Spartan Equipment SEHLS1224 User manual

Operator’s Manual

Keep this manual with the machine at all times

Hydraulic

Limb Saw

SEHLS1224

Do not attempt to operate the equipment without thoroughly

reviewing this manual for safe and proper operation.

Rev 121123

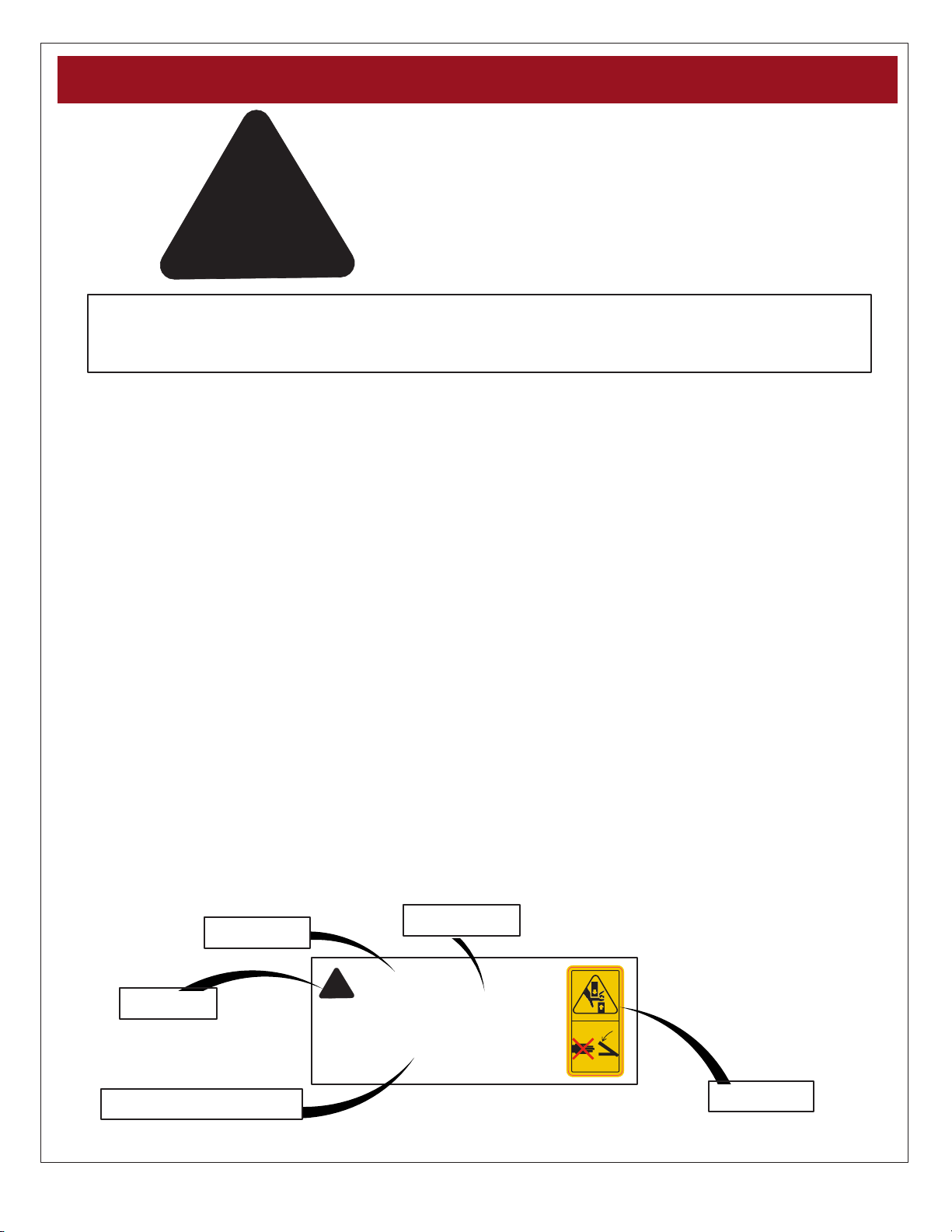

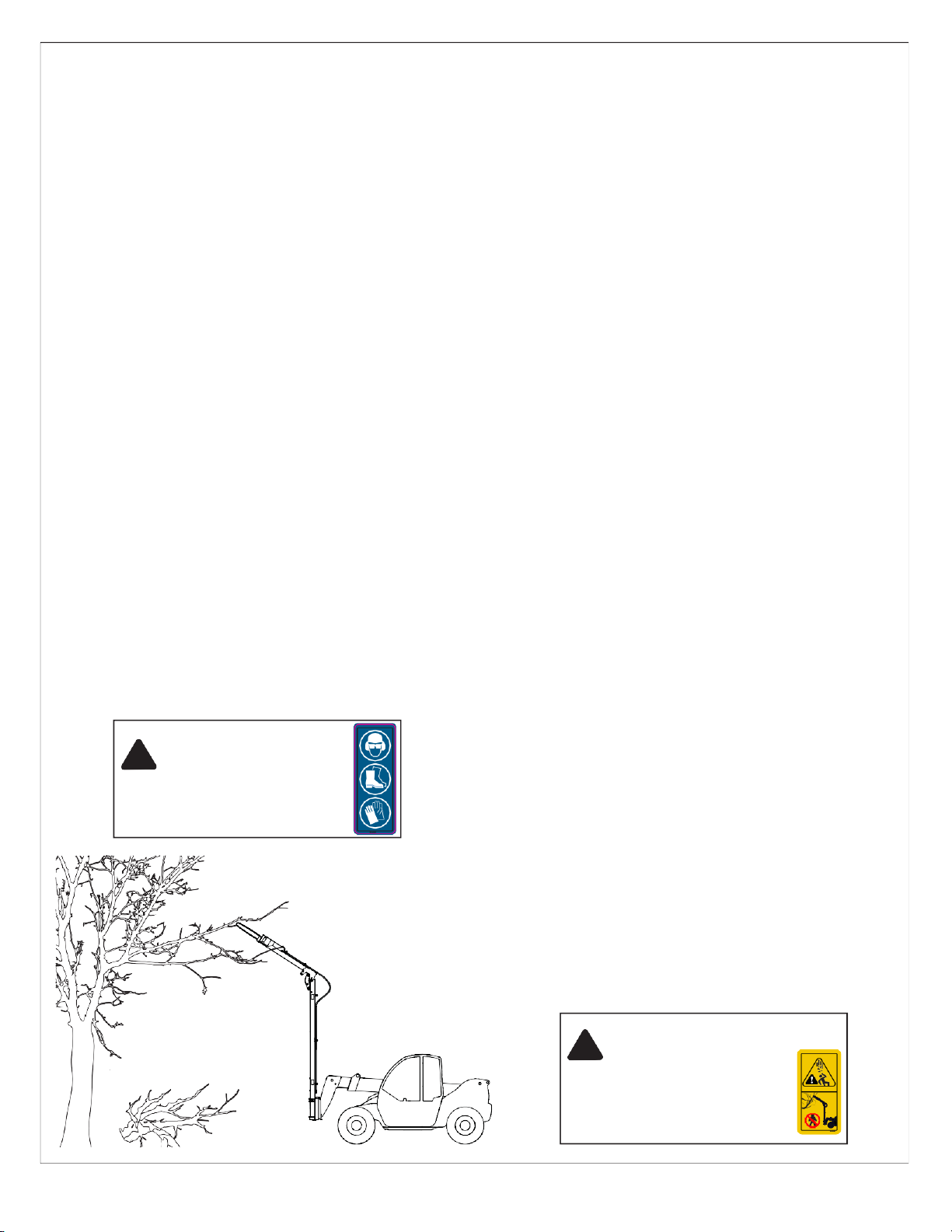

!

CAUTION

Operational Hazard

!

Personal Protection Equipment

(PPE)

is required when

operating

or maintaining this machine.

SNL00001

!

Overhead Hazard

Be

aware of falling debris under,

around

the attachment and

on

the power unit. Cut branches

CAUTION

can fall unpredictably.

2

Notes

3

Introduction…..………………………………..4

General Information.………………………… 5

Serial Number Location.……………………. 5

Safety Messages ..................................................6

Accident Prevention ..............................................7

Safety Guidelines ..................................................8

Safety Training ......................................................8

Preparation............................................................9

Transport Safety....................................................9

Operation Safety ...................................................9

Maintenance Safety ..............................................9

Hydraulic Safety..................................................10

Storage Safety ....................................................10

Safe Work ...........................................................10

Chain Saw Safety................................................10

Assembly & Inspection……………………….10

Safety Labels…………..……………………….10

Safety Label Descriptions................................... 11

If labels need to be replaced: ............................. 11

Safety Label Layout ............................................12

Specifications………….……………………….10

Specifications & Dimensions ..................................13

Components and Features..………………….14

SEHLS1224 Limb Saw Components ..................14

SEHLS1224 Limb Saw Features ........................15

Automatic Chain Oiler .............................................. 15

Pivot Stop................................................................. 15

Main Boom Mount

.................................................... 16

Initial Setup……………..……………………….17

Mount the Limb Saw ...........................................17

Check Chain Tension..........................................17

Hydraulics ...........................................................18

Test .....................................................................18

Field Operation……………………………….19

Operation Safety Checklist................................. 19

Prepare .............................................................. 19

Material .............................................................. 19

Operating ........................................................... 20

Safety .......................................................................20

Begin Work...............................................................20

Trimming Tips...........................................................20

Storage………………….……………………….21

Storage Safety Checklist .................................... 21

Placing in Storage: ............................................. 21

Service & Maintenance……………………….22

Maintenance Safety Checklist ............................ 22

General Maintenance ......................................... 22

Hydraulic Oil....................................................... 22

Lubrication:..........................................................

