this Limited Warranty. The purchaser must first contact SP Tools (contact details described above) and request the

delivery address of an SP Tools authorised repair agent.

2.2 The purchaser must deliver to the repair agent written reasons why the purchaser considers that the purchaser has a claim

under this Limited Warranty and must provide all necessary details, including:

•The place, date and from whom the unit or part was purchased.

•The unit or part involved, Model and Serial Number.

•The defect, malfunction or failure in respect of which the claim is being made.

•Proof of service of the unit or part (if applicable)

•Proof of purchase in respect of the unit or part.

2.3 If the Limited Warranty claim is valid, the repair agent will carry out repairs and return the product at no charge to the

purchaser. These repairs are limited to the Limited Warranty fault identified and as such will not include any other faults due to

misuse, abuse, failure to maintain, fair wear and tear or the replacement of serviceable items such as oil, spark plugs, air filters,

fuel etc.

Our goods come with guarantees that cannot be excluded under Consumer Law. You are entitled to a replacement or refund for a

major failure and for compensation for any other reasonably foreseeable loss or damage. You are also entitled to have the goods

repaired or replaced if the goods fail to be of acceptable quality and the failure does not amount to a major failure.

Note: Units which are failing to perform in accordance with specifications due to non-warrantable causes will be subject to freight,

repair and or quote charge

Table of contents

Other SP tools Multimeter manuals