SPAD Demon User manual

Demon

file:///C|/Users/Frank/Documents/Demon/dem1.html[6/14/2011 4:30:30 PM]

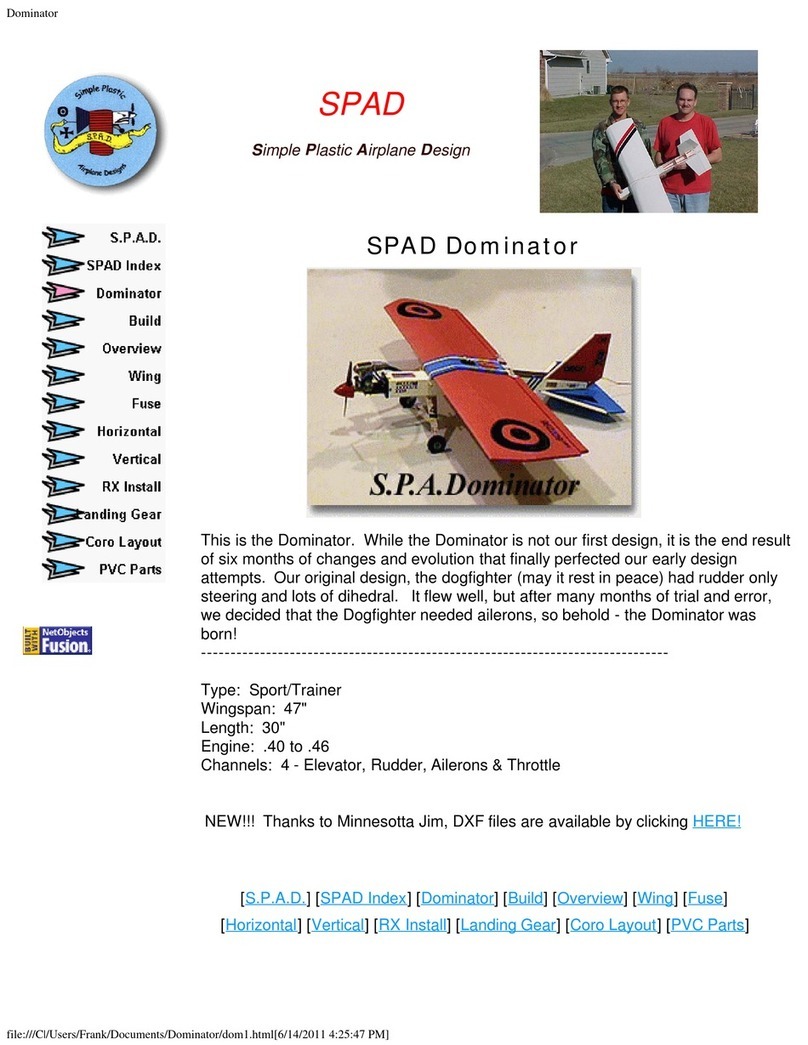

SPAD

Simple Plastic Airplane Design

SPAD Demon

After building high winged airplanes for several months, we agreed that we

needed something a bit sleeker that also did away with rubber bands. That

inspiration led us to the development of the Demon. This plane flies like a Scat

Cat! Very solid flight characteristics with no bad habits and it looks so good on

the ground and in the air!

