Spartan 81 User manual

M o d e l 8 1

Owners Manual

( 8 0 0 ) 4 3 5 - 3 8 6 6

SPARTAN TOOL L.L.C.

RecordtheSerialNumberofyour

Model 81

andgivethenumbertothefactory

whenordingparts.

SerialNumber..............................................

Whenordering,specifyquantityanditemnumbers

ALLPRICESNET,F.O.B.FACTORY,AND

SUBJECTTOCHANGEWITHOUTNOTICE

Page2

Table of Contents

OPERATING SECTION

How to Assemble....................................................................................................3

Operating Instructions.............................................................................................3

How to Repair 1/4” and 5/16” Cables.....................................................................4

Operating a Power Driven Cleaning Tool................................................................4

How to Install Cable in Model 81 ............................................................................5

Safety Instructions .............................................................................................. 6-7

PARTS & ACCESSORIES SECTION

Power Unit BSP04703300 ................................................................................. 8-9

Control Box ..................................................................................................... 10-11

Wiring Diagram .....................................................................................................11

Drum Unit ........................................................................................................12-13

Cables for Model 81 ....................................................................................... 14-15

Page3

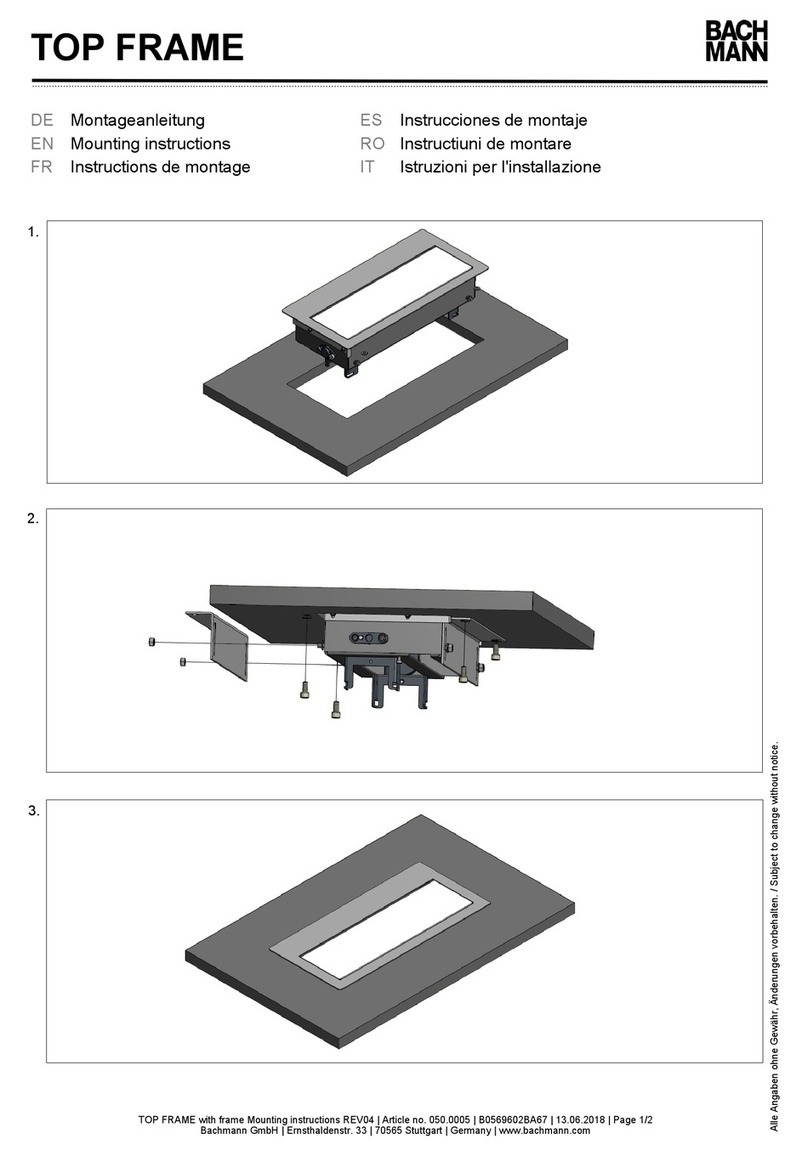

How to Assemble

Removedrumandpowerunitfromcartons.

Step 1 Set power unit in verticalposition.(Seepictureonfrontpage)

Step 2 Mount drum on power unit. Lock drum to power unit by tightening (2) thumb screws. (Thumb screw

shouldermustenterholeincollarbeforetightening.)

Step 3 Loosen (3) wing nuts onmotormountplate.PutV-beltaroundpulleyanddrum.Movemotormounting

plateuntilV-beltisfirm. If thebeltistootight,machinewill notoperate.Tighten(3)wingnuts.

Operating Instructions

1. Insert proper size ofcableinmachine.Useopenhookcablesinupto11/2”lines,use5/16” innercore cable for

11/2”to 2” lines.

WE DO NOT RECOMMEND USING YOUR 1/4” CABLE IN LINES LARGER THAN 1 1/2” IN DIAMETER.

2. Place unit closetopipeopening(ideally12”ifpossible).

3. Pull out enough cabletoenterwasteline or cross bar.

4. PositionswitchinForward(F)position.Don’treverse motororuseReverseActionSwitchuntilmachinecomes

todead stop andthenonly to remove cablethroughcross bar.

5. Depress foot switch pedal,causingcabletorotatethroughcross bar or into pipeopening.(Forwardonly).

6. Take6”to8”lengthofcable,andslowlyfeeditintothelinegivingthecabletimetoroundfittingsandtoremove

stoppage.

7. Whenmotorslowsup,indicatingaloadonsame,pullcablebackabitandstartmovingitforwardsandbackwards.

Thisreciprocatingactionkeepsthecablerotating- keepscablefromgetting“hung-up”-themaincause ofcable

kinkageorbreakage.

