Sparta Huskie Tools PRO LINE 7 Series User manual

OPERATION MANUAL for MODEL: SL-7ND

Battery Operated Hydraulic Compression Tool

WARNING To reduce the risk of injury, user must read and understand manual

completely before rst using this product and save this manual for future use.

195 Internationale Blvd Glendale Heights, IL 60139

Phone 800-860-6170 Fax 800-345-3767 www.spartacogroup.com

SpartacoGroup.com 800-860-6170

2

Table of Contents

Safety............................................................................ 3-4

Operation..................................................................... 5

LED Screen.................................................................. 6

Bluetooth Connectivity.............................................. 7

Parts Breakdown and Parts List.............................. 8-9

Warranty........................................................................ 10

THANK YOU...

for purchasing a Huskie Tools product. Our mission is to supply the nest cable

connecting and cutting tools and cable-related products to the transmission and distribution

markets. Huskie Tools products will represent state-of-the-art tools and be dependable and

safe.

Please take the time to read this manual carefully to learn how to correctly operate and

maintain your tool.

SL-7ND 6 Ton Compression Tool

Specications

Crimp Force 6 Ton

Weight 5.9 lbs. (2.7 kg)

Size 15.8”L x 4.5”H x 3.3”W (401mm x 115mm x 84mm)

Connector Range

Lugs and Splices #8-500 MCM Cu

#8-350 MCM Al

H-Taps Up to 4/0-4/0

Crimping Estimates with BP-185

Material Cycles

4/0-4/0 H-Tap 375

500 MCM Cu 480

Cutting

Capacities

SLCHACSR SLCHCUAL SLGWJAW

Copper 350 MCM 500 MCM Up to 4/0

Aluminum 350 MCM 10 O.D. Up to 4/0

ACSR 336 MCM Do Not Cut Up to 4/0

EHS Guy Wire Do Not Cut Do Not Cut Up to 3/80

Soft Locks Do Not Cut Do Not Cut Up to 3/80

Soft Steel Bolts Do Not Cut Do Not Cut Up to 3/80

SpartacoGroup.com 800-860-6170

3

Read all instructions - Failure to follow all instructions listed below may result in electric shock, re and/

or serious injury. The term “power tool” in all the warnings listed below refers to your battery operated

(cordless) power tool.

• This device contains a lithium button/coin cell battery. A new or used battery can cause severe

internal burns and lead to death if swallowed or enters the body. Keep it away from children. If

you think batteries may have been swallowed or entered the body, seek immediate medical attention.

Work Area Safety

• Keep work area clean and well lit. Cluttered or dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such as in the presence of ammable liquids, gases

or dust. Power tools create sparks which may ignite the dust or fumes.

• Keep bystanders away while operating a power tool. Distractions can cause you to lose control.

Personal Safety

• Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use

a power tool while you are tired or under the inuence of drugs, alcohol or medication. A moment of

distraction while operating power tools may result in personal injury.

• Use personal protection equipment. Always wear eye protection. Safety equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce personal

injuries.

• Do not overreach. Keep proper footing and balance at all times. This enables better control of the power

tool in unexpected situations.

Tool Use and Care

• To prevent leakage, overheating, smoke generation, re, and rupturing from occurring, follow these

instructions when handling our rechargeable power tools (tool main body/battery pack/charger).

• Do not force the tool. Use the correct tool for your application. The correct tool will do the job better and

safer at the rate for which it was designed.

• Do not use the tool if the switch does not turn it on and o. Any tool that cannot be

controlled with the switch is dangerous and must be repaired.

• Disconnect the battery pack from the tool before making any adjustments, changing

accessories, or storing. Such preventive safety measures reduce the risk of starting the tool accidentally.

• Store idle tools out of the reach of children and do not allow persons unfamiliar with the tool or these

instructions to operate the tool. These tools can be dangerous in the hands of untrained users.

• Maintain tools. Check for misalignment or binding of moving parts, breakage of parts and any other

condition that may aect the tools operation. If damaged, have the tool repaired before use.

• Use power tools only with specically designated battery packs. Use of any other battery packs may

create a risk of injury and re.

•Under abusive conditions, liquid may be ejected from battery; avoid contact. If contact accidentally occurs,

ush with water. If liquid contacts eyes, additionally seek medical help. Liquid ejected from the battery may

cause irritation or burns.