--------------------------------------------------------------------------------

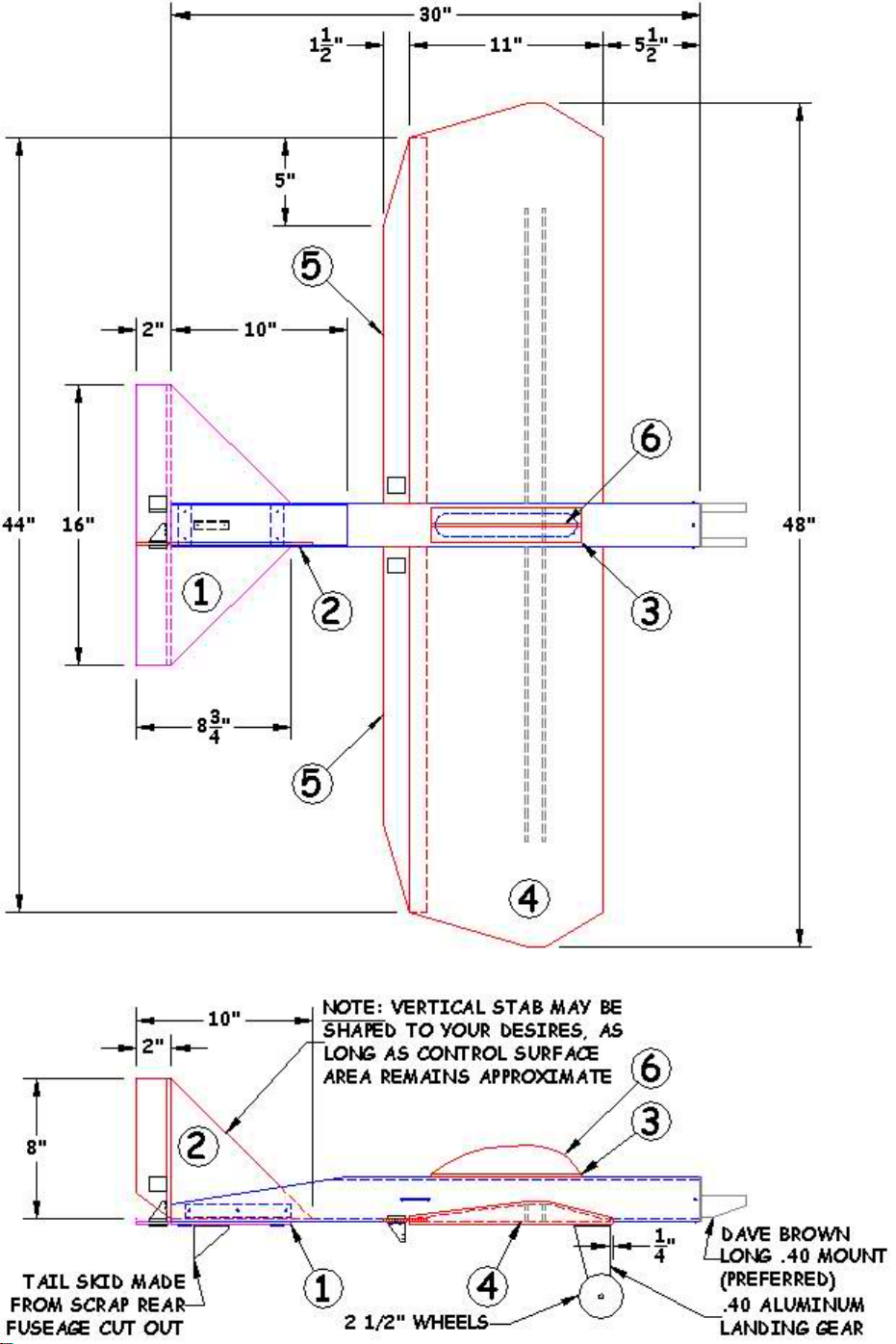

Type: Sport

Wingspan: 47"

Length: 30"

Engine: .40 to .46

Channels: 4 - Elevator, Rudder, Ailerons & Throttle

[S.P.A.D.] [SPAD Index] [Building] [Overview] [Fuselage] [Wing] [Horizontal]

[Vertical] [Rx Install] [Landing Gear] [PVC Parts] [Parts Layout]

Building

file:///C|/Users/Frank/Documents/Demon/dem2.html[6/14/2011 4:30:56 PM]

Fuselage:

1. Using a 30" long PVC fuselage "blank" measure, mark, and cut out rear fuselage taper as shown on drawing 2.

The Dagger has no down thrust or right thrust.

2. Measure, mark and cut out the radio access hole as shown on drawing 2, leaving a 3/8" lip between the radio

access hole and fuselage side for strength. If you’re using a utility knife or saw (rather tough) this can be

made easier by drilling a 1/4" hole in each corner and cutting between them.

3. Measure, mark and cut out for the wing spar slot in the fuselage (see drawing #2). Insure the slot is cut big

enough to allow the yardstick to seat completely flush with outside surface of fuselage bottom, yet not too big

as to be sloppy!

NOTE: The fit of your wing is dependent on how accurately you cut the spar slot!