8. If cable gets “hung-up”, stop your machine and reverse the direction of same through Reverse Switch, pulling

back as you do so to free working end of cable.

WARNING: Do not use Reverse Switch until you motor unit comes to dead stop!

9. Repeat this action as often as necessary tocleantheline.

10. When jobiscompleted, feed all cablebackinto drum 6” to8”at a time -DON’Ttake long bites.

11. You must reverse rotation of the drum to removecablethroughacrossbar.

12. Youmaydrainthedrumofexcessliquidsbyremovingthedrainplugwhichisthesmallerhexboltonthebackof

thedrum.

Page4

How to Repair 1/4” and 5/16” Cables

All1/4”and5/16”cables canberepairedwithareplacableend. Ifyoukinkyoucable,cutthecable offatthekinked

portion.Grindtheend ofsametoprovidealead thread.Now,pickupyourrepairendandthreadsameontheregular

cable,asyouwouldanutonabolt,turning same about three turns,whichwillfastenittothecablesecurely.Repair

endscan be purchased.

Operating a Power Driven Cleaning Tool

1. Stayclosetopipeopening,(ideally12”ifpossible)duringoperationsespeciallywhenroundingfittingsorremoving

stoppageinlines.

2. Moveyourcablebackwardsandforwardsconstantlywhenyougetintostoppage,therebypreventingyourcable

fromgetting“hung-up”,causingunnecessarykinkage.Remember-arotatingcablecannotkinkorbreak.Kinkage

ofcabletakesplaceonlywhentheworkingendofthecablegets“hung-up”andyoukeepon twisting the other

end.

3. Don’t attempt to roundfittingsorremovestoppage until your drumreachesfullspeed.It is the rotation ofthe

cablethatenables it to either(a)roundfittings, or (b) removestoppage-NOTpushpower.

Page5

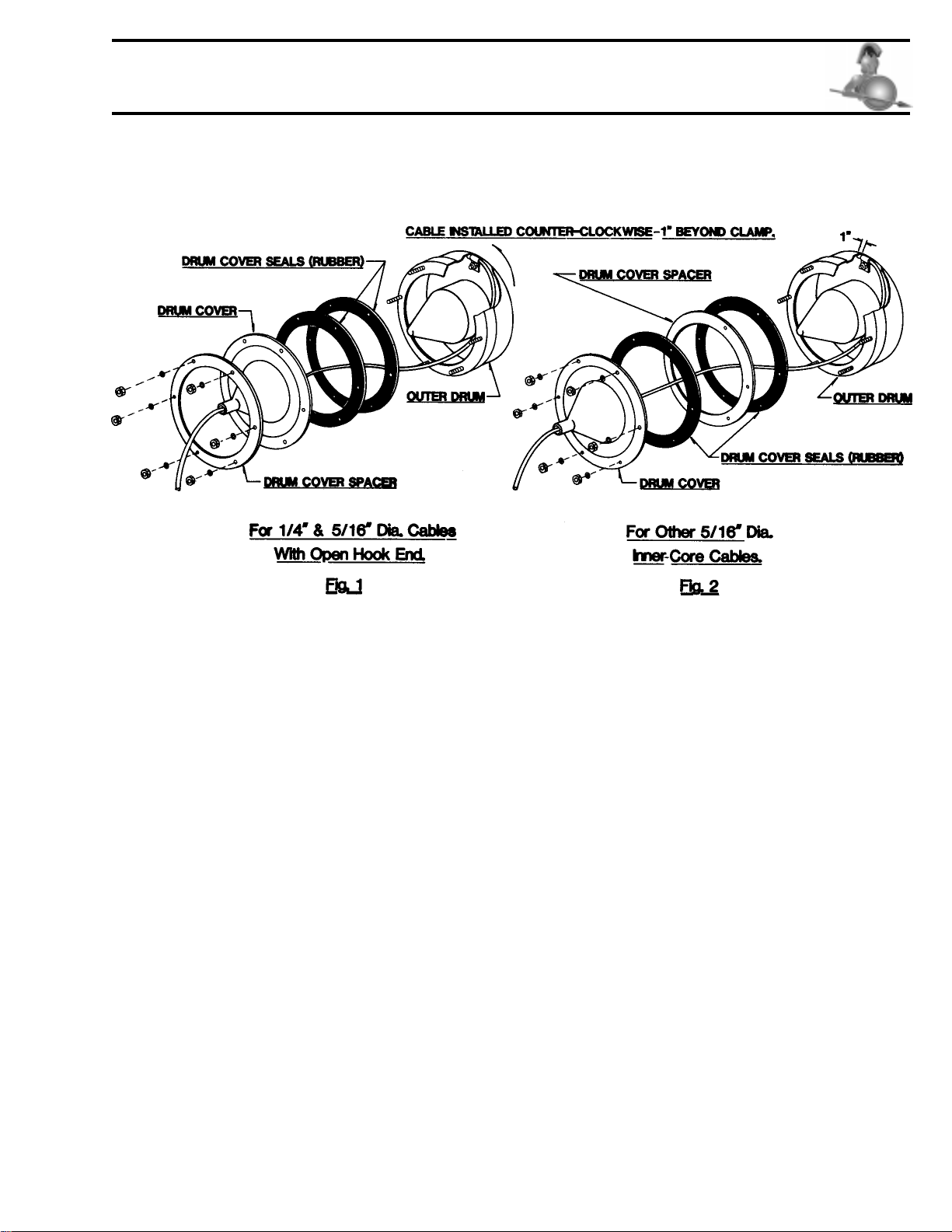

How to Install Cable in Model 81

1. Position drum unitin a verticalposition.Remove (6) nuts,washers, drum cover,drum cover spacer, and (2)

drumcoverseals.