23

Lubricate:..................................................................23

Clean and Inspect the Chain Saw ...................... 24

Disassemble the Chain Saw ....................................24

Power head ..............................................................24

Guide Bar .................................................................25

Saw Chain................................................................25

Reassemble Chain saw............................................25

Saw Chain Tension ..................................................26

Saw Chain Sharpening.............................................26

Replacing the Drive Sprocket...................................27

Bolt Torque Table ............................................... 28

Troubleshooting……………………………….29

Accessories…………………………………….30

Optional 90” Hose Kit ......................................... 30

Optional Spring Hose Mount Kit ......................... 30

Table of Contents

4

Thank you for purchasing your new SEHLS1224 Hydraulic Limb Saw. Your limb saw has been designed and manufactured

to give you many years of dependable service by ensuring safe, effective and speedy completion of tree trimming chores.

The Spartan Equipment SEHLS1224 unique loader arm mounted design with up to 14’ reach and 22 hp hydraulic

powered chain saw motor to enable you to quickly and precisely complete tree trimming from the safety of your power

unit cab.

Only minor maintenance, such as adjusting, cleaning and lubricating, is required to keep it in top working condition.

Safe, efficient and trouble free operation of your Spartan Equipment hydraulic limb saw requires that you or any other

person, who will be assembling, operating, maintaining or working with this product, are required to read and completely

understand the information and instructions contained in this manual.

If anyone does not fully understand every part of this manual, please obtain further assistance by contacting the dealer

from which this product was purchased or by contacting Spartan Equipment with the information listed on the cover of this

manual.

Keep this manual available for reference whenever this product is being handled or used. Provide this manual to any new

owners and/or operators.

This manual covers model: SEHLS1224 Hydraulic Limb Saw.

Introduction

5

The purpose of this manual is to assist you in safely operating and maintaining your SEHLS1224 Hydraulic Limb Saw in a

safe manner. Read this manual carefully to obtain valuable information and instructions that will help you achieve safe and

dependable service. The illustrations and data used in this manual were current at the time of printing, but due to possible

engineering and or production changes, this product may vary slightly in detail. Spartan reserves the right to update and or

change components as necessary without notification.

In this manual the SEHLS1224 Hydraulic Limb Saw may be referred to as chain saw, limb saw, product, implement,

attachment or machine. Power unit is the engine driven machine that the limb saw is mounted to.

Intended Use

The Spartan Equipment SEHLS1224 limb saw is intended for attachment and use on qualified power units for the sole

purpose of trimming branches from trees.

Parts List

The parts lists for this product can be found online. Visit spartanequipment.com and click on the PARTS tab to be directed

to our on-line parts catalog.

Operator Orientation

The directions left, right, front, and rear, as mentioned throughout this manual, are determined when sitting in the power

unit driver’s seat, and facing in the direction of travel.

California Proposition 65

You may see a warning label like the following:

WARNING

Cancer and Reproductive Harm

www.P65 Warnings.ca.gov

SNL00010

This warning is required by the California Proposition 65 (Prop 65), which is meant to notify California residents of

exposures to Prop 65-listed chemicals. For more information go to ‘www.P65Warnings.ca.gov’.

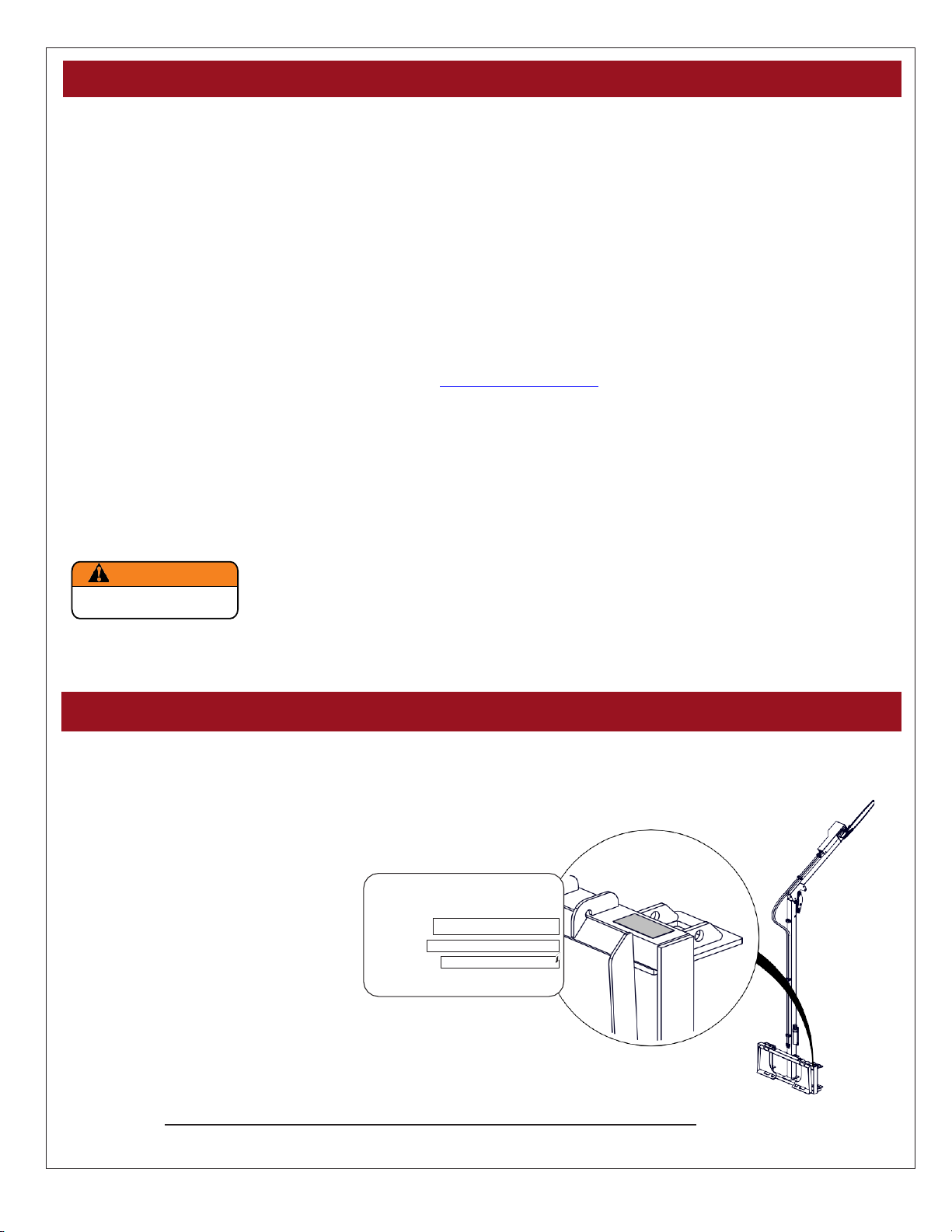

The serial number for your limb saw is located on the top right side of the limb saw frame assembly.

Please record your serial number here as a handy reference. In case of warranty issues, your dealer will ask for the

serial to verify your warranty.

Spartan Equipment

SERIAL #

MODEL #

CAPACITY

Model Number SEHLS1224

Serial Number

General Information

Serial Number Location

HLAA

ATTACHME N

SERIAL

#

MODEL

#

CAPACI

H

LA

MADE

6

The Safety Alert symbol identifies important safety messages on the implement and in the

manual. When you see this symbol, read and understand the message, be alert to the potential

hazard in the message. Follow the instructions in the safety message.

Safety Term Safety Hazard

This Safety Alert Symbol means:

ATTENTION!

BECOME ALERT!

YOUR SAFETY IS INVOLVED!

Safety Messages

Throughout this manual, the terms DANGER, WARNING, CAUTION and IMPORTANT are used to indicate the degree of

hazard to personnel if proper safety procedures and guidelines are not followed. The appropriate term for each message

has been selected using the following guide-lines:

DANGER - Indicates an imminently hazardous situation that, if not avoided, will result in death

or serious injury, and includes most extreme situations typically for implement com-

ponents which, for functional purposes, cannot be guarded.

