Spectris Servomex Servopro PureGas User manual

Part Number: 02005001A

Revision: 0

Language: UK English

SERVOPRO PureGas

OPERATOR MANUAL

OPERATOR MANUAL

This page is intentionally blank

SERVOPRO PureGas Gas Purifier

02005001A / Revision 0 2

LIST OF CONTENTS

1 DESCRIPTION AND DEFINITIONS.................................................................. 3

1.1 Scope of this Manual................................................................................... 3

1.2 Safety Information....................................................................................... 3

1.3 Warning Symbols........................................................................................ 3

1.4 General Warnings and Cautions ................................................................. 4

1.5 Description.................................................................................................. 5

1.6 Lifetime of the Purifier ................................................................................. 5

1.7 Construction................................................................................................ 5

2 SPECIFICATION............................................................................................... 6

2.1 General....................................................................................................... 6

2.2 Environmental Limits................................................................................... 6

2.3 Electrical Data............................................................................................. 6

2.4 Sample Gas................................................................................................ 7

2.5 Purge Gas................................................................................................... 7

3 UNPACKING THE PURIFIER............................................................................ 8

3.1 Handling...................................................................................................... 8

3.2 Unpacking and Inspection........................................................................... 8

4 INSTALLATION AND SETUP............................................................................ 9

4.1 Mounting..................................................................................................... 9

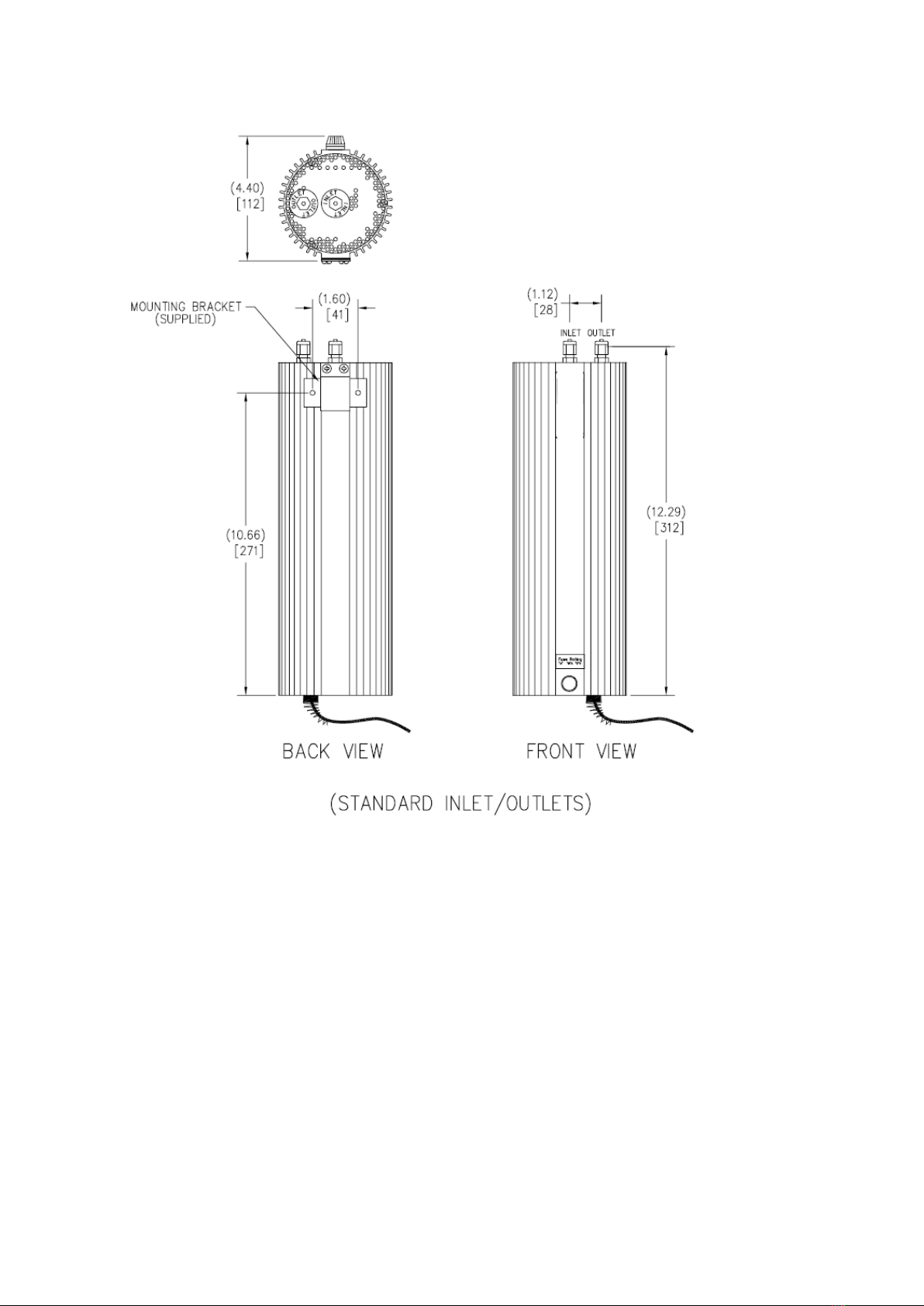

4.1.1 Figure 1 –Overall and Fixing Dimensions (Standard)........................ 10

............................................................................................................................ 11

4.1.2 Figure 2 –Overall and Fixing Dimensions (VCR)).............................. 11

4.2 Mechanical Installation and purging .......................................................... 12

5 Operation......................................................................................................... 13

5.1 Activating .................................................................................................. 13

5.2 Electrical Safety ........................................................................................ 13

6 Disconnecting the Purifier................................................................................ 14