SAFETY

SpartacoGroup.com 800-860-6170

4

SAFETY

Battery and Charger Use and Care

• Before using battery charger, read all instructions and cautionary markings on battery charger, battery

pack, and product using battery pack.

• To reduce the risk of injury, charge only Huskie Tools Battery Pack model BP-185. Other

types of batteries may burst causing personal injury and damage.

• Do not leave charger and battery pack exposed to rain or snow, submerge in water, or stored in damp or

wet locations.

• To reduce risk of damaging the electric plug and cord, pull by plug rather than cord when disconnecting

charger.

• Make sure cord is located so that it will not be stepped on, tripped over, or otherwise subjected to damage

or stress.

• Do not disassemble charger or battery pack, contact Huskie Tools service dept. at 800-860-6170 when

service or repair is required. Incorrect reassembly may result in a risk of electric shock or re.

• Do not store the tool and battery pack in locations where the temperature may reach or exceed 50°C

(122°F) (such as a metal tool shed, or a car in the summer), which can lead to deterioration of the storage

battery.

• Do not charge battery pack when the temperature is BELOW 0°C (32°F) or ABOVE 40°C (104°F). This is very

important to maintain optimal condition of the battery pack.

• The charger is designed to operate on standard 120V AC electrical power only. Do not

attempt to use it on any other voltage.

• Charge the battery pack in a well ventilated place, do not cover the charger and battery pack with a cloth,

etc., while charging.

• Use of an attachment not recommended may result in a risk of re, electric shock, or personal injury.

• Do not short the battery pack or allow metal objects to touch the terminals. A battery short

can cause a large current ow, over heating and create the risk of re or personal injury.

• Huskie Tools is not responsible for any damage or accident caused by the use of recycled or counterfeit

battery pack.

• Do not incinerate the battery pack or dispose of the battery pack in a re, or expose it to excessive heat.

• Do not charge the battery pack in a high-temperature location, such as next to a re or in direct sunlight.

Otherwise, the battery may overheat, catch re, or explode.

• After removing the battery pack from the tool or the charger, always re-attach the pack cover. Otherwise,

the battery contacts could be shorted, leading to a risk of re.

• When the Battery Pack Has Deteriorated, Replace It with a New One. Continued use of a damaged battery

pack may result in heat generation, ignition or battery rupture.

• When storing, remove any material cuttings and dust from the battery pack, and place the battery pack

separately from metal objects (screws, nails, etc.) when storing in the tool case.

