SPEED-O-CONTROLS ST 515 User manual

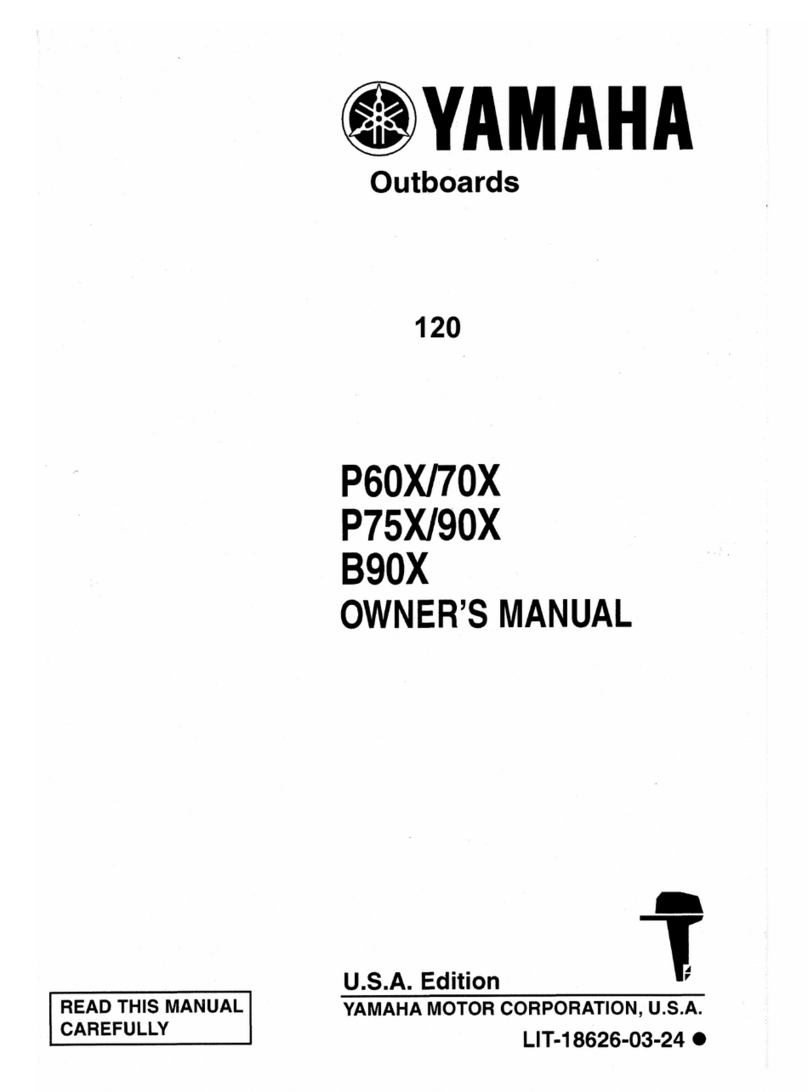

MILL DUTY THRUSTER BRAKES

ELECTRO HYDRAULIC ELECTRO HYDRAULIC

Visit us at :

www.speedocontrols.com

www.socremote.com

H. O. Unit -I : C-15/16, Nand Jyot

Industrial Estate, Andheri-Kurla

Road, Mumbai - 400072 ,

Tel : (022) 42469700/730

E-mail : [email protected]

Unit - II: Plot No. 4912, G. I. D. C.,

Phase IV, Vatva,

Ahmedabad - 382445

Tel.