WARNING - Indicates a potentially hazardous situation that, if not avoided, could result in death

or serious injury, and includes hazards that are exposed when guards are removed.

It may also be used to alert against unsafe practices.

CAUTION - Indicates a potentially hazardous situation that, if not avoided, may result in minor or

moderate injury. It may also be used to alert against unsafe practices.

IMPORTANT - Indicates a situation that could result in damage to the implement or other property.

In the owners manual, when a hazard is present you will see a safety message box. The box may contain:

• The safety alert symbol

• The safety term

• The safety hazard

• The safety hazard explanation

When applicable you may also see the appropriate safety label displayed with the message, as shown below.

WARNING

Pinch Point Hazard

The top rail and beam form a poten-

tial pinch point, be aware of where

hands and feet are while adjusting

the top rail.

SL00002

The safety information given in this manual does not replace any safety codes, insurance needs, government and local laws.

Safety

Safety Hazard Explanation Safety Label

Safety Alert

!

!

7

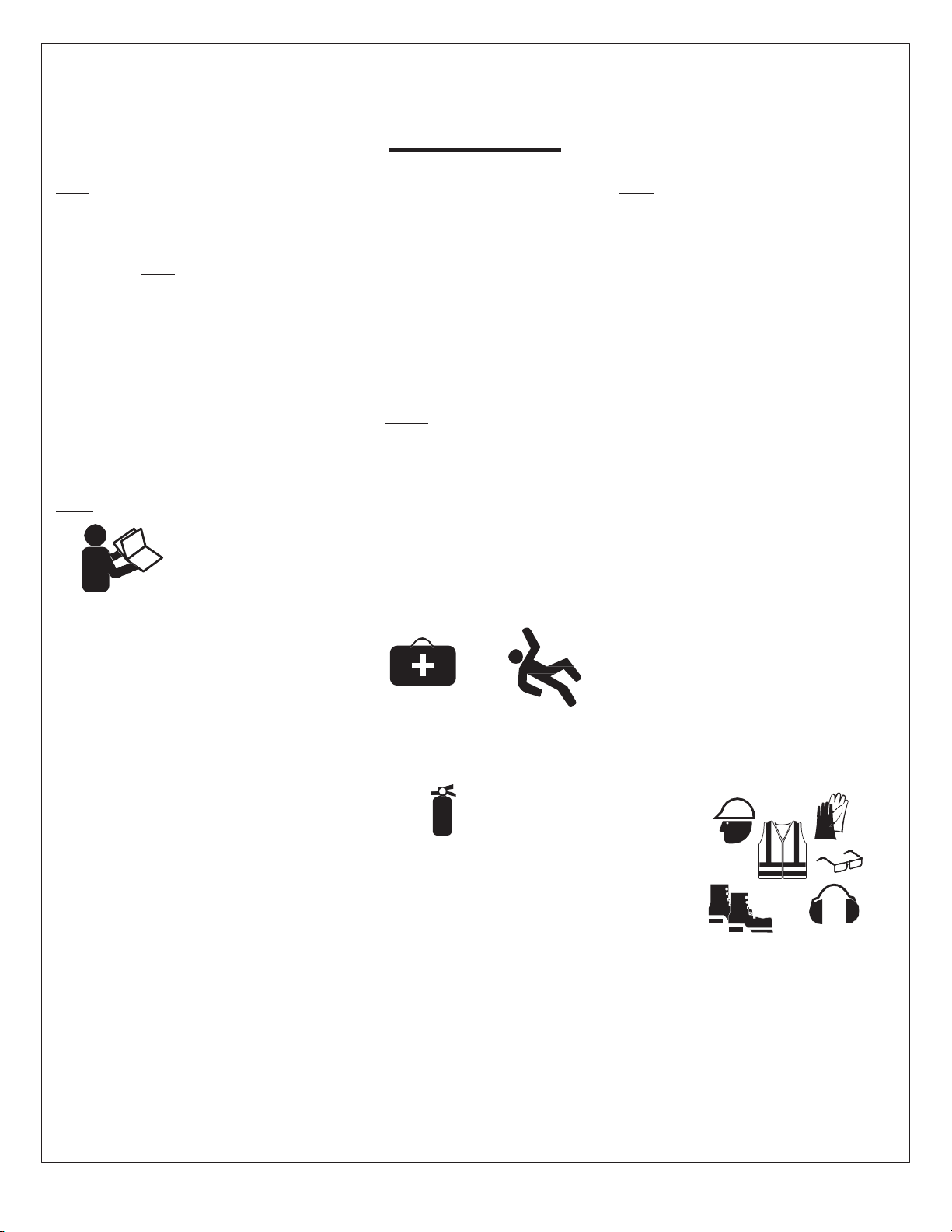

Accident

Prevention

ACCIDENTS CAN BE PREVENTED WITH

YOUR HELP!

YOU are responsible for the SAFE operation and maintenance of your implement. YOU must ensure that you and anyone

else who is going to use, maintain or work around the implement be familiar with the work and maintenance procedures

and related SAFETY information contained in this manual. This manual will take you step-by-step through your working

day and alerts you to all good safety practices that should be used.

Remember, YOU are the key to safety. Good safety practices not only protect you but also the people around you. Make

these practices an effective part of your day to day work habits. Be certain that EVERYONE using this implement is

familiar with the recommended maintenance and work procedures and follow all the safety precautions. Most accidents

can be prevented. Do not risk injury or death by ignoring good safety practices.

The best accident prevention is a careful operator.

Spartan and your dealer ask that YOU be that careful, responsible equipment operator.

YOU ARE THE KEY TO SAFETY:

•

Familiarize yourself, and anyone else

who will operate, maintain, or work around

this product, with the safety and operation

information contained in this manual.

• Read and understand the safety labeling which

appears on the implement.

• Have a first-aid kit available for use should

the need arise and know how to use it.

• Pay attention to the job at hand. Do not let your mind

lose concentration on what you are doing. No accident

prevention program can be successful without the

wholehearted cooperation of the person who is

directly responsible for the operation of the implement.

• Have a fire extinguisher available for use should

the need arise and know how to use it.

• Reduce the risk of injury or death by following all

safety precautions and by using good safety practices.

• Accidents can to be prevented: that prevention will

come from equipment operators who accept their

complete responsibility and anticipate the results of

their actions.

• Never exceed the limits of the implement. Safety of

the operator and safe operation are the main concerns

in designing a safe product, however ignoring

implement specifications by the operator can result in

a accident which could have been prevented.

• Do not allow riders on the implement,

loaded or empty.

• Do not operate this implement under the

influence of drugs or alcohol.

• Be responsible for the SAFE operation and

MAINTENANCE of YOUR implement.

• Wear appropriate personal protective equipment

(PPE). This list includes but is not limited to:

• Hard hat

• Heavy gloves

• Hearing Protection

• Protective foot wear

• Protective eye wear

• Safety Vest

8

Safety Guidelines

Safety of the operator and bystanders is one of the chief concerns in developing and designing equipment. However,

every year many accidents occur which could have been avoided by a few seconds of thought and a more cautious

approach to handling equipment.

You, the operator, can avoid many accidents by observing the following precautions in this section. To avoid personal

injury or death, study the following precautions and insist those working with you, or for you to follow them.

In addition to the design and configuration of this implement, including safety labels and safety devices, hazard control

and accident prevention are dependent upon the awareness, concern, and proper training of personnel involved in the

operation, transport, maintenance, and storage of the implement. Refer also to safety messages and operation instruction

in each of the appropriate sections of the tractor and implement manuals. Pay close attention to the safety labeling affixed

to the implement.

1. In order to provide a better view, certain illustrations

in this manual may show an assembly with a safety

device removed. However, equipment should never be

used in this condition. Keep all safety devices in place,

if removal becomes necessary for repairs, replace the

device prior to use.

2. Replace any safety label or instruction sign that is

unreadable or is missing. Location of safety signs is

indicated in this manual.

3. Never use alcoholic beverages or drugs which can

hinder alertness or coordination while using this

implement. Consult your doctor about using this

implement while taking prescription medications.

4. Under no circumstances should young children be

allowed to work with this implement.

5. This implement is dangerous to persons unfamiliar

with its operation.

Safety Training

6. Do not allow persons to use or assemble this unit until

they have read this manual and have developed a

thorough understanding of the safety precautions and

of how it works. Review the safety instructions with all

users annually.

7. If the elderly are assisting with work, their physical

limitations need to be recognized and accommodated.

Assistants should be a responsible, properly trained

and physically able person familiar with machinery

and trained in this implement’s operations.

8. Never exceed the limits of the implement. If its ability

to do a job, or to do so safely, is in question - DON’T

TRY IT.

9. Do not modify the implement in any way. Unauthorized

modification may result in serious injury or death and

may impair the function and life of the implement.

10. Recognize the hazards associated with working

overhead. Your power unit should be equipped with a

cab or suitable overhead guard to offer protection from

the impact of falling limbs and branches.