SpartacoGroup.com 800-860-6170

5

OPERATION

Compression

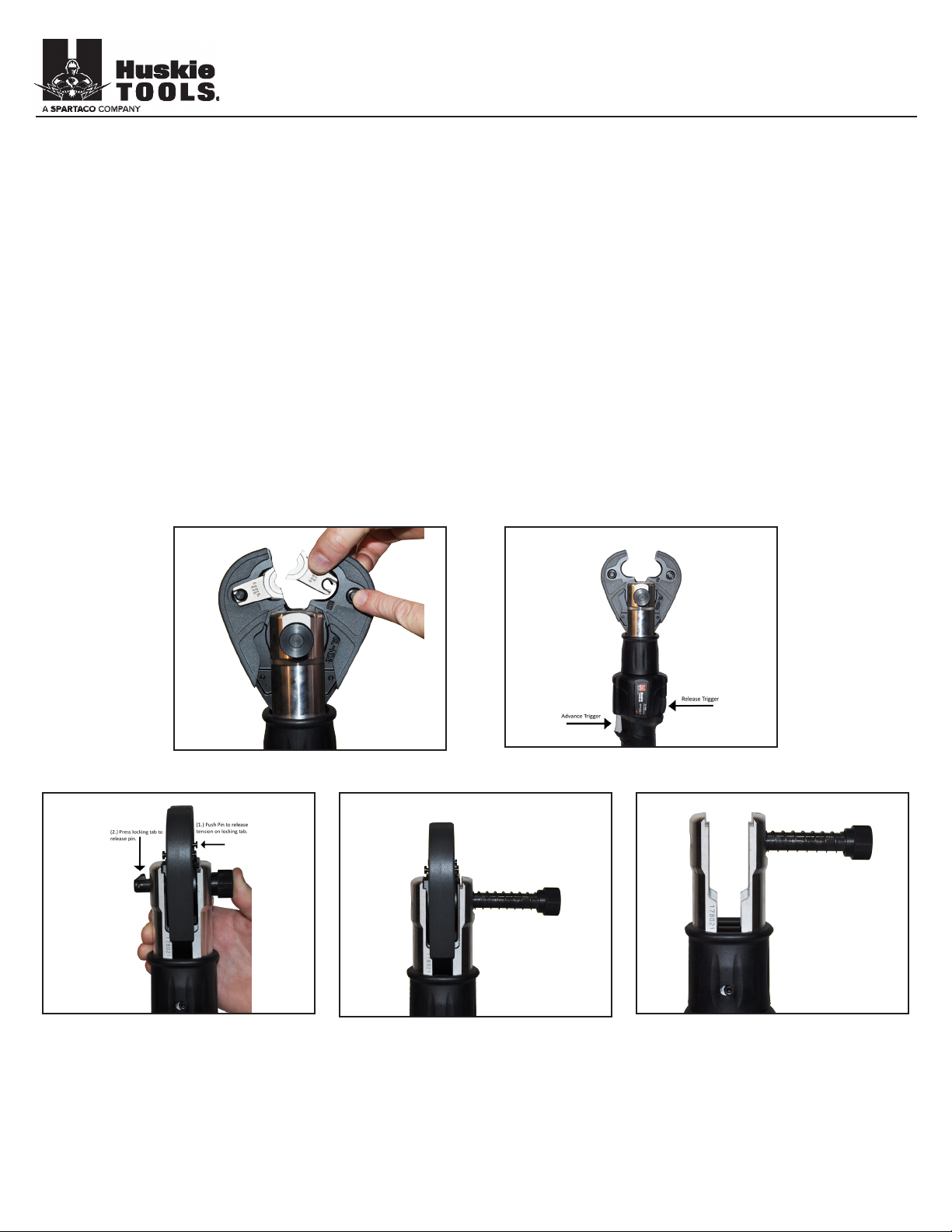

1. Select an appropriate size of die for the connector.

2. Insert the dies into the jaw by pressing the push pins. When released, they will hold the die in place. (Figure 1)

3. Place the connector between the dies and press the trigger to advance the ram so that the connector is held

between the dies and insert conductor into the terminal.

4. Press and hold the trigger until the compression is completed. (Figure 2) The ram will advance and once

the cycle is complete, the tool will automatically shut o and retract. A green LED will appear on the display

followed by an audible beep to alert the user the compression was completed. If the cycle was not completed,

the LED will ash red and a series of audible beeps will sound alerting the user the cycle was not completed.

Figure 1

To Remove Jaw Pin Released Jaw Removed

Figure 2

SpartacoGroup.com 800-860-6170

6

LED SCREEN

ADVANCED TOOL AND BATTERY PERFORMANCE MONITORING

The SERIES 7 tools feature newly developed PCB integrated into the tools hydraulic circuit for monitoring

battery capacity, recording cycle count and output pressure, as well as the time, date, and location stamp.

There is a visual display integrated into the tool housing on all “REC” and “SL” models. This display is a

visual for complete or incomplete tool cycle, battery status indicator, conrming GPS recorded location,

Bluetooth connection indicator, and service alert visual LED when needed.

AUDIBLE ALERTS

The audible alerts on the tools can be turned “ON” or “OFF”. From the factory, the compression tools are set

to be “ON” and all cutting tools are set to“OFF”. This can be changed on any tool by pressing and holding

the “SOUND” button for 5 seconds until the battery indicator LED illuminates. The rst LED indicates audible

alerts “ON”, and by pressing the“SOUND” button again, will illuminate the second LED which will indicate

the audible alerts “OFF”The third LED indicates “ON” for “Good” and “OFF” for “Error” – this can be toggled

back and forth by pressing the check button until the desired audible alert status is reached.

Flashing green LED for BLUETOOTH connection

AND Red LED when service is needed

Green LED when GPS signal is active

Green LED indicates complete “GOOD” cycle

Red LED indicates incomplete“ERROR”

Press once to check battery capacity,

twice to activate BLUETOOTH

ON OFF Audible only on complete cycle

SpartacoGroup.com 800-860-6170

7

BLUETOOTH CONNECTIVITY

The tools use a Bluetooth signal to connect to a laptop, desktop, or smart device via an APP which is

estimated to be available by the end of rst quarter 2018. This connection will serve as a means by which

the software can “read” and “write”data stored in the tool circuitry.

The stored data can be read and exported to .pdf document or a Microsoft Excel document via the

proprietary software “Huskie SERIES 7 Data Management System”, which is available for free download at

Microsoft Store.