7 Service ............................................................................................................ 15

7.1 Cleaning the Purifier.................................................................................. 15

8 STORAGE AND DISPOSAL............................................................................ 16

8.1 Storage..................................................................................................... 16

8.2 Disposal.................................................................................................... 16

9 APPENDIX...................................................................................................... 17

9.1 APPENDIX A1 MATERIALS IN CONTACT WITH SAMPLE GAS ........... 17

9.2 APPENDIX A2 DISPOSAL IN ACCORDANCE WITH THE WASTE

ELECTRICAL AND ELECTRONIC EQUIPMENT (WEEE) DIRECTIVE............. 18

9.3 APPENDIX A3 REACH REGULATION..................................................... 19

9.4 APPENDIX A4 COMPLIANCE AND STANDARDS INFORMATION ......... 20

9.5 APPENDIX A5 CONTACT INFORMATION.............................................. 21

© This manual is copyright, and no part of it may be reproduced without Servomex’s written approval.

SERVOPRO PureGas Gas Purifier

02005001A / Revision 0 3

1 DESCRIPTION AND DEFINITIONS

1.1 Scope of this Manual

This operation manual provides the information required to operate the purifier.

This manual is not intended to provide servicing instructions to the user.

The purifier should be operated only by personnel who are familiar with the

procedures required for safe operation.

It is strongly recommended that the factory be consulted before any maintenance or

repairs are attempted.

1.2 Safety Information

This manual must be read and its contents fully understood before any attempt is

made to install, operate or maintain the purifier. Important safety information is

highlighted in this manual as WARNINGs and CAUTIONs, which are used as follows:

This manual also incorporates ‘Be Aware of’ information, which is used as follows:

This highlights information which is useful to be aware of (for example,

specific operating conditions).

1.3 Warning Symbols

The identification label on the front of the purifier displays the following warning

symbols, which are defined as follows:

Surface of enclosure will become hot.

Refer to manual.

WARNING

Warnings highlight specific hazards which, if not taken into account, may

result in personal injury or death.

CAUTION

Cautions highlight hazards which, if not taken into account, can result in

damage to the purifier or to other equipment or property.

SERVOPRO PureGas Gas Purifier

02005001A / Revision 0 4

1.4 General Warnings and Cautions

The purifier is intended for operation in fixed installations indoors, or enclosed in a

cabinet.

WARNING

The purifier must only be used with inert gases. The intended gas type

will be stated on the front of the purifier. Do not use any other gas type.

This purifier should never be used to purify oxygen, air or other gas

containing oxygen above trace levels. If this purifier is used to purify

oxygen, air or other gas containing oxygen above trace levels, the

purifier will rapidly and uncontrollably overheat and could cause a fire or

permanent damage to the purifier, voiding the factory warranty.

