SPE CS230 User manual

1 | P a g e

User Guide

CS230 Floor Saw

Martello Hire & Logistics Limited

Unit 12 Riverside Industrial Estate

West Hythe Road

Hythe

Kent

CT21 4NB

Tel: 01303 901399

2 | P a g e

User Guide CS230 Floor Saw

It is important that all persons who are working or maintaining this machine read the manual carefully and understand it fully.

Keep this manual near to the machine, so it can always be consulted.

Only authorised and trained personnel may operate this machine.

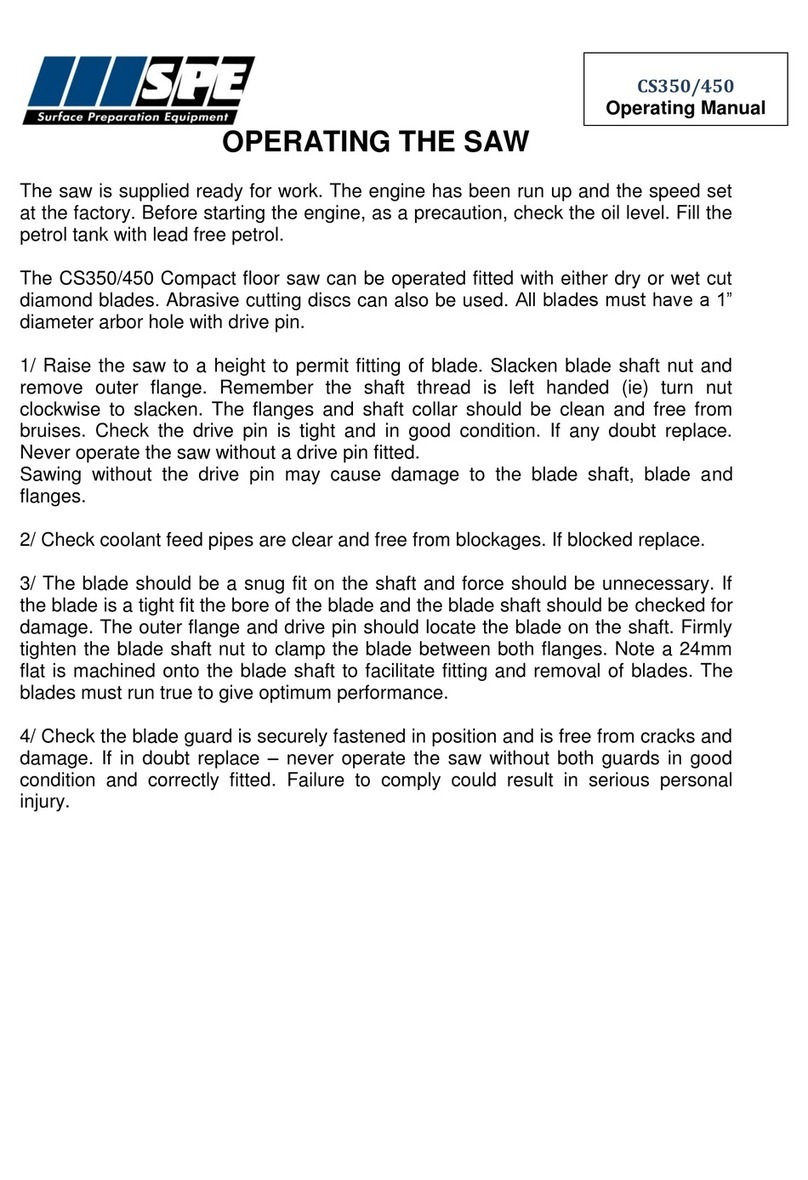

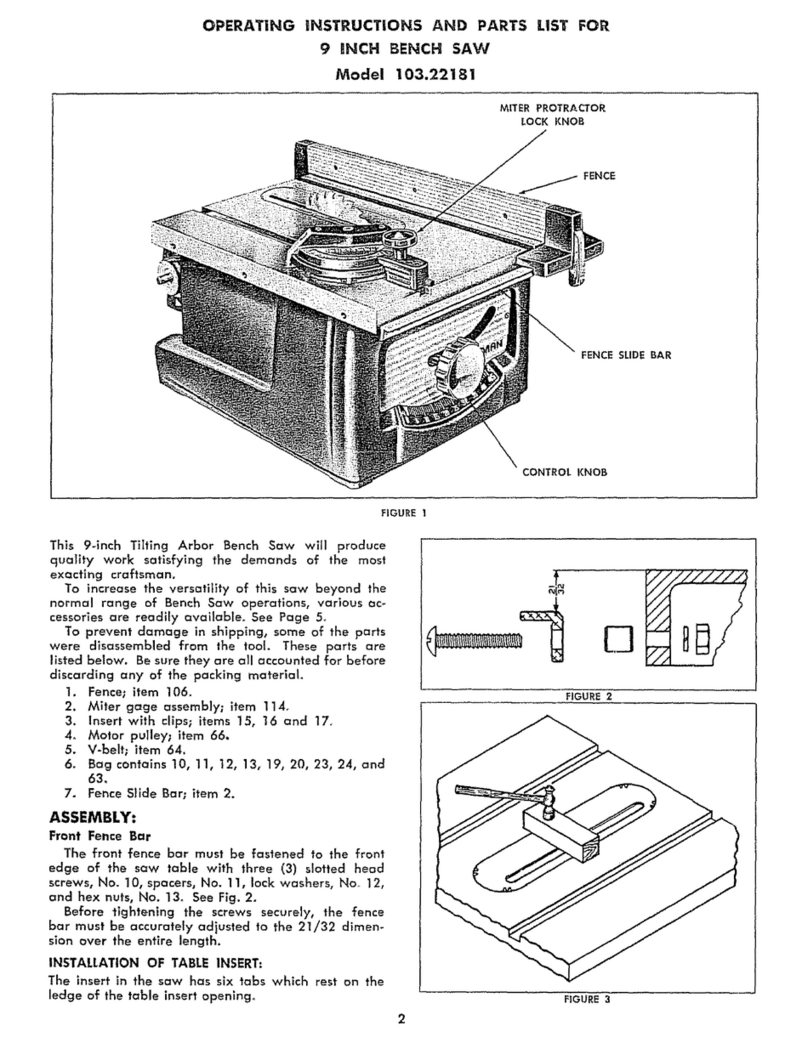

Starting Work

Check the following prior to starting equipment:

•Check the condition of the blade(s)

•Check blade retaining nut and all other bolts for tightness

•Check drive belt condition and tension

Before starting the machine ensure that the blade(s) are clear of the ground, by turning the crank handle in an anti-clockwise

direction.

If fitting a new blade(s) ensure the power supply is disconnected, lift the cutter guard clear of the blade shaft assembly, remove

the blade retaining nut and the blade spacers from the shaft. If fitting a single blade, locate the blade onto the shaft centrally with

an equal quantity of spacers either side. If fitting two blades, use spacers to give the required cutting width.

Adjust the handles to a comfortable height and position. Connect power supply. Connect a vacuum hose to the dust port on the

front of the cutter guard, if a dust control vacuum is being used. Start the motor by turning the switch on the panel to the start

position, hold for 3-4 seconds and release to allow switch to return to the run position. Slowly rotate the crank handle clockwise

to lower the blade(s) to cut to the required depth.

General Operation

The CS230 Floor Saw is designed for dry cutting only.

Slowly lower the blade(s) into the surface. If the blade speed drops, raise the blade until the speed rises again and re-lower blade

until required depth is achieved. It may be advantageous to make several shallow cuts to achieve the final depth of cut required.

For example, if a finished depth of 50mm is required two cuts of 25mm each may be achieved faster and with possible less wear

on the machine, blade and operator.

Push the saw forward gently with a controlled and constant pressure. Never force the saw forward, always allow the blade to cut.

When the required cut is finished raise the saw clear of the surface. To turn off, rotate switch to the off “O” position.

Electrical Instructions

The points raised are based on many years practical experience not on textbook theory. If you follow these guidelines your time

on site will be productive rather than frustrating.

The CS230 machine is supplied with a specially commissioned 110v electric motor and starter switch assembly. Each unit is fully

tested, and the safety overload relays have been calibrated and set according to the manufacturer’s specifications. In the event

of the malfunction on a new machine the owner should first check that the power supply on the site is suitable and adequate.

The motor requires a 32amp 100v power supply. To avoid voltage, drop the cable size must be a minimum of 4.0mm 3 core.

Maximum length of cable not to exceed 30 meters. The transformer and all cables should be fitted with 32-amp 110v plugs and

sockets.

All cables should be fully uncoiled and never left wrapped around cable reels or tied in loops. If the power is to be generated the

CS230 required a minimum 8kva generator.

The motor is protected with a safety trip in the panel. Should the trip be activated then you must isolate power, open panel and

reset trip. If the motor repeatedly cuts out, then it will be damaged. The possible causes are either an inadequate power supply,

overloading of the machine, or an electrical fault. The machine can only be overloaded by setting the depth of cut to low.

3 | P a g e

Maintenance

Prior to any maintenance or adjustment always isolate the power supply.

After use: Clean the machine to remove all the build up of dust and surface residue. Never allow water onto electrical components

(motors and switches are not waterproof). Ensure the height adjustment thread is cleaned and then lightly oiled. Periodically it

should be removed, and the female threaded section cleaned out and oiled regularly to maintain a light, smooth height

adjustment.

Daily checks of the drive pulleys for damage and drive belts for condition and tension should be carried out. The belt tension is

adjusted by means of an adjuster bolt on the motor mount plate which when raised/lowered will tighten/slacken the belts. Take

care not to over tension the belts as this may result in damage to the motor and/or bearings.

Check the condition and wear of the blade(s) fitted and the blade nut for tightness. Periodically check that the thread of the blade

shaft is clean and undamaged. Check all bolts daily and tighten if necessary.

Basic Maintenance Checklist

Daily:

•Check condition and wear of blade(s)

•Check blade nut for tightness

•Check all nuts and bolts for tightness

•Check belt tension

•Check plugs and cable

Safety

Only trained operatives should be allowed to work the CS230 Floor Saw. Always make sure belt and blade guards are securely in

place before starting the machine. All operatives should wear ear defenders, goggles and an effective dust mask. To control dust,

it is recommended that a VAC Dust Control unit is used in conjunction with the machine.

Never leave the CS230 unattended while in use. Always stop the motor and set the height adjustment to fully raised before leaving

the machine. Never remove the blade guard or belt guard until the blade(s) have come to a complete standstill.

Vibration will occur at various levels dependent on the attachments and the work being completed. SPE have assessments

conducted under test conditions detailed below. However, it is recommended that additional tests are taken on site to provide

the operator with accurate information on using the equipment within the guidelines laid down by the Health and Safety

Executive.

Record of Noise and Vibration Assessment

Manufacturer: SPE

Type: Floor Saw

Model No: CS230-1

Operation: Concrete floor surface

HAV Note: Operc

Hand-Arm Vibration

Frequency Weighted Energy Equivalent Accelerations

Measurement Position

Acceleration (m/s²)

Vector Sum

Handle

4.702

For a fully copy of the User Manual please visit www.martellohire.co.uk

This manual suits for next models

1

Table of contents

Other SPE Saw manuals