Sparkfun Electronics Simon SMD Owner's manual

Page 1

Simon SMD

Kit Information & Instructions

This is a kit of loose components that go along with the SMD Soldering Lecture. This is

considered an intermediate kit for people who have soldered through-hole components

before and wish to learn how to solder surface mount components. This kit comes with

a preprogrammed ATmega328. All parts are listed below.

Kit includes:

Additional Tools Needed:

•NCP1402 IC

•10k Ohm Resistor

•47μF Capacitor

•10μF Capacitor

•0.1μF Capacitor (qty: 2)

•MBRA140 Diode

•22μH Inductor

•330 Ohm Resistors (qty: 4)

•Pre-programmed ATmega328 TQFP IC

•Tweezers

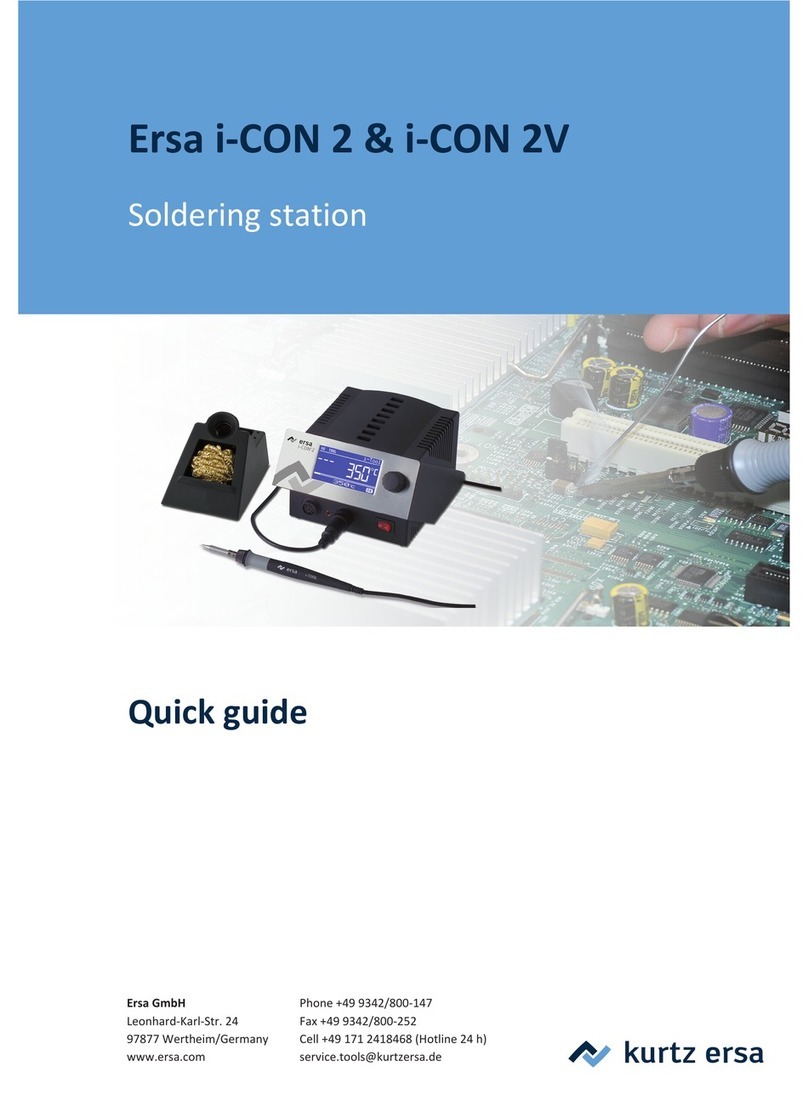

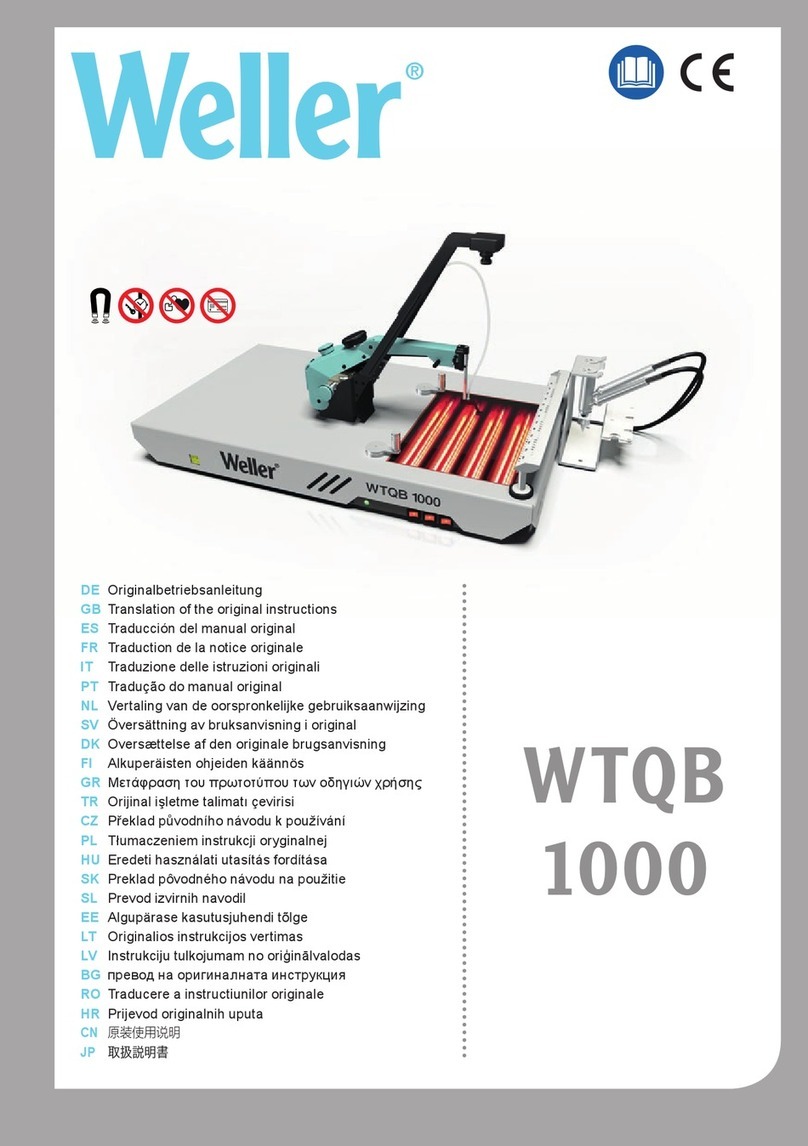

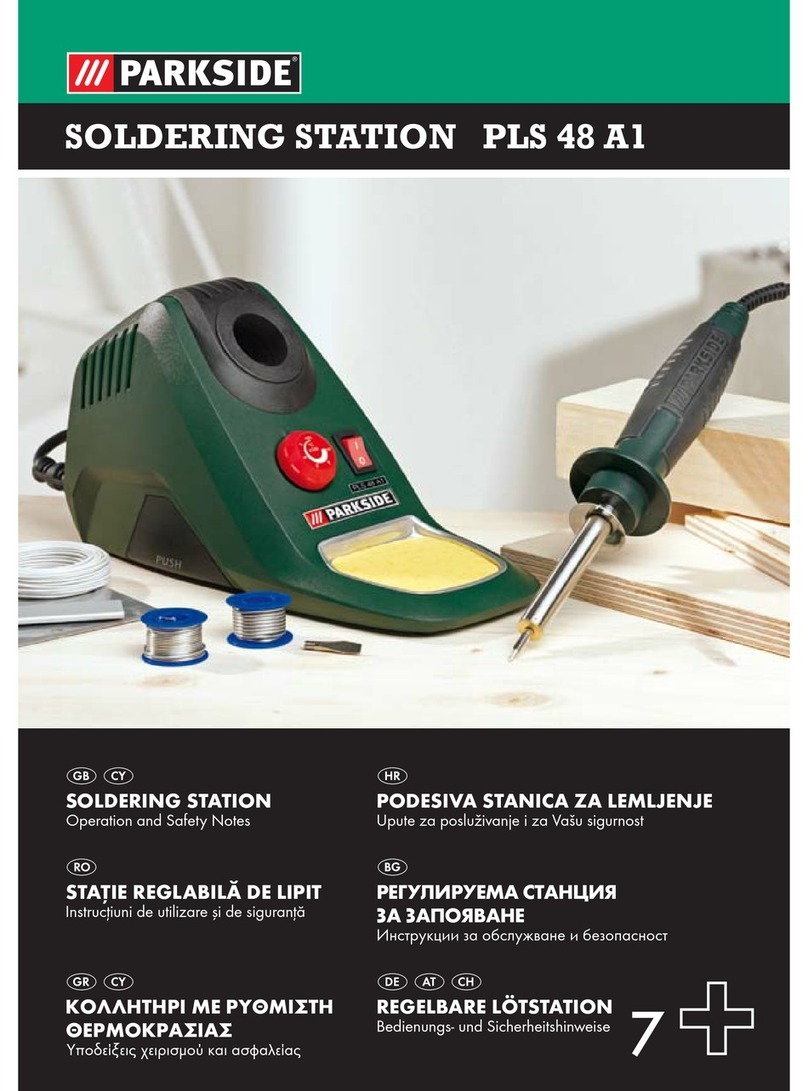

•Soldering Iron

•Solder

•Solder Wick

•Flux

•Eye Protection

•Buzzer

•LEDs (qty: 4)

•Battery Clips (qty: 2)

•Switches (qty: 2)

•Screws (qty: 4)

•Standoffs (qty: 4)

•Bezel Frame

•Button Pad

•Battery

