GB 12

The combustion air openings and lines must not be closed or blocked unless

it has been ensured that the fireplace can only be operated with an open

lock by means of special safety equipment. The cross-section must not be

narrowed by a fastening or a grille. A shut-off valve must be installed, if

this combustion air feed pipe runs outside the building. In doing so, it must

be possible to easily determine the shut-off device setting from outside of

the connecting line. This arrangement allows the feed pipe to be insulated

to guard against the formation of condensation. The pipe should be posi-

tioned so that no water or other foreign substances from outside cannot get

into the stove, and that any condensation formed can run out of the pipe.

Even with a separate combustion air line for the stove, its operation can be

impaired by a ventilation system. Therefore, simultaneous operation is not

possible.

In accordance with regulations, combustion air lines crossing a fire wall in

buildings with more than two floors must be established in such a manner

that smoke or fire cannot be transmitted to other floors or fire compart-

ments. Country-specific and local fire safety regulations must be observed!

2.4.3 CLOSED FLUE OPERATION

The SEO S / SEO L closed flue stoves have been developed for use with

residential ventilation systems for a vacuum range of up to 8 Pa in the

installation area and can be operated without additional safety equipment.

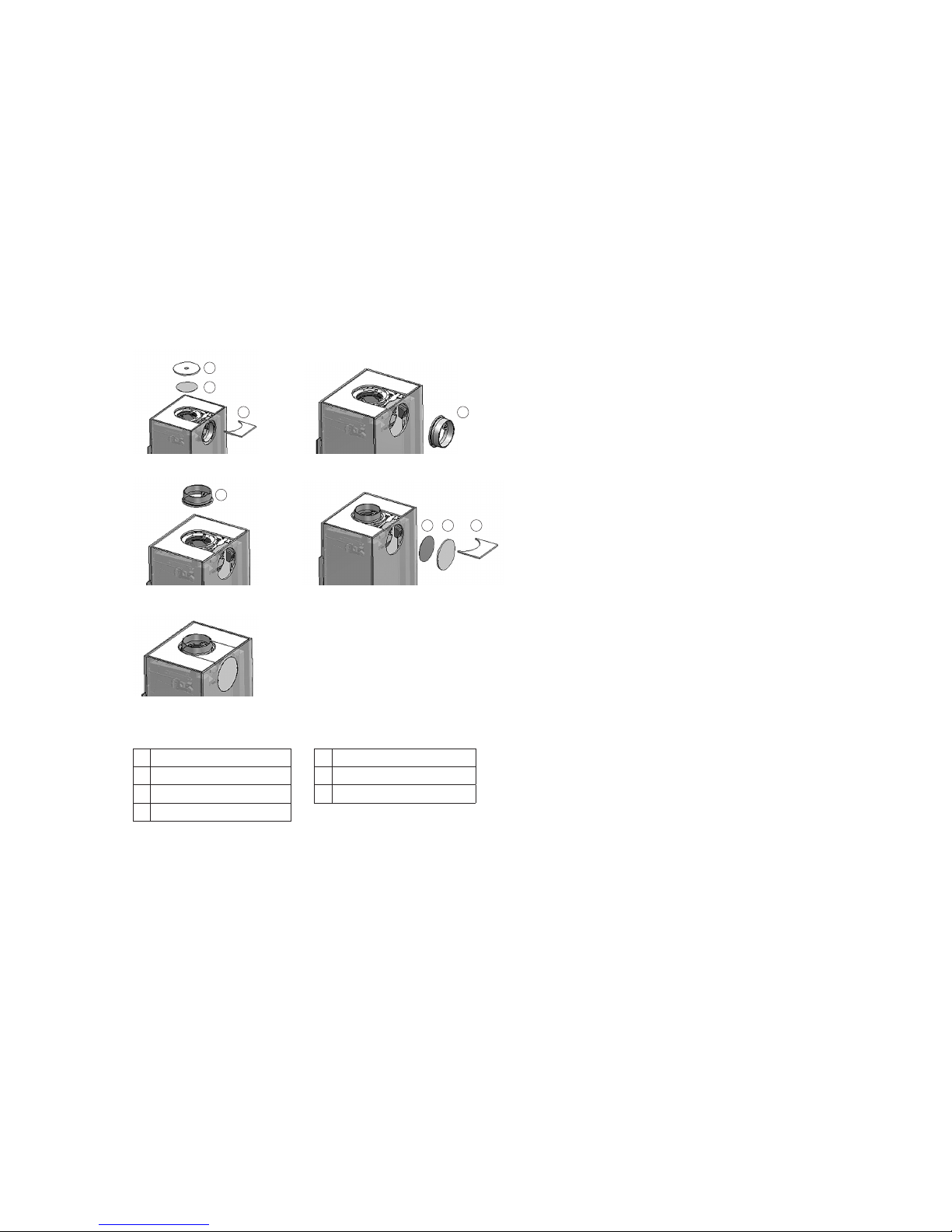

The combustion air must be supplied in airtight lines from the outside or

via an LAS system to the device for room-air-independent operation without

fail. To do this, the combustion air duct must be permanently sealed to the

combustion air neck (connection type back or bottom) of the stove.

When connecting the close flue stove to a combustion air line, the TROL

instructions (technical rules) and DIN 18896, etc. must be observed and

applied. In particular, ensure that the dimensions are adequate! Comply

with all country-specific and local fire safety regulations! Make sure that

the pipes are always airtight.

2.5 FIRE PROTECTION

The handover inspection of your stove before commissioning is performed

by the chimney sweep responsible. You can also advise the chimney sweep

prior to installation about installation conditions on site, and can provide

advice on how to install your stove properly.

General information on fire prevention

Stoves are heat generators and are subject to regulations and necessary

measures for fire protection. Right from selection of the installation site

stage, fire regulations and recommended minimum individual clearances for

the appliance must be observed.