WARNING

Improper installation, operation, or service of the purifier can cause fire

and electrocution.

WARNING

If a fire occurs inside the purifier, extinguish the fire with sand or an

extinguisher intended for class d (metal) fires only. Do not attempt to

extinguish a purifier fire with any other materials.

WARNING

The purifier is not a medical device as defined in the Medical Devices

Directive 93/42/EEC (as amended), and is not intended for use with

medical equipment.

CAUTION

The purifier must have electrical power and applicable gas pressure for proper

operation. If proper electrical power and applicable gas pressure are not

supplied, the purifier could be permanently damaged and the factory warranty

will be void.

SERVOPRO PureGas Gas Purifier

02005001A / Revision 0 5

1.5 Description

The purifier is designed for the purification of carrier gases used in Gas Chromatography

(GC).Outlet impurity levels for H2, O2, H2O, CO, CO2, CH4(and N2in noble gases) are

reduced to low parts per billion (ppb) levels.

The purifier comes completely assembled with a 1/8” compression fitting for both the gas inlet

and the outlet. Both fittings are located on the top of the purifier. Optional 1/8” VCR

connections are also available if requested.

1.6 Lifetime of the Purifier

At the rated flow of 200 sccm and at rated working temperature, the purifier has the capacity

to purify up to sixty B50 200 Bar cylinders of typical 5 nines quality (99.999%) carrier gas or

one hundered and twenty cylinders of typical 6 nines quality.

1.7 Construction

The purifier comprises of an aluminium enclosure which has ventilation holes at the

top and bottom. There is a mounting bracket at the rear of the purifier.

Anodized enclosure maintains a 45º C surface temperature.

Ceramic fibre insulation with encapsulated heater coil

20 µm sintered filter on inlet and outlet

1/8” compression fittings (Optional 1/8” VCR)

CAUTION

The purifier does not incorporate integral flow or purity sensors.

Therefore, it is the responsibility of the operator to manually adjust the

values of sample gas flow rate and impurity levels if these change from

the initial configuration during operation. If not, the calculation of the

remaining life of the purifier may not be accurate.

SERVOPRO PureGas Gas Purifier

02005001A / Revision 0 6

2 SPECIFICATION

2.1 General

Purifier height (envelope)

312 mm (~12.3 in)

347 mm (~13.67 in) [optional VCR connections]

Purifier width (envelope)

112 mm (~4.4 in)

Purifier weight

1.8 Kg (~4 lbs)

Feed gas inlet

1/8” compression fittings (optional 1/8” VCR)

Purified gas outlet

1/8” compression fittings (optional 1/8” VCR)

Heater power consumption

40 W

Particle filter

20 µm sintered filter on inlet and outlet

Gas wetted surface finish

Up and downstream of Getter vessels = 304L SST, all

welded construction

2.2 Environmental Limits

2.3 Electrical Data

Installed Power

(Customer to specify voltage at time of order)

120 VAC, 1 Phase, 50/60 Hz

220 VAC, 1 Phase, 50/60 Hz

Plug Style

(Customer to specify which power plug is

required in their area at time of order)

USA (120 VAC)

EU (220 VAC)

UK (220 VAC)

* The purifier is supplied configured for operation with one of these voltage ranges.

The voltage range must be specified when ordering the purifier.

Indoor Installation, Ambient

Temperature (min –max)

0°C to 35°C (32°F to 95°F)

Operating ambient humidity range

0% to 95% RH, non-condensing

Maximum operating altitude

2000m

Ingress protection

IP20

SERVOPRO PureGas Gas Purifier

02005001A / Revision 0 7

2.4 Sample Gas

The sample gas must have a minimum purity of 5N (<10 ppm).

2.5 Purge Gas

The purge gas must have a minimum purity of 5N (<10 ppm).

Recommended gases to be purified

Ar, He, Ne, Xe, Kr,

Recommended input purity

5N minimum (<10 ppm)

Expected output purity

8N minimum (<10 ppb)

CAUTION

The caps fitted to the gas inlet and outlet must be kept on until just prior to

installation. The length of time that the purifier is left open to the air must be

kept to a minimum, or the getter material may be prematurely depleted.

