Spartan Quark User manual

SPECIFICATION

Radio compatibility: All PCM, PPM and 2.4GHz radios

supporting the standard servo connector pinout (signal,

power, ground).

Servo compatibility: Digital servos as specified in this user

guide.

Servo pulse resolution: 250nSec

Operating voltage: 3.8V – 8.4 Volts, current draw <75mA

Dimensions: 20.6mm x 20.6mm x 9.1mm

Weight: Alloy case 10.2g, plastic 8.2g with all cables.

Operating conditions: -15 to 55 deg C, 5 to 131 deg F, 20

to 85 % humidity non condensing.

Storage: 10 to 70 deg C, 50 to 158 deg F, 20 to 90 %

humidity non condensing.

TROUBLESHOOTING, WARRANTY & REPAIRS

Should you encounter any problems, please do not return this

product to the store until you have carefully read this user

guide, consulted the knowledge base on the Spartan website

and sought advice from our technical support staff.

For repairs, servicing, technical support or questions

regarding the distribution of this product visit the support

page at the Spartan website: http://www.spartan-rc.com/

1

CONTENTS

Specification................................................... inside cover

Overview ...................................................................... 3

Interconnections ............................................................ 3

Status Light .................................................................. 4

Setting up your gyro for the first time ............................... 5

Gyro Mounting ............................................................... 6

Linkage Setup................................................................ 8

Servo Type Selection ...................................................... 9

Gyro Configuration ....................................................... 11

Gyro Gain and Mode ..................................................... 14

Tail Rotor Pitch ............................................................ 16

Operation.................................................................... 17

Advanced Configuration Options ..................................... 19

Copyright and Licence................................................... 19

Warranty and Product Registration.................................. 20

Spare Parts and Accessories .......................................... 21

Liability Disclaimer ....................................................... 21

Important: This user guide [Doc. v1.0] was accurate at the

time of printing. As the firmware evolves some of the

configuration options described in here may have changed.

For firmware release notes visit the support knowledge base

on the Spartan website and consult topic 89.

2

WARNING!

Model helicopters are not toys and have the potential to be

very dangerous. Failure to follow the safety precautions and

warnings in this user guide may result in severe injury to

yourself and others. Beginners are advised to seek further

advice from an experienced adult pilot.

Read through the entire manual before operating this product.

This product contains chemicals known to the State of

California to cause cancer and birth defects or other

reproductive harm.

Safety Precautions

BEFORE EACH FLIGHT:

• Verify that the gyro operates correctly.

• Verify that the gyro compensates in the correct direction.

• Verify that the gyro is operating in the desired mode.

• Verify that the gyro mounting pads are in good condition.

• Verify that the gyro wires are not contacting the frame of

the helicopter.

• Verify that all tail linkages, ball links and tail hub bearings

can move freely without excessive friction.

3

OVERVIEW

Measuring a mere 20.6mm square and 9.1mm tall (0.81 x

0.81 x 0.36 inch) your new Spartan QuarkTM gyro is the

smallest and lightest heading hold gyro in its class. Its

cutting-edge MEMS (Micro Electrical Mechanical System)

sensor, powerful Digital Signal Controller and Spartan’s

market leading adaptive tail control technology offer optimal

gyro performance and exceptionally consistent yaw rates on

any size helicopter from tiny electric to the largest nitro

helicopters. The holding ability of the gyro is excellent and

precise giving a very solid and dependable feel.

