Spaceman 6455-C User manual

Counter or Floor Standing

........................................................................................................................

.................................................................................................................

.....................................................................................................

.............................................................................................................

...................................................................................................................

..........................................................................................

Disassemble Parts ..........................................................................................................................6

Wash Parts .....................................................................................................................................7

Assemble Parts............................................................................................................................... 8

Sanize .........................................................................................................................................10

.......................................................................................................................

Introducon .................................................................................................................................11

Add Product to Machine ..............................................................................................................11

Freeze Product ............................................................................................................................11

Dispense Product ........................................................................................................................12

Wash ............................................................................................................................................12

Standby ........................................................................................................................................12

Low Mix Alarm .............................................................................................................................12

Light Box.......................................................................................................................................12

Spinner .........................................................................................................................................13

Adjust Product Consistency .........................................................................................................13

Machine Power Reset ..................................................................................................................13

........................................................................................................................

This machine has many built-in safety features to protect the operator while the machine is

running.

All personnel operang this machine read and understand this manual in its enrety. Failure to

comply with this manual may damage the machine and cause severe injury to the operator.

Denotes an acon that WILL cause

harm to the operator or machine if performed

incorrectly.

Informs the operator of a task that

may lead to harm if protocol is not properly

performed.

Represents a vital mechanical step

or note that the user must be aware of.

Non-hazard, but pay extra aenon.

Welcome to your Spaceman frozen beverage machine, engineered and designed to provide dependable

operaon and a consistent quality product. Your machine is approved for dairy and nondairy products, with

hopper refrigeraon funcon to maintain product temperature below 4oC (40oF), and with more automated

analog control system for operaonal ease and eciency . All models, countertop or oor, single or two avor,

operate in the same fashion.

This manual is a universal version that provides instrucons on installaon, operaon, cleaning and roune

maintenance. Informaon contained in this manual may be subject to change. Please check online or contact

your local Spaceman distributor for connued updates and detailed informaon about your Spaceman machine.

Unpack and inspect machine,

parts, and accessories.

Place machine in appropriate

food preparaon area. Comply

with all installaon requirements.

Read and understand

ALL safety and standard

operang procedures.

Fully disassemble machine,

and prepare parts for

cleaning.

Thoroughly clean and scrub

machine hoppers, cylinders,

and all parts.

Lubricate and re-assemble

all machine parts.

Prepare product in a separate

container, and ensure product

is thoroughly mixed.

Add product to hoppers

and prime the cylinder

using the prime plug.

Turn machine to FREEZE

mode, and wait for product

to reach frozen consistency.

Slightly adjust viscosity

seng as necessary to

adjust product rmness.

Inspect the machine for any shipping damage. If you nd any, contact Spaceman Technical Service immediately

aer unpallezing. Our technicians will help you assess the damage and determine the appropriate acon prior

to accepng the delivery.

1. Cut packing straps, and remove cardboard lid and outer sides from the pallet. DO NOT cut cardboard.

2. Remove plasc wrapping around machine.

3. Cut stabilizing straps, being careful not to scratch or dent the machine panels.

4. Prepare the area where the machine will be placed, remove packing cardboard from underneath machine,

and place ramp wedges near front casters.

5. Unlock front casters, and roll machine down the wedges o the pallet.

6. Place the machine in its nal locaon according to the Installaon Requirements.

: Unpallezing requires liing.

Failure to do so may result in severe injury or damage.

Inspect equipment for hidden damage before signing for delivery.

Refer to the detailed parts diagrams on the back pages if necessary.

1. Remove all packaged parts and accessories from your machine.

2. Organize items on a clean table or operang area using the checklist.

3. Inspect for damage immediately upon unpacking and call Spaceman

Technical Service if you discover any damaged or missing parts.

4. Clean and properly lubricate machine parts prior to machine operaon.

Included Parts:

• Hopper Cover (1 or 2)

• Front Drip Tray + Splash Shield

• Dispensing Handles

• Start-Up Kit

• Operator’s Manual

Fully sanize

machine.

Torque Arm

Dispensing Door with

Prime Plug, and Gasket

Draw Valve

with O-Rings

Ice Buster

Draw Valve Pin

Draw Handle Beater

Scraper Blade

Feed Tube

Beater Guide

Door Hand Screws

Torque Assembly

with O-Ring

Drive Sha Drive Sha Gasket

Brush Kit

(Oponal)

Internal Drip Tray O-Ring Removal Tool

Hopper Cover

Hopper Agitator

(if present)

Front Drip Tray

with Splash Shield

Torque Guide

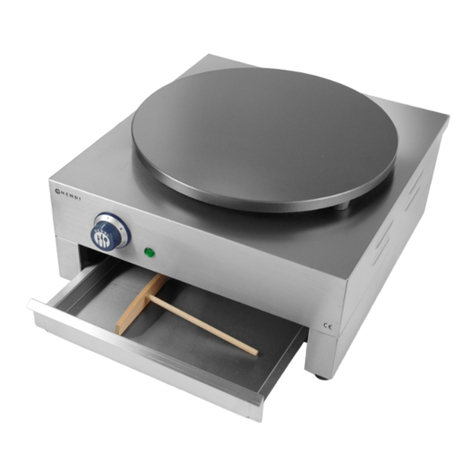

The image displayed is for illustraon purpose only and may

dier from the actual product.