4. Use some course grit sandpaper or a file to get all the white fuzzies off and to help clean up the cut edges.

Tail Feathers:

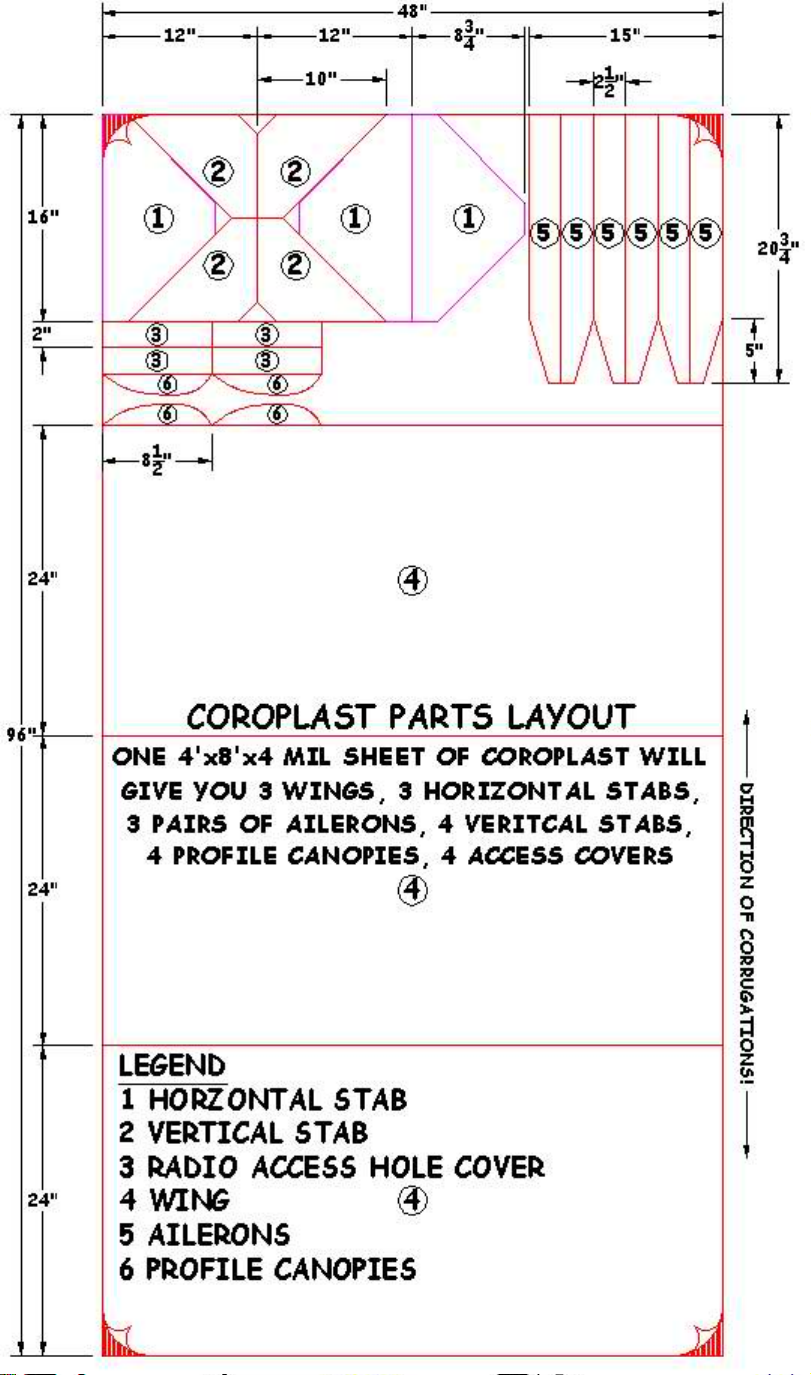

1. Refer to drawing 6 for the best layout we have come up with to get the most parts (and spare parts) from

one 4'x 8' sheet of Coroplast®.

2. Cut out horizontal and vertical tail feathers as shown on drawing 4.

3. Elevator and rudder are created by cutting out ONE SIDE ONLY of the hinge line corrugation. This can be a

little tricky. We use an adjustable blade, box opener type knife and straight edge. Wrapping an X-acto® knife

with masking tape leaving just the tip exposed will work also.

Can you believe it? The tail feathers are done already! Let’s attach them to the fuselage.

