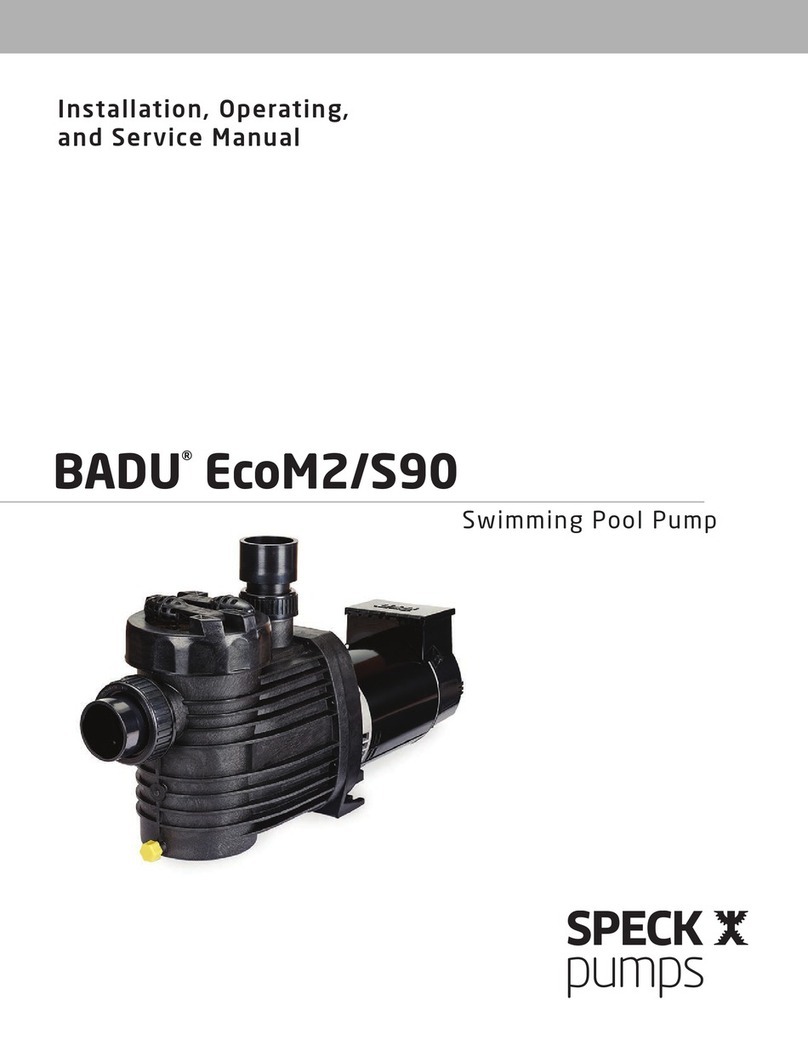

2999999927 - Rev. 0420 - Model S90

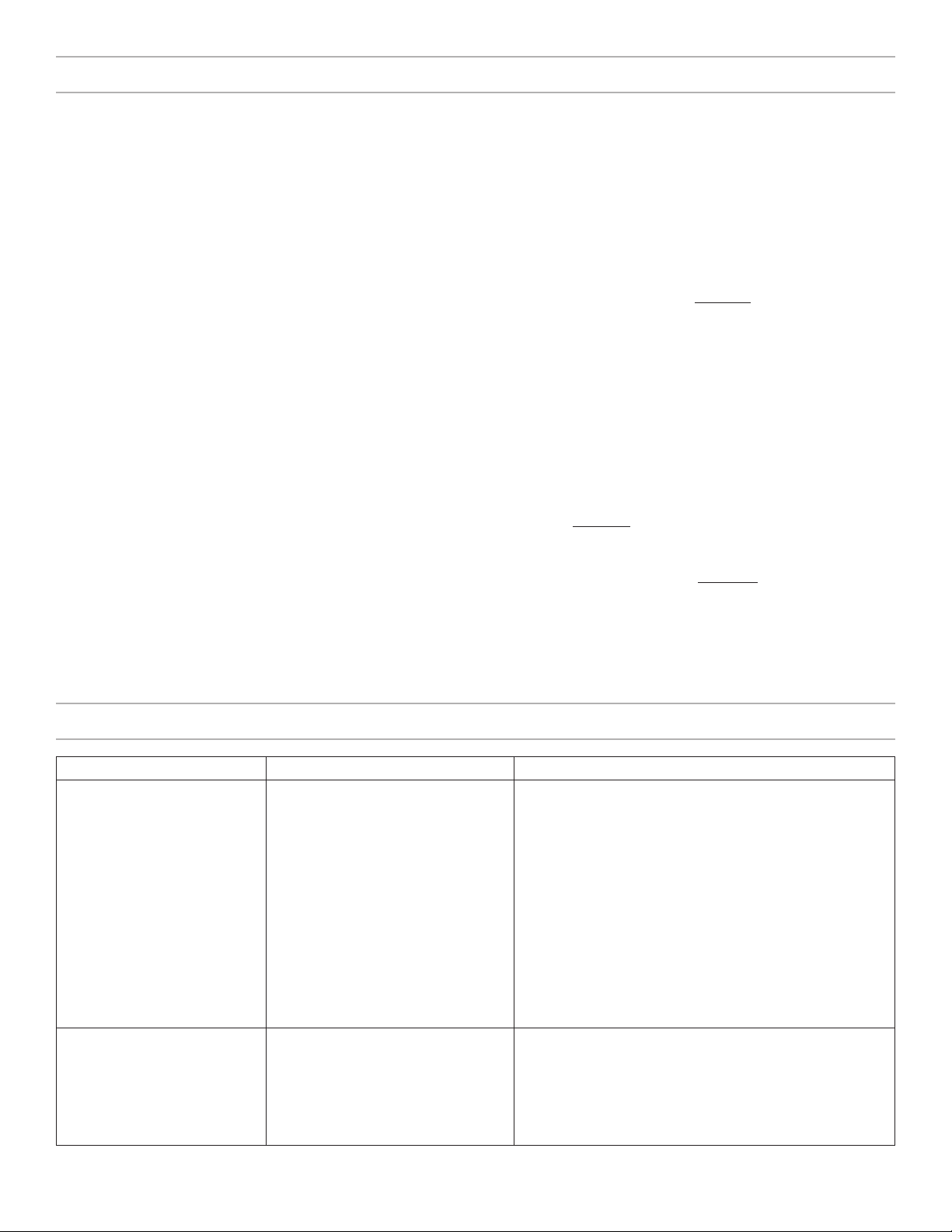

strainer basket cover

discharge port

to filter or pool

bonding lug

pump may be bolted to level

foundation or mounting bracket

suction port

from pool or

vacuum filters

drain plug

disconnect

unions disconnect unions

SECTION 1 EQUIPMENT OPERATION AND MAINTENANCE

1/1 LOCATION

1. Locate the pump as close to the pool as practical. Consult

local codes for minimum distance between pool and pump.

2. The piping should be as direct and free from turns or

bends as possible, as elbows and other fittings greatly

increase friction losses.

3. Place pump on a solid foundation which provides a rigid

and vibration-free support so that it is readily accessible for

service and maintenance.

4. Though the pump is designed for outdoor use, it is advised

to protect the pump from continuous direct heat. Install the

pump in a well ventilated location protected from excessive

moisture (flooding, sprinklers, rain downspouts, etc.).

5. Protect the pump against flooding and excess moisture,

prevent foreign objects from clogging air circulation around

motor. All motors generate heat that must be removed by

providing proper ventilation.

6. DO NOT store or use gasoline or other flammable vapors

or liquids in the vicinity of this pump. DO NOT store pool

chemicals near the pump.

7. DO NOT remove any safety alert labels such as DANGER,

WARNING, or CAUTION. Keep safety labels in good

condition and replace missing or damaged labels.

8. Provide access for future services by leaving a clear area

around the pump. Allow plenty of space above the pump to

remove lid and basket for cleaning.

1/2 INSTALLATION

1. When connecting pipework to pump with threaded ports,

it is recommended that thread seal tape be used. If the

suction pipe is not sealed correctly, the pump will not prime

properly and pump small volumes of water or none at all.

2. When installing the pump, care should be taken to see that

the suction line is below water level to a point immediately

beneath and in front of the pump to ensure quick priming

via a flooded suction line. The height between the pump

and water level should not be more than five (5) feet.

3. Suction and discharge line should be independently

supported at a point near the pump to avoid strains being

placed on the pump.

4. It is advisable to install a gate valve in both the suction

and discharge line in the event that the pump must be

removed for servicing. (Flooded suction application only)

5. Before starting the pump for the first time, remove the

see-through lid. (Turn lid ring counterclockwise to remove.)

Fill strainer tank with water until it is level with the suction

inlet. Replace lid with locking ring. Hand-tighten the lid to

make an air-tight seal. DO NOT use any tools to tighten

the lid.