:

(079) 68169700/702/712

MILL DUTY THRUSTER BRAKES

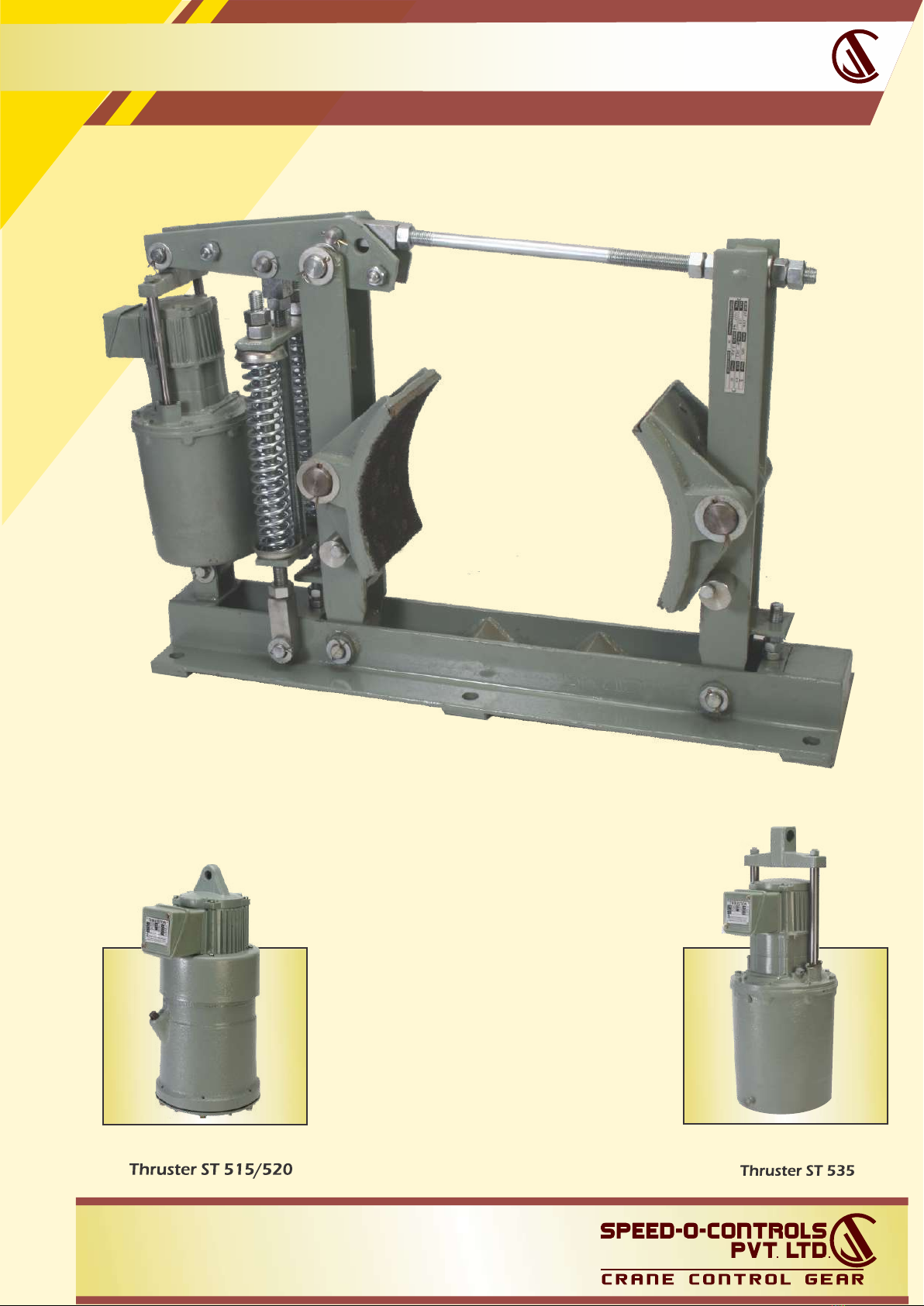

INSTALLING BRAKE IN POSITION

INSTALLING THRUSTER ON BRAKE

1

2

17

8

9

6

7

14

11

12

13

15

17

3

16

4

5

18

5

INTRODUCTION

CONSTRUCTION AND OPERATION

Thruster brake is a device to retard the speed of moving machinery

and to stop it accurately to the desired position. The braking