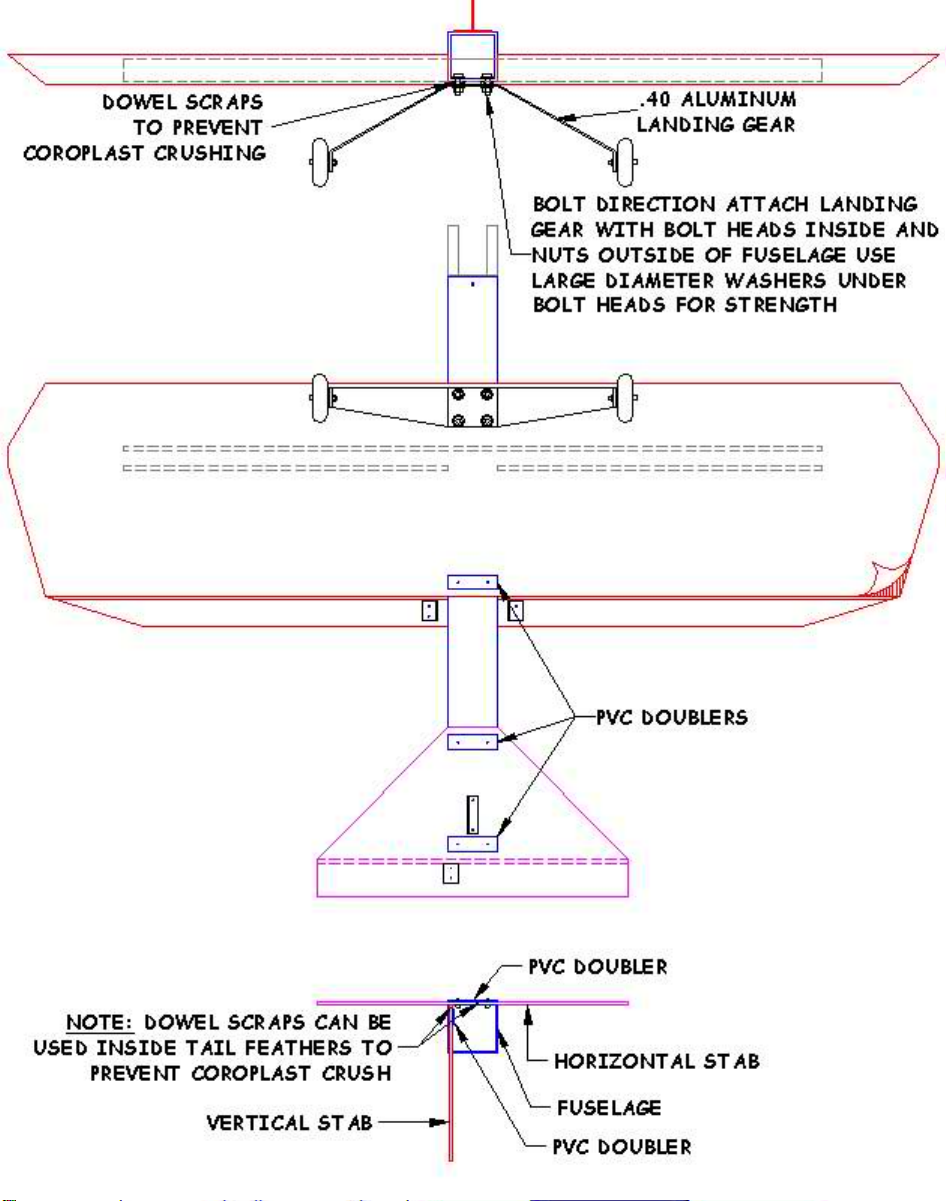

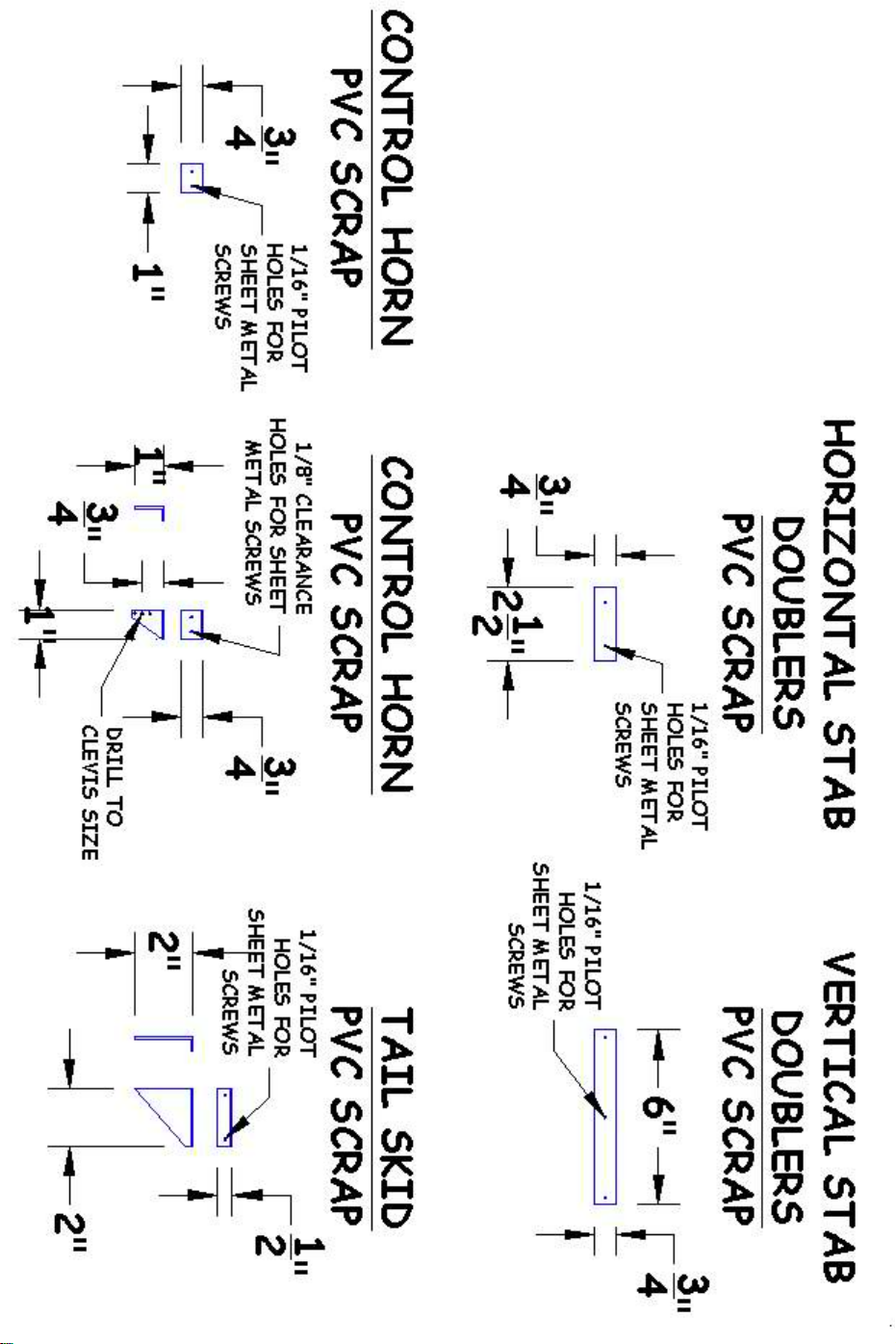

1. Fabricate 2 horizontal, and one vertical stab attach doublers as shown on drawing 7, from the PVC scrap

removed from the fuselage cutouts.

2. Fabricate a tailskid as shown on drawing 7 from the PVC scrap removed from the rear fuselage cutout.

NOTE: Exact doubler hole location measurements are not given because this is not critical, and could change

slightly from plane to plane. When positioning the doublers and tailskid, keep in mind that the screws will go

through the Coroplast® very easily in the middle of a corrugation, and will almost certainly go crooked at the

edge of a corrugation.

3. Drill 1/16" pilot holes in doublers and tailskid.

4. Using the doublers and tailskid as templates, drill 1/16" holes in the fuselage for each screw attach location.

Enlarge holes IN FUSELAGE ONLY to 1/8".

6. When satisfied with positioning, fasten tail feathers to fuselage using sheet metal screws, self-tapping into

doublers and tail skid.

NOTE: Dowel scraps can be used in the corrugations at the attach points to prevent Coroplast® crush.

6. Optional panel edging can be added to the stab leading edges for dress up and to keep dirt & fuel out if

desired.

Building

file:///C|/Users/Frank/Documents/Demon/dem2.html[6/14/2011 4:30:56 PM]

Wing:

1. Fabricate a wing as follows:

2. Refer to drawing 3. The wing is laid out on a 2' x 4' piece of Coroplast® with the corrugations running

CHORDWISE.

3. Mark all centerlines, fold lines, spar lines, and wing tips on the Coroplast®.

4. Cut Coroplast® material away from the outside edges of the bottom panel wing tips.

5. Measure 1 1/4" from the top wing centerline out each way and mark. Then cut out the piece (this allows for

snug fuselage clearance when folding the upper sheet). Cut to the leading edge fold line ONLY!