Page 2 Page 3

Don’t: Use the very tip of the iron.

Do: Use the side of the tip of the iron, “The Sweet Spot.”

Do: Touch the iron to the component leg and metal SMD pad at

the same time.

Parts List

Soldering Tips

SMD Soldering • Level 1

SMD Soldering • Level 2

PTH Soldering

Final Assembly

Additional Info

Troubleshooting LEDs

Troubleshooting Jumpers

Notes

Learning More

Section

1

3

4

16

22

34

36

38

40

42

44

Page

Do: While continuing to hold the iron in contact with the leg

and metal pad, feed solder into the joint.

Do: Use a sponge to clean your iron whenever black oxidization

builds up on the tip.

Don’t: Glob the solder straight onto the iron and try to apply the

solder with the iron.

SMD SOLDERING TIPSTABLE OF CONTENTS

Page 4 Page 5

QUICKSTART • LEVEL-1 SMD SOLDERING [ STEPS 1 T0 8 ]

1

Locate the Buzzer.

Locate the Buzzer position on the board.

Steps highlighted in yellow represent a polarized component.

Pay special attention to the component’s markings indicating how

to place it on the board.

3

Touch iron’s sweet spot to the start-pad for 2-3 seconds.

4

Pre-tin the start-pad by feeding solder into the joint.

2

BOTTOM OF BOARD

Page 6 Page 7

5

6

First, pull solder away.

Second, remove the iron.

7

Solder should cover the entire pad and look like this - a tiny pillow.

8

Using your tweezers, position the buzzer slightly away from the pad.

Page 8 Page 9

9

Reheat Start-Pad

Add solder to second pad.

Slide Into Place

Remove Iron

For step 9, understand that alignment of the buzzer is very important.

You want to ensure the buzzer is centered and laying flat against the

board. See possible errors to the right (Page 9).

I

II

III

IV

To fix these potential problems, reheat the solder while moving the buzzer

into place with your tweezers.

BAD BAD GOOD

Page 10 Page 11

Now that you’ve successfully soldered down your

first SMD component, use the same method to

place and solder the following components.