Some data elds are locked such as tool model and serial number, as well as certain parameter settings

that function as control points for output pressure, cycle counts, and service interval cycles. These elds are

password protected but can be changed by service technicians that need to reprogram new boards in the

case of damage. Other data elds are writable for record keeping such as eld notes for service, assignment

to a truck number or crew, jobsite, etc.

The data will give a user the ability to see the last recorded 500 cycles the tool made with time, date, and

location stamp, viewable on Google Maps as well as pressure output and a tool diagnosed“complete”or

“incomplete”cycle. They can also view the output pressure settings, and adjust if necessary. Like all the

stored data, it too can be exported to .pdf document or Microsoft Excel document.

The GPS chip located inside the tool is not connected to a service provider for the use of tracking a

misplaced or stolen tool in such an event. If the tool is in a location where it cannot receive a satellite signal

to record the location, that recorded line is simply blank where a MAP icon would normally be. All other

parameters are recorded.

BLUETOOTH CONNECTIVITY

SpartacoGroup.com 800-860-6170

8

PARTS BREAKDOWN

SpartacoGroup.com 800-860-6170

9

PARTS LIST

SpartacoGroup.com 800-860-6170

10

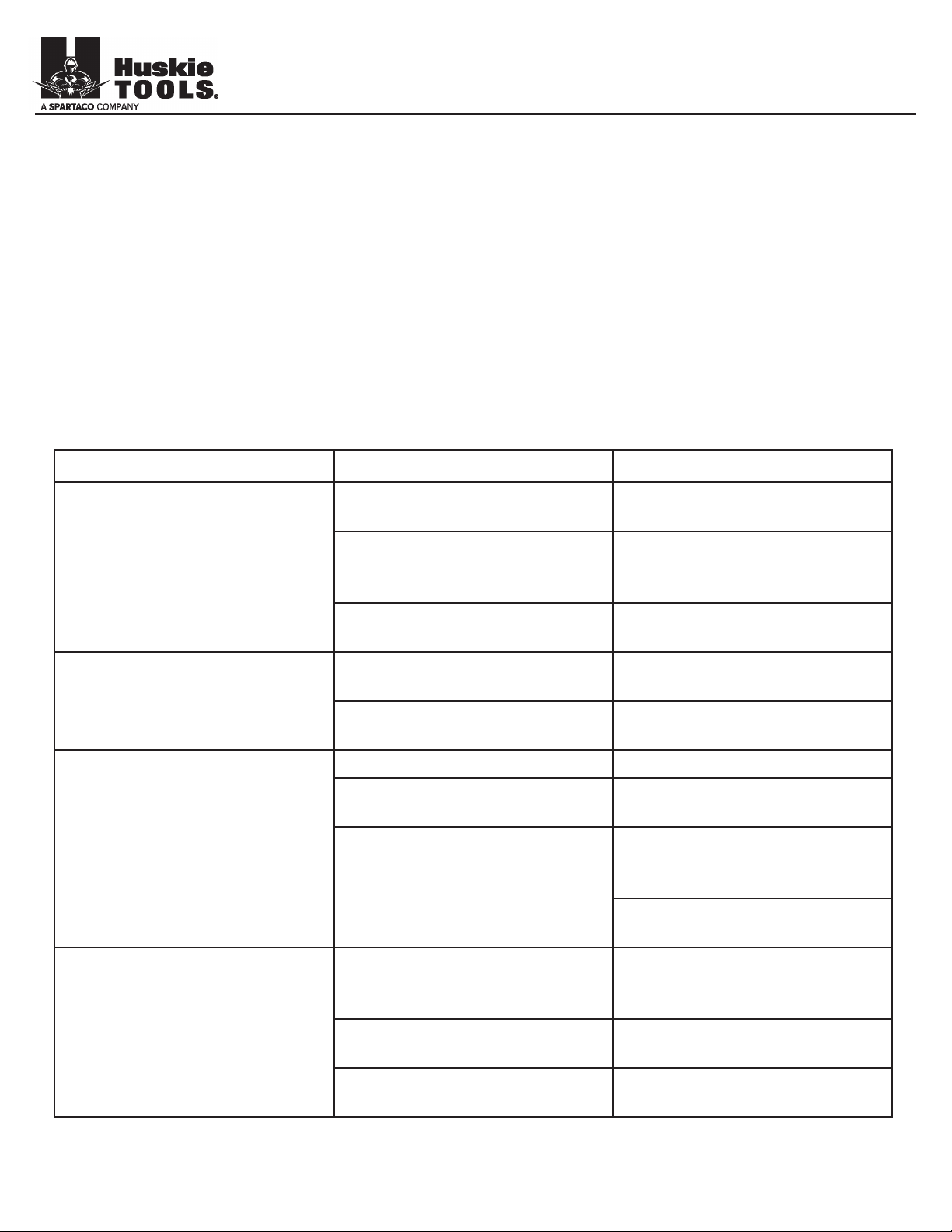

TROUBLESHOOTING

Troubleshooting

Before You Begin

1) Make sure that the battery is charged. Recheck the battery after several minutes to make sure the battery

is holding its charge.

2) Use a nonammable contact cleaner or pencil eraser to clean the electrical contacts on the battery and

tool.

3) Reinstall the battery and check the tool again.

PROBLEM CAUSE SOLUTION

MOTOR RUNS, BUT THE

TOOL JAWS WILL NOT

ADVANCE

Insufficient Hydraulic Oil Consult Factory for Repair

Service

Air Block in Hydraulic System

Invert tool to allow air to rise

towards the top of the oil

bladder

Defective Hydraulic Circuit Consult Factory for Repair

Service

MOTOR RUNS, TOOL JAWS

ADVANCE, BUT WILL NOT

BUILD PRESSURE

Insufficient Hydraulic Oil Consult Factory for Repair

Service

Defective Suction Valve or

Bypass Cartridge

Consult Factory for Repair

Service

MOTOR WILL NOT RUN AT

ALL

Defective Battery Charge or Replace Battery

Bad Contact or Loose Battery

Connections

Check all Connections and

Wires

Misaligned Switch

Check to Make Sure that

Switch is Properly Aligned with

Trigger

Consult Factory for Repair

