Specim FX17 User manual

Specim FX17 - Reference Manual 1.1

| Contents | 2

Contents

Specim FX17..............................................................................................................4

Legal Information................................................................................................................................................. 4

Description................................................................................................................. 6

Overview............................................................................................................................................................... 6

External Interfaces................................................................................................................................................ 7

Power Connector.......................................................................................................................................7

Camera Link Camera External Interfaces................................................................................................ 8

GigE Camera External Interfaces.............................................................................................................8

Frame Grabbers.....................................................................................................................................................9

Compatible Frame Grabbers.....................................................................................................................9

Frame Grabber Relevant Configuration................................................................................................... 9

Installation Guide................................................................................................... 11

Installation Setup Overview............................................................................................................................... 11

Camera Mounting............................................................................................................................................... 11

Cabling the Camera Link Camera......................................................................................................................13

Cabling the GigE Camera.................................................................................................................................. 14

Setting the Jumbo Frame Value......................................................................................................................... 15

Software Options.....................................................................................................18

Lumo Software....................................................................................................................................................18

SpecSensor SDK.................................................................................................................................................18

ASCII Commands...............................................................................................................................................18

GigE Vision.........................................................................................................................................................18

Functionality............................................................................................................ 19

Image Aqcuisition...............................................................................................................................................19

Readout Modes....................................................................................................................................... 19

Readout Timing.......................................................................................................................................21

Reduction of Image Size.................................................................................................................................... 23

Region of Interest (ROI)........................................................................................................................ 23

Multiple Regions of Interest...................................................................................................................24

Trigger and Strobe.............................................................................................................................................. 25

Image Correction................................................................................................................................................ 30

Digital Gain and Offset...................................................................................................................................... 32

Status Line.......................................................................................................................................................... 32

Test Images......................................................................................................................................................... 33

Configuration Options............................................................................................37

MROI Configuration in Lumo........................................................................................................................... 37

Changing AIE Settings....................................................................................................................................... 37

Triggering and Strobe through Power Connector.............................................................................................. 38

External Trigger Configuration.......................................................................................................................... 39

| Contents | 3

Maintenance Guide.................................................................................................40

Important Maintenance Information...................................................................................................................40

Cleaning the Fore Optics....................................................................................................................................40

Troubleshooting....................................................................................................... 41

Troubleshooting FX............................................................................................................................................ 41

Technical Information............................................................................................ 42

Optical Performance........................................................................................................................................... 42

Performance Characteristics............................................................................................................................... 42

Mechanical Specifications.................................................................................................................................. 43

Electrical Specifications......................................................................................................................................44

Environmental Specifications............................................................................................................................. 45

| Specim FX17 | 4

Specim FX17

Legal Information

Certification

Specim, Spectral Imaging Ltd has developed Quality Management System for its use covering design, development,

manufacturing, sales and support of optical measurement devices. QMS follows ISO9001:2015 and enables more

efficient operation and product management in a systematic way utilizing metrics. Specim QMS has been audited by

Bureau Veritas Certification Holding SAS – UK Branch and found to be in accordance with the requirements of the

management system standards.

Warranty Conditions

SPECIM warrants the Product, provided the serial number appears on the Product and it is as originally configured by

the factory, against defects in materials or due to faulty workmanship, as follows:

For a period of two years (24 months) from the date of delivery to the customer there will be no labor and material

charges for repairing or replacing (depending on the defect type) the defective Product. When the parts are sent

to SPECIM for repair the customer will cover the delivery costs and after the repair the parts are sent back to the

customer at SPECIM’s cost.

SPECIM's liability to user of the Product shall in no event exceed the actual cash amount received by SPECIM for the

defective Product. If failure of the Product has resulted from accident, abuse, or misapplication, SPECIM shall have

no responsibility under this limited warranty. SPECIM shall not be liable for any direct or indirect damages arising

out of the use of, or inability to use this product.

Limited Liability

1. SPECIM shall in no event be liable for loss of production, loss of business, loss of profits or loss of use, loss of

data or revenue, damage to property, or for any special, indirect, incidental or consequential damages.

2. The aggregate liability of SPECIM is limited to the sum of money, actually paid by the Customer to SPECIM for

the system delivered.

The Warranty and Limited Liability clauses above in this quote shall supersede other possible contract clauses

between SPECIM and the customer regarding SPECIM's warranty responsibility and liability.