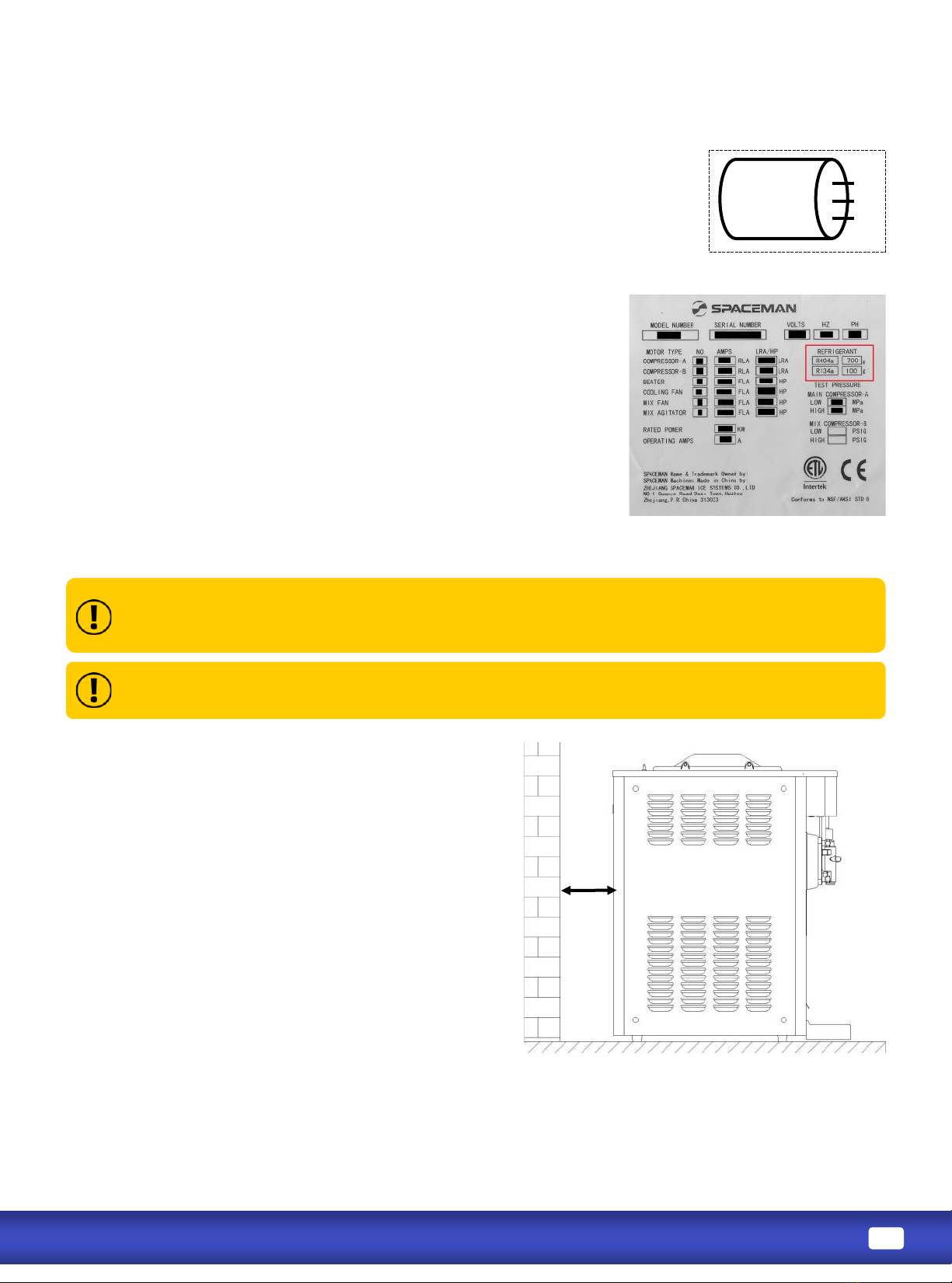

Spaceman requires that only the specied refrigerant be used

in your machine.

Alternave refrigerants may cause damage to the cooling

system and/or prevent the machine from operang at opmal

performance.

If you require an alternave refrigerant, please call Spaceman

Technical Support for a list of compable alternaves for your

compressor.

• Place on a at, level, and solid surface ed to

the machine dimensions

• Ensure a minimum 152mm (6'') clearance on

the exhaust side (Side or Back)

• Completely clear area of dust, grease, and

airborne parcles

• Place away from hot equipment such as stoves,

frying baskets, ovens, etc.

Failure to comply will damage the machine and refrigeraon components and will void all

warranes.

Operang in higher ambient temperatures will result in degraded performance.

1. Connect all wires to Circuit Breaker (including neutral & ground bus

terminals) or Local Plug according to supply voltage and wire codes on

machine power cable.

2. Verify Incoming Supply Cable is wired the same way on Circuit Breaker or

Wall Receptacle before switching on or plugging in the machine.

The image displayed is for illustraon purpose only and may

dier from the actual product.

• Daily

•: Every 1 to 3 months*

• Quarterly**

* Based on machine usage and cleaning intervals; a Tune-Up Kit is available with all

wearable parts (O-rings, gaskets, etc.) except scraper blades

** Based on cleanliness of locaon and proximity to powder-based machines.

Preventave maintenance includes cleaning condensers, checking belt tensions, and

cleaning the interior of the machine frame as required.

For opmal machine performance and many years of eciency and reliability

from your machine, Spaceman recommends cleaning and sanizing the

machine and its parts . The machine comes equipped with a brush kit

specically designed to eciently and properly clean the machine.

Cleaning and sanizing schedules are governed by state or local regulatory agencies

and MUST be followed accordingly. Roune maintenance MUST be performed a minimum of once

every 3 days.

• Do NOT run the machine without properly lubricang required parts

• Do NOT clean the machine with abrasive or toxic chemicals and cleaners. Doing so may cause

damage to the stainless steel material

• ONLY use Spaceman-included cleaning brushes and lubricaon

• NEVER use metal objects to clean or operate the machine

• ALWAYS replace wearable parts a minimum of every 3 months

• ALWAYS prime machine prior to operang

• ALWAYS inspect parts for excess wear and damage

Addional brushes, lubricaon, wearable parts, and tools can be purchased from Spaceman

to ensure proper maintenance. Extra wearable parts (except scraper blades) are found in the Start-

Up Kit.