Service

TOOL JAWS WILL NOT

RELEASE

Tool Did Not Complete a Full

Cycle and Bypass

Press Trigger and allow Tool

to Bypass, Then Release Tool

Jaws

Connector is Jammed in Tool

Jaws

Press and Hold Release Trigger

While Prying Tool Jaws Apart

Release Trigger is Bent or Mis-

aligned

Consult Factory for Repair

Service

SpartacoGroup.com 800-860-6170

11

WARRANTY

Series 7 Pro Line Battery Operated Products 5 Years

Series 7 Power Tools 3 Years

REC-Series Battery Operated Products 5 Years

ECO-Series Battery Operated Products 1 Year

Batteries

BP-185 3 Years

BP-80, BP-84 5 Years

BP-82 1 Year

Chargers

CH-185 3 Years

CH-90, CH-94 5 Years

The warranty does not cover any damages incurred from a Huskie tool including damages to property,

bodily injuries and lost wages resulting from such injuries. This warranty solely covers the repair or

replacement of tools supplied by Huskie. These remedies are exclusive, and the total liability of

Huskie Tools, LLC whether based on contract, warranty, negligence, indemnication, strict liability or

otherwise, shall not exceed the purchase price of the tool. In no event, shall Huskie Tools, LLC be liable for

consequential, incidental or special damages.

HUSKIE TOOLS, LLC MAKES NO OTHER WARRANTIES OF ANY KIND, EXPRESSED OR IMPLIED, AND ALL

IMPLIED WARRANTIES INCLUDING ANY

WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE DISCLAIMED.

Huskie reserves the right to determine all warranty claims. Huskie will not warranty tools containing parts or

batteries not originally supplied by Huskie. Failure due to misuse, improper maintenance, misapplication, not

following instructions or warnings, abuse or repairs attempted by anyone other than Huskie Tools, LLC, or an

authorized service center renders this warranty null and void.

REPAIR AND WARRANTY CLAIMS

All claims must be sent to Huskie for inspection and authorization. A Return Goods Authorization (RGA) is

required before shipping tools to Huskie. Secure the authorization by telephoning or writing to Huskie’s

main oce with details of the claim. Non-warranty repairs are handled using the same procedure. Repairs

exceeding 50 percent of the cost of a new tool will be advised before repairs are made.

Do not discard this product or throw away!

For recycling information, contact 800-822-8837

NOTES

NOTES

NOTES

NOTES

195 Internationale Blvd

Glendale Heights, IL 60139

Phone 800-860-6170

Fax 800-345-3767

www.spartacogroup.com

This manual suits for next models

1

Other Sparta Power Tools manuals