2. Assembledrumcoverspacerand(2)sealstoouter drumasrequiredforvariouscables.See Figure1andFigure

2.

3. Insert cable throughdrumcoverasillustratedinFigure1.

4. Place end of cable in outer drum. Slide cable under clamp. Cable should enter clamp in counter-clockwise

direction and extend approximately 1” beyond clamp. See Figure 1. tighten clamp screw.

5. Place drum cover on outer drum assembly and secure with (6) nuts and washers. Assemble all (6) nuts,

tightening all nuts a little at a time; about 3 times around. Then give nuts a final tightening.

6. Feed remainder of cable into drum while drum is operating in forward only.

Page6

Safety Instructions

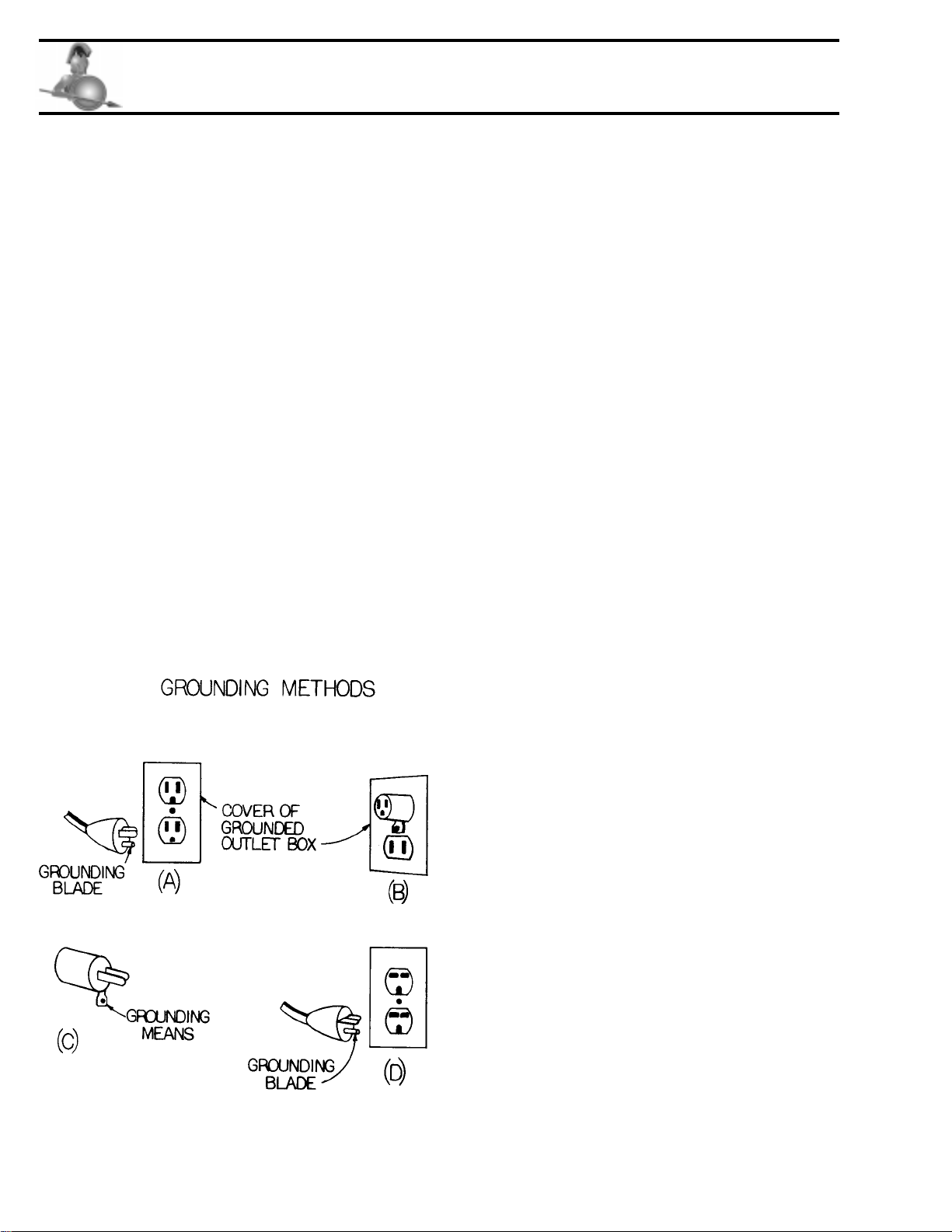

A. ForAllGroundedTools

1. GroundingInstructions

This tool should be grounded while in use to

protect the operator from electric shock. The

tool is equipped with a 3-conductor cord and

3-prong grounding type plug to fit the proper

grounding type receptacle. The green (or

green and yellow) conductor in the cord is

the grounding wire. Never connect the green

(or green and yellow) wire to a live terminal.

If your unit is for use on less than 150V, it

has a plug that looks like that shown in sketch

(A). If it is for use on 150 to 250 V, it has a

plug that looks like that shown in sketch (D).

An adapter, see sketches (B) and (C), is

availablefor connecting sketch(A) type plugs

to a 2-prong receptacles, except in Canada.

The green-colored rigid ear, lug, or the like,

extendingfrom the adaptermust be connected

to a permanent ground, such as a properly

grounded outlet box. No adapter is available

for a plug as shown in sketch (D).

2. ExtensionCords

Useonly3-wireextensioncordsthathave3-prong

grounding-typeplugsand3-polereceptaclesthat

acceptthetool’splug.Replaceorrepairdamaged

cords.

B. ForAllDouble-InsulatedTools:

ReplacementParts

Whenservicinguseonlyidenticalreplacementparts.

C. ForAllTools:

1. Keep WorkArea Clean

Clutteredareasandbenches inviteinjuries.

2. ConsiderWorkArea Environment

Don’texposepower tools to rain.

Keepworkareawell lit.

Donotusetool inpresenceofflammableliquids

orgases.

