SPE VAC316-3 User manual

VAC316-3

Operating Manual

VAC316-3

Operating Manual

This manual is provided to persons purchasing an

SPE machine and may not be reproduced in part or full

without written permission of

SPE International Ltd.

This manual provides the basic information required

and is only to be used as a guideline.

The SPE machines are manufactured and covered by

SPE design registrations granted and pending.

SPE International Ltd reserves the right to alter the

equipment design and specification as required

without notice.

The SPE product range is subject to amendment and

improvement as a result of on going research

Honeyholes Lane, Dunholme, Lincoln LN2 3SU, England

Tel: +44 (0) 1673 860709 Fax: +44 (0) 1673 861119

Email: sales@spe-int.com

VAC316-3

Operating Manual

316 VACUUM

This manual covers to the best of our knowledge, the operation and maintenance of the SPE

316-3 vacuum. Before operation of the equipment the manual should beread and understood

by the operator. The safety regulations must be followed at all times. Service of electrical

components should be carried out by authorisedpersonnel. Failure to followtheseinstructions

could result in damage to the machine and/or serious personal injury or death.

WARNING

Failure to follow these instructions may result in serious personal injury or death. SPE

disclaims all responsibility for damage to persons or objects arising as a consequence of

incorrect handling of the machine and failure to inspect the machine fordamage orotherfaults

that may influence the operation prior to starting work.

VAC316-3

Operating Manual

INDEX

1. Starting Work

2. General Operation

3. Directions to Invert Phases

4. Maintenance

5-6. Hepa Filter Fitting Instructions

7. Spare Parts Breakdown

8. Machine Diagram

9-11. Parts Listing

12. Filter Assembly

13. Specification Sheet

14. Warranty

15. Declaration of Conformity

16. Conditions of Sale

VAC316-3

Operating Manual

STARTING WORK

The 316 vacuum cleaner is designed to handle a wide range of cleaning and debris

collection in industrial areas.

CAUTION

This vacuum cleaner must not be used for the collection of health endangering, flammable

or explosive materials. Nor must it be used or stored in wet conditions i.e. outside in the

rain, swimming pools etc. The electrical supply should be isolated prior to carrying out any

maintenance of the equipment.

ELECTRICAL CONNECTIONS

Ensure the power supply is correct for the machine. The machine lead is fitted with a

32amp 5pin phase reversing plug.

Before use, check that the 3 phase power supply is phased to suit the machine. To do this,

connect the machine to the power supply and start by pressing the green button on the

panel. Check the rotation of the belt through the viewing window in the belt guard, which

should be turning in an anti-clockwise direction. If not, the phases will need reversing in the

plug. Stop the machine by pressing the red button on the panel and disconnect the plug

from the power supply. To change the phases refer to page 3 for details.

There is also an auxiliary 32amp 5pin socket mounted on the machine to enable a suitable

secondary machine to be operated from the same power supply.

HOSES AND ACCESSORIES

The machine is supplied with hose, and various accessories can be supplied separately.

Tools and hose fit together by using a twist and thrust movement. Joints are separated by a

twist and pull movement.

Noise Emission: 81 dB (A) @ 1m

1

VAC316-3

Operating Manual

GENERAL OPERATION

FILTER CLEANING

1. The clear flow filters may be cleaned on the machine by switching the machine off,

operating the filter shaker approximately 10 times and allowing the dust to settle.

2. The clear flow filters may be periodically removed for cleaning, if required, by blowing

off the dust with compressed air or brushing/vacuum cleaning. This should be carried

out as follows: -

(a) electrically isolate the machine prior to maintenance

(b) operate the shaker 10 times and allow dust to settle

(c) access to the clear flow filters is gained by removing the induction head which is

held in position by two lower toggle clips.

COLLECTION DRUM REMOVAL AND FITTING

To lower the drum, stand behind the cleaner and pull the catch upwards. This will allow the

handle to rise and the drum, will descend to the ground. The drum can now be rolled away

from the cleaner on its own castors.

To replace the drum push it back against the support pins and raise it by pulling the handle

down until it engages under the catch.

COLLECTION OPTIONS

WET PICK UP (can be used with swarf basket & stand)

The float valve assembly must be used when collecting liquids to prevent entry of liquids

into the motor.

1. Do not leave the hose end immersed in the liquids being a collected. Ensure that air is

entrained as well as liquid. (This helps prevent a whirlpool action of the liquid in the

collection bin)

2. Frequently check that the float valve is clean and free to operate.

Part no: 546339900 wet option assy, 546338400 float assy

SWARF BASKET

Do not fill the swarf basket so full that it overflows or is too heavy to lift.

If the material being collected is very wet, or in liquid, a float valve assembly must be used.

Part no: 546340100 Swarf basket (inc stand)

PLASTIC BAG COLLECTION (Light materials collection only)

1. Remove the drum from the machine. Lift the spring plunger knob, on the inlet casting,

upwards and insert the stub pipe. Ensure that the slot in the casting of the stub pipe in the

12 o’clock position and push in until it is inline with the spring plunger knob. Release the

plunger knob to lock the stub pipe in position.

2. Fit the plastic bag into the collection bin and stretch the open end of the plastic bag over

the top of the collection bin.

3. Push the plastic bag over the stub pipe so that the stub pipe penetrates the plastic bag.

(It helps if a hole or cut is made in the bag first)

4. The collection bin with plastic bag may be fitted to the machine in the normal way.

5. When emptying, it may be easier, dependent on how full the bag is, to remove the stub

pipe.Part no: 016724400 Plastic bag (500g), 536313800 Stub pipe

2

VAC316-3

Operating Manual

MAINTENANCE

Always disconnect the machine from the power supply prior to carrying out any

maintenance.

1. Check the mains lead, plug and auxiliary socket frequently for damage - do not pull the

machine along by the mains lead.

2. Electrical safety checks should be carried out at least once a year or more frequently if

used in an arduous environment.

3. Only use correct spare parts.

4. Empty the cleaner before it becomes too full, otherwise the pick-up effectiveness of the

cleaner may be reduced.

5. Clean the filters frequently to maintain pick up effectiveness. This can be done by

blowing-off with compressed air or brushing/vacuum cleaning but care must be taken

not to damage the filter material.

6. The exhauster has pre-greased bearings which require little maintenance. The non

drive end bearing is sealed and will need no maintenance. The drive end bearing should

be inspected every six months for excessive play.

7. To fit or adjust the drive belt. Check the motor support, then lightly tension the belt using

the motor support adjusters so that any sag is removed and ensuring that the ribs on

the belt are a snug fit into the pulley grooves. Mark two lines on the belt carefully,

rotating the drive slowly, until the distance between the two lines has increased by

1.0mm(ie 0.5% increase). Ensure the motor support adjusters are fully locked. Check

the belt frequently in the first 24 hours of operation and re-adjust if necessary. If the belt

will not run true, the pulley shafts are either twisted in relation to one another or not

parallel to one another. Ensure that the driving and driven shafts are parallel and that

the pulleys are aligned by using a straight edge and adjusting the motor position

accordingly. Always ensure that the motor is secured in position when adjustments are

completed.

4

VAC316-3

Operating Manual

INSTRUCTIONS TO FIT A HEPA FILTER TO VAC316-3

(OPTIONAL)

1. Undo the clips securing the induction head, detach the hose and lift the head clear of

the machine.

2. Undo the two bolts holding the top handle to the induction head and remove the bolts.

3. Fit a flat washer and M8 dome nut to each of the two lengths of M8 studding. Use these

two studs to refit the top handle to the induction head, with the dome nut/washer to the

top and the stud protruding inside the induction head.

4. Insert the Hepa filter inside the induction head and then fit the filter support by aligning

the studding with the support fixing holes so as to protrude through.

5. Attach a flat washer and M8 nylon nut to the bottom of each studding and then tighten.

6. Re-fit the induction head to the machine, fasten the securing clips and reattach the

hose.

5

VAC316-3

Operating Manual

HEPA FILTER KIT (part no 546340000)

6

These 2 items not supplied as part of this option.

Already supplied with standard cleaner

Fig No.

Part No.

Description

Qty

1

536305300

Hepa Filter

1

2

536331400

Filter Support

1

3

990993460

M8 Studding x 200mm

2

4

860801758

M8 Dome Nut

2

5

560800858

M8 Nyloc Nut

2

6

870800158

M8 Plain Washer

4

7

016718900

Seal

3.5mtr

VAC316-3

Operating Manual

7

VAC316-3

Operating Manual

8

VAC316-3

Operating Manual

PARTS LISTING

Figure no

Part no.

Description

Qty

1

546337900

Inlet Assembly

1

2

530592200

Oval Flange

1

3

018602500

2” M & F Elbow

1

4

018619300

2” Barrel Nipple

1

5

536331102

Frame

1

6

546305401

Bottom Drum

1

7

546305501

Filter Housing

1

8

536331302

Induction Head

1

9

536313601

Tubular Handle

1

10

536314302

Latch

1

11

536315701

Hinge Block L/H

1

12

536315601

Hinge Block R/H

1

13

536316900

Pivot Pin (Latch)

1

14

536314200

Link Pin

2

15

536314000

Locked Pick-up Pin

2

16

536301900

Spacer

4

17

536314100

Pivot Pin

2

18

536301300

Linkage

2

19

536331602

Side Rail

2

20

536418102

Side Cover

2

22

536374502

Tool Tray

1

23

536266203

Inlet Casting

1

24

536268401

Inlet Seal

1

25

536275201

Coupling Seal

1

26

536268601

Plunger

1

27

536275501

Plunger Spring

1

28

536273901

Plunger Retaining Plate

1

29

536337202

Head Handle

1

30

815750400

4kw Motor

1

31

536044102

Motor Pulley

1

32

018713500

Drive Belt

1

38

536374600

Cable Holder

1

39

543531900

Adjusting Screw Assy

2

40

536138802

Motor Platform

1

41

536342100

Induction Head Hose

2mtr

42

536138501

Body Pin

2

43

536138601

Platform Hinge Pin

2

44

536330400

Machined Bush

1

45

536314600

Shaker Tube Locator

1

46

818901700

Starter

1

019030500

Anti Vib Mounts

4

48

536290201

Silencer

1

49

556149806

Exhauster

1

9

VAC316-3

Operating Manual

50

016724200

Drum Seal

1.5mtr

51

017516100

Plunger Knob

1

52

280001250

Toggle Clip

2

53

019307400

300 Dia Wheel

2

54

019306900

63mm Dia Castors (Bucket)

4

55

019307500

4” Castor

2

56

280001260

Hook

2

57

018107800

Circlip (E Type)

6

58

018106600

Circlip

2

59

016725000

Rectangular End Plug

4

60

016723800

Circular End Plug

2

61

016725100

Wheel Plug

2

63

016725500

Decorative Cap

1

64

018412300

Clevis Pin Clip

1

65

546061902

Belt guard- Back

1

66

546061803

Belt guard - Front

1

67

018400700

Hose Clip

2

68

016718900

Induction Head Seal

1

69

016726700

Tool Tray Clip

6

70

016726600

Rubber Guard

2

73

818900110

Overload

1

74

019100800

Grub Screw ¼” BSW x ¾”

2

75

019103058

Grub Screw ¼” BSW x ⅜”

2

76

016727100

Panel Edging

0.7mtr

78

018107400

Circlip

4

79

533571400

Spacing Pillar

1

80

851066958

M10 x 80 Bolt

2

81

835084058

Screw M5 x 40

6

82

928103025

Screw Pan HD M3 x 12

4

83

835081058

Screw Pan HD M5 x 10

12

84

835081258

Screw Pan HD M5 x 12

12

85

835082058

Screw Pan HD M5 x 20

1

86

928104534

Screw Button HD M6 x 20

5

87

835021058

Screw CSK M5 x 10

2

88

835002058

Screw Cap HD M5 x 20

2

89

536062558

Screw Hex HD M6 x 25

2

90

841060858

Screw Hex HD M5 x 16

2

91

838061258

Bolt Hex HD M8 x 12

2

92

840863758

Bolt Hex HD M8 x 75

2

93

841061358

Bolt Hex HD M10 x 25

4

94

841062058

Screw M10 x 40

4

95

870500158

Plain Washer M5

24

96

870800158

Plain Washer M8

16

97

871200258

Plain Washer M12

10

98

872000258

Steel Washer M20

2

99

016727200

Dished Washer

2

100

870800458

Shakeproof Washer M8

16

101

870600458

Spring Washer M6

7

10

VAC316-3

Operating Manual

102

990994118

Spring Washer M8

2

103

871000651

Spring Washer M10

13

104

870500551

Crinkle Washer M12

8

105

016725600

Unicap Washer

1

106

016725300

Nylon Washer

1

107

871000358

Lock Washer M10

10

108

860500858

Nylon Nut M5

12

109

860600858

Nylon Nut M6

5

110

861000158

Lock Nut M10

2

111

861000858

Nylon Nut M10

2

112

860600258

Nut M6

4

113

860800258

Nut M8

16

114

860801758

Domed Nut M8

2

116

861000258

Nut M10

4

117

871000158

Washer M10

10

118

815900100

Ring Terminal 2BA

3

119

013704958

Nut ¼” BSW

2

120

013707858

Nut ⅜” BSW

4

122

536408800

Machined Nut

1

124

928105567

Seloc Washer M6

6

125

928104532

Screw ButtonHD M6x12

1

Not Illustrated

Part no.

Description

Qty

7522

6mm Armoured Cable

5mtr

SP230PH

32a 5pin Phase Rev T/Plug

1

SP130

32a 5pin Surface Socket

1

SPCG/LNM25

Cable Gland

3

SP608-828

Gland Lock Nut

3

11

VAC316-3

Operating Manual

FILTER ASSEMBLY

12

Figure no.

Part no.

Description

Qty

1

536306000

Spigot Plate

1

2

536215400

Filter Sleeve

16

3

546315400

Filter Spring

16

4

018400700

Jubilee Clip

16

Option

5363154TEF

Filter Sleeve (Teflon)

16

VAC316-3

Operating Manual

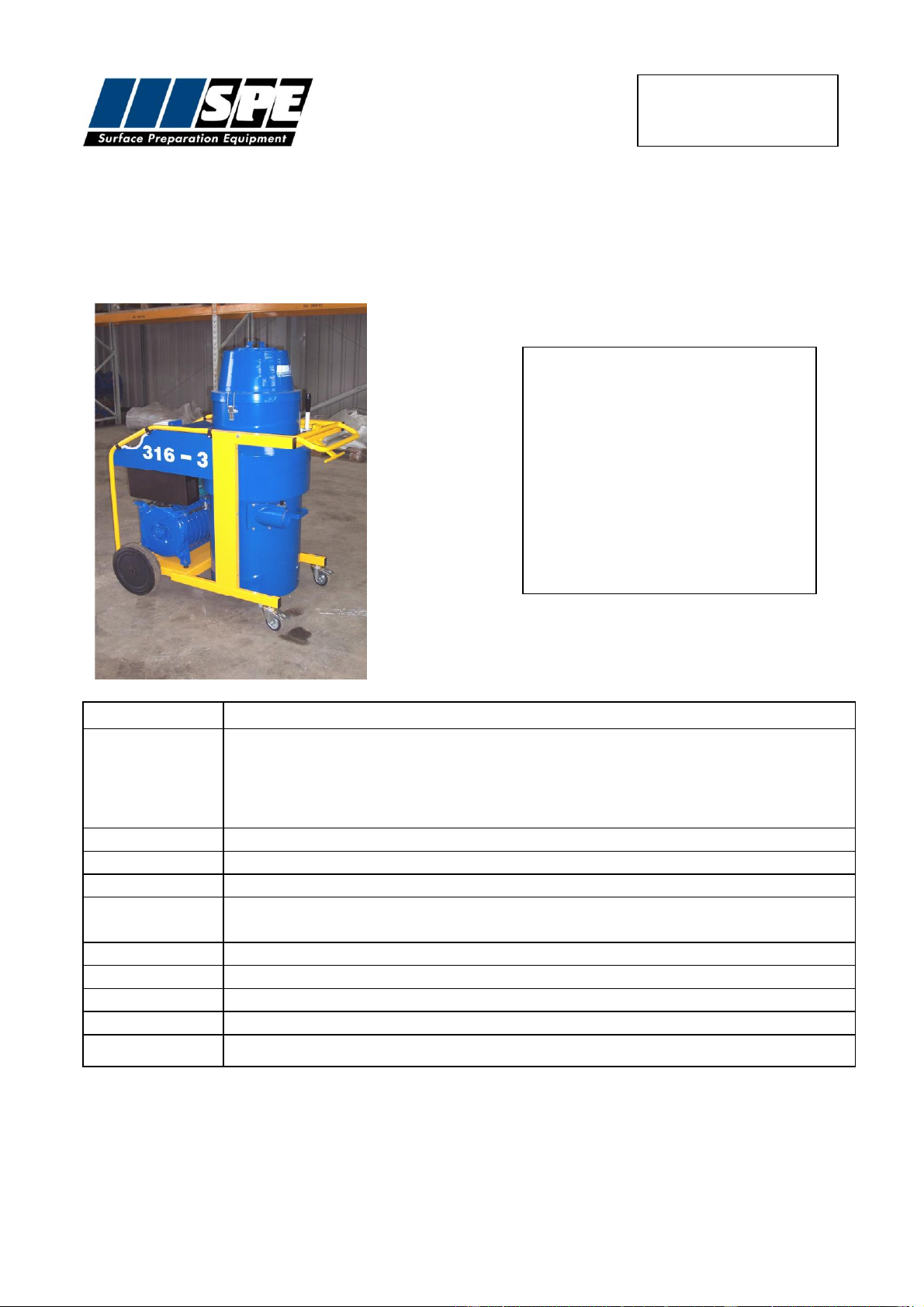

Type

316

Part Number

VAC316 -3

415v

Power

4kw

Max Vacuum

2900mm H2O

Max Airflow

5280 l/min

Filtering

Surface

16600 cm2

Capacity

60L

Inlet

76mm

Dimensions

124x70cm

Height

139cm

Weight

160kg

Features:

- Practical drop bins for easy

disposal of debris

- Wheels fitted with a brake

- External filter shaker

- 16 Cartridge filters

- Larger rear wheels for easier

movement

- Wet conversion kit available.

SPECIFICATION SHEET

13

VAC316-3

Operating Manual

WARRANTY

The standard warranty period of this equipment is 12 months from the despatch date in

accordance with the company Conditions of Sale (copy attached).

Warranty start date:

As despatch date

Model:

VAC316

Serial no:

Customer name:

Customer Address:

Manufacturer:

SPE International Ltd

Honeyholes Lane

Dunholme

Lincoln

LN2 3SU

England

Telephone:

+44 (0) 1673 860709

Fax:

+44 (0) 1673 861119

Email:

sales@spe-int.com

Web site:

www.spe-int.com

14

VAC316-3

Operating Manual

DECLARATION OF CONFORMITY

WE

SPE INTERNATIONAL LTD

OF

Honeyholes Lane

Dunholme

Lincoln

LN2 3SU

DECLARE that under our sole responsibility for the supply/manufacture of the product

(Description/name) VAC316 Vacuum

(Model/type) VAC316-3

To which this declaration relates is in conformity with the following standards and other

normative documents following the provisions of Directive 2006/42/EC.

....................................................

Brian Jacklin –Technical Manager

SPE INTERNATIONAL LTD

15

VAC316-3

Operating Manual

The quotation overleaf and any order placed following such quotation are subject to the following conditions of sale in which SPE

International Limited is referred to as the “Company”.

1. Validity of quotation

No order received from a customer by the Company shall constitute a contract until accepted in writing by the Company.

2. Prices

Prices quoted by the Company are firm for 30 days only or until previously withdrawn. Unless otherwise stated all prices are exclusive

of any applicable Value Added Tax for which the customer shall be additionally liable to the Company.

3. Delivery

Delivery periods and dates are given in good faith but are not the subject of any warranty or condition and time shall not be of the

essence of the contract in these respects. No liability will attach to the Company if delivery periods or dates are not met for any reason

whatsoever.

4. Payment

Save as may otherwise be agreed in writing the customer shall pay the price in full on or before the estimated delivery date

whereupon the Company shall raise a receipted invoice. Each invoice includes an Overdue Account Levy of 5% of the total invoice

value inclusive of VAT. Subject to payment in full being made on or before the due date a sum equal to the Overdue Account Levy

shall be credited to the customers account with the Company. Until such time as payment in full has been made the Company shall

be under no obligation to allow or effect of any goods to the customer.

5. Warranty

The Company warrants that all goods supplied by it will correspond to their specifications and will be free from defects in materials or

workmanship for a period of 12 months from the date of delivery. The Company’s obligation in the event of a breach of this warranty is

limited to the repair or replacement of any defective goods which shall be returned at the cost and expense of the customer to the

Company. This warranty is given in lieu of all the other warranty or conditions expressed or implied (whether by statute or otherwise)

and is subject to the following conditions:-

5.1 Claims must be notified in writing to the Company within seven days from the date of delivery or (where the defect is not

apparent on reasonable inspection) as soon as practicable after discovery of the defect.

5.2 The Company shall be under no liability in respect of any defect in the goods arising from any drawing, design or specification

supplied by the customer.

5.3 The Company shall be under no liability if the defect or failure in the reasonable opinion of the Company arises from wilful

damage or misuse, negligence by the customer or any third party. Failure to follow the Company instructions, usage of non-

recommended parts and materials, alteration or repair of the goods without the prior approval of the Company or non-recommended

maintenance.

5.4 The Company shall be under no liability if the price for the goods has not been paid by the due date for payment.

5.5 The above warranty does not extend to:-

5.5.1 Parts, materials or equipment not manufactured by the company in respect of which the customer shall be entitled only to the

benefit of any such warranty or guarantee as is given by the manufacturer to the Company.

5.5.2 Any component part of the goods or associated parts coming into contact with abrasive elements or dust within surface

Preparation equipment.

5.5.3 Fair wear and tear of moving parts within the goods.

5.6 Except in the case of death or personal injury caused by the Company negligence, the Company shall not be liable for any

consequential loss or damage (whether for loss of profit or otherwise) or other claims for consequential compensation.

6. Carriage

Packing, carriage and insurance charges in respect of delivery of the goods to the customer will be charged to the customer at cost to

the company.

7. Damage in Transit

The company does not accept any liability for loss or damage to the goods while in transit to the customer.

8. Risk

The risk in the goods shall pass to the customer on delivery to the customer or (if earlier) when possession of the goods is taken by a

carrier for delivery to the customer.

9. Force Majeure

The Company shall not be liable to the customer or be deemed to be in breach of any contract with the customer by reason of any

delay in performing or any failure to perform any obligation of the Company obligation in relation to the goods if the delay or failure

was due to force majeure or to any other cause beyond the Company’s reasonable control.

10. Reservation of Title

The goods sold under these conditions shall remain the absolute property of the Company and legal title in the goods shall remain

vested in the Company until payment in full of all amounts invoiced or due to the Company in respect of the goods. If the customer

shall enter into liquidation have a winding up order made against it or have a Liquidator, receiver, administrator or administrator

receiver shall be appointed over its assets, income or any part there of before the property in the goods has passed in accordance

with this condition the Company shall be entitled immediately after giving notice of its intention to repossess any goods to enter upon

the premises of the customer with such transport as may be necessary and to repossess any goods to which it has title under this

condition. No liquidator, receiver, administrator or administrative receiver of the customer shall have authority to sell goods to which

the Company has title without the prior written consent of the Company.

11 Insolvency of Customer

If the customer being a body corporate, shall pass a resolution or suffer an order of the Court to be made for winding –up, or if a

Receiver, Administrator or Administrative Receiver shall be appointed or, being an individual or partnership, shall suspend payment ,

propose or enter into any composition or arrangement with his or their creditors, or have a bankruptcy order made against him or

them, then the Company shall have the right, without prejudice to any other contract with the customer, not to proceed further with the

contract and shall be entitled to charge for work already carried out ( whether completed or not) and for goods and materials already

purchased for the customer such charge to be an immediate debt due from the customer.

12. Patent Rights, etc

The acceptance of a quotation includes the recognition by the customer of the Company under any patents, trademarks, registered

designs or other intellectual property rights relating to the goods and the customer undertakes that patent numbers, trademarks or

other trade markings on goods supplied shall not be obliterated, altered or defaced.

13. Applicable Law

These conditions shall be governed by and construed in accordance with English law and parties acknowledge and accept the

exclusive jurisdiction of the English Courts.

CONDITIONS OF SALE

16

Table of contents