Recommended purge gas

Gas to be purified in process

Recommended input purity

5N minimum (<10 ppm)

Inlet/outlet flow rate

100 ml/min

Maximum inlet pressure

1000 kPa gauge (145 psi gauge)

SERVOPRO PureGas Gas Purifier

02005001A / Revision 0 8

3 UNPACKING THE PURIFIER

3.1 Handling

The level of performance depends upon the care and attention to the proper handling of the

purifier. Exposure to non UHP environments, and physical contact of sealing surfaces will

reduce the quality and life of the purifier.

The purifier should be packaged and stored in a clean, dry environment until used. Do not

open until the intended time of installation.

3.2 Unpacking and Inspection

Each purifier is backfilled with argon and sealed in a polyethylene bag. The ends of the

purifier are plugged with caps. Check the label on the outlet connection and verify the

application. “R” refers to rare gas applications.

• Remove packaging containers and materials such as boxes, crates, and cushioning

outside the clean area.

• Do not tear the polyethylene bag. Use a sharp instrument to cut the seal, taking care

not to damage the item inside the bag.

Retain the shipping documentation and packaging for future use (for example,

return of the purifier to Servomex for servicing or repair).

WARNING

Argon (Ar) is a simple asphyxiant. Exposure to atmospheres containing

less than 19.5% oxygen may cause suffocation. Refer to the chemical

supplier’s precautions and the material safety data sheet (msds) before

using.

WARNING

Strict adherence to uhp component handling procedure is required to

maintain the factory specifications.

CAUTION

Check that the gas type (shown on the rating label) is correct. If not, contact

Servomex or the local Servomex agent immediately, as the purifier may be

damaged by the exothermic reaction resulting from using the incorrect gas.

SERVOPRO PureGas Gas Purifier

02005001A / Revision 0 9

4 INSTALLATION AND SETUP

4.1 Mounting

A mounting bracket is supplied to simplify mounting. Any convenient location allowing the

purifier to be mounted vertically is sufficient.

Only mount the purifier in a vertical position.

Overall dimensions for mounting of the standard and VCR versions are shown in figures 1

and 2 respectively.

WARNING

The purifier must be installed by a suitably skilled and competent

technician or engineer in accordance with this manual.

WARNING

The purifier must be installed and operated in accordance with this and

subsequent sections of the manual. Failure to do this may cause damage

to the purifier and invalidate the manufacturer’s warranty.

WARNING

Do not apply electrical power until directed to do so by the start-up

procedure. Incorrect application of electrical power may cause

electrocution, electrical shock, fire or other damage to the purifier.

WARNING

The purifier is not suitable for installation in hazardous areas.

SERVOPRO PureGas Gas Purifier

02005001A / Revision 0 10

4.1.1 Figure 1 –Overall and fixing

dimensions (Standard)

SERVOPRO PureGas Gas Purifier

02005001A / Revision 0 11

4.1.2 Figure 2 –Overall and fixing

dimensions (VCR))

SERVOPRO PureGas Gas Purifier

02005001A / Revision 0 12

4.2 Mechanical Installation and purging

The purifier comes sealed in an argon atmosphere and must be purged before

purification can begin.

Purge the lines, with an inert gas, upstream of the purifier thoroughly.

While under purge, using standard UHP procedures, remove the inlet cap and

connect the inlet fitting to the line as quickly as possible, no longer than 30 seconds.

Remove the outlet fitting cap and, using standard UHP procedures, connect the

downstream gas line as quickly as possible, no longer than 30 seconds.

The purifier should be purged with the application gas for at least ten minutes prior to

the start of heating.

The purifier can now be activated.

WARNING

Do not remove any fittings or open any valves until the inlet and outlet

lines are connected and purged.

WARNING

The purging process must be carried out at room temperature. Do not

switch the purifier on at this stage.

WARNING

Ensure that the pipes to be connected to the purifier are routed so that

they do not present a trip hazard to people.

WARNING

Purge and sample gases are asphyxiant in high concentrations. Ensure

that the purge outlet pipe is vented to an area where the gases will not be

a suffocation hazard to people.

WARNING

Purge and sample gases are asphyxiant in high concentrations. To

prevent the build-up of such gases, ensure that the purifier is used in a

sufficiently well-ventilated environment.

WARNING

Strict adherence to UHP components handling procedures is required to

maintain the factory specifications. Do not allow the purifier column and

the internal piping surface to be exposed to atmosphere. The purifier

should be purged with the application gas only.