A person who has not been trained or has not read and understood all use and safety instructions is not qualified to use

the implement. An untrained operator exposes himself and bystanders to possible serious injury or death.

• Train all new personnel with the instructions alongside

the implement. Be certain only a properly trained and

physically able person will use the machinery.

• Working with unfamiliar equipment can lead to

careless injuries. If this implement is used by any

person other than yourself, or is loaned or rented, it is

the implement owner’s responsibility to make certain

that the operator, prior to using:

• Reads and understands the operator’s manuals.

• Is instructed in safe and proper use of the implement

• If the elderly are assisting with the work, their physical

limitations need to be recognized and accommodated.

• Operators or maintenance personnel who are not fully

able to read and understand this manual should not

operate or work on the implement.

• Make certain that all operators and maintenance

personnel have complete understanding of the full and

exact contents of this manual and safety labeling.

• ALL information contained in this manual and labeling

on the implement must be conveyed CLEARLY and

FULLY, in order to be able to operate safely and

knowledgeably.

• Review the implement and instructions regularly with

existing workers.

9

Preparation

1. Inspect implement for shipping damage. If damage

does exist, do not use. Notify your dealer immediately

to have damaged parts replaced or repaired.

2. When traveling on public roads at 40 km/h (25 mph) or

less, ensure slow-moving-vehicle (SMV) emblem has

been properly installed at rear of power unit.

3. Inspect all fasteners that they are not lose or missing.

Ensure all fasteners are torqued according to the

torque chart at the back of this manual.

4. Ensure that all applicable safety decals are installed

and legible.

5. Personal protection equipment (PPE) including hard

hat, safety glasses, safety shoes, and gloves are

recommended during assembly, installation, operation,

adjustment, maintaining, repairing, removal, cleaning,

or moving the unit. Do not allow long hair, loose fitting

clothing or jewelry to be around equipment.

6. PROLONGED EXPOSURE TO LOUD NOISE MAY

CAUSE PERMANENT HEARING LOSS!

Gas or diesel powered equipment can often be noisy

enough to cause permanent, partial hearing loss. We

recommend that you wear hearing protection on a full-

time basis. Noise over 85dB on a long-term basis can

cause severe hearing loss. Noise over 90db adjacent

to the Operator over a long-term basis may cause

permanent, total hearing loss.

7. Your power unit should be equipped with a cab or

suitable overhead guard to offer protection from the

impact of falling limbs and branches.

Transport Safety

1. Fold and secure the top saw arm during travel.

1. When traveling on public roads at 40 km/h (25 mph)

or less, ensure slow-moving-vehicle (SMV) emblem

has been properly installed at rear of power unit.

2. If traveling at night, ensure provincial, state and local

lighting requirements laws have been met.

3. Do not permit riders while transporting this implement.

4. Carry the attachment low when transporting to reduce

the potential of the power unit tipping over.

5. Be aware of the limb saw boom length. Additional

swing clearance is required in front when making

turns, avoid sharp turns.

6. Slow down and use care when approaching blind

corners or other objects that obscure vision.

7. Use a “spotter” when it is hard to see in the direction

you are traveling and when preparing a cut that

obstructs your vision.

8. Always look behind you before backing up. Make

sure you are looking in the direction of travel to avoid

objects or people.

Operation Safety

1. NEVER allow helpers or bystanders under or near the

machine.

2. Make sure work is performed while on solid level

ground. Avoid operating near ditches, embankments

and holes.

3. Power unit should have a cab or overhead guard for

protection from falling objects.

4. Power unit should have ROPS installed for protection

from roll over.

5. Inspect all fastening devices, do not use if worn or

damaged.

6. Make sure that everyone is clear before moving the

implement. NEVER position yourself between the

power unit and the implement.

7. Do not place your hand or any part of your body on or

near the saw chain. Teeth are very sharp and present

a laceration hazard even when not running under

power and may cause serious injury. Keep saw chain

covered with chain saw scabbard when not in use.

8. Do not raise the implement near electrical power lines.

Contact with power lines can result in serious injury or

death.

9. Do not attempt to operate the power unit while

not seated in the operators seat with the seatbelt

fastened.

10. Do not enter area around the limb saw boom. Moving

boom assembly presents a potential collision and

crush hazard and could result in a serious injury.

11. Consult the power unit’s operator manual to determine

if a rear ballast is required.

12. Follow safe tree maintenance recommendations of

your local farm safety association.

13. Be aware if operating this equipment in areas where

stinging insects may reside. Swarming insects may

cause loss of control of the equipment.

14. Be aware of falling branches protruding into the cab

area.

Maintenance

Safety

1. Good maintenance is your responsibility, poor

maintenance is an invitation to trouble.

2. Follow good shop work practices.

3. Never work under or around the implement unless it is

blocked and chocked securely.

4. Use personal protection equipment (PPE) such as

eye, hand and hearing protectors.

5. Never adjust, service, clean or lubricate the implement

until all power is shut off when attached to the power

unit.

6. Ensure hardware is torqued according to the torque

chart at the back of this manual.

10

Hydraulic

Safety

1. Make sure that all the components in the hydraulic

system are kept in good condition and are clean.

2. Before applying pressure to the system, inspect

for leaks at all components, and that lines, hoses,

connections and couplings are not damaged and leak

free.

3. Do not attempt any makeshift repairs to the

hydraulic lines, fittings or hoses by using tapes,

clamps or cements. The hydraulic system operates

under extremely high pressure. Such repairs will

fail suddenly and create a hazardous and unsafe

condition.

4. Wear proper hand and eye protection when searching

for a high pressure hydraulic leak. Use a piece of

wood or cardboard as a backstop instead of hands to

isolate and identify a leak.

5. If injured by a concentrated high-pressure stream of

hydraulic fluid, seek medical attention immediately.

Serious infection or toxic reaction can develop from

hydraulic fluid piercing the skin surface.

6. Relieve pressure on hydraulic system before

maintaining or working on system.

7. All hydraulic work must be done by qualified personnel.

Storage

Safety

1. Store the unit in an area away from human activity.

2. Fold and secure the top saw arm.

3. Ensure the saw chain cover is on to prevent injuries

from the sharp chain.

4. Do not allow children to play on or around the stored

implement.

5. Store the unit in a dry, level area. Cover if stored

outside.

6. Guard any sharp corners.

7. Ensure components and safety features are not

damaged and in good condition before storing the

implement. Make repairs now to be ready for the

following season.

8. Secure the implement to prevent unwanted

movement.

Safe Work

Not all work spaces are the same, but the principles

presented here can be applied to any work space.

Survey the work site, make note of nearby or overhead

obstructions, embankments, holes or any surface that may

cause the power unit to overturn. Knowing your work area

will make the job easier and safer.

Use extreme care at work sites that impair or partially

block the operator’s line of sight. Know where you are

traveling and ensure there are no bystanders in the area

of travel.

Recognize the hazards associated with working overhead.

Your power unit should be equipped with a cab or suitable

overhead guard to offer protection from the impact of

falling limbs and branches.

Wear appropriate personal protection, particularly if the

work site uses chemicals or other materials that become

hazardous when airborne.

Be aware of:

Bystanders or anyone not directly involved with the

work are only allowed outside of the work area, minimized

hazards.

Workers helping the operator must wear the appropriate

PPE and must always make eye contact with the operator

before entering the work area. Unauthorized Workers or

bystanders are not allowed in the work area. Hazards are

present.

Operator, do not operate the implement outside of the

operator area.

Chain Saw Safety

1. A chain saw is inherently dangerous. Potential

hazards and injuries can be minimized by using

proper protective equipment and safe operating

procedures.

2. Good cutting action and increased chain life result

with correct chain tension and sharpness. Check saw

chain tension and sharpness every three hours of

operation.

3. Be aware that tree’s may contain nails, spikes or other

metals, inspect the tree before beginning the job.

4. Never use a saw chain that:

• Is severely damaged.

• Has excessive saw chain stretch.

• Has broken or cracked components.

• Has loose rivet joints.

Before putting the SEHLS1224 limb saw into service the first time, inspect the machine for shipping damage or

missing / loosened parts. If damaged or loosened parts exist, do not use. Notify your dealer immediately to have

affected parts replaced or repaired.