2A.GuardAgainstElectricShock

Preventbodycontactwithgroundedsurfaces.For

example; pipes, radiators, ranges, refrigerator

enclosures.

3. KeepChildrenAway

Donotletvisitors contacttoolorextensioncord.

Allvisitorsshouldbekeptawayfromworkarea.

4. Store IdleTools

When not in use, tools should be stored in dry,

and high or locked-up places - out of reach of

children.

5. Don’t Force Tool

It will do the job better and safer at the rate

for which it was intended.

6. UseRightTool

Don’t force small tool or attachment to do the

job of a heavy-duty tool.

Page7

Safety Instructions

7. Dress Properly

Do not wear loose clothing or jewelry. They

can be caught in moving parts. Rubber gloves

and non-skid rubber foot-wear are

recommended when working outdoors.

Wear protective hair covering to contain long

hair.

8. Use Safety Glasses

Also use face or dust mask if cutting operation

is dusty.

9. Don’t Abuse Cord

Never carry tool by cord or yank it to

disconnect from receptacle. Keep cord from

heat, oil, and sharp edges.

10. Secure Work

Use clamps or a vise to hold work. It’s safer

than using your hand and it frees both hands

to operate tool.

11. Don’t Overreach

Keep proper footing and balance at all times.

12. Maintain Tools With Care

Keep tools sharp and clean for better and safer

performance.

Follow instructions for lubricating and

changing accessories.

Inspecttool cords periodically andifdamaged,

have repair by authorized service facility.

Inspect extension cords periodically and

replace if damaged.

Keep handles dry, clean, and free from oil and

grease.

13.DisconnectTools

When not in use, before servicing, and when

changing accessories, such as blades, and

cutters.

14.RemoveAdjustingKeysandWrenches

Form habit of checking to see that keys and

adjusting wrenches are removed from tool

before turning it on.

15. Avoid Unintentional Starting

Don’t carry plugged-in tool with finger on

switch. Be sure switch is off when plugging

in.

16. Outdoor Use Extension Cords

Whentoolis used outdoors, useonlyextension

cordsintendedfor use outdoors and somarked.

17. Stay Alert

Watch what you are doing. Use common

sense. Do not operate tool when you are tired.

18. Check Damaged Parts

Before further use of the tool, a guard or other

part that is damaged should be carefully

checked to determine that it will operate

properly and perform its intended function.

Check for alignment of moving parts, binding

of moving parts, breakage of parts, mounting,

and any other conditions that may affect its

operation. A guard or other part that is

damaged should be properly repaired or

replacedby an authorized servicecenterunless

otherwise indicated elsewhere in this

instruction manual.

Have defective switches replaced by

authorized service center.

Do not use tool if switch does not turn it on

and off.