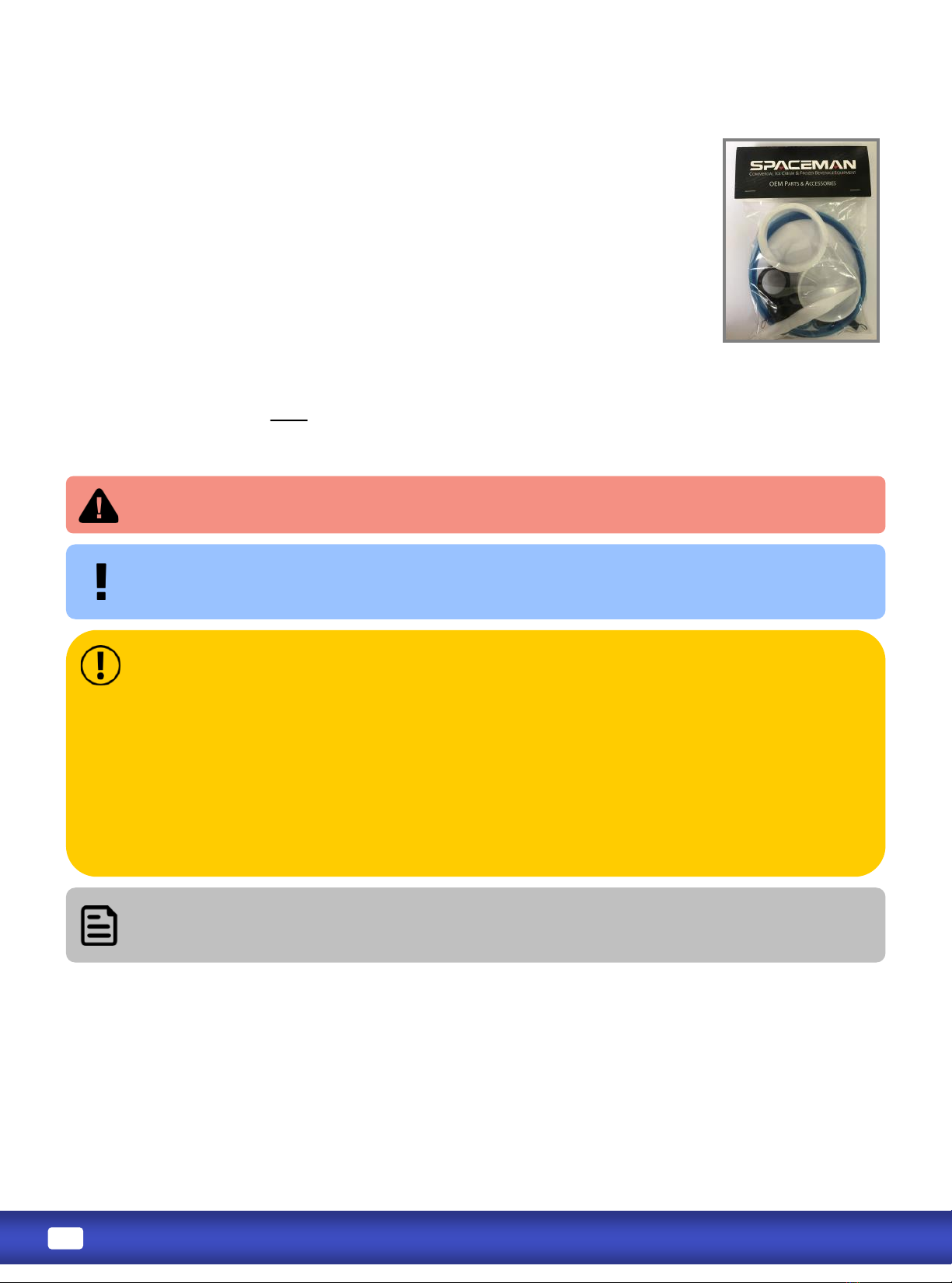

If this is the rst me operang the machine, you MUST clean and sanize ALL parts

prior to running the machine.

The image displayed is for illustraon

purpose only and may dier from the

actual product.