Assembly & Inspection

11

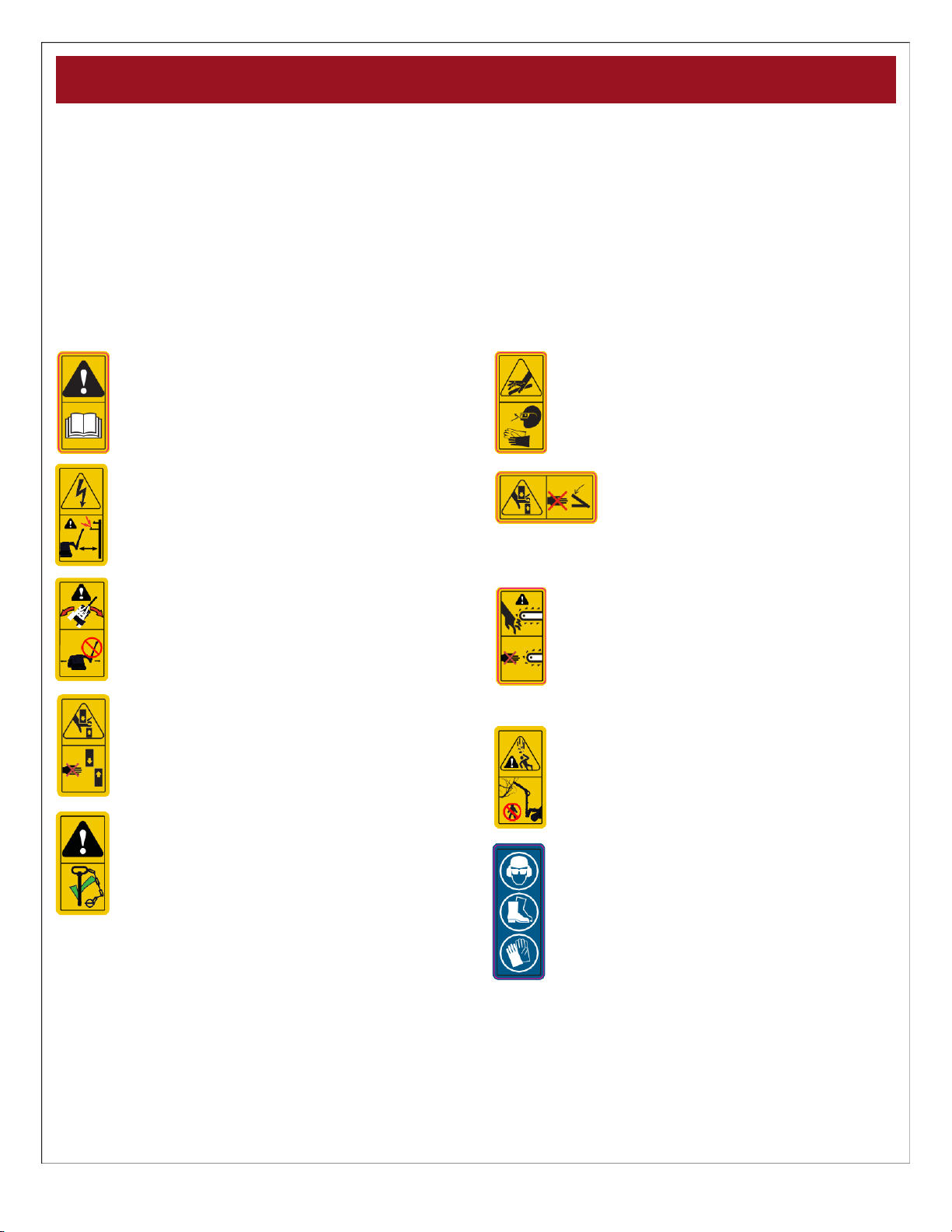

Safety labeling is an important part of the overall safe use of the implement. Safety labeling alerts and warns against

potential injury or death, and is important to follow these points to help keep your implement safe for you and others who

may be using it.

• Keep safety signs clean and legible at all times.

• Replace safety signs that are missing or have become

illegible.

• Replaced parts that displayed a safety sign should

also display the current sign.

• Safety signs are available from your authorized

Distributor or the factory order desk.

Safety Label Descriptions

Caution: read and understand ALL safety and

operating instructions in the manual, read and

understand ALL safety labels located on the

machine. The most important safety device on

this equipment is an informed SAFE operator.

SL00004

Danger: Keep boom 3 m (10 ft) or more away

from overhead electrical cables. Electrocution

from arcing is possible without direct contact.

SL00015

Caution: Hydraulic fluid is under pressure, be

aware that hydraulic leaks could develop with

out warning. Do not check for leaks with your

hand or fingers while the system is pressurized,

serious injury could result. Possible burns or

poisoning from pressurized fluid injection.

Caution: do not place your hand or any part

of your body on or near the limb saw boom

pivot points while the adjusting the boom

Possible serious personal injury or death.

3m

SL00002

Parts moving together present a pinch

(10 ft)

SL00058

SL00056

SL00057

SL00066

Warning: Do not transport with the boom raised

overhead. A raised boom is inherently unstable

and could cause a roll over. Possible serious

personal injury, crushing or death.

Caution: do not place your hand or any part

of your body on or near the front mount while

coupling to the power unit. Parts moving

together present a pinch point and may cause

serious injury Possible laceration, crushing,

amputation hazard.

Warning: Prior to use ensure the lock pin is

installed and secured with a hitch pin. Machine

damage and possible serious personal injury,

crushing or death.

SL00065

SL00067

point and may cause serious injury. Possible

laceration, crushing, amputation hazard.

Danger: do not place your hand or any part of

your body on or near the saw chain. Teeth are

very sharp present a laceration hazard even

when not running under power and may cause

serious injury. Possible laceration, amputation

hazard or death. Keep saw chain covered with

chain saw scabbard when not in use.

Warning: Be aware of falling debris under,

around the attachment and on the power unit.

Cut branches can fall unpredictably. Possible

impact or crushing could result in death or

serious injury.

Caution: Personal Protection Equipment (PPE)

is required when operating or maintaining this

machine. Failure to wear PPE will result in

personal injury.

If labels need to be replaced:

• Be sure that the installation area is clean and dry.

• Be sure temperature is above 50°F (10°C).

SNL00001

• Determine exact position before you remove the backing paper.

• Remove the smallest portion of the split backing paper.

• Align the sign over the specified area and carefully press the small portion with the exposed sticky backing in place.

• Slowly peel back the remaining paper and carefully smooth the remaining portion of the sign in place.

• Small air pockets can be pierced with a pin and smoothed out using the piece of sign backing paper.

Safety Labels

12

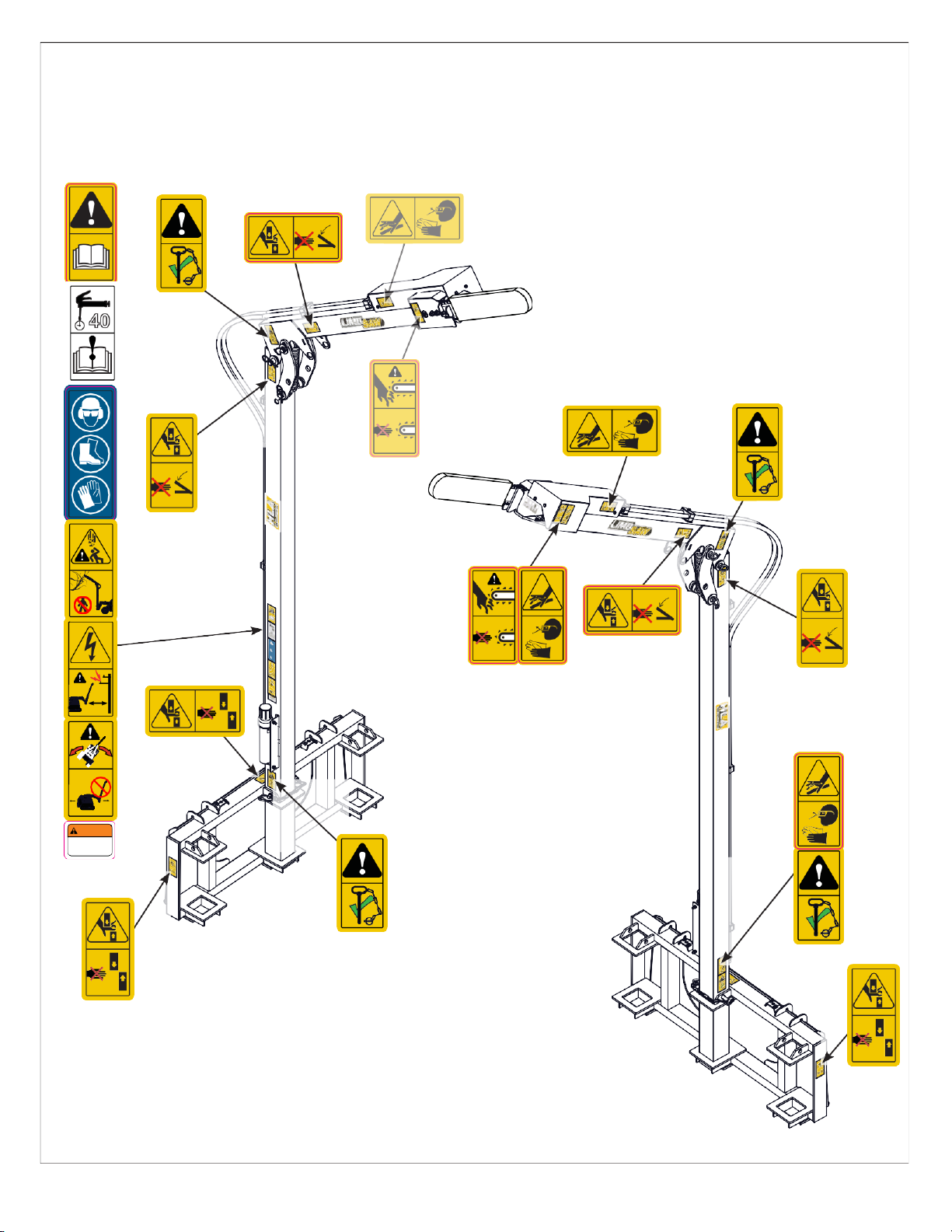

Safety Label Layout

Safety signs and locations on the equipment are shown in the illustrations below.