Page8

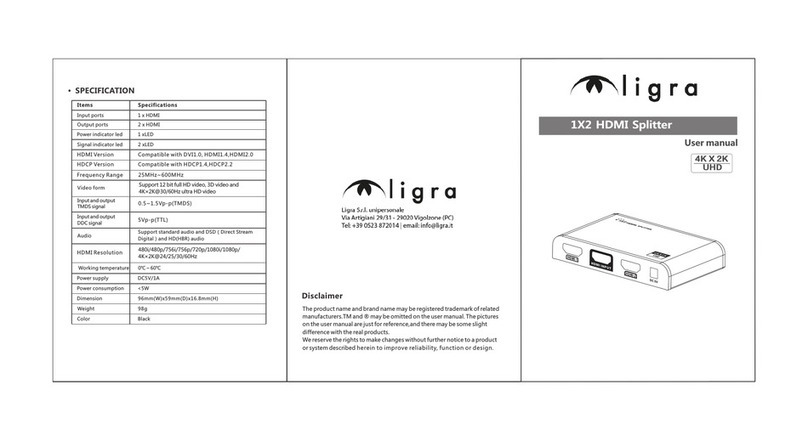

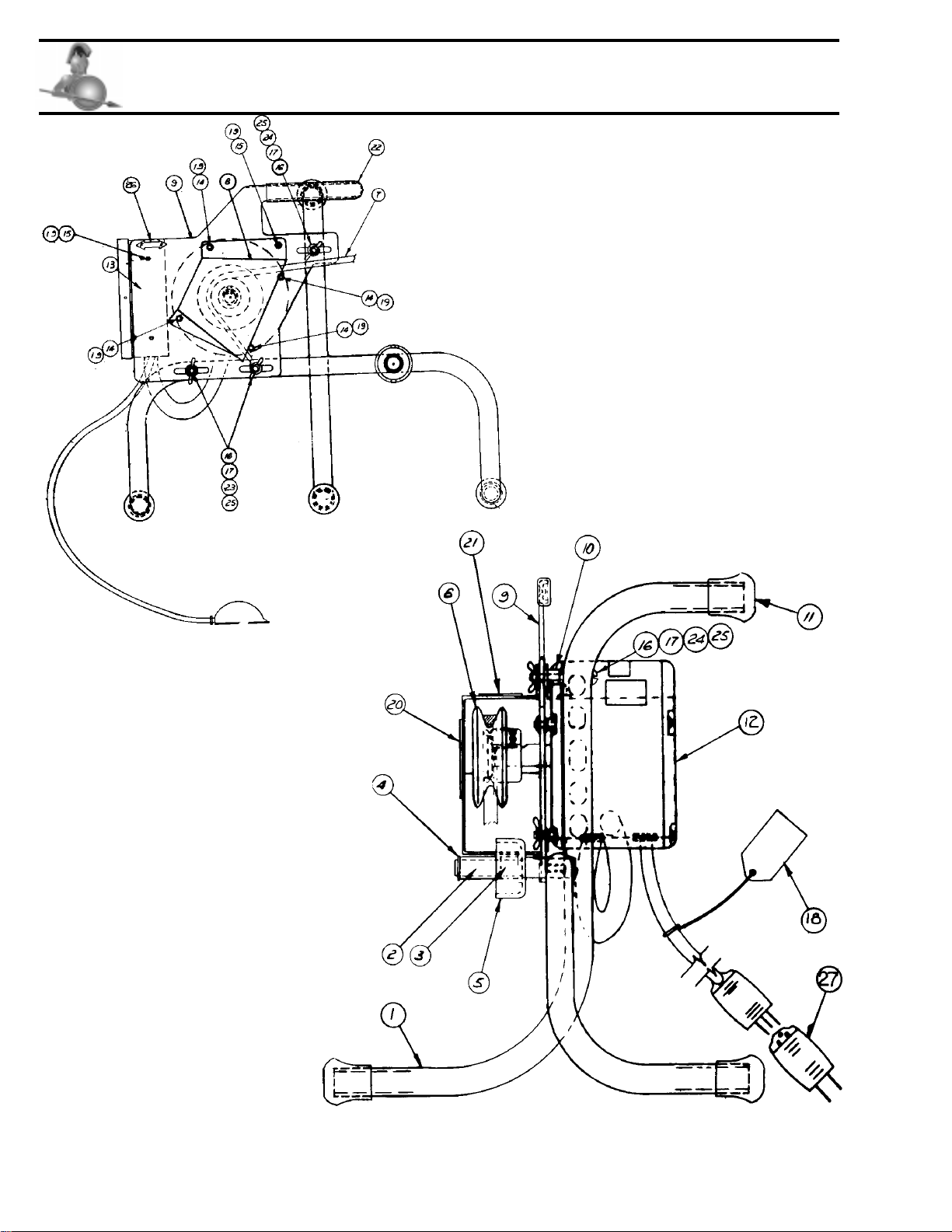

BSP04703300 Model 81 Power Unit

Page9

BSP04703300 Model 81 Power Unit

Item

Number PartNumber Description

1 ASP04733400 Frame Assy. Includes item 2, 3, 4, 5, 10, 11, 16,

17, 23, 24 & 25

2 AXX03421300 Bronze Bearing

3 ASP04700400 Flanged Bearing

4 XXX02822500 Retainer Ring

5 ASP04700300 Shaft Collar

6 ASP04700600 Sheave

7 ASP04233200 V-Belt

8 ASP04733500 Sheave Guard Assy, Includes items 20 & 21

9 ASP04733600 Motor Mount Plate Assy., Includes items 22 & 26

10 ASP04700700 Space 3/8" O.D. x .058 Wall x 11/16"

11 ASP04699800 Tip Mounting

12 DSP04708700 Motor and Terminals Assembly

13 See Page 4 for Control Box

14 XXX03850101 Kep Nut #10 - 32

15 XXX00125801 Machine Screw#10 - 32 x 3/8"