-

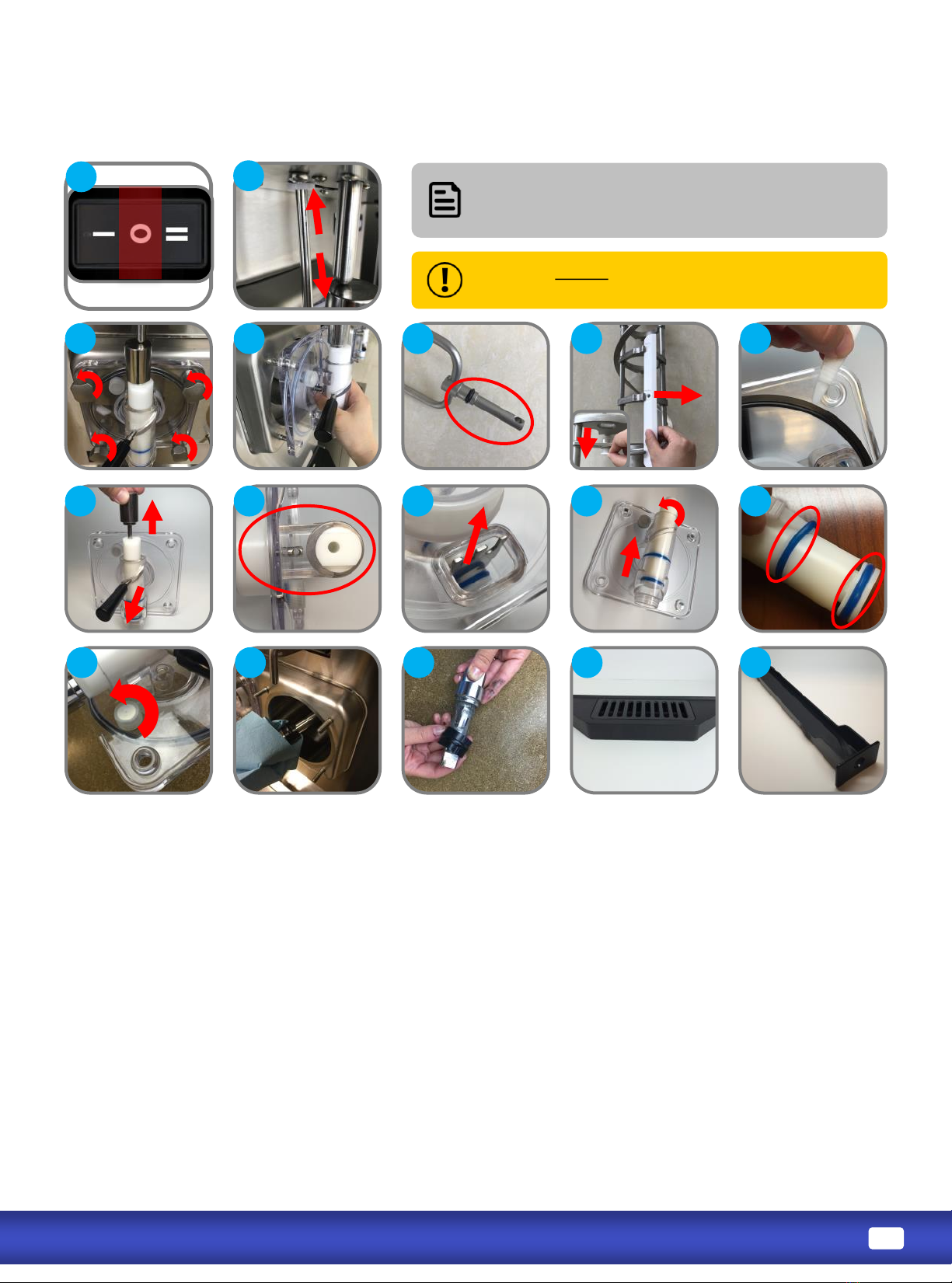

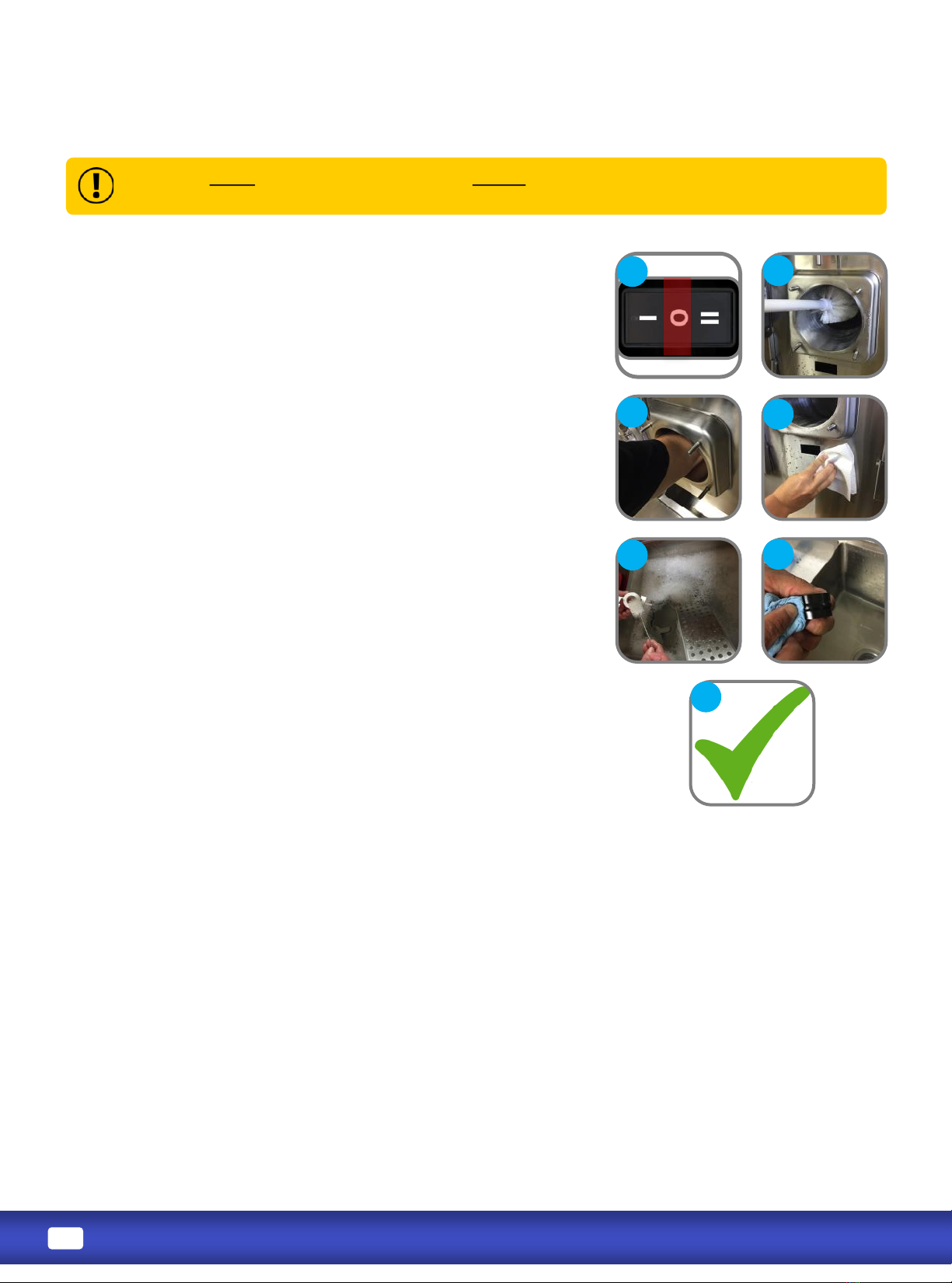

1. Verify the power switch is turned to OFF.

2. Remove the torque arm, rst pulling up out of

the torque assembly and then down out of the

at sensor arm.

3. Remove dispensing door hand-screws (4).

4. Remove dispensing door assembly, torque

assembly, and beater assembly.

5. Remove torque assembly O-ring using O-ring

tool; remove torque guide.

6. Remove scraper blades from beater assembly

7. Remove dispensing door gasket using O-ring

tool.

8. Rotate draw valve unl the at part at the top is

perpendicular to the clear face of the dispensing

door (use towel if necessary).

9. Remove ice buster.

10. Remove draw valve, twisng it while removing.

11. Remove draw valve O-rings (2) using O-ring tool.

12. Unscrew and remove prime plug from

dispensing door.

13. Use a towel to remove drive sha at the back of

the cylinder.

14. Separate drive sha gasket from drive sha.

15. Remove front drip tray and internal drip tray.

Prepare dishwashing area prior to

disassembly, and use a bucket to temporarily store

removed parts.