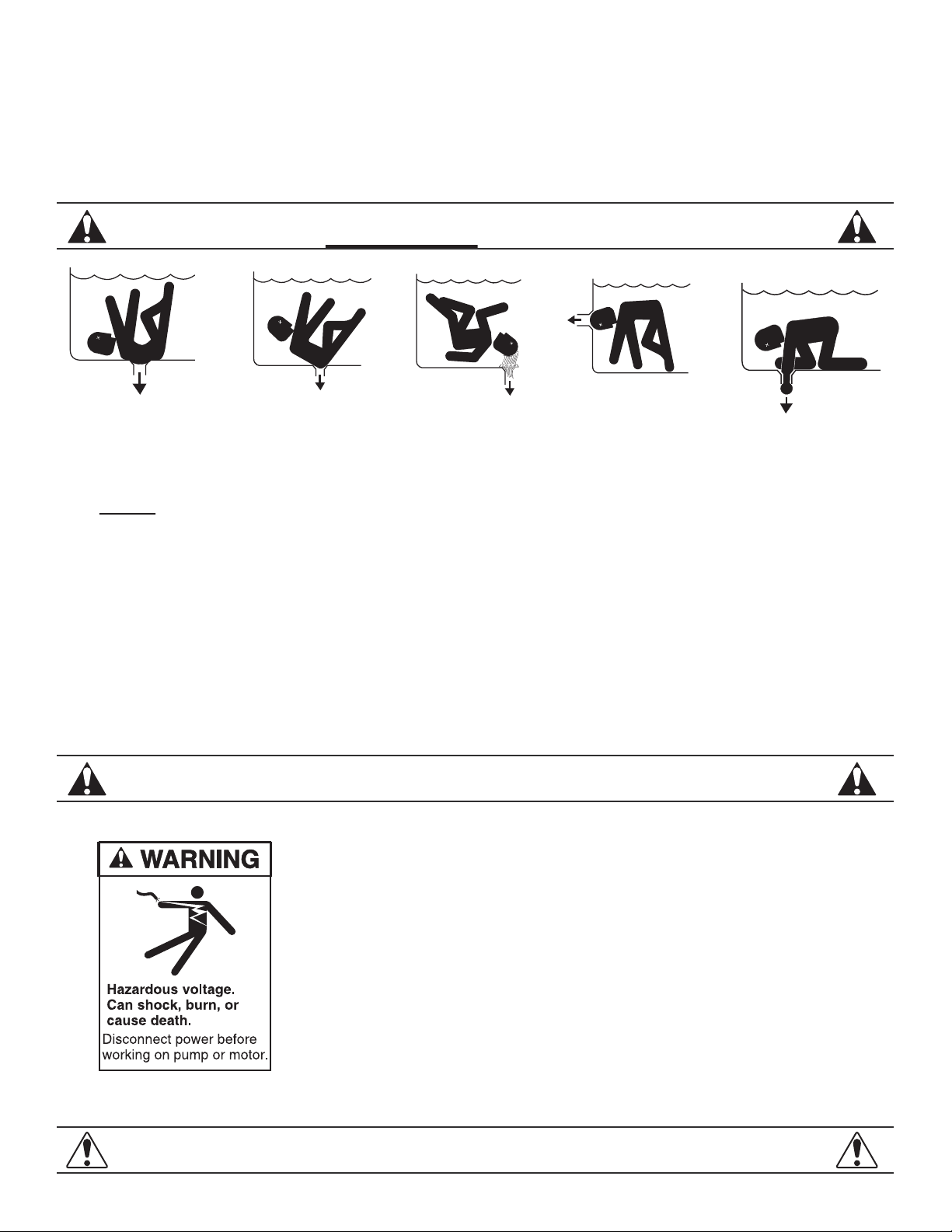

6. When installing and using the motor, basic safety

precautions should be done by a licensed electrician in

accordance with local codes. Be certain that the motor

frame is grounded. Motor name plate has voltage, phase,

ampere draw and other motor information as well as wiring

connection instructions.

BONDING: As required by National Electrical Code Article

680-22, the pump motor must be electrically bonded to

the pool structure (reinforced bars, etc.) by a solid copper

conductor not smaller than #8 AWG (8.4 mm2) wire via the

external copper bonding lug on the pump motor (#6 AWG

Canada).

GROUNDING: Permanently ground the pump motor using

a conductor of appropriate size. Connect to the #10 green

headed ground screw provided inside the motor terminal

box.

NOTE: DO NOT connect to electric power supply until the

unit is permanently grounded

Figure 1.0

1/3 MAINTENANCE

The pump requires little or no service other than reasonable

care and periodic cleaning of the strainer basket. DO NOT

strike basket to clean. When cleaning the basket inspect

the lid o-ring for damage and replace if necessary.

NOTE: It is normal for a few drops of water to escape from

the mechanical seal from time to time. This is especially

true during the break-in period.

The mechanical seal may become worn and/or loose during

the course of time, depending on the running time and water

quality. If water continually leaks out, a new mechanical

seal should be fitted. After long periods of NON operational

(seasonal storage, etc.), the pump must be checked for ease

of rotation while it is switched o.