Disclaimer

All information provided in this guide and provided manuals is believed to be complete, accurate and reliable at the

time of delivery. No responsibility is assumed by Specim, Spectral Imaging Oy Ltd. for its use. Specim, Spectral

Imaging Oy Ltd reserves the right to make changes to this information without notice. Reproduction of this manual

in whole or in part, by any means, is prohibited without prior permission having been obtained from Specim, Spectral

Imaging Oy Ltd.

Specim IQ ® and Specim IQ Studio ® are registered EU trademarks (Nos. 016777393 and 016777419) owned by

SPECIM, Spectral Imaging Ltd.

Contacting support

Further information and technical support are available from Specim, Spectral Imaging Oy Ltd. in Finland. Contact

information:

All rights reserved - Specim, Spectral Imaging Oy Ltd.

| Specim FX17 | 5

•WWW: www.specim.fi

•Email: [email protected]

• Tel: +358 (0)10 4244 400

All rights reserved - Specim, Spectral Imaging Oy Ltd.

| Description | 6

Description

Overview

FX17 camera is built around the monochrome InGaAs image sensor. It is designed for standard applications in

industrial and laboratory use. FX17 works in a push-broom mode, and collects hyperspectral data in the NIR (950 to

1700 nm) region through single fore optics.

There are two versions of the FX17 camera:

• FX17 with Camera Link interface

• FX17e with GigE interface

These specifications apply to all FX17 camera versions.

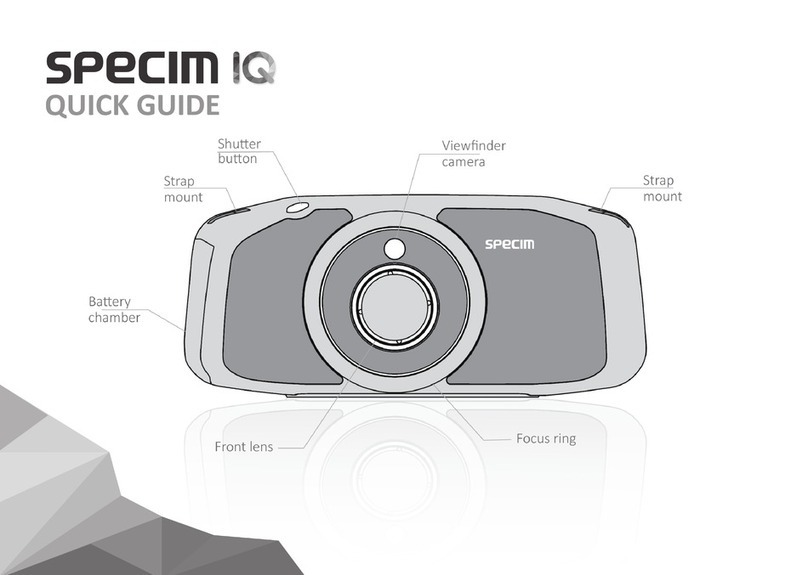

Figure 1: FX17 Spectral Camera

Camera data path

A diagram of the camera data path is shown in the figure below.

Figure 2: Camera data path

Feature Overview

Feature Characteristics

Image sensor CMOS

Operating range 950 to 1700 nm

Image correction • Offset and hot pixel correction

All rights reserved - Specim, Spectral Imaging Oy Ltd.

| Description | 7

Feature Characteristics

• Automatic Image Enhancement (AIE)

Image size reduction Multiple Regions of Interest (MROI)

Trigger modes Opto isolated trigger input and opto isolated strobe

output

Image correction

The camera includes the following image corrections:

• Offset and hot pixel correction

• Automatic Image Enhancement (AIE) means that spectral calibration will be the same for every FX camera, and

that smile and keystone will be corrected to practically zero for all cameras.

A customer with several cameras can replace one camera with another and still have the same spectral calibration

and smile/keystone without additional calibration.

All the corrections are enabled by default.

Image size reduction

The image sensor in FX series cameras is larger than the actual image size. Therefore the image area on the sensor

is defined using the Region of Interest (ROI) feature, and the ROI values are provided in the calibration pack. ROI

feature is reserved for this purpose alone, and the values must not be changed.

You can use Multiple Regions of Interest (MROI) feature to define one or several regions of interest. Using MROI

feature requires 1 x 1 binning.