Always separate O-rings and gaskets from

metal parts to prevent damage while washing.

1. Verify power switch is turned to OFF.

2. Use the large brush and cool water to thoroughly clean

inside the cylinder; be sure to scrub the back of the

cylinder and verify the cylinder is free of ALL product.

3. Thoroughly clean and dry the rear of the cylinder with

the supplied black brushes and a clean, dry towel.

4. Gently clean and wipe down the outside of the

machine.

5. Carefully and thoroughly wash all parts removed from

the machine using supplied brushes, sponges, and clean

towels; when cleaning the dispensing door, clean the

priming port with a small brush.

6. Carefully and thoroughly clean all gaskets and

O-rings removed from the machine; be sure to wipe

gaskets and O-rings to remove excess lubricant.

7. Verify all parts are clean and free of all food product

prior to re-assembling machine.

Never wash parts in a dishwasher. Always hand-wash components with nontoxic,

food-safe cleaners.

Never force the installaon of any parts. All parts t correctly without force. If parts

don’t seem to t, remove all parts and repeat assembly.

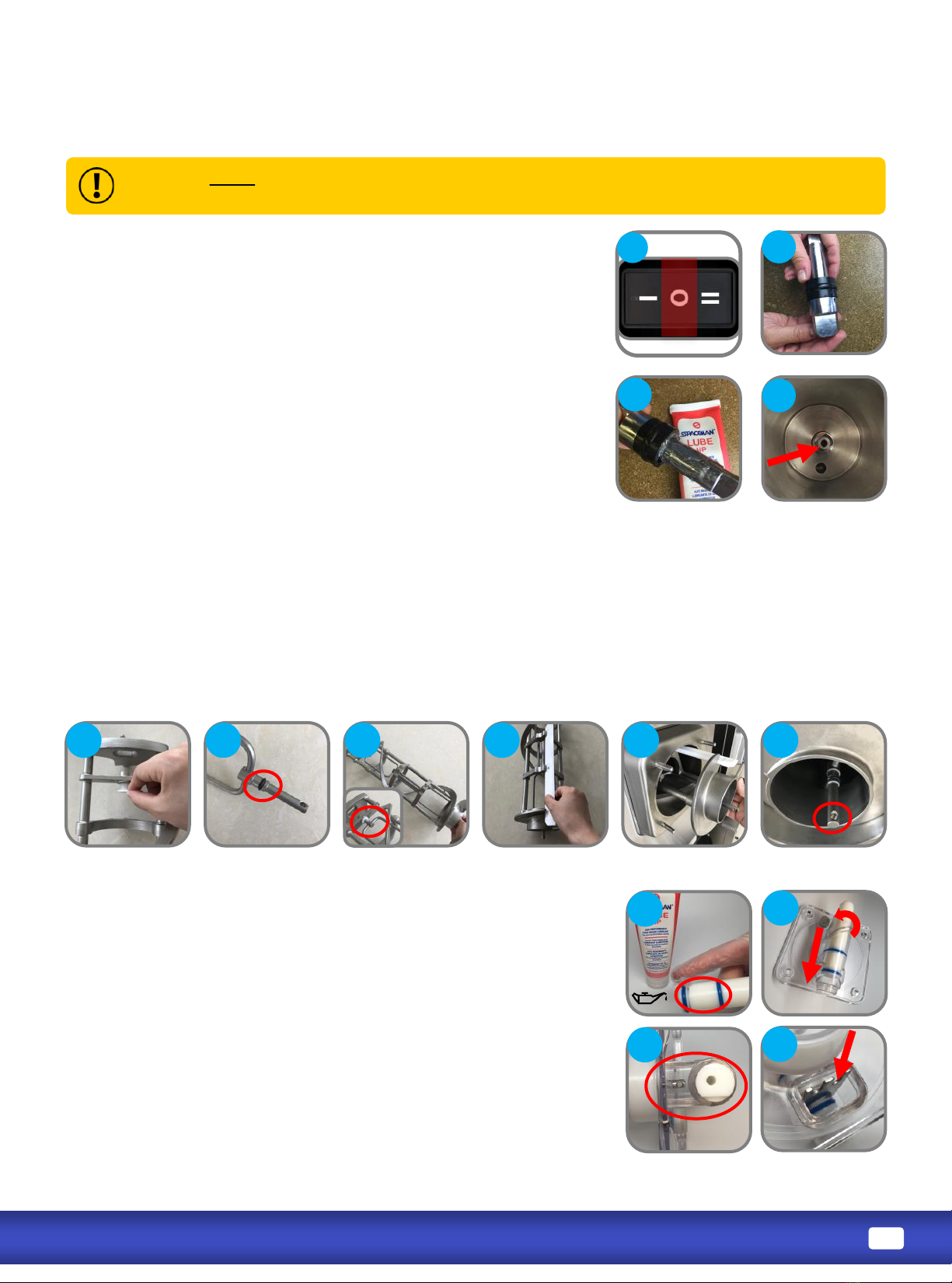

a. Place drive sha gasket on drive sha.

b. Seal gasket open space with Spaceman lubricant,

extending onto drive sha and avoiding the top square

part.

c. Insert drive sha into rear shell bearing at the back of

the cylinder, and turn it unl the key engages rmly into

the socket (when inserted correctly, the drive sha will

no longer turn 360°).

a. Place torque guide onto the end of the beater assembly; DO NOT lubricate this component.

b. Place O-ring on torque assembly, coang with Spaceman lubricant.

c. Insert torque assembly into torque guide at the end of beater assembly.

d. Fit scraper blades onto beater.

e. Insert the complete beater assembly into cylinder; turn assembly unl it engages the drive sha

key and no longer turns 360°.

a. Place O-rings (2) on draw valve, coang with Spaceman

lubricant.

b. Insert draw valve 7/8 way into the dispensing door from

the top, rotang as you install.

c. Turn draw valve so the at poron at the valve top is

perpendicular to the clear face of the dispensing door .

d. Insert ice buster through the dispensing spout at the

boom of the door and into the slot on the draw valve.

e. Rotate draw valve to lock ice buster in place; turn valve unl the hole for the draw handle is

accessible on front.

f. Insert draw handle; secure in place with valve pin.

g. Screw prime plug onto dispensing door.

h. Place dispensing door gasket on door, coang with Spaceman lubricant; Place beater guide onto

dispensing door, with ange ush with the back of the door.

i. Align door assembly with torque assembly and mounng bolts; install dispensing door unl ush

with machine; if needed, gently wiggle dispensing door to get the beater guide to line-up correctly

inside the beater; DO NOT force the dispensing door onto the machine.

j. Tighten dispensing door hand-screws (4) in a cross-paern.

k. With tapered end down, install torque arm up through the sensor pin hole under the overhead and

then down into the torque assembly; torque am should move freely back and forth.

a. If machine has hopper agitator,

lubricate inside it and install with arrow

poinng up.

b. Install hopper lid and drip trays (internal

and front).