6. Refer to drawing 6 (parts layout) and cut two 2 1/2" x 20 3/4" pieces of Coroplast® with corrugations running

LENGTHWISE for ailerons. Refer to drawing 3, and mark the hinge line, and notch the outboard

edge 1/4", forward of the hinge line only (this is for wing tip folding clearance).

7. Hinge the ailerons by cutting away the BOTTOM portion of one corrugation, forward of the hinge line as

shown in the profile view of drawing 3.

NOTE: If the Coroplast® is relatively stiff (it does vary), you might have to cut TWO corrugations out to

make the hinge pliable enough. This is perfectly acceptable.

OK! We now have all the pieces, let’s build the wing!

8. Score and pre-bend ALL fold lines. Pre-bend leading edge 180°, the upper spar lines 90°, wing tips 45°,

NOTE: Scoring is accomplished by using a straight edge and blunt tipped object (Small Allen wrench or Apex

works well) and running it firmly along the fold line until you are satisfied a bend can be accomplished. Folds

ALONG a corrugation require little scoring, and bend easily. (score one corrugation for the wing tips). Folds

AGAINST the corrugations require heavy scoring (sounds like a baseball card in bicycle spokes) and are best

accomplished by turning the wing over and bending along a straight table top edge. Use palm pressure, and

work along the fold. Please be patient, this is not easy and takes a little getting used to. But once mastered,

it sure beats balsa wood and Monokote®!

9. Lay the wing out flat, and glue the two spars to the bottom panel as shown on drawing 3.

NOTE: IF USING EPOXY, ROUGHEN UP THE COROPLAST® WITH COURSE GRIT SANDPAPER AT ALL

SURFACES TO BE GLUED. IF USING CA, QUICKLY HEAT “FLASH†THE GLUING SURFACES WITH

A PROPANE TORCH (CAREFUL NOW!). USE SMALL 1/8" DROPS EVERY INCH OR SO. A BEAD OF GLUE MAY

NOT WORK! USING TOO MUCH GLUE IS THE BIGGEST MISTAKE HERE!

10. Test fold the wing, and trim the trailing edge excess off the top panels, to make them flush with the bottom

panels.

NOTE: When folding the wing, the top panel pressure will tend to pull up on the leading edge, causing the

lower panel to curve slightly up. A small amount of this is acceptable, and will even improve your planes

performance!

11. Glue the ailerons to the lower wing panel trailing edges, with the hinge fully exposed, and outboard edge even

with the wing tip fold line. If desired, trim aileron outboard edges to contour with the wing tips.

12. Working one top panel at a time, fold over and glue upper wing to the top of the spar. (a board and weights

works good here)

13. Glue the top panel trailing edges down, using care not to get glue on the aileron hinge area.

14. Fold the wing tips up into the top panels, and glue in place. When dry, trim off the excess.

15. Test fit the fuselage into the wing center cutout. When you are satisfied the wing is correct, make a wing

mount doubler then mark and drill the REAR wing mount holes (see drawing #7). Use the same drill sizes you

used when you mounted the tail feathers. Using two ¾†#6 sheet metal screws, mount the wing to the

fuselage.

NOTE: The landing gear will retain the forward edge of the wing.

Landing Gear:

Building

file:///C|/Users/Frank/Documents/Demon/dem2.html[6/14/2011 4:30:56 PM]

1. With the wing in place, position landing gear on bottom of the wing/fuselage with leading edge of gear 5 1/2â€

from front of fuselage (1/4" behind the leading edge of the wing). Mark and drill for bolt installation. Next,

insert 4 short scraps (approx. 2" long) of 5/32" dowels into the corrugations in the wing Coroplast®, from the

leading edge (dowels should straddle the landing gear holddown bolts) to prevent the Coroplast® from crushing

when you tighten the landing gear bolts!

NOTE: Exact hole diameter, and location measurements are not given, as this will vary with different types of

gear. Keep in mind there must be enough room inside of fuselage, between the boltheads for the "powerpack"

assembly yardstick. (see drawing #5)

2. Install landing gear to wing/fuselage with boltheads inside, and nuts outside of fuselage as shown on drawing 7.

NOTE: Use large diameter washers under bolt heads for strength.

3. Make sure the front of each wheel "toes in" towards the fuselage slightly. This will greatly improve the

ground handling of your plane!

Power pack assembly: (firewall, engine, engine mount, fuel tank, throttle servo)

1. Fabricate a firewall to fit the inside diameter of your fuselage from 3/4" plywood and test for a snug fit. The

firewall will be installed flush with the forward edge of the fuselage.