Good safety practice requires that you familiarize yourself with the label and the safety message it is delivering. Be aware

of the equipment or particular equipment feature that requires your SAFETY AWARENESS.

SL00015H

SL00002

SL00004

SL00066

40

ML00007

SL00065

SL00015H

SL00066

SL00002

SNL00001

SL00067

SL00002

SL00065

SL00015

SL00002

3m

(10 ft)

SL00056

SL00058H

SL00057

WARNING

Cancer and

Reproductive Harm

www.P65 Warn ings.ca.g ov

SNL00011

SL00015

SL00066

SL00066

SL00058

If safety labels have been damaged or removed, new

labels must be applied. New safety signs are available

from your dealer or contact Spartan Equipment.

SL00058

13

Storage 98° 120° Width

Specifications & Dimensions

SEHLS1224 Limb Saw BP120

Recommended Power unit size

The SEHLS1224 is designed for various

sizes of power units.

The power unit must have the rated

operating capacity (ROC) to safely lift

and

operate the attachment.

Attachment

Attachment specific per power unit at time of

ordering from the dealer.

Weight

395 lb

Saw Chain

25" STIHL-33RS Rapid Super

Guide Bar

Stihl Rolomatic ES 25"

Hydraulic Motor

Minimum Hydraulic Flow

15 GPM @ 3000 PSI

RPM:

2550 @ 15 GPM

Torque

45 ft-lb

Power

22 hp

Dimensions

A - Height

B - Depth

C - Width

Position 1: Storage

121"

20"

50.75

Position 2: 98°

138"

87"

50.75

Position 3: 120°

169"

73"

50.75

Accessories

HK90

Optional 90" Hose Kit c/w Flat Faced

Couplers

SHMK

Optional Spring Hose Mount Kit

A

C

Specifications

B

B

A

A

B

14

Motor shield

Power head

Saw boom pole

(48”) Saw chain tension

adjuster

Main boom pole

(120”)

Spring hose

mount locations

Manual tube

Automatic saw chain

oiler adjuster

Adaptor frame

assembly

The Spartan SEHLS1224 Limb Saw unique design helps to increase productivity by ensuring safe, effective and speedy

completion tree and branch trimming chores.

The owner or operator has the responsibility of being familiar with all the features of the limb saw and know how to

operate them. Each owner or operator must train all other operators before they start working with the machine.

Read this section carefully to learn how to use the limb saw safely and how to set it to provide maximum field efficiency.

By following instructions in conjunction with a good maintenance program, your SEHLS1224 will provide many years of

trouble-free service.

Do not operate this product if you are not familiar with its features.

The SEHLS1224 is illustrated below, showing its basic components and features. Review the various components and

their position, the names of the components will be used to describe where they are and how they work throughout the

manual.

SEHLS1224 Limb Saw Components

Three position pivot

stop plate

Three boom mount

locations

Components and Features

Tension

spring

Chain guard

Saw chain cover

25” saw chain &

guide bar

15

SEHLS1224 Limb Saw Features

Automatic Chain Oiler

The SEHLS1224 is equipped with an automatic chain oiler

system fed from the hydraulic circuit. The system is preset

at the factory for optimum lubrication of the saw chain, but

is adjustable if required.

To change the setting:

• Hold the adjuster knob and loosen the knurled lock

nut.

• Turn the knob to the desired position: clockwise to

increase, counter clockwise to decrease.

• Use caution using no more than ½ turns to make

adjustments.

• Position piece of paper or cardboard on ground and

lower chainsaw blade over the paper.

• From the power unit seat, run your saw several

seconds. Look to see if there is any oil splatter on the

paper.

• Adjust oil flow until you have a fine spray of oil on

paper.

• When you have achieved the correct flow, hold the

knob, and tighten the knurled lock nut to lock the knob

in position.

Knurled nut

Adjuster

knob

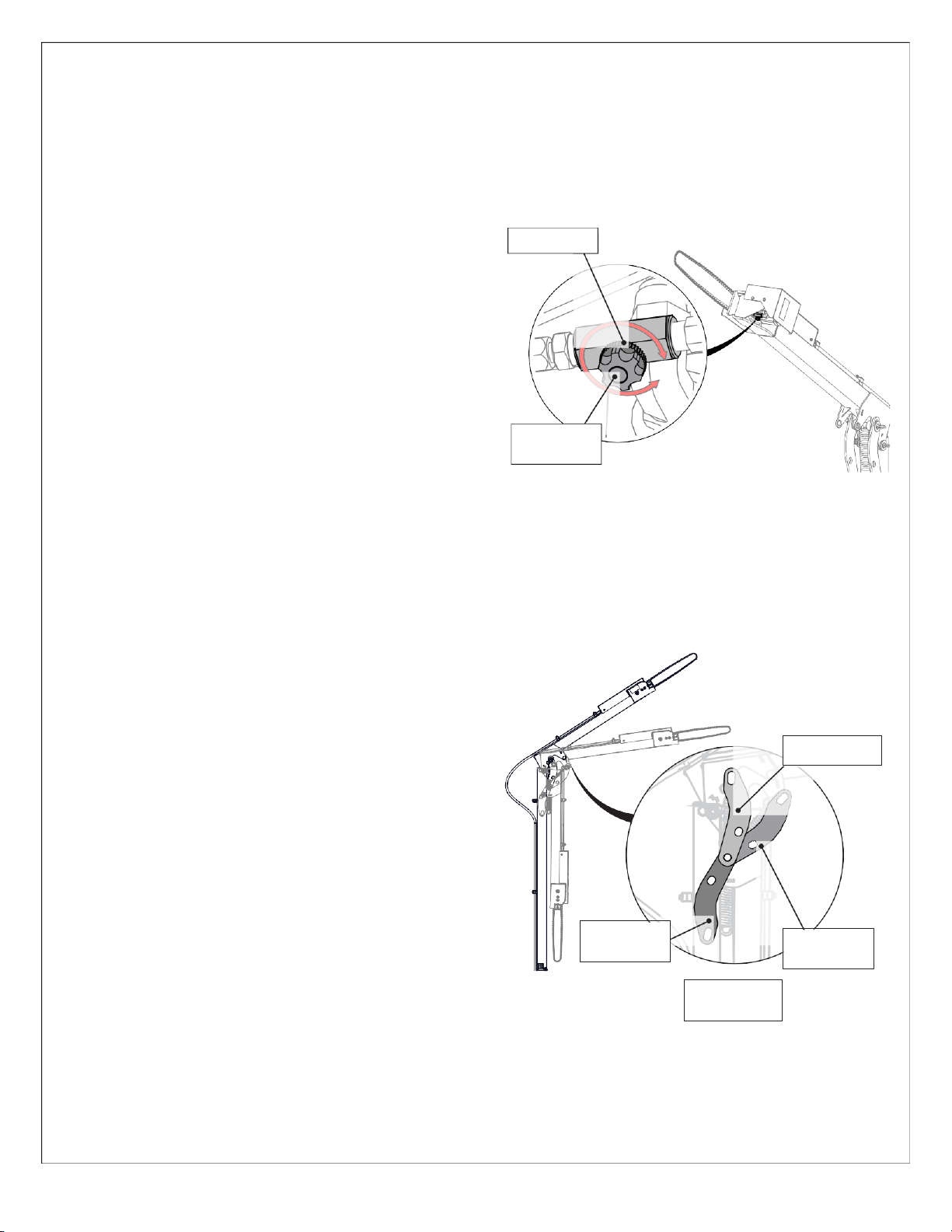

Pivot Stop

The saw boom pole is able to be locked into three

positions via the pivot stops:

• Storage position - 0°

• 98° position

• 120° position

To change position, lower the limb saw so its easily

accessible.

• With a helper support the saw boom pole.

• Remove the saw boom pole hitch pin and pin

assembly.

• Pivot the saw boom pole to the new position, and line

the spring loop up to the appropriate bracket / pin

holes.

• Rotate the two pivot stops to the appropriate bracket

holes and insert the pin assembly through the holes

and spring loop, and lock with the hitch pin.