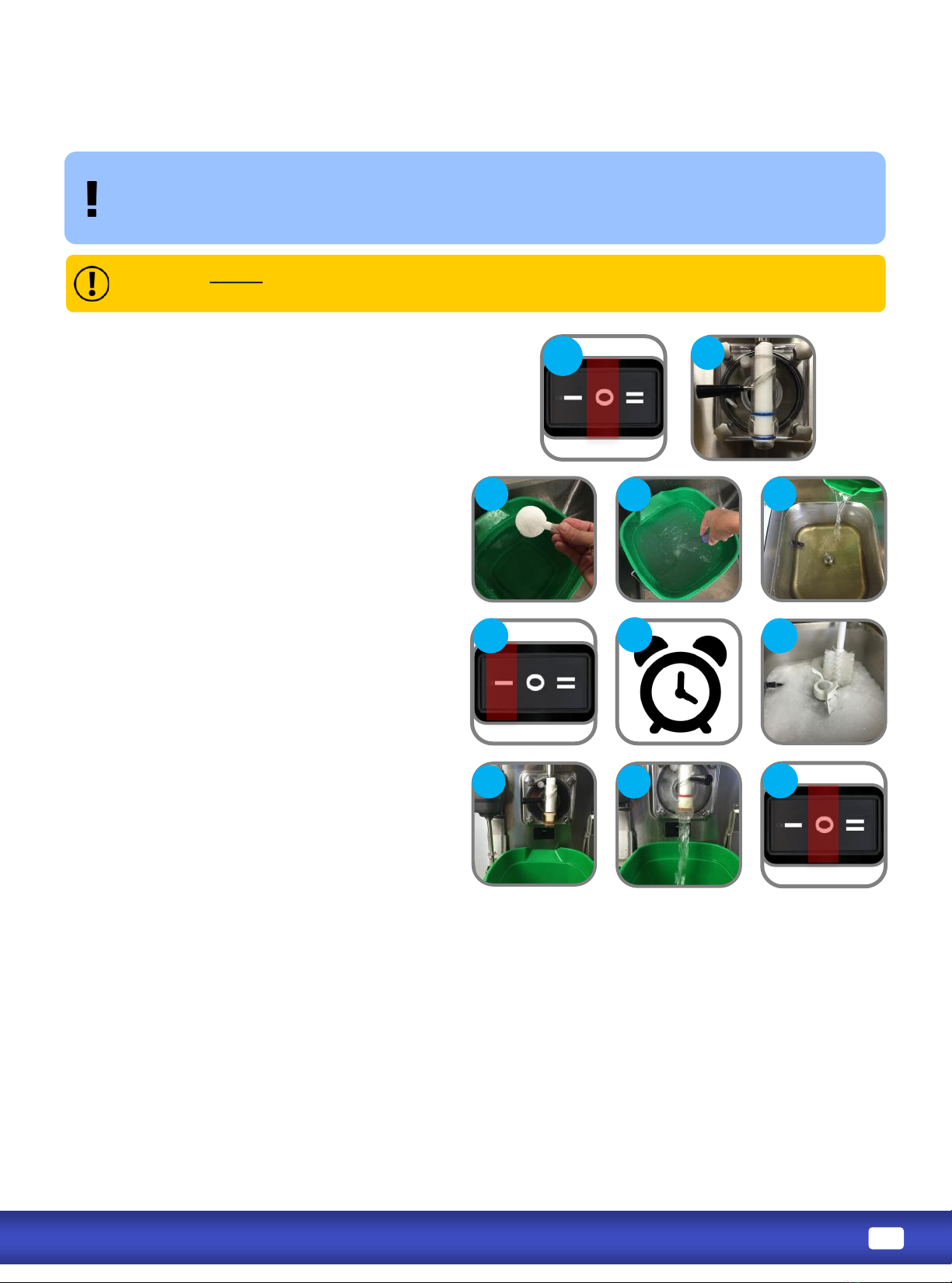

Aer sanizing the machine, DO NOT rinse or touch areas that have been sanized.

Product must be added immediately. If new product will not be added immediately, rinse machine

with clean water and loosen door hand-screws to allow cylinder to air-dry. Sanize machine before

using again.

1. Verify assembly is complete and machine

power is OFF.

2. Verify the draw valve is in the CLOSED

posion (LEFT).

3. Mix a minimum of 7.57 liters (2 gallons) of

food-grade sanizer in a bucket or

container.

4. Pour a minimum of 7.57 liters (2 gallons)

of food-grade sanizer soluon into the

hopper.

5. Turn power switch to WASH.

6. Allow soluon to agitate for 5 to 10

minutes; NEVER leave machine on WASH

for more than 10 minutes.

7. While agitang, gently use a clean brush to

scrub and distribute sanizer soluon

along hopper walls and hopper agitator (if

present).

8. Place a bucket or container below the

draw valve.

9. OPEN the draw valve (RIGHT) and drain

soluon from the machine.

10.Turn power switch to OFF.

Always use food-grade, no-rinse sanizer to sanize. If warm water is required to

dissolve sanizer, allow the soluon me to cool before adding to machine.

1. Verify machine has been recently sanized (within

1 hour); if machine has not been recently

sanized, verify door hand-screws are ght, and

perform sanizing steps (Page 13).