If you use AIE together with MROI, there must be additional 3 rows in the beginning and in the end of each MROI to

prevent corruption. These extra rows must then be discarded in data processing as their data may be invalid.

See the technical notes Setting MROI's in FX10/10e and FX17/17e and Maximum frame rates in FX10/10e and

FX17/17e for more information.

External Interfaces

Power Connector

There is one Fischer Connector DBPLU1031Z012|130G in the camera back panel.

Power Connector Pin numbering

All rights reserved - Specim, Spectral Imaging Oy Ltd.

| Description | 8

Table 1: Power Connector Pin-out

pin # I/O Type Name Description

1 O ISO_OUT0 General purpose Output 0, single-ended output

2 O ISO_STROBE Default Strobe out, single-ended output

3 O RESERVED Reserved, do not connect

4 PWR CAMERA_GND Camera GND, 0V

5 PWR CAMERA_PWR Camera Power 12V (+/- 10%)

6 PWR ISO_GND I/O GND, 0V

7 I ISO_IN0 General purpose input 0

8 I ISO_TRIGGER Default Trigger in (5-15 V)

9 O RESERVED Reserved, do not connect

10 O RESERVED Reserved, do not connect

11 O RESERVED Reserved, do not connect

12 O RESERVED Reserved, do not connect

Camera Link Camera External Interfaces

Camera Link Connector

There is a standard MDR 26-pin camera link connector on the back panel of the camera for camera control signals

and serial communication.

For more information on Camera Link connector, refer to Camera Link interface standard specifications.

LED Indications

There is one green LED in the FX camera back panel.

LED Status

Not lit Power off

Blinking green in startup Starting up

Stable green Power on, not recording

Blinking green Recording, data being transferred

Note: Camera blinks briefly during startup. This period can be very short and therefore easy to miss.

GigE Camera External Interfaces

GigE Connector

There is a standard GigE M12 X-coded Ethernet connector on the back panel of the camera for camera control signals

and serial communication.

All rights reserved - Specim, Spectral Imaging Oy Ltd.

| Description | 9

LED Indications

There are three green LEDs in the FX camera back panel, one for status and two for GigE traffic indication.

Status LED Status

Not lit Power off

Stable green Power on

GigE LED 1 Status

Not lit No data connection

Blinking green Data connection active

GigE LED 2 Status

Not lit No data traffic

Blinking green Data being transmitted

Frame Grabbers

Compatible Frame Grabbers

When you use a Camera Link camera, the system requires a frame grabber installed on the data aqcuisition PC.

The frame grabbers that have been tested to work with LUMO in WIN10 are:

• NI 1430

• Dalsa Xtium-CL_MX4

• Epix PICXi EB1

Frame Grabber Relevant Configuration

The parameters and settings, which are essential to configure the frame grabber are shown in the following table.

Table 2: Summary of parameters needed for frame grabber configuration

Pixel Clock per Tap 80 MHz

Number of Taps 2

Greyscale resolution 12 bit / 10 bit / 8 bit

Line pause 18 clock cycles

All rights reserved - Specim, Spectral Imaging Oy Ltd.

| Description | 10

CC1 18 clock cycles

CC2 not used

CC3 not used

CC4 not used

Camera Link port and bit assignments are compliant with the Camera Link standard

Table 3: Camera Link 2 Tap port and bit assignments

Bit Tap 0 Tap 1 Tap 0 Tap 1 Tap 0 Tap 2

8 Bit 8 Bit 10 Bit 10 Bit 12 Bit 12 Bit

0 (LSB) A0 B0 A0 C0 A0 C0

1 A1 B1 A1 C1 A1 C1

2 A2 B2 A2 C2 A2 C2

3 A3 B3 A3 C3 A3 C3

4 A4 B4 A4 C4 A4 C4

5 A5 B5 A5 C5 A5 C5

6 A6 B6 A6 C6 A6 C6

7 (MSB of 8

Bit)

A7 B7 A7 C7 A7 C7

8 - - B0 B4 B0 B4

9 (MSB of 10

Bit)

- - B1 B5 B1 B5

10 - - - - B2 B6

11 (MSB of 12

Bit)

- - - - B3 B7

All rights reserved - Specim, Spectral Imaging Oy Ltd.

| Installation Guide | 11

Installation Guide

Installation Setup Overview

The basic installation setup requires camera, data cable, power cable, data aqcuisition PC and illumination.