Note: when putting the saw boom in storage position allow

the spring to hang down.

Pivot stop

positions

98° position

Storage

position

120° position

16

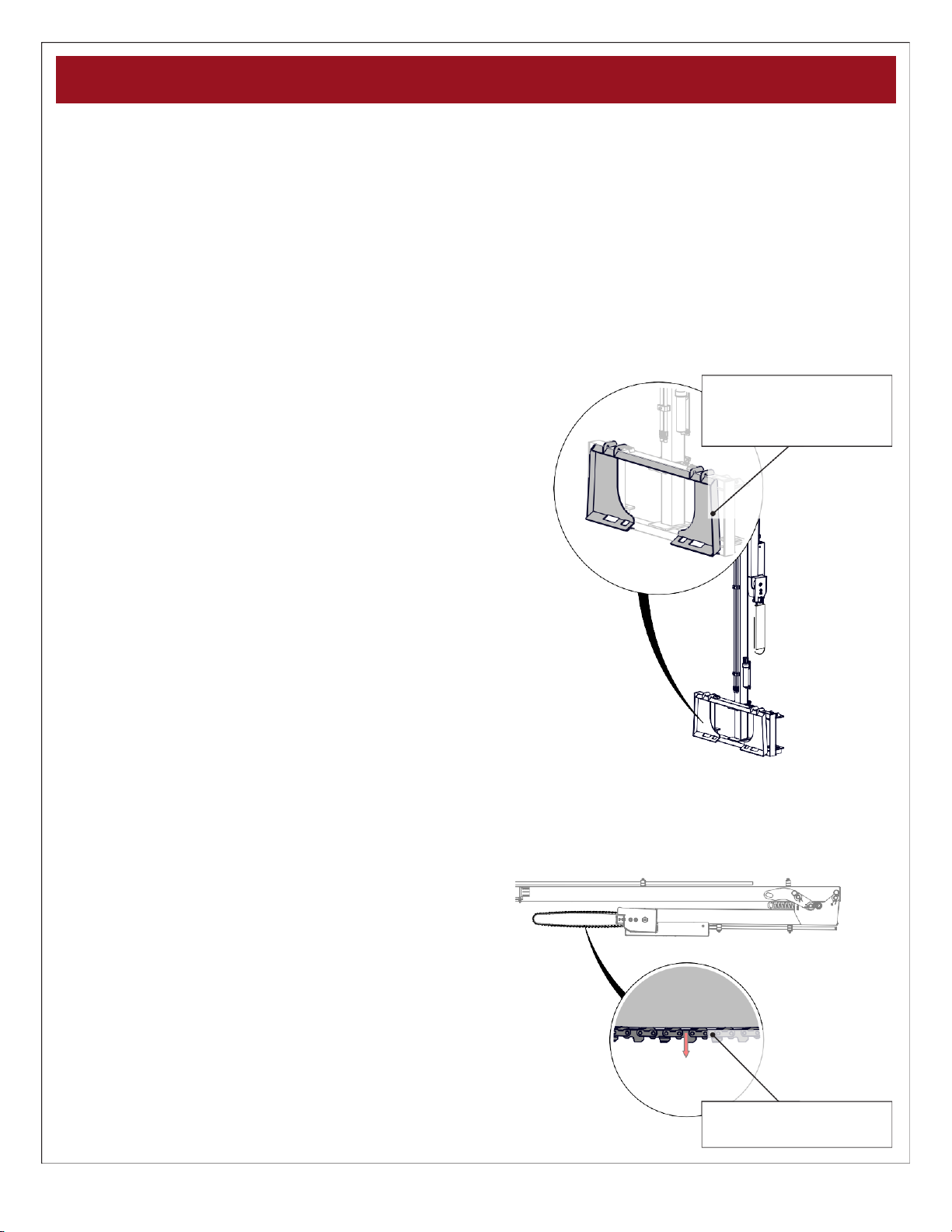

Main Boom Mount

The main boom pole is able to be mounted into one of

three positions on the adapter frame assembly.

To change position, have limb saw mounted on the power

unit and lock the top saw boom into the storage position.

• Roll the bucket position to full dump (so the limb saw

is horizontal) at waist height.

• Undo the lock pin from the draw pin and remove from

the main boom.

• With two people carefully slide the limb saw out of the

adapter frame.

• Carefully move it to the new position and insert into

the adapter frame.

• Insert the draw pin and secure into place with the lock

pin.

Draw pin

Limb saw in

storage position

17

To prevent potential injury during installation and to ensure safe working conditions, avoid working around the power unit

while it is running. Shut off the power unit and ensure the brakes are applied or the wheels have been secured with wheel

chocks to prevent unwanted movement during the installation process.

The following describes the typical connection procedure with supplied materials. Before proceeding, lubricate the

unit. Refer to the maintenance section in this manual. Before putting the limb saw into service the first time, inspect the

machine for shipping damage. If damage does exist, do not use. Notify your dealer immediately to have damaged parts

replaced or repaired.

This is a one-time set-up procedure, and will not have to be repeated.

The initial setup of the limb saw model involves a few basic steps.

• Prepare and attach the limb saw to the power unit, the saw boom should be in storage position.

• Install hydraulic hoses.

• Test and inspect.

Mount the Limb Saw

Ensure your attachment system is secure on the power

unit. The limb saw should be in position according to the

power unit’s mounting instructions.

• Position the hydraulic connectors away from the quick

attach points to prevent damage from pinching.

• Prepare your particular attachment system, follow the

attachment instructions for your power unit.

• Close and secure any locks or pins to lock the limb

saw to the quick attach.

• Attach the hydraulic hoses to the power unit’s auxiliary

ports.

When traveling from point to point, always travel with the

limb saw lowered and saw boom in storage position for

better stability.

Quick Attach Adaptor.

Machine specific adaptor

configured at purchase.

Check Chain Tension

Ensure your limb saw is secure on the power unit. The

limb saw should be lowered and in storage position for

easy access.

• Grasp the chain at the midpoint of the guide bar and

pull the saw chain away from the bar rails. The drive

link tangs should lift away but not clear the bar groove.

• Check that the saw chain is adequately lubricated.

Chain should be snug but move freely around the guide

bar.

If saw chain needs to be adjusted see the maintenance

section for adjustment procedure.

Tangs should lift from but

not clear guide bar.

Initial Setup

18

!

CAUTION

Operational Hazard

Do not lock the auxiliary hydraulics in the

“ON” position, dangerous and unexpected

movement will occur.

!

High Pressure Hazard

Be

aware that hydraulic leaks

could

develop with out warning.

Do not check for leaks with your

hand or fingers while the system is

WARNING

pressurized

!

CAUTION

Operational Hazard

At first use the hydraulic motor and hoses

on this product may contain air or an air

-

fluid

mixture. Failure to remove all the air from the

hydraulic

circuit can cause dangerous

uneven,

jerky movement during use.

!

WARNING

Amputation Hazard

Do not enter area of chain saw. A

running

chain saw presents a

potential

laceration

and amputation hazard

and

could result in death.