SERVOPRO PureGas Gas Purifier

02005001A / Revision 0 13

Leak testing the purifier is recommended before activating. The purifier has

been certified helium leak tight to less than 10 -9 scc/sec of He (inboard).

Once installed, the purifier connections should be tested for leak integrity.

The ventilation slots at the top and bottom of the purifier must not be

obstructed.

The wall fixings must be capable of supporting the purifier wall bracket, plus

any connected pipes not supported by other means.

5 Operation

5.1 Activating

Activation starts when the heater is plugged in. The purifier should be operated for at least

two hours prior to injecting any sample into the purifier.

The effluent carrier gas should be vented and not directed to the process

during this period. The use of high purity purge gas through all purging and

activation procedures is strongly recommended.

5.2 Electrical Safety

The purifier does not incorporate an integral on/off switch. A suitable means of

externally isolating the electrical supply from the purifier must be provided: a suitable

switch or circuit breaker must be located close to the purifier, clearly marked as the

disconnecting device for the purifier.

The electrical supply coupler or plug must be easily accessible for disconnection from

the electrical supply.

The electrical supply circuit must incorporate a suitable fuse or over-current

protection device.

Ensure that the available electrical supply can provide the necessary maximum

power consumption: refer to Section 2.1.

WARNING

Do not allow the getter alloy to be exposed to atmosphere in a heated

(greater than 50°C) condition. The purifier should be purged with the

application gas until it is down to room temperature.

WARNING

Ensure that the electrical installation of the purifier conforms with all

applicable local and national electrical safety requirements.

WARNING

Obey the safety instructions given below when the purifier is installed. If

not, the manufacturer’s warranty may be invalidated, the purifier may not

operate safely, correctly or it may be damaged.

SERVOPRO PureGas Gas Purifier

02005001A / Revision 0 14

6 Disconnecting the Purifier

If it is necessary to disconnect the purifier to carry out plant/factory maintenance, for example,

and the purifier will not be used for several days, the following procedure must be followed:

Prior to removal, the power must be shut off and the purifier allowed to cool to room

temperature (this takes approximately 3 hours).

While cooling, purge the purifier with inert gas.

While under purge, quickly disconnect the outlet line and replace the outlet cap.

Next, quickly disconnect the inlet line and replace the inlet cap.

Remove the purifier from the mounting bracket.

Upon replacement, follow the mounting, purging and activating instructions.

WARNING

Do not attempt to disconnect any of the components while the purifier is

in a heated (greater than 50OC) condition. Exposure of the getter alloy to

atmosphere under these circumstances could be hazardous.

SERVOPRO PureGas Gas Purifier

02005001A / Revision 0 15

7 Service

The purifier is maintenance free. It is designed to operate continuously without service

throughout its rated capacity as long as the gas flowing is the carrier gas.

The only service encountered is at the end of the life, when the purifier has to be replaced.

7.1 Cleaning the Purifier

When necessary, use a dry brush or cloth to wipe clean the outer surfaces of the purifier, to

prevent the entry of dust or other particulates into the interior of the purifier.

WARNING

The user must not attempt to open the purifier as there are no serviceable

parts inside. Any attempt to open the purifier would invalidate the

warranty on the purifier, the purifier may not operate safely or provide

reliable data.

WARNING

Liquids must never be applied when cleaning the purifier, due to the risk

of electric shock.

WARNING

Liquids must never allowed to enter the inlet/outlet pipework as the

purifier may not operate safely or provide reliable data.

SERVOPRO PureGas Gas Purifier

02005001A / Revision 0 16

8 STORAGE AND DISPOSAL

8.1 Storage

Refit the protective caps securely on the purifier inlet and outlet (see Section 4.2) and place

the purifier and any associated equipment in its original packaging before storage.

Alternatively, seal it inside a waterproof bag or storage box.

Store the purifier and any associated equipment in a clean, dry area. Do not subject it to

excessively hot, cold or humid conditions: see Section 2.2.

8.2 Disposal

Follow proper disposal procedures for the purifier. The disposal of the material, as with any

other industrial waste, should be performed in accordance with specific local and national

laws and regulations.