1. Check the delivery.

1. Check that the package is undamaged.

2. Check the delivery contents and make sure that all the items mentioned in the post list are included in the

delivery.

2. Arrange the illumination.

3. Have the data aqcuisition PC ready.

4. Have the scanner, conveyor belt or some other method for movement ready.

5. Mount the camera.

6. Connect the cabling.

7. Install Lumo software on the data aqcuisition PC.

8. Test the signal.

Camera Mounting

The following mounting options are available:

• Standard Camera Thread (1/4-20 UNC) in the bottom for tripod mounting

• Mounting Kit + dovetail joints located on four sides of the camera

This chapter describes the mounting kit installation option.

Figure 3: Mounting Kit dimensions

Note: Make sure to leave adequate space behind the camera for cabling.

Note: Pay attention to the slit orientation when mounting the camera.

All rights reserved - Specim, Spectral Imaging Oy Ltd.

| Installation Guide | 12

Figure 4: Slit orientation

1. Attach the mounting kit bottom plate.

2. Slide the camera holder part to the mounting kit bottom plate.

Figure 5: Mounting Kit parts

3. Slide the camera dovetails to the camera holder.

Figure 6: Dovetail joints for the Mounting Kit

All rights reserved - Specim, Spectral Imaging Oy Ltd.

| Installation Guide | 13

Figure 7: Mounting Kit assembly

4. Tighten the camera holder screws to secure the camera in position.

Once the camera mounting is complete, move on to cabling.

Cabling the Camera Link Camera

There are two connectors in the camera back panel (on the left picture below):

• Camera Link Connector

• Power Connector for 12V DC

Figure 8: Back panel connectors

Note: Leave at least 150 mm space behind the camera for cabling.

Note: Make sure that the Camera Link cable is connected before powering up the camera.

Connect the cables:

All rights reserved - Specim, Spectral Imaging Oy Ltd.

| Installation Guide | 14

1. Connect the interface connector (Camera Link) to the camera.

2. Connect the interface cable to the PC.

3. Insert the power cable to the camera, make sure the red dots are aligned.

4. Connect power cable to the wall socket.

5. Camera is on when the Status LED is stable green.

1.

2.

Figure 9: Powering Order

When powering off the camera, pull the power cable first from the wall socket. After removing the

power cord, wait at least 30 seconds before connecting the power cord and starting camera again.

Cabling the GigE Camera

There are three LEDs and two connectors in the camera back panel (on picture below):

• GigE connector

• Power Connector for 12V DC

Figure 10: Back panel connectors

Note: Leave at least 60 mm space behind the camera for cabling.

Note: Make sure that the GigE data cable is connected before powering up the camera.

Connect the cables:

1. Connect the interface connector (GigE) to the camera.

All rights reserved - Specim, Spectral Imaging Oy Ltd.

| Installation Guide | 15

2. Connect the interface cable to the PC.

3. Insert the power cable to the camera, make sure the red dots are aligned.

4. Connect power cable to the wall socket.

5. Camera is on when the Status LED is stable green.

1.

2.

Figure 11: Powering Order

When powering off the camera, pull the power cable first from the wall socket. After removing the

power cord, wait at least 30 seconds before connecting the power cord and starting camera again.

Setting the Jumbo Frame Value

When using the GigE camera version, set the jumbo frame value to maximum to ensure that the data is not corrupted

when tranferred to the data acquisition PC.

1. Open Windows start menu and search for network status.

Figure 12: Network status in Windows start menu

2. Open the network status window and click Change adapter options.

All rights reserved - Specim, Spectral Imaging Oy Ltd.

| Installation Guide | 16

3. In the Network Connections window, click the right mouse button on the network adapter used by the camera.

Select Properties.

4. Click Configure.

All rights reserved - Specim, Spectral Imaging Oy Ltd.

| Installation Guide | 17

5. Open the Advanced tab and select Property: Jumbo frame.

6. Set the property to the maximum value (typically 9KB MTU).

All rights reserved - Specim, Spectral Imaging Oy Ltd.

| Software Options | 18

Software Options

Lumo Software

Lumo is a family of software products for hyperspectral sensor data acquisition.

• Lumo Recorder, for when there is no Specim scanner used in the setup

• Lumo Scanner, for when there is a Specim scanner in use

With Lumo Software you can select camera and scanner, adjust acquisiton parameters, and save raw data of the

camera. It can also control other external devices, required for certain sensors, such as thermal calibrator, triggering

electronics, motors, and so on.