2. Turn power switch to OFF.

3. Thoroughly mix and prepare at least 7.57 liters (2

gallons) of product according to manufacturer

instrucons; mix should be cool and smooth (free

of large chunks).

4. Place a bucket or container below the draw valve.

5. OPEN draw handle (RIGHT).

6. Pour 0.95 liters (0.25 gallons) of product into the

hopper; sanizer will start to ow out of the draw

spout.

7. Once sanizer has been purged from the machine

and a steady stream of product is owing from the

spout, CLOSE draw handle (LEFT).

8. Pour remaining product into the hopper.

9. Open the prime screw (counter-clockwise) on the

front of the dispensing door and allow the cylinder

to ll with product to the desired level;

cylinder must be at least 75% full to operate.

10. Close the prime screw and ghten completely.

11. Replace hopper lid.

1. Verify cylinder is full of mixed product.

2. Turn power switch to FREEZE and verify STANDBY mode is o .

3. The motor will begin to agitate the product, and the cooling system will begin to

freeze the product.

4. Freezing product takes approximately 10 minutes; product is at the adjusted viscosity

when the at sensor arm is switched to the RIGHT.

5. When the product reaches the desired viscosity, it is ready to dispense.

Standby Buon

Light Box Buon

(If present)

Power Switch

Mix Low Light

Standby Light

STANDBY WASH STOP FRREZE

Pull boom of light panel assembly towards you then down to take it

o. Do not disconnect wires.

On back of light panel, loosen hand screws (a few turns only without

taking it o) of tabs that hold light panel onto the frame.

Push light panel up from the frame and insert Flavor Card in between

light panel and the frame. Put light panel back in place.

Turn tabs 90 degrees back to hold light panel. Tighten hand screws.

1. OPEN draw handle (RIGHT) unl the desired amount is dispensed.

2. CLOSE the draw handle (LEFT) when nished dispensing.

In STANDBY, product remains below 5oC (41oF) in both the

cylinder and hopper, but will NOT be frozen.

Press on STANDBY buon underneath overhead.

Light on front panel illuminates blue when machine is in

STANDBY mode.

Turn power switch to WASH.

The motor will begin to agitate the product or water.

Mix low light is located on front panel of machine. Light will illuminate

RED and the alarm beeper will go o when mix level in hopper is low.

Hopper should be relled as soon as possible.

Alarm beeper can be turned o by pressing the Beeper Reset buon

on side panel of machine.

Always maintain at least 2cm of mix in the hopper. If you neglect to

add mix, a freeze-up may occur. This will cause eventual damage to the

beater assembly, the dispensing door, and gear box.

On front panel of machine, Mix Low and Standby lights on

standard machines will be replaced by a light panel.

Press on Light Box buon underneath overhead, light panel will

illuminate.

Light panel will illuminate WHITE under Freeze and Wash modes.

Light panel will illuminate RED when mix is low.

Light panel will illuminate BLUE under Standby mode.

STANDBY

MIX LOW Beeper Reset

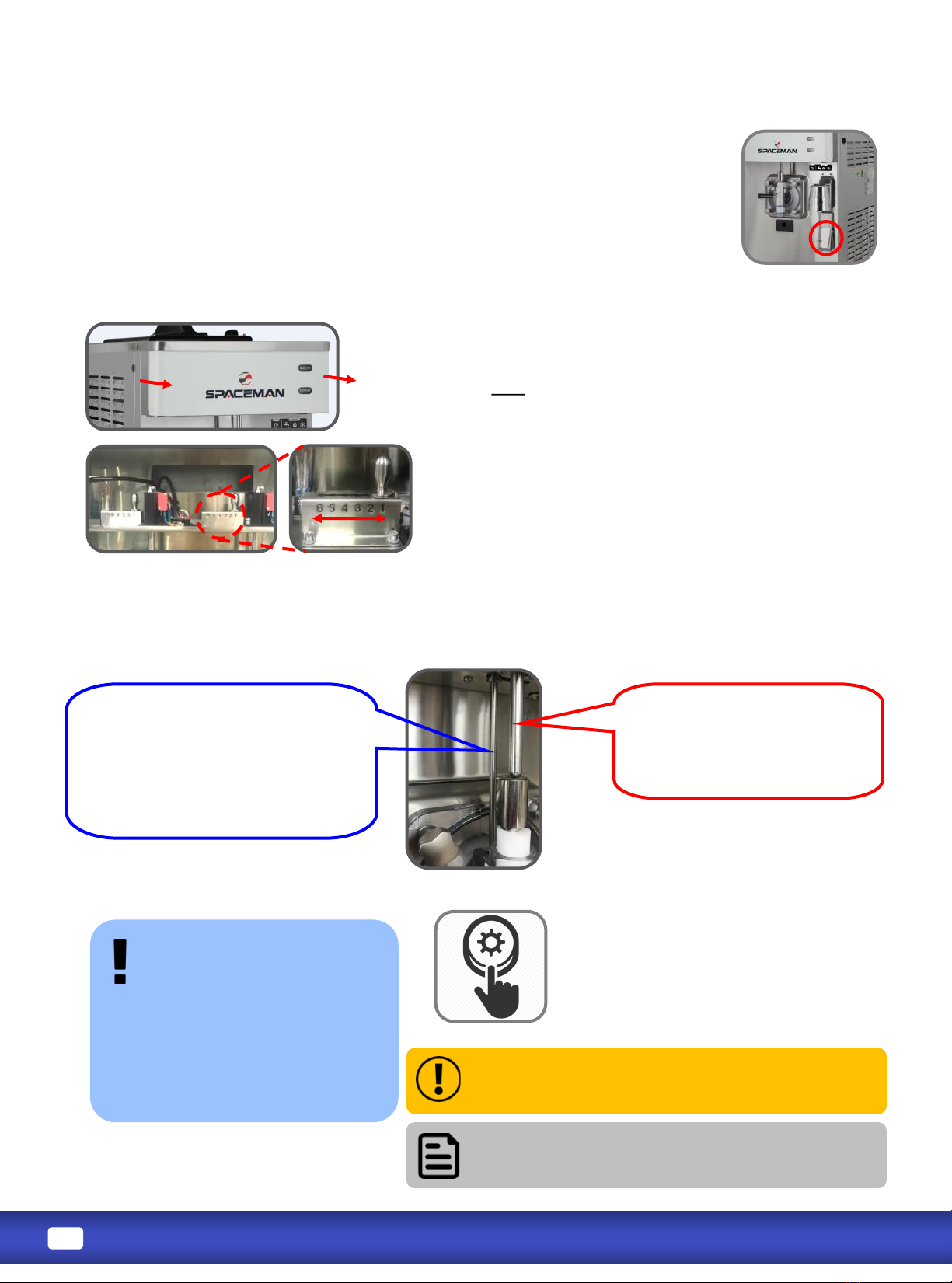

Located directly above the draw valve, this arm tells the machine when product is being dispensed

and how rm the product is. Beater and cooling systems are turned on and o based on

informaon from the sensor arms.