16 XXX0140501 Wing Nut 1/4" - 20

17 XXX0076330 Flat Washer 1/4"

18 ASP02828800 Caution Tag

19 XXX04725200 AcornNut #10 - 32

20 ASP04715000 Spartan Label

21 DSP04703600 Cover Position Label

22 ASP04715200 Handle Grip

23 XXX00128601 Round Hd. Mach. Screw 1/4" - 20 x 1 3/4"

24 XXX03337601 Round Hd. Mach. Screw 1/4" - 20 x 2 1/2"

25 XXX00137301 HexNut 1/4" - 20

26 ASP04714900 Switch Direction Label

27 ASP02768901 Ground Wire Adapter

Page10

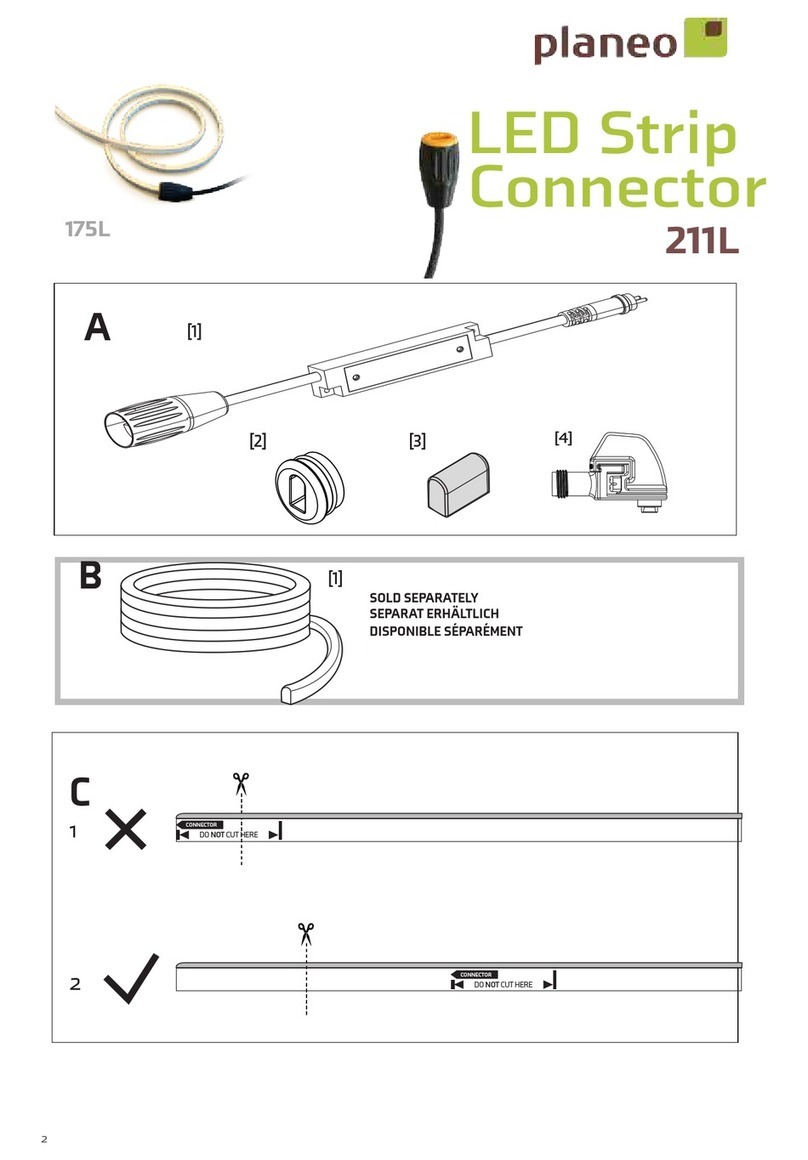

Control Box

Item

Number Part Number Description

1 CSP4402200 Control Box Weldment

2 ASP04225800 Toggle Switch

3 ASP04229900 Capacitor

4 ASP04230900 Capacitor Clamp

5 ASP04230000 Terminal Cap

6 XXX01921801 Rd. Hd Slotted Mach. Scr. #8-32 x 1/2" Lg.

7 XXX03312001 Kep Nut#8 - 32