10uF Capacitor

MBRA140 Diode

22uH Inductor

10

12

11

10uF Capacitor The white end of the capacitor should point

towards the rounded end on the PCB’s silkscreen.

MBRA140 Diode Before soldering, double-check that the white

line on the diode matches the line on the PCB’s silkscreen. The

white line is similar to the line on the 10uF capacitor in step 10.

22uH Inductor Make sure the inductor remains inside it’s

white outline after you’ve soldered both legs.

BOTTOM OF BOARD

CONTINUE WITH THE BOTTOM OF THE BOARD [ STEPS 10 T0 16 ]

Remember, components highlighted yellow are polarized.

Page 12 Page 13

0.1uF Capacitors

330 Resistors

14

13

330 Resistors These resistors are not polarized. However,

they do have a value marking on the top side. Make sure the

marking is facing up.

0.1uF Capacitors Ceramic capacitors like these are

not polarized. They don’t have a value marking. This means

they can be soldered into place in any rotation.

BOTTOM OF BOARD

Page 14 Page 15

10K Resistor

16

10K Resistor Just like the 330 resistors, these are not

polarized. Make sure the writing on the part (‘103’) is facing up.

47uF Capacitor The white line on the capacitor should point

towards the rounded end on the PCB’s silkscreen.

BOTTOM OF BOARD

Remember, components highlighted yellow are polarized.

47uF Capacitor

15

Page 16 Page 17

QUICKSTART • LEVEL-2 SMD SOLDERING [ STEPS 17 T0 21 ]

Now that you’ve successfully soldered down all Level-1 components, you

are ready to move on to Level-2. The next set of components have 5 or more

pads each, and the pad size is smaller. Although this is more challenging,

you will use the same methods as before.

17

Locate the NCP1402. Be sure to match up the legs with the pads on

the PCB. This component is polarized.

Locate the NCP1402 position on the board.

18

Remember, components highlighted yellow are polarized.

19

Touch iron’s sweet spot to the start-pad for 2-3 seconds.

20

Pre-tin the start-pad by feeding solder into the joint.

Page 18 Page 19

21

Reheat Start-Pad

Slide Into Place

Remove Iron

For step 21, use the same 3-step process you learned earlier (Step 8,

Page 8). A common error for these smaller types of components is a

jumper. To help avoid these, try not to use too much solder.

Understand the alignment of the component is important, and should

be oriented to look like the picture.

I

II

III

BAD GOOD

Learn how to fix a jumper on Page 40 in the Troubleshooting section.

Add solder to the remaining 4 pads.

IV

Page 20 Page 21

Now that you’ve successfully soldered down your

Level-2 SMD component, use the same method

to place and solder the next component. You can

choose any pad to be your Start-Pad.

ATMega328

22

ATMega328 Microcontroller Match up the circle on the IC

with that on the PCB’s silkscreen. Solder a corner leg of the

IC, and verify that the chip is well-alligned. Continue to solder

the remaining 31 legs.

BOTTOM OF BOARD

Remember, components highlighted yellow are polarized.

CONTINUE WITH THE BOTTOM OF THE BOARD

Page 22 Page 23

Don’t: Use the very tip of the iron.

Do: Use the side of the tip of the iron, “The Sweet Spot.”

Do: Touch the iron to the component leg and metal ring at the

same time.

Do: While continuing to hold the iron in contact with the leg and

metal ring, feed solder into the joint.

Do: Use a sponge to clean your iron whenever black oxidization

builds up on the tip.

Don’t: Glob the solder straight onto the iron and try to apply the

solder with the iron.

QUICKSTART • PTH SOLDERING PTH SOLDERING TIPS

Page 24 Page 25

TOP OF BOARD

23

Locate the LEDs (qty. 4).

Turn the board over and

locate one of the LED

positions on the board.

24

CONTINUE WITH THE TOP OF THE BOARD [ STEPS 23 T0 27 ]

25

Insert the LED into the PCB, so that the short leg goes into the hole

labeled with the “-” sign.