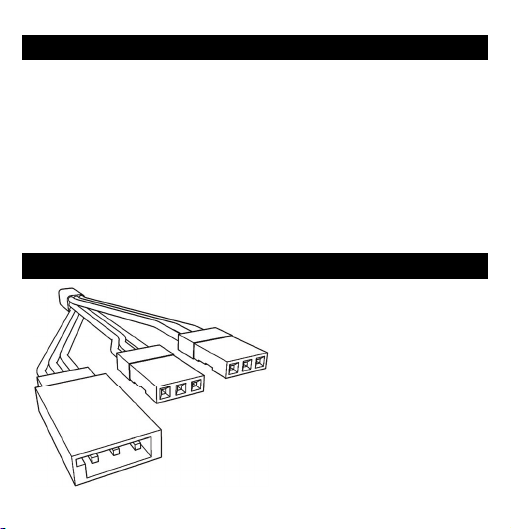

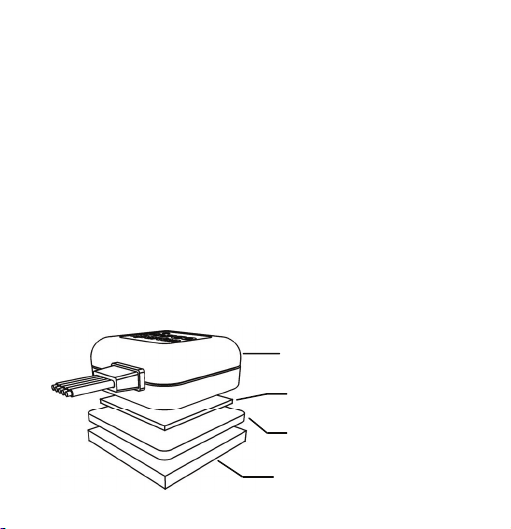

INTERCONNECTIONS

(red plug)

Connect to receiver’s

gyro gain output. Also

used for data link.

(black plug)

Connect to receiver’s

rudder output.

Connect to digital

tail servo.

4

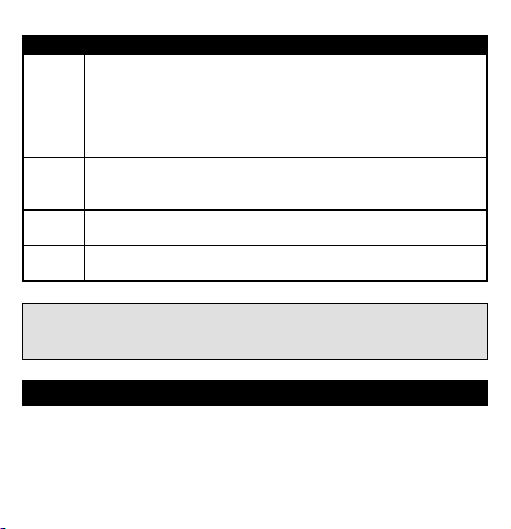

STATUS LIGHT

Status Light

Description

Operating Mode

Steady

r

ed

Rate mode.

Steady blue

AVCS mode.

Blue 2 flashes

AVCS mode -

Rudder stick not

centred.

Blue slow

flashing

Start conditions not met. Gyro gain

is set to less than 5%.

Alternating

blue/red

Gyro calibrating.

Error Codes

Red slow

flashing

Gyro not receiving both rudder and

gain signals. Possibly not produced

by the receiver.

Red 1 flash

Gyro not receiving rudder signal.

Rudder plug is fitted incorrectly or

broken yellow wire.

Red 2 flashes

Gyro not receiving gain signal.

Gain plug is fitted incorrectly or

broken orange wire.

Red 3 flashes

Power on calibration or self-test

failed. Cycle power. If the problem

persists contact technical support.

Set

up

Steady violet

or

flashing

See Servo Type Selection and Gyro

Configuration sections.

5

SETTING UP YOUR GYRO FOR THE FIRST TIME

Follow the steps below in the specified order to successfully

deploy your new Spartan gyro.

Fix the gyro on your model following the instructions shown

in the Gyro Mounting section later in this guide.

Connect the gyro to the receiver as shown in the

Interconnections section of this guide. Do not connect

the servo to the gyro at this time.

Ensure that the transmitter trims and sub-trims are set to

zero and that collective pitch to tail pitch mixing is disabled.

Select the correct servo type as described in the Servo

Type Selection section of this guide.

Connect the servo to the gyro.

Follow the instruction in the Linkage Setup section of this

guide to set the correct mechanical geometry of the tail.

Adjust rudder direction reversing at your transmitter.

Configure gyro reversing and servo endpoint as described

in the Gyro Configuration chapter if this guide.

Adjust gyro gain for both Rate and AVCS modes via your

transmitter. See Gyro Gain and Mode section.

Confirm tail rotor pitch changes in the correct direction to

oppose any movement of the tail. Confirm the rudder stick

produces the desired tail pitch movement and that there is

no mechanical binding. See Tail Rotor Pitch section.

6

GYRO MOUNTING

The correct operation, performance and stability of your

Spartan gyro can be greatly affected by the way it is fixed on

the aircraft.

WARNING!

• It is essential that the gyro is mounted on a rigid flat

surface accurately perpendicular to the main shaft.

• Do not mount the gyro in locations where it may be

subjected to high levels of oily smoke, fuel, or other liquids.