The purifier is not suitable for disposal in municipal waste streams (such as landfill sites,

domestic recycling centres and so on). Refer to Appendix A2 for disposal requirements in

accordance with the WEEE Directive within the EC.

If the purifier is sent to Servomex or the local Servomex agent for disposal, it must be

accompanied by a correctly completed contamination certificate.

WARNING

Dispose of the purifier and any associated equipment safely, and in

accordance with all local and national safety and environmental

requirements.

WARNING

Dispose exhausted purifiers in full compliance with federal, state,

provincial, and local regulations.

SERVOPRO PureGas Gas Purifier

02005001A / Revision 0 17

9 APPENDIX

9.1 Appendix A1 MATERIALS IN CONTACT WITH SAMPLE GAS

The materials of the parts of the purifier in contact with the sample gas are listed

below. These materials have a wide range of chemical compatibility and corrosion

resistance.

Purifier for Inert Sample Gas

316 stainless steel

316L stainless steel

Zr-V-Fe alloy

SERVOPRO PureGas Gas Purifier

02005001A / Revision 0 18

9.2 APPENDIX A2 DISPOSAL IN ACCORDANCE WITH THE WASTE ELECTRICAL AND

ELECTRONIC EQUIPMENT (WEEE) DIRECTIVE

The logo shown in Figure A1 is displayed on the identification label on the purifier.

Figure A1 –The WEEE logo

This logo identifies that:

The purifier is considered to be within the scope of the Waste Electrical and

Electronic Equipment (WEEE) Directive.

The purifier is not intended for disposal in a municipal waste stream, but shall be

submitted for material recovery and recycling in accordance with the local

regulations which implement the WEEE Directive.

For additional information and advice on the disposal of the purifier in accordance

with the WEEE Directive, contact Servomex or the local Servomex agent.

If the purifier is sent to Servomex or the local Servomex agent for disposal, it

must be accompanied by a correctly completed contamination certificate.

SERVOPRO PureGas Gas Purifier

02005001A / Revision 0 19

9.3 APPENDIX A3 REACH REGULATION

In pursuance of the requirements included in Article 33 of the European REACH Regulation

on the Registration, Evaluation, Authorisation and restriction of CHemicals, information on

Substances of Very High Concern (SVHC) contained in Servomex products is provided on

www.servomex.com

Table of contents

Popular Water Filtration System manuals by other brands

Siemens

Siemens FDCL221 Technical manual

US Water Systems

US Water Systems Fusion Oxi-Gen 089-FSF OG Series Installation, operation and maintenance manual

Coway

Coway AQUAMEGA 100 user manual

Waterdrop

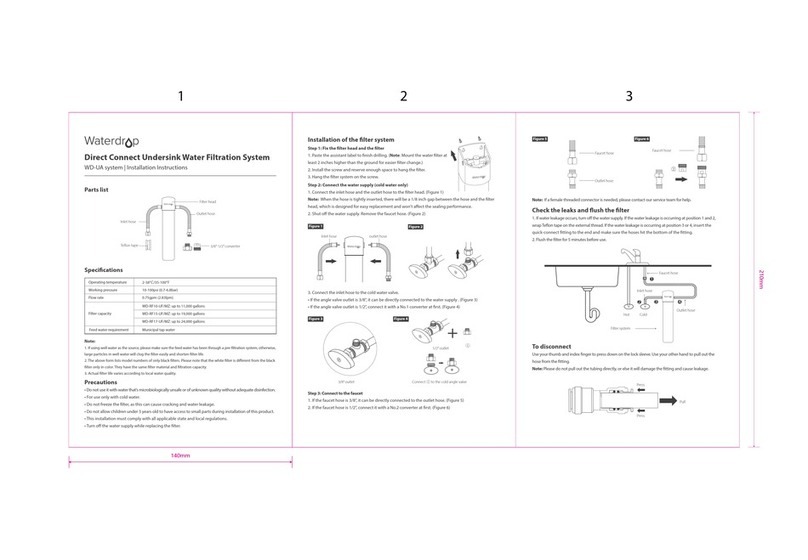

Waterdrop WD-UA system installation instructions

Premier

Premier CT-1 Installation, operation and maintenance manual

US Water Systems

US Water Systems Greenwave Plus 385-GWP-1000-UV owner's manual