26

Push the LED in so it is flush with the board.

27

Slightly bend the legs outward to hold it in place.

Remember, components highlighted yellow are polarized.

Page 26 Page 27

28

Flip the board over. Hold the soldering iron’s “Sweet Spot” so it

touches both the leg and the metal ring. Hold for 2 seconds.

Pull the solder away.

Feed solder into the joint.

Remove the iron.

For step 28 there are four sub-steps.

I

III

II

IV

CONTINUE WITH THE BOTTOM OF THE BOARD [ STEPS 28 T0 31 ]

[ BOTTOM OF BOARD ]

Page 28 Page 29

29 31

30

Your solder joint should look like this - a tiny volcano.

Clip off any excess legs.

Using the same PTH methods, add solder to the second leg.

Page 30 Page 31

Now that you’ve successfully soldered your first

PTH component, use the same method to place

and solder the next components.

LEDs

32

LEDs (indicator lights)Just as you did with the first LED make

sure the short leg goes into the hole labeled “-”. Also make

sure it sits flush with the PCB. Then solder into place.

TOP OF BOARD

CONTINUE WITH THE TOP OF THE BOARD [ STEPS 32 T0 34 ]

Remember, components highlighted yellow are polarized.

Page 32 Page 33

TOP OF BOARD

Battery Clips Both clips need to be pointed towards each

other. The solid backing on each clip should face the outside

of the board. These require a lot more heat to melt the solder,

you need to leave the iron tip on a bit longer than usual

(5-6 seconds). Don’t touch the clip after soldering! Give it some

time to cool off.

Slide Switches Keep the iron tip away from the black part of

the switch! Plastic melts easily (and stinks).

Slide Switches

33

Battery Clips

34

Remember, components highlighted yellow are polarized.

Page 34 Page 35

[ STEPS 35 T0 38 ]

FINAL ASSEMBLY

Screws x 4

37

AA Battery (power source) Insert the battery, following “+”

and “-” indicators on the board. Turn on the board and verify

the LEDs are flashing.

Standoffs and screws (mechanical) Insert the screws

through the bezel and button pad, then twist standoffs onto

the protruding screw. Hand tighten.

AA Battery

38

Bezel (holds button pad) Attach to top. Lay bezel over button

pad, with notches for the screws pointing up.

Bezel

36

Button Pad (game control) Attach to top. Lay rubber button

pad over LEDs.

Button Pad

35

No screwdriver necessary.

Please only hand-tighten the screws and standoffs.

38

37

37

35

36

TOP SIDE VIEW

Page 36 Page 37

CREATE YOUR OWN PROJECT WITH SIMON

CONGRATULATIONS, YOU’RE DONE!!!

Your Simon game is now completed. Turn it on and have fun! If something is not

working (i.e. an LED won’t light up), please check out the Troubleshooting LEDs

section at the end of this booklet for more help (Pages 38-41).

Did you know that your Simon is much more than it seems? It can be

re-programmed to do many different things! You can write code to change your

Simon into a new unique project. To learn more, please check out our online

tutorial here: sparkfun.com/tutorials/203

And for even more fun stuff go here: learn.sparkfun.com

EXTRA FUN

As an example of how the Simon is more than just a game, we have included a

special feature in the code. Just for fun, try this out. Don’t worry it won’t change

your Simon permanently.

Turn off power switch.

I

Press any one button.

II

While holding button down, turn back on.

III

Page 38 Page 39

Using a soldering iron, close both jumpers.

II

Using a hobby knife, cut both traces directly over the white dots.

I

Failing LEDs? Don’t fret, there is an easy way to fix it! The most

common cause of a failing LED is incorrect polarity. We have

designed a special trick into the Simon PCB. You can simply

cut the two traces and close two jumpers. This will swap the

polarity without having to remove the LED.

TROUBLESHOOTING LEDSTROUBLESHOOTING LEDS

Table of contents

Other Sparkfun Electronics Soldering Gun manuals