NOTE: If you wish to get fancy and you have a table or radial arm saw, "step" the firewall by cutting one

and a half of the ply layers to the fuselage outside diameter, and the rest to the fuselage inside diameter.

This will give you a nice firewall "cap" and greatly increase it's impact strength.

2. Cut a groove, two plies deep, at the bottom of the rear side of the firewall, to receive a 1" yard stick stand

off and glue stand off to firewall as shown on drawing 5.

3. Cut a 7" section of yardstick, and glue to stand off and firewall, then glue the ½†standoff to the rear of the

powerpack.. Test fit this assembly into fuselage, and assure the yardstick clears the landing gear mounting bolt

heads.

4. Measure mark and drill holes for engine mount, fuel lines, and throttle wire housing, and install engine mount

blind nuts.

5. Fuel proof the firewall with epoxy or dope.

6. Install engine mount, engine, and throttle wire housing to firewall.

7. Position fuel tank on a layer of foam on the yardstick as shown on drawing 5, and secure with at least two #64

rubber bands. Also install fuel lines.

8. Test fit this assembly into fuselage and decide on the best throttle servo positioning. When satisfied, remove

assembly from fuselage. And install throttle servo to yardstick.

NOTE: Throttle servo is attached to yardstick with double face mounting tape. Then drill a hole on each side

of servo and secure with a tie strap as shown on drawing 5.

9. Plug your throttle servo into the receiver, and turn on the radio. Install the throttle wire and rig to your

satisfaction.

10. Install the "power pack" assembly into the fuselage. Secure in place using at least one sheet metal screw on

each fuselage side as shown on drawings 1 and 2. You may wish to use silicone sealer for a good fuel proof

firewall seal.

NOTE: Exact measurements for location of firewall mount screws is not given as this may vary from plane to

plane, taking care not to puncture a fuel line or hit the throttle wire or an engine mount bolt.

Radio Installation:

1. Wrap your battery and receiver in foam and comfortably position them as shown on drawing 5.

NOTE: The "power pack" assembly should already be installed at this point.

2. Cut and drill the necessary holes, and mount the switch in the location of your choice. We like to put it on the

left side of the fuselage, near the top, at the mid point of the radio access hole.

3. Measure, mark and cut out the hole in the bottom of the wing (just aft of the spar) for the aileron servo.

Building

file:///C|/Users/Frank/Documents/Demon/dem2.html[6/14/2011 4:30:56 PM]

NOTE:

Elevator and rudder servos are mounted by sticking them in place with double face foam type

mounting tape, drilling a hole on each side of the servo, and securing with a tie-strap (Be careful not to drill a

hole in your servo!!!) When mounting the aileron servo, use servo mounting screws and attach the servo to the

bottom of the wing/fuselage, screwing directly into the PVC. We have found that different engine and mount

combinations vary the airplanes CG greatly. Positioning of the rudder and elevator servos is the best way to

achieve proper CG.

4. Fabricate 4 control horn doublers from the PVC scrap as shown on drawing 4, then install control horns, and

doublers to ailerons, elevator and rudder.

NOTE: Exact dimensions for control horns and doublers are not given as this will vary from plane to plane,

with different styles of control horns. Also note that control horns can be “homemade†from PVC scrap from

the rear fuselage cut-out!

5. Fabricate the pushrods of your choice. We have used conventional 1/4" square balsa, ¼†dowels, nyrod, and

even 3/8" wide scrap yardstick for our elevator & rudder pushrods, and they all work just fine. We simply use

1/16" music wire for the ailerons.

6. Install pushrods, plug in all your radio gear, and rig the ailerons, elevator and rudder to your satisfaction. For

the elevator and rudder, we recommend ½†to 1" travel (1†to 2" TOTAL). For the ailerons, we recommend 3/8"

to 1/2" travel (3/4" to 1" TOTAL)

NOTE: When rigging your ailerons, ensure that the bottom of the ailerons are parallel to the bottom of the

fuselage! Do not allow then to droop (like flaps)! If your ailerons droop, they will drastically affect pitch trim!

7. Secure the battery and receiver in place by placing a piece of foam over them. The foam will tuck nicely under

the radio gear access hole side lip.

8. Make a radio hole access cover and profile canopy from the Coroplast® scraps and fasten it down with four 3/4"

#6 screws in each corner (see drawings #1, #2 & #6).