8 CSP44002100 Control Box Cover

9 XXX03394400 Sheet Metal Screw #6 x1/4" Ph (A) Pt.

10 ASP44002600 Pressure Switch

11 ASP04704500 StrainRelief (Bushing) Power Cord

12 ASP44002500 StrainRelief (Bushing) Motor Cord

13 ASP04652700 Crimp Type Hose Clamp

14 ASP04577100 Air Hose

15 ASP04576900 Pressure Transmitter

16 ASP44055500 Ass'y, Air Foot Switch (Includes 13, 14 & 15)

17 DSP04701701 Power Cord & Terminals

18 ASP44003000 Jumper Wire Assy. (Black - 3 3/4" Lg.)

19 ASP04234400 Jumper Wire Assy. (Yellow - 5" Lg.)

Page11

Control Box

Wiring Diagram

Page12

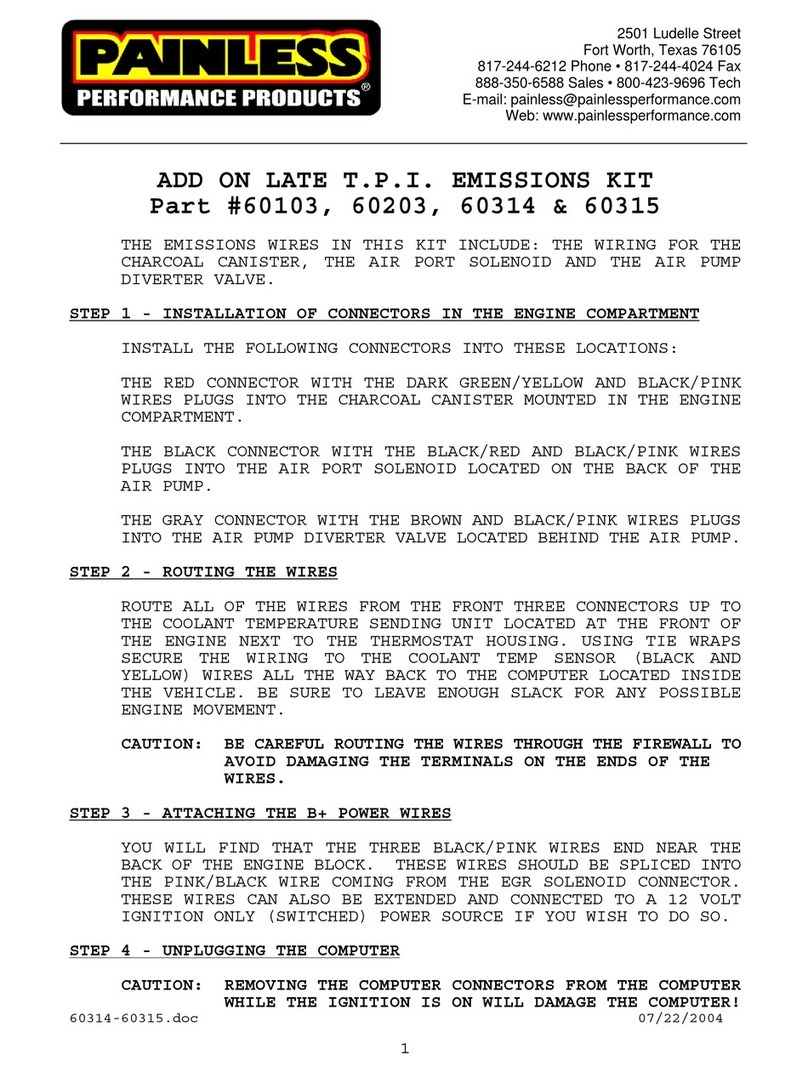

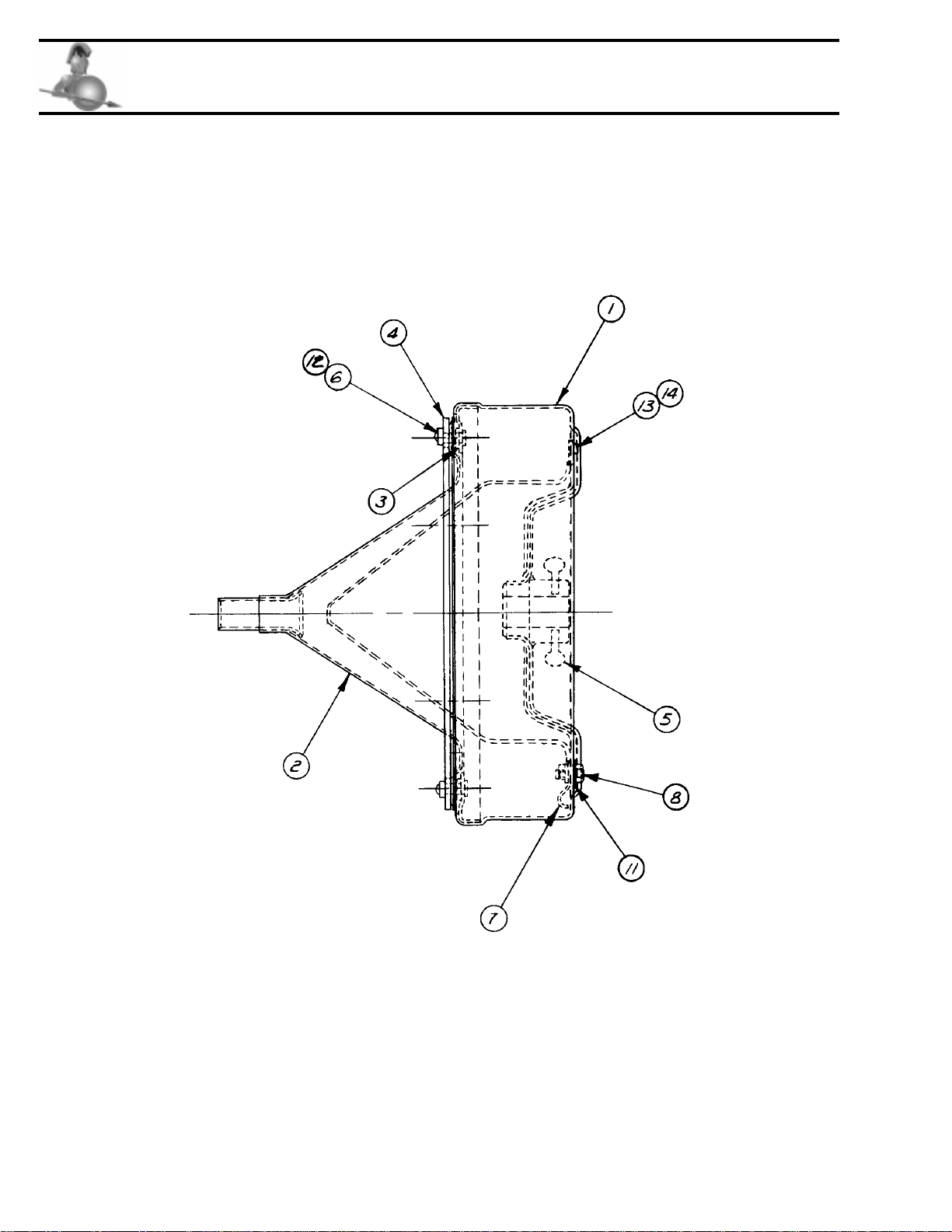

Drum Unit For Model 81

Page13

Drum Unit For Model 81

Item

Number Part Number Description

BSP04722600 Drum Unit Complete Assy.