• Do not allow the gyro case to touch other objects.

• Do not allow the gyro cable to touch the sharp edge of the

helicopter frames.

• Avoid mounting the gyro in direct proximity to other

electronic equipment and particularly servos.

• Avoid fixing the cable to the helicopter for the first 5cm (2

inches) from the gyro end to reduce transmission of vibrations

through the cable.

• Do not fit cable braid over the gyro wires.

• Inspect the condition of the adhesive pads as part of your

regular pre-flight checks.

7

3mm adhesive foam pad

Stainless steel

p

late

1mm tape o

r

3mm foam pad

SET button on rea

r

side of gyro

The supplied mounting kit contains a stainless steel plate and

adhesive foam pads which have been selected by Spartan to

give the correct mass and shore hardness for effective

vibration damping. Always use the supplied mounting pads or

the Spartan replacement mounting pads available from your

Spartan gyro retailer.

Small electric helicopters (250, 450 and 500 size) – Use

a single 3mm foam pad without the steel plate.

Larger electric and nitro helicopters – Use a piece of the

1mm adhesive tape to mount the gyro on the steel plate and

a 3mm foam pad to mount the plate to the helicopter.

High vibration environments – Use a 3mm foam pad on

each side of the supplied steel plate.

8

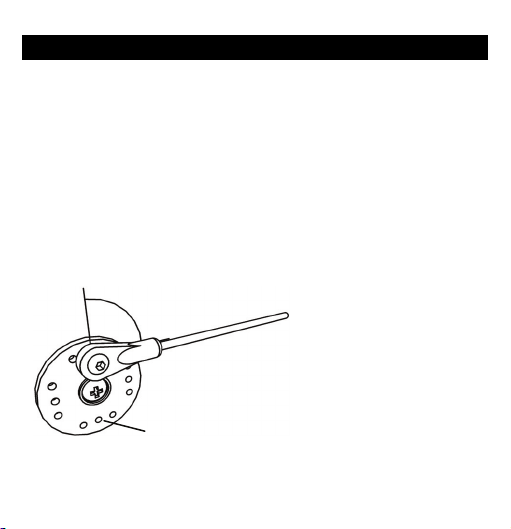

90°

Small Electric

Helicopters

(250, 450 and 500)

Ball link 7.5mm

from servo shaft

LINKAGE SETUP

The optimal mechanical setup is essential for getting the best

performance from your high end Spartan gyro. Ensure that

any slop in the system is kept to a minimum and that the tail

pitch linkages can move freely without excessive friction

through any guides, ball links or other joints.

With the gyro set to Rate mode and the rudder stick

positioned at the centre the servo arm should be at a 90°

angle with the pushrod as illustrated. To fly in Rate mode set

the linkage lengths for approximately 8° tail pitch in the

direction that compensates the main rotor torque.

Follow the advice in

the helicopter’s

assembly manual

regarding the

placement of the ball

link onto the tail

servo horn. When

such advice is not

provided or has

resulted in poor tail

performance we

recommend placing

9

90°

Larger Electric and

All Nitro Helicopters

13.5 -

16.5mm

from servo shaft

the ball link at

7.5mm in the

case of small

electric

helicopters and

13.5 - 16.5mm

for the larger

electric and all

nitro

helicopters.

Alternatively

you may choose to place the ball link at a distance that allows

the servo to have a combined travel of around 80° from the

low endpoint to the high endpoint.

SERVO TYPE SELECTION

Spartan gyros are designed to work with all modern digital tail

servos and offer a selection of servo pulse modulations in

order to achieve such broad compatibility.

To access the servo configuration mode hold the SET button

pressed before powering on the gyro. Continue to hold the

SET button pressed until the Status light starts flashings in

10

violet colour. The number of flashes indicates the currently

selected servo type.

WARNING!

The selected servo type must match the servo you are using.

Incorrect setting may damage the servo and possibly

resulting in a loss of tail control during flight.

You must change the servo type before connecting the servo

to the gyro. Disconnect the servo if already connected.

Do not attempt to use analogue servos. Severe damage may

be caused to your servo or loss of tail control during flight.

Do not attempt to fly your model while the servo type

selection mode is active, tail stabilisation will not function.

To change the servo type move the rudder stick left or right

until the desired option is reached. Press the SET button once

to store your selection. The Status light turns on in steady

violet colour to acknowledge that the servo type is changed.