9. Antenna exit routing is a matter of personal preference. Collin glues a piece of scrap plastic tubing to the inside

bottom of the rear fuselage for the antenna to run through. Dean drills several holes into the left rear fuselage

side and tie-straps a portion of plastic tubing in place for the antenna to run through. We have also ran the

antenna up through the vertical stab.

Flight Preparations:

1. Using a finger tip under each wing tip at the FORWARD spar, pick up your new airplane to check it's center of

gravity. It must balance level or slightly nose heavy.

NOTE: If your plane balances tail heavy--DO NOT ATTEMPT TO FLY IT UNTIL THIS CONDITION

IS CORRECTED!

2. If your airplane does not balance to your satisfaction, correct it by shifting radio gear, adding prop shaft

weights, bolt on weights, or stick on weights as you see fit.

That's it! Your SPAD is done! We sincerely hope you found our instructions and drawings clear enough for you to build your airplane

without complications. If you found any errors, or procedures confusing, please e-mail us, we welcome your input and will do our best

to improve any problem areas. (We are in the military and are greatly influenced by staring at Air Force technical manuals all day

long).

Now lets go flying!

Flying the SPAD:

1. All procedures and dimensions we have presented in these instructions are tailored to flying your airplane with a

.40 to .46 sized engine. We have however, seen a SPAD sustain flight with a .15 sized engine, and fly like a

guided missile with a .60 (We don't recommend this!). Your flight performance will be superb with a standard

bushing engine, and be downright wild with a ball bearing engine.

2. Lets go over a few things before the first take off roll!

a. Assure you have range checked your radio.

b. Assure your elevator, rudder and ailerons are neutral, and have 1/2" to 1" travel each way (1’ to 2" total)

on the rudder and elevator, and 3/8†to ½†travel each way (3/4" to 1"total) on the ailerons. Any more

than that, and you better be pretty good!

c. Assure your airplane balances LEVEL at the wing spar if you are an experienced pilot - or slightly NOSE

HEAVY

if you wish a little more forgiving flight performance. DO NOT ATTEMPT TO FLY YOUR SPAD TAIL HEAVY!!!

Building

file:///C|/Users/Frank/Documents/Demon/dem2.html[6/14/2011 4:30:56 PM]

d. Assure the front of your wheels toe inward slightly, if they don't you may do some entertaining ground

acrobatics!

4. Fuel up, turn on the radio, fire up the engine, tune to your satisfaction, and LET’S GO!

5. Line up into the wind, hold full up elevator, and SLOWLY advance the throttle to begin a conservative take off

roll.

6. When you are comfortable that your airplane is tracking straight, and you have built up a little ground speed,

let up on the elevator, advance the throttle, let the tail come up, pull back, and you will jump into the air all

within about ten feet! Note: Your airplane may attempt to torque roll slightly to the left on take off, be ready

for it with a little right rudder.

7. Trim your airplane for straight and level hands off flight, and then have a ball!

8. The SPAD will do almost anything you tell it to, and do it quick and tight. While the SPAD does perform

inverted maneuvers well, we do NOT recommend inverted flight or "outside" type aerobatics unless you are a

very experienced pilot! Make sure you have plenty of altitude to bail out, while learning the inverted

characteristics of your airplane.

9. Your SPAD will remain stable and hang on the elevator beautifully during slow flight and landing. With it's

long wing chord, the SPAD will fly like a kite against a 10 mph+ wind! Keep in mind that the SPAD has quite a

high drag front profile, and will slow down fairly quickly when throttled back or dead stick. If you’re an

experienced pilot, the SPAD will perform a truly wild carrier landing! Just remember when you’re back on

the ground, hold full up while taxiing.

We hope you have as much fun with your SPAD as we have with ours!

[S.P.A.D.] [SPAD Index] [Building] [Overview] [Fuselage] [Wing] [Horizontal]

[Vertical] [Rx Install] [Landing Gear] [PVC Parts] [Parts Layout]

Table of contents

Other SPAD Toy manuals

Popular Toy manuals by other brands

SMC Networks

SMC Networks DC3-DAKOTA instruction manual

Lionel

Lionel SD80MAC owner's manual

Fisher-Price

Fisher-Price MIGHTY LOADER Owner's manual with assembly instructions

Fisher-Price

Fisher-Price Laugh&Learn Puppy's Mixtape quick start guide

Seagull Models

Seagull Models MINI CHRISTEN EAGLE II N54CE Assembly manual

Bontempi

Bontempi 15 3100 manual