1 CSP04726900 Outer Drum & Flange Assy. includes items

5, 7, 8, 11,13 & 14

2 CSP04727000 Drum Cover Assy. includes items 9 & 10

3 CSP04720300 Drum Cover Seal

4 CSP04720400 Drum Cover Spacer

5 ASP04701400 Thumb Screw

6 XXX04725200 AcornNut #10 - 32

7 ASP04725300 Cable Clamp Assy

8 XXX00114901 Hex Head Cap Screw 5/16" - 18 x 3/4"

9 ASP04714800 Warning Label

10 ASP04714700 Drum Label

11 XXX02825101 Flat Washer 5/16"

12 XXX01588200 Flat Washer #10

13 XXX04728200 Hex Head Cap Screw 1/4 - 20 x 3/8

14 ASP04707700 Rolled Collar 1/4"

Page14

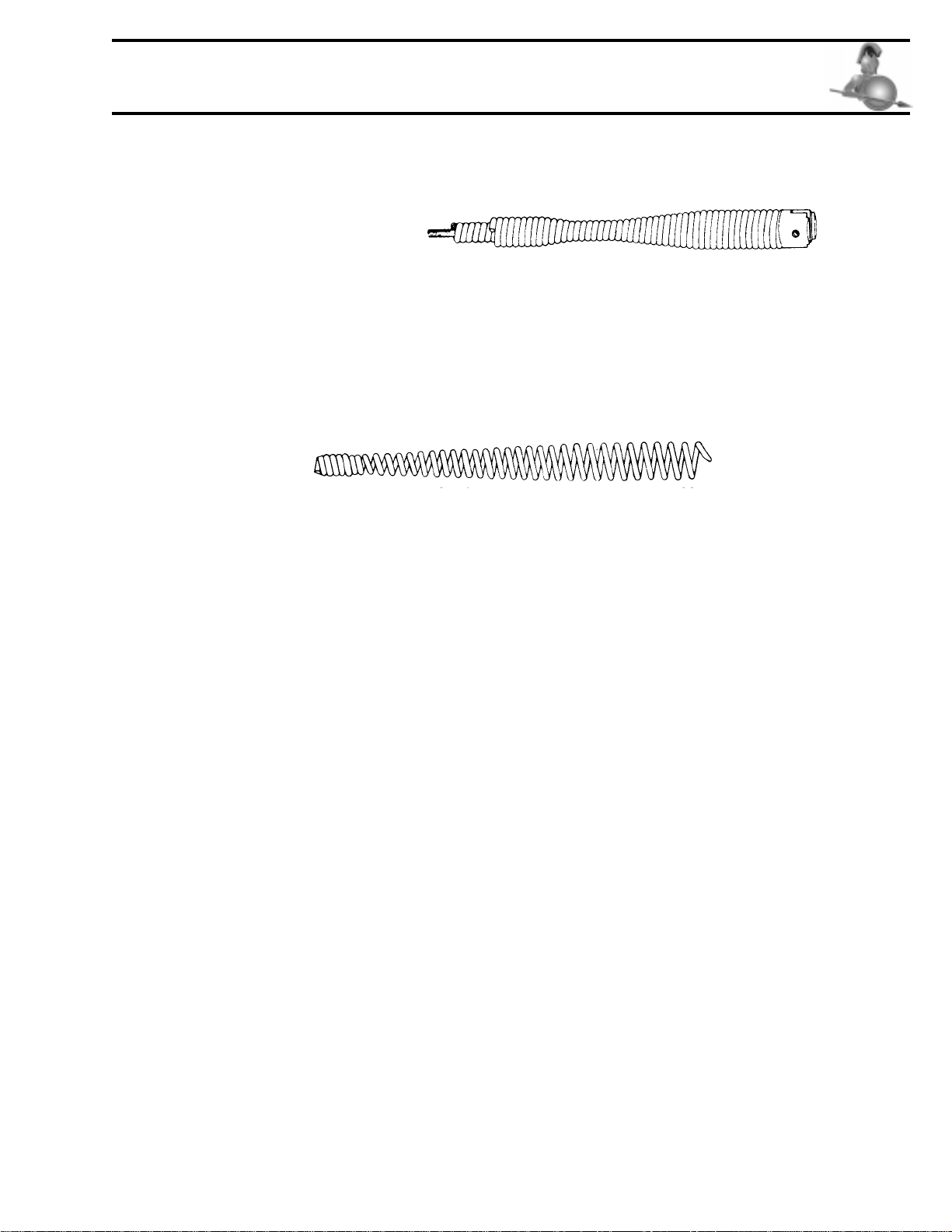

Spartan Swedish Steel Cables Without Inner Core

Flexibleopenhookendenables operatortothreadcablethroughcrossbars -eliminatingnecessityofremovingtrap

-todoa thorough job quickly.Onerepairhookfurnished with each cable.

¼”OpenHookEndCableDesignedforrodding1¼”lines only.

DSP04212102 ¼” x 25'

DSP04212103 ¼” x 30'

DSP04212104 ¼” x 35'

DSP04212105 ¼” x 50'

5/16"OpenHookEndCableDesignedforrodding1¼”to1½”lines, such as those leading from lavatories, bath

tubs,showerstalls.

DSP04212402 5/16" x 25'

DSP04212403 5/16" x 30'

DSP04212404 5/16" x 35'

DSP04212405 5/16" x 50'

Spartan Swedish Steel Inner-Core Drop-Head Cable

ASP44104301 ¼” x 25' D.H.*

ASP44104302 ¼” x 35' D.H.*

CSP03449002 5/16" x 25'

CSP03449003 5/16" x 30'

CSP03449004 5/16" x 35'

CSP03449005 5/16" x 50'

5/16"Multi-PurposeInner-CoreCable. Designed for rodding 1¼” to 1½” lavatory, sink line waste andforlight

dutyin2"lines.

PartsFor5/16" Inner-CoreCable:

ASP02867200 Blade,¾”Wide XXX02882200 ExpansionPin¼” x 5/8"

ASP02867300 Blade,1"Wide XXX02827700 AllenKey for Blades

ASP02871100 DropHeadAssembly XXX02827400 Socket Set Screw for Blades

ASP02814700 Bagofpartsfor5/16"including

drophead

Cables For Model 81

Page15

Cables For Model 81

Repair Bulbs

For5/16"Inner-Core Cables:

ASP02885200 RepairBulb

Repair Hooks

How to Use Repair Hook or Repair Bulbs

Ifcableiskinked,simplyremovekinkedportionbycuttingitoffatapointabout1"backofbentsection.Attach

RepairHookbythreadingitovercableendaboutfourturns.

ASP02789700 for¼” Cable RightHandWound

DSP02789800 for5/16" Cable RightHandWound

* - Not Inner-Core

SPARTAN TOOLL.L.C.

1506 W. Division Street

Mendota, IL 61342

(815)539-7411 u(800)435-3866 uFax (815)539-9786

spartantool.com

04726800 op AR3/11/98

04716700 pa AR6/11/98

AR7/7/00

ONEYEAR WARRANTY

SpartanTool warrants itsequipmenttofreefromdefectsinmaterialandworkmanshipforoneyearfromthe date

ofpurchase. To obtainwarrantyservice,apurchasershouldnotifySpartanToolinwriting,attheaddressprovided

below,withinthewarranty period,andSpartanToolwilldirectwheretotakeor sendtheequipmentforservice. If

thedefectis covered by thewarranty,SpartanTool will repair orreplace,at its option, the defectiveequipment,

withoutcharge forlaborormaterials. (Freightandinsurancearethepurchaser’sresponsibility.)

Thiswarrantyislimitedtotheoriginalretailpurchaserandisnottransferable. SpartanToolassumesnoresponsibility

fordamageduetoaccident,neglect,abuse,tamperingor misuse,nordamagefromrepairs oralterationsbyothers.

This warranty does not cover damage to the equipment resulting from the use of placement parts other than

SpartanToolparts.

SpartanTool’ssoleobligationand theoriginalretailpurchaser’sexclusiveremedyunderthiswarrantyshallbefor

repairorreplacementasdescribedabove. ALLOTHERWARRANTIES,WHETHEREXPRESSORIMPLIED,

INCLUDINGBUTNOTLIMITEDTOIMPLIEDWARRANTIESOFMERCHANTABILITYANDFITNESS

FOR A PARTICULAR PURPOSE ARE DISCLAIMED. IN NO EVENT SHALL SPARTAN TOOL BE

LIABLEFORANYINCIDENTALORCONSEQUENTIALDAMAGES.

SPARTANTOOLL.L.C.

MENDOTA, ILLINOIS 61342

Other manuals for 81

1

Table of contents