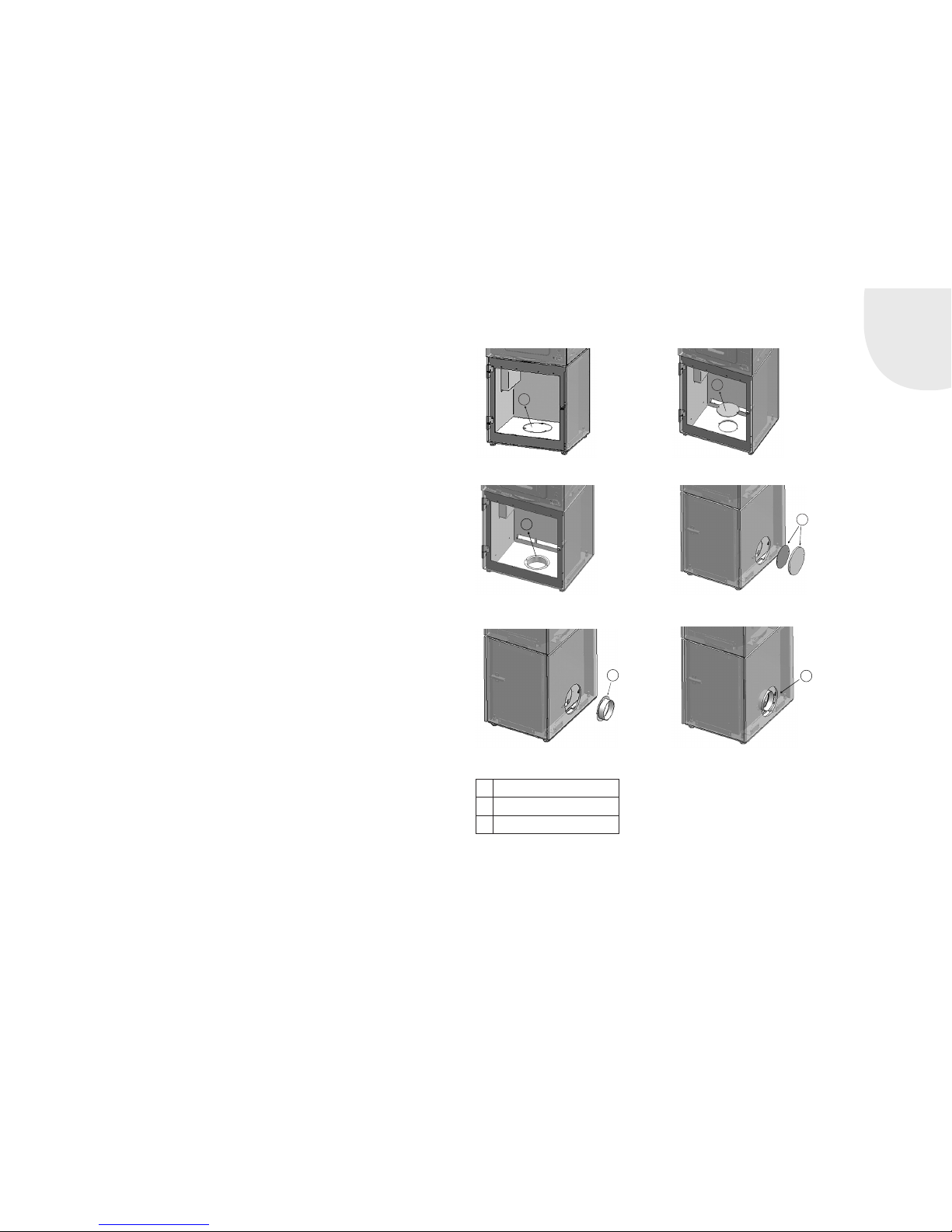

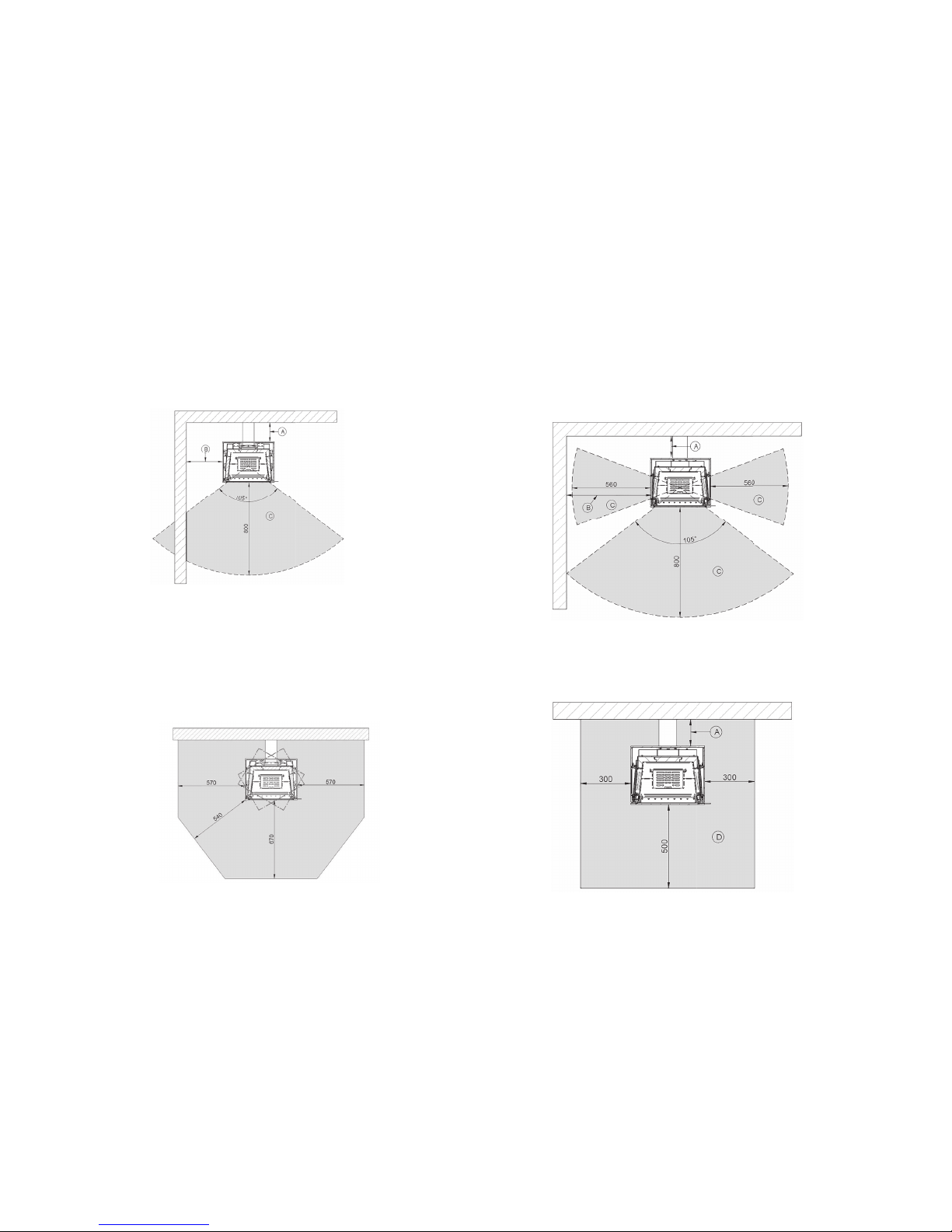

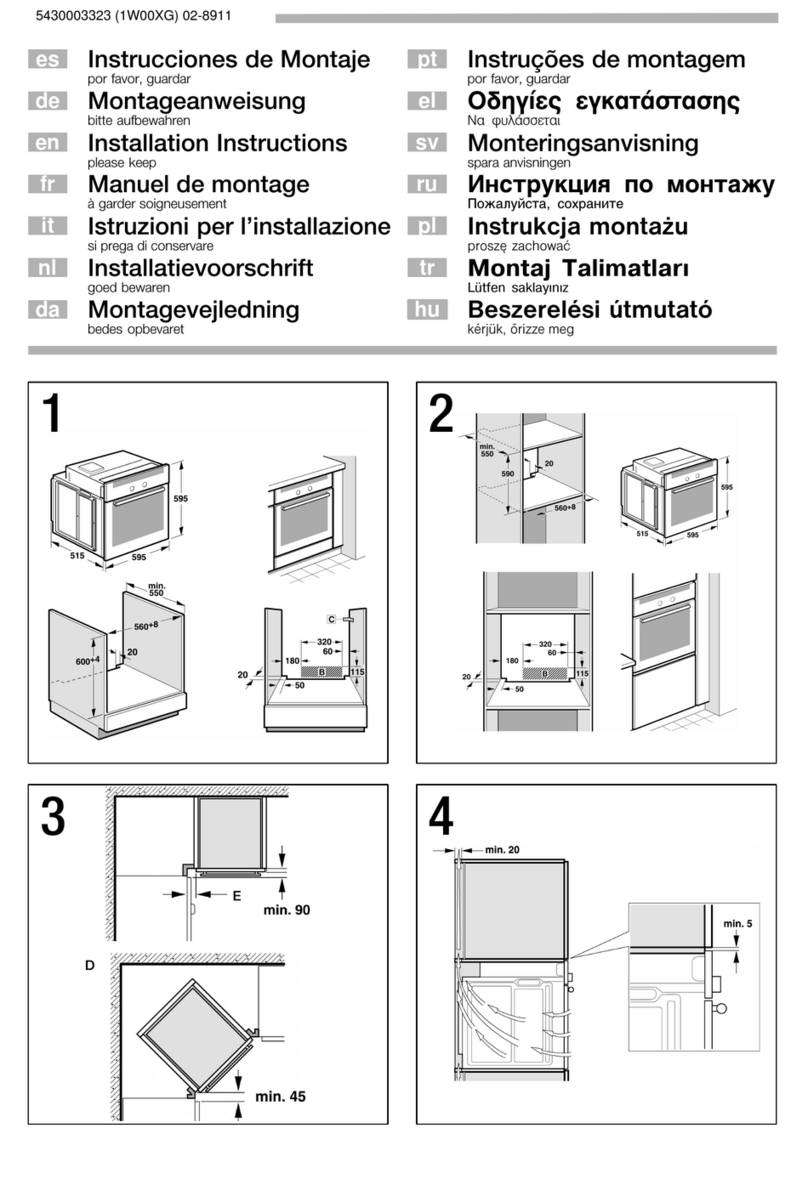

Basically, a minimum wall clearance of 5 cm to the back wall must be

adhered to. For reasons of safety and fire protection, make sure that large

distances to walls to be protected or combustible components are main-

tained. See the following installation examples.

The following table documents the permissible safety distances. Using the

diagrams (Figs. 4a-4f), match the mounting situation, taking into account

the specified distances that need to be complied with.

During installation, please pay attention to the fire protection instructions

and contact your local chimney sweep with any questions you may have.

• Mounting walls that are non-combustible or which do not require protec-

tion are able to withstand permanent exposure to tempera-tures > 85°C

thanks to their structure and material type.

• Combustible mounting walls in need of protection (e.g. stud partition

construction) must be protected from temperatures above 85°C.