You may now power off the gyro.

11

Light Servo modulation

1 flash

(default)

1520uSec at 333Hz

Futaba S9253 / S9254 / S9257 / S9650 / S3153 /

S3154, BLS254, JR 8900G / 3400G / 3500G, Align

DS410 / DS420 / DS510 / DS520 / DS610 / DS620 /

DS650, Sanwa ERG-WRX, Airtronics 94758 / 94761,

Hitec 5925MG / 6965HB / 5083MG, Robbe FS61BB

2 760uSec at 560Hz

Futaba S9251 / S9256 / BLS251, MKS DS8910 /

BLS980

3 1520uSec at 250Hz

JR 2700G / 8700G / 810G, Sky HDS-577 / HDS-877

4 960uSec at 333Hz

LogicTech 6100G / 3100G, Hitec 5083MG

Not listed servos - If your servo is not listed in the above

table please visit the support knowledge on the Spartan

website and consult topic 12.

GYRO CONFIGURATION

To access the configuration mode power on the gyro and wait

until it has finished calibrating. Press and hold the SET button

for a few seconds. Once the configuration mode is active the

tail servo chatters twice then rests in its centre position.

12

WARNING!

Do not attempt to fly your model while the gyro configuration

mode is active, tail stabilisation will not function.

Before configuring your gyro ensure that the rudder reversing

has been correctly set at the transmitter. The gyro relies on

this configuration to adjust its internal gyro direction

reversing as required. Failure to follow this step correctly

could result in violent pirouetting on take-off and loss of tail

control. Before proceeding confirm the correct operation of

the rudder stick by observing the tail rotor blades as

explained in the Tail Rotor Pitch section of this guide.

To prevent damage to the servo disconnect the tail control

linkage from the servo before entering the gyro configuration

mode. During adjustments simply hold the linkage over the

linkage ball.

Step 1: Gyro direction reversing

The first parameter to be configured is gyro direction

reversing. Simply push the rudder stick to the left and the

gyro will automatically match your radio system. As the

rudder stick is operated the tail blades move to allow visual

confirmation of the correct rudder behaviour. The Status light

switches on/off in violet to indicate if reversing is active.

13

When satisfied, press the SET button briefly. The servo will

chatter once to confirm completion of this step.

Important: If the gyro is mounted in an inverted orientation

you will need to push the rudder stick to the right instead.

Step 2: Adjust low servo endpoint

The servo is now resting at the low endpoint position and the

Status light is flashing violet twice. Using the rudder stick

adjust the servo position until you achieve maximum tail rotor

pitch without binding on the mechanical limits. When

satisfied, press the SET button briefly. The servo chatters

once to confirm completion of this step.

Important: Always set the gyro endpoints for the maximum

available tail rotor pitch. This defines how much pitch the gyro

can use and has no effect on how responsive the gyro feels in

flight. If you find the yaw very responsive or very slow for

your preference you may adjust this via the transmitter’s

endpoints or Dual Rate setting for the rudder channel.

Note: Whilst crossing the 100% endpoint value the servo

pauses momentarily and the status light flashes blue.

14

Step 3: Adjust high servo endpoint

The servo is now resting at the high endpoint position and the

Status light is flashing violet three times. Using the rudder

stick adjust the servo position for maximum tail rotor pitch

without binding. When satisfied, press the SET button briefly.

The servo chatters twice to confirm completion of the

configuration mode.

Upon completion the gyro stores the new configuration to its

internal memory and the Status light is steady violet. You

may now power off the gyro.

GYRO GAIN AND MODE

Spartan gyros offer two operating modes, the classic Rate

type and the AVCS (Angular Velocity Control System). To

control the operating mode assign the gain channel to a two

position switch of your transmitter. This switch now selects

the operating mode whilst the gain channel endpoints control

gyro gain for each mode. Your radio may also offer a

dedicated gyro menu with more advanced configuration

options for the gyro gain setting.