The viscosity adjustment, located behind the faceplate,

controls the rmness of dispensed product. The higher the

viscosity, the more rm the product. Viscosity sengs

should NOT need connuous adjustment.

Take o the faceplate. Viscosity is from Soer to Harder

from level 1- 6. Make small adjustments each me, and

allow at least 10 to 15 minutes between adjustments to

evaluate product rmness.

Arm moves up and down and

tells machine when product is

being dispensed.

It moves UP when draw handle

is in the OPEN posion.

Flat arm moves le and right and

tells machine when product is at

desired consistency.

Switched RIGHT means consistency

is correct. Switched LEFT or IN THE

MIDDLE means consistency is not

yet correct.

If machine doesn’t turn on, turn power switch

OFF, wait 30 minutes, and repeat steps 1 to 4. If

problem persists, contact service team.

If machine makes any abnormal noise

during reset, immediately turn power switch OFF

and contact service team.

-(usually

because the viscosity is set too

high for the selected product to

prevent motor damage.

Use the green reset buon on

the machine’s back panel to

return the machine to normal

operaon.

1. Turn power switch to OFF.

2. Firmly press green reset buon.

3. Wait 15 to 20 minutes.

4. Turn power switch to WASH.

5. Observe machine performance.

Spinner operaon is controlled by the paddle switch on lower poron of the

spinner mount.

The paddle switch is designed for one-hand operaon. Hold cup up towards

the spindle while pressing in the paddle switch with the same hand. Spinner

will turn on and stay on. Spinner will stop as soon as paddle switch is released.

1. Product is over-frozen in cylinder.

2. Inadequate mix in hopper.

3. Power switch is in the OFF posion.

4. Unit is unplugged.

5. Tripped circuit breaker or blown fuse.

6. Improper mixing of product.

7. Machine has tripped safety reset.

8. Up down sensor arm not engaging

1. Lower viscosity seng as required (Page

13).

2. Ensure hopper is at least half full.

3. Turn power switch to FREEZE.

4. Verify machine is plugged into power

source.

5. Verify and reset circuit breaker and/or fuse.

6. Follow manufacturer instrucons for mixing

product; ensure correct mix raos.

7. Reset machine (Page 13).

8. Verify sensor arms are installed and

operang according to the manual.

1. Improper or inadequate lubricaon of drive

sha gasket.

2. Damaged, missing, or improperly installed drive

sha gasket.

3. Debris build up in back of cylinder

1. Use sucient food-grade lubricant, and add

sucient lubricant inside drive sha gasket

during assembly (Page 8).

2. Replace drive sha gasket every 1 to 3 months;

replace torque assembly guide every 1 to 3

months.

3. Clean back of cylinder well taking special note

around the lips of rear shell bearing connecon.

1. Improper or inadequate lubricaon of draw

valve and draw valve O-rings.

2. Cracked, broken, or worn draw valve O-rings.

1. Use sucient food-grade lubricant when

assembling draw valve (Page 8).

2. Replace O-rings every 1 to 3 months.

1. Broken torque or beater assembly.

2. Beater guide worn or missing.

3. Incorrect assembly of beater, blades, and guide

1. Repair or replace torque or beater assembly.

2. Replace or install beater guide.

3. Assemble machine to manual instrucons.

Cylinders are experiencing freeze-up (usually

due to viscosity being set too high for selected

product).

1. Reset machine (Page 13), conrm there is

product in the hopper, conrm there is no

blockage from hopper to cylinder.

2. Conrm product was premixed properly.

3. Lower viscosity as required (Page 13).

1. Inadequate mix in hopper.

2. Improper mixing of product.

3. Torque arm is not installed correctly.

4. Viscosity adjustment is set incorrectly.

5. Le/right sensor not engaging and/or is

stuck to the le.

6. Up/down sensor is engaged and stuck in up

posion.

1. Ensure hopper is at least half full.

2. Follow manufacturer instrucons for mixing.

product; ensure correct mix raos.

3. Install torque arm on dispensing door.

4. Lower viscosity seng as required (Page 13).

5. Verify sensor arms are installed and

operang according to the manual

1. Improper mixing of product.

2. Missing, damaged, or incorrectly installed

scraper blades.

3. Viscosity adjustment is set incorrectly.

4. Beater is rotang counter-clockwise.

1. Follow manufacturer instrucons for mixing

product; ensure correct mix raos.

2. Inspect scraper blades for damage and correct

installaon.

3. Increase viscosity seng as required (Page 13).

4. Call Spaceman Technical Support.

1. Machine is unplugged.

2. Tripped circuit breaker or blown fuse.

3. Machine has tripped safety reset.

1. Verify machine is plugged into power source.

2. Verify and reset circuit breaker and/or fuse.

3. Reset machine (Page 13).

Machine has tripped safety reset due to motor

overload.

Reset machine (Page 13).

Check sensor arms.

1. Lubricaon on square ends of drive sha.

2. Scoring due to lack of lubricaon.

1. Do NOT lubricate the square end of the drive

sha; contact Spaceman Technical Support for

instrucons on removing and inspecng drive

sha and gear box for damage.

2. Replace Drive Sha, use addional lubricaon.

This manual suits for next models

2

Table of contents

Other Spaceman Kitchen Appliance manuals