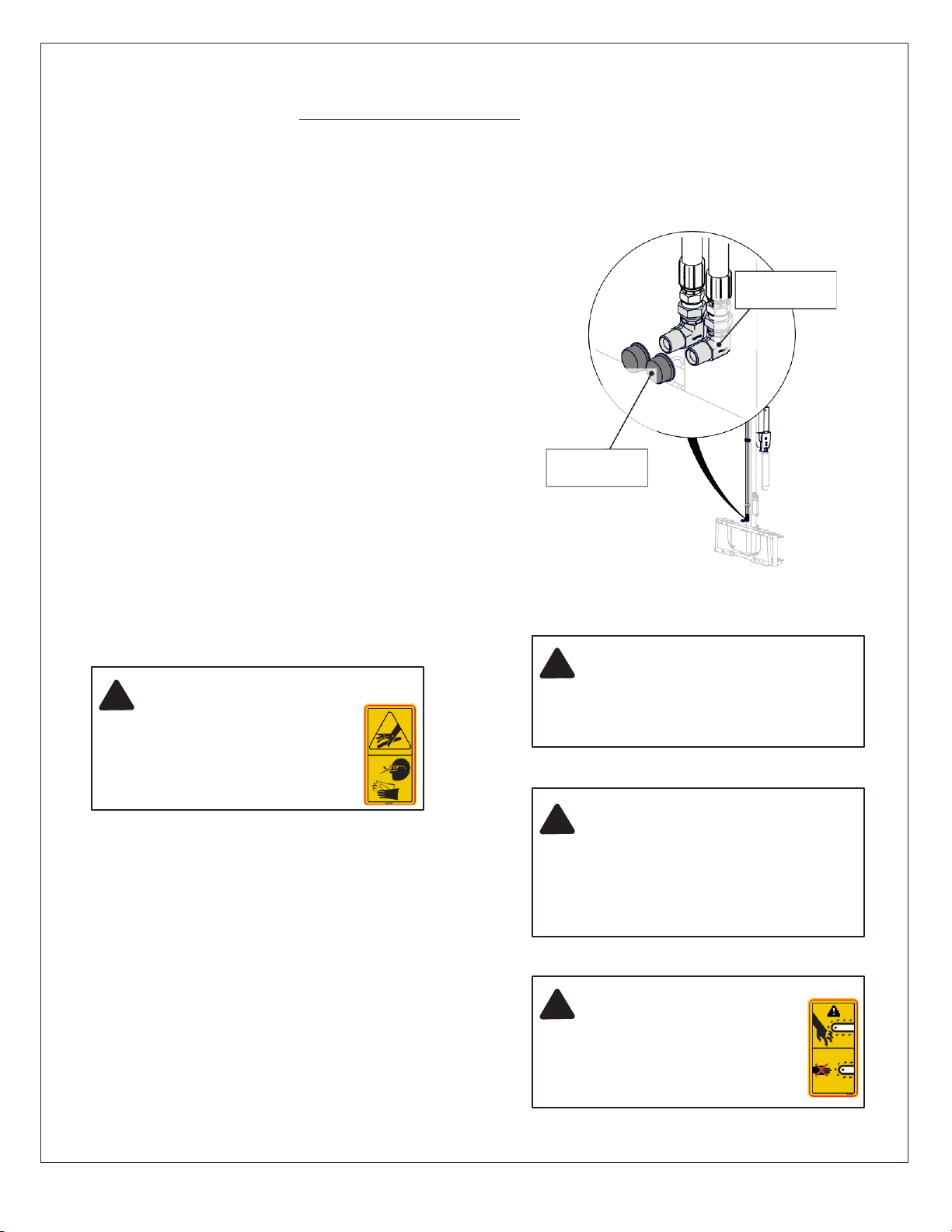

Hydraulics

Hydraulic connections from the power unit to the limb saw are made at the limb saw. Hydraulic hoses and connectors

from the limb saw to the power unit is the responsibility of the owner. HK90 Optional 90” Hose Kit c/w Flat Faced Couplers

is available from your dealer.

The following describes the typical connection procedure, however customizing the connections is possible (single

point hydraulic couplers, etc) and is up to the customer. See your power unit manual on how to operate your auxiliary

hydraulics.

Caution: only qualified personnel should make

modifications and connections to the power unit’s

hydraulic system.

• The hydraulic hoses must be:

• Good quality, 3000 psi min

• Sufficient length to reach the auxiliary ports

• 3/8 i.d. minimum.

• Limb saw end of the hose must have female 1/2”

NPT fittings.

• Power unit end, connectors to fit your auxiliary

ports.

• Remove the protective end caps on the hydraulic

connectors and hoses.

• At the power unit, route the hydraulic hoses from the

power unit’s auxiliary remote hydraulic connections to

the limb saw hydraulics connection.

• Ensure the hydraulic hose is secured and protected

from snags, crimping or pinching. Note: limb saw

comes equipped with mounting plates for the SHMK

spring hose mount kit, ask your dealer.

• Mark the connections appropriately on the hoses.

End caps

Hydraulic

connectors

Test

Once the limb saw is securely attached and hydraulics

connected, move the saw boom from storage position to a

position of your choice. Remove the saw chain cover then

start up the power unit. Ensure there are no bystanders

in the working area around the limb saw or power unit to

avoid potential injury.

Test the function of the chain saw hydraulics: check

clearances for the hydraulic hoses, lift the loader arms

up and down, curl the bucket cylinders and look for any

interference.

The hydraulic motor on this product may contain air or

an air-fluid mixture. Cycle the hydraulic chain saw motor

several times until all air has been completely removed.

Do not lock the auxiliary hydraulics in the “ON” position.

19

!

CAUTION

Prepare

Read and understand ALL safety and

operating instructions in the manual,

read and understand ALL safety

labels located on the machine.

!

WARNING

Amputation Hazard

Do not enter area of chain saw. A

running

chain saw presents a

potential

laceration

and amputation hazard

and

could result in death.

This section describes how to safely and effectively operate the limb saw in the field of operation. By following

recommended procedures, a safe working environment is provided for the operator, bystanders and the area around the

work site. Not all situations and conditions can be addressed, proceed with care & caution and use safety as your guide.

The owner or operator has the responsibility of being familiar with the operation of the limb saw and must train all other

operators before they start working with the machine.

Work in a safe manner and follow all instructions exactly, safety is everyone’s business. Untrained operators are not

qualified to use the machine.

Operation Safety Checklist

NEVER allow helpers or bystanders under or near

the machine while mounting the power unit.

Make sure that the machine is securely mounted

before using.

Be aware of overhead hazards: falling branches.

Power units should be equipped with a cab for

overhead protection.

Inspect all fastening devices, do not use if worn or

damaged.

Prepare

• Clear the area of bystanders, especially small

children.

• Training: each operator must be trained and familiar

with the set up and operation of the product and its

components.

• Review:

• Components and Features

• Operation Safety Checklist

• Power unit safe operating instructions

• It is recommended that each person wear appropriate

Personal Protective Equipment (PPE). This list

includes but is not limited to:

• Safety shoes with slip resistant soles.

• Safety glasses.

• Hearing protection.

• Heavy or leather gloves.

• Survey the work site, and make note of any

hazards such as holes, ditches nearby or overhead

obstructions. Never assume the work area is safe and

never skip the site inspection before start of operation.

Ensure your power unit has a ROPS installed.

Do not permit riders while using or transporting

machine.

Do not allow bystanders near front or sides of the

machine. Falling objects are a potential hazard.

Drive slow and carry low.

Where possible, avoid operating near ditches,

embankments and holes.

Before use, inspect the limb saw (see service &

maintenance section) and check the following:

• Inspect your power unit, it must be in good

operating condition (see power unit owner

manual).

• Check all nuts, bolts and screws and ensure they

are all properly secured.

• Check hydraulic connections, ensure they are

clean and free of dirt. Run the machine and

power unit through all hydraulic functions.

• Inspect the saw chain for correct tension and

sharpness.

Material

The Spartan Equipment limb saw is designed for the

purpose of trimming branches from trees.

Do not use the limb saw to lift, push or pull objects,

damage to the limb saw will result.

Field Operation

20

!

CAUTION

Operational Hazard

Personal Protection Equipment

(PPE)

is required when

operating

or maintaining this machine.

!

CAUTION

Overhead Hazard

Be aware of falling debris under,

around the attachment and on

the power unit. Cut branches

can fall unpredictably.

Operating

It is important to follow the safety information and operating procedures in this operator’s manual. How and when to use

the SEHLS1224 and power unit features will be dictated by a combination of variables:

• Power unit characteristics.

• Condition and type of working surface.

• Your experience using the limb saw.

Knowing the capabilities and features of your power unit and limb saw, coupled with your experience is the best way to

safely and efficiently tackle any baling operation.

Safety

Always inspect the work area before starting the job. Ensure any rocks or any other objects in the area either removed or

are noted and marked. Inspect the tree for any nails, spikes or metal objects.

• Power units must have overhead protection and a ROPS system installed.

• Review loader instructions for your power unit and ensure your quick attach system is secure.

• During transport carry the limb saw low and slow and in storage position. Be aware of overhead hazards and

obstructions.

Begin

Work

As you gain experience with your saw, you will become

more skilled at determining how many cuts it will take for a

clean, final cut. When in doubt, make an extra cut.

Note: At first start of the day, allow a short run time before

beginning to trim to lubricate the saw chain.

• To begin a cut, position the limb saw over the branch

to be trimmed, around the halfway point or closer on

the guide bar from the motor.

• Activate hydraulic flow to start the chain saw running.

• Lower your loader to begin cutting, constant pressure

is supplied by the spring, keep lowering to complete

the cut.

Trimming Tips

• Always be aware of helpers. Make eye contact and

have a hand signal system in place.

• When cutting long, or large heavy limbs, make

several shorter cuts to remove weight from the limb

before making the final cut at the base. This will

minimize the chance of the bark peeling and

catching and also decrease the chance of the limb

rolling and pinching the saw.

• Always keep the chain, bar and sprocket clean.

Replace worn out parts as needed.

• Always operate with a sharp chain. Cutting with a

dull saw chain will increase the time it takes to cut

and will cause vibration and excessive wear on

your guide bar. Sharpen chain daily.

• If burn marks appear on the wood that you are

cutting, or soft wood is hard to cut, it’s time to

sharpen or replace your saw chain.

• Always keep saw chain at proper tension, check

tension every three hours of operation.

• Clear away or have a helper clear away trimmed

branches around the tree to make it easier and

safer to maneuver around the work site.

• Align the power unit to cut branches at a 90° or

greater angle so that falling branches fall off to the

side and not on the power unit.

• Be sure to clean saw chain after each use, and

sharpen if required. (see maintenance section)

Table of contents

Other Spartan Equipment Saw manuals