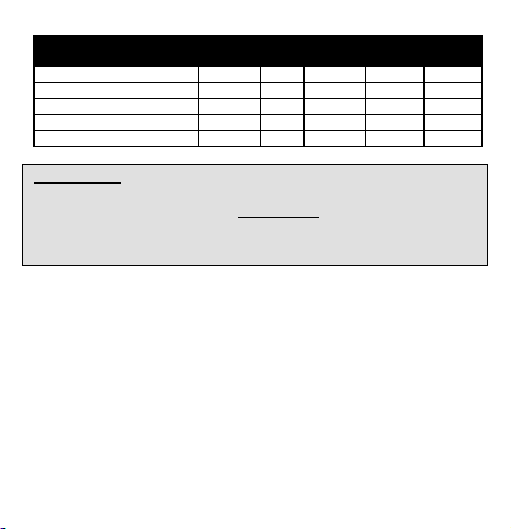

The following table shows the relationship of the gyro

operating gain in respect to the displayed value on the screen

of some popular radio control transmitters.

15

Gyro Operating Gain > 100%

Rate

80%

0% 77% 100%

AVCS

Gain Pulse Width 1020uS

1520uS

2020uS

Futaba Gyro Menu 100% 0% 100%

Futaba Endpoints 90% 0% 90%

JR/Spektrum Gyro Menu - 0% 51% 100% -

JR/Spektrum Endpoints 126% 1% 129%

Important:

• The optimal gain value is the highest value you can reach

that does not cause tail wag at any time during flight.

• Do not use any type of stick priority mixing or other gain

reduction mixing.

The optimal gain value is a function of several parameters

including rotor speed, tail rotor diameter, tail blade efficiency,

servo arm length, servo make/model and mechanical design

of the aircraft. As such, it is not possible to make a general

recommendation and therefore the gain will need to be

adjusted experimentally. Start with a gain of 30%, this should

provide enough stability to at least hover; however you

should always proceed with care. If insufficient stabilisation or

tail wag is seen the gain should be raised or lowered

respectively. It is not uncommon to find that the optimal gain

value for a helicopter could be as small as 35-45%. A small

16

value does not mean that the gyro will be limited in

performance. Any gain value performs well as long as it is the

optimal gain value. However, a gain below 30% indicates that

the mechanical gain of the tail is too high and therefore it is

recommended to move the servo arm ball link further in.

Similarly if 100% is reached and no tail wagging is seen the

ball link needs to be moved further out.

TAIL ROTOR PITCH

Left rudder

input

Right rudder

in

p

ut

Airframe

manually

rotated

CW

|

OR

|

Airframe

manually

rotated

CCW

|

OR

|

Tail rotor

thrust

Tail rotor

thrust

Tail blades as

seen from above

Tail blades as

seen from above

17

OPERATION

It is advisable to power on the gyro in AVCS mode which

enables it to recalibrate the rudder stick neutral. Stick neutral

recalibration is not possible in Rate mode as any tail rotor

mixing will interfere with the accuracy of this measurement.

However should the gyro be accidentally powered on in Rate

mode it will make use of the last known calibration value.

WARNING!

Immediately after powering on, the gyro performs automatic

calibration of the rudder stick and gyro sensor resting

positions. During this time the helicopter must remain

undisturbed and the rudder stick must be left at the centre

position. Calibration lasts approximately 4 seconds and upon

completion the gyro will enter flight mode and the tail servo

will move to its midpoint. During calibration the Status light

colour alternates rapidly between red and blue.

The calibration will not start if the gyro is not receiving the

required rudder and gain signal from the receiver, or the start

conditions are not met. In both cases the Status light will emit

a flashing pattern to indicate the cause. These flashing

patterns are listed in Status Light section of this guide.

18

WARNING!

If you plan on using the gyro in Rate mode you may need to

program collective to tail rotor mixing on your transmitter.

You must ensure that such mixing is active in Rate mode only.

If the tail rotor mixing remains active in AVCS mode it can

result in violent pirouetting and loss of tail control.

If tail drift is seen in Rate mode it is advisable to trim the

model mechanically by adjusting the linkage lengths. Small

corrections can be done using the transmitter’s rudder trim,

though this is not recommended. In the event that the

transmitter’s trim is changed the gyro needs to recalibrate the

rudder stick neutral. To do this, land and spool down the

model, then rapidly toggle the gain switch three times

(transitioning between Rate and AVCS modes) before

returning it to the AVCS position. The rudder stick must be

resting at the centre position while recalibration takes place.

Important: If the radio’s rudder endpoints are set to a very

high value, which results in a yaw demand above the sensing

range of the gyro, the tail pitch will open fully producing ultra-

fast yaw rate of over 3 turns per second. While such fast yaw

rates are spectacular you must ensure that your model is

mechanically capable to withstand the increased loads.

Table of contents