Lumo Software has a built-in scripting and sequential workflow engine controlling all the steps and automation to be

performed for each measurement.

For instructions on how to use your Lumo software, refer to the relevant Lumo Software User Manual.

SpecSensor SDK

SpecSensor SDK is a unified SDK for all our cameras, and it is typically used by OEM and integrators. C style API

can be used from different programming languages.

SpecSensor SDK sends commands to cameras and gets the frames from the cameras, however it does not have a GUI

or record data to the disk.

For instructions on how to use your Specim SDK, refer to the SpecSensor SDK User Manual.

ASCII Commands

the Camera Link version of the FX camera can be controlled with ASCII commands, for example in cases where

hyperspectral imaging is intregated in an existing ASCII based system or when required features are not supported by

LUMO or LUMO SDK Software.

ASCII commands are availabe in separate ASCII documentation. Note, that Specim does not provide support

packages for ASCII use cases.

GigE Vision

GigE version of the FX camera is complient with GigE Vision interface standard, which is a global standard for

video transfer and device control over Ethernet networks. For more information, refer to GigE Vision Standard

Specification.

All rights reserved - Specim, Spectral Imaging Oy Ltd.

| Functionality | 19

Functionality

Image Aqcuisition

Readout Modes

The FX cameras provide two different readout modes:

•Sequential readout: Frame time is the sum of exposure time and readout time. Exposure time of the next image

can only start if the readout time of the current image is finished.

•Simultaneous readout (interleave): The frame time is determined by the maximum of the exposure time or

of the readout time, which ever of both is the longer one. Exposure time of the next image can start during the

readout time of the current image.

The following figure illustrates the effect on the frame rate when using either the sequential readout mode or the

simultaneous readout mode (interleave exposure).

Figure 13: Frame rate in sequential readout mode and simultaneous readout mode

Sequential readout mode For the calculation of the frame rate only a single formula applies: frames per second equal

to the inverse of the sum of exposure time and readout time.

Simultaneous readout mode (exposure time is less than readout time) The frame rate is given by the readout time.

Frames per second equal to the inverse of the readout time.

Simultaneous readout mode (exposure time is greater than readout time) The frame rate is given by the exposure

time. Frames per second equal to the inverse of the exposure time.

The simultaneous readout mode allows higher frame rate. However, if the exposure time greatly exceeds the readout

time, then the effect on the frame rate is neglectable.

Note: In simultaneous readout mode image output faces minor limitations. The overall linear sensor reponse

is partially restricted in the lower grey scale region.

Note: When changing readout mode from sequential to simultaneous readout mode or vice versa, new

settings of the BlackLevelOffset and of the image correction are required.

All rights reserved - Specim, Spectral Imaging Oy Ltd.

| Functionality | 20

Sequential readout

By default the camera continuously delivers images as fast as possible ("Free-running mode") in the sequential

readout mode. Exposure time of the next image can only start if the readout time of the current image is finished.

Figure 14: Timing in free-running sequential readout mode

When the acquisition of an image needs to be synchronised to an external event, an external trigger can be used. In

this mode, the camera is idle until it gets a signal to capture an image.

Figure 15: Timing in triggered sequential readout mode

Simultaneous readout (interleave exposure)

To achieve highest possible frame rates, the camera must be set to "Free-running mode" with simultaneous readout.

The camera continuously delivers images as fast as possible. Exposure time of the next image can start during the

readout time of the current image.

Figure 16: Timing in free-running simultaneous readout

mode (exposure time is greater than readout time)

Figure 17: Timing in free-running simultaneous readout

mode (exposure time is greater than than readout time)

When the acquisition of an image needs to be synchronised to an external event, an external trigger can be used. In

this mode, the camera is idle until it gets a signal to capture an image.

All rights reserved - Specim, Spectral Imaging Oy Ltd.

This manual suits for next models

1

Table of contents

Other Specim Digital Camera manuals

Popular Digital Camera manuals by other brands

Konica Minolta

Konica Minolta DiMAGE X60 instruction manual

Sanyo

Sanyo Xacti VPC-S3 instruction manual

Teletechno

Teletechno Vista WIFI Quick installation guide

Allied Vision

Allied Vision Alvium Series Safety and Usage Instructions

Konica Minolta

Konica Minolta DiMAGE X50 instruction manual

Philips

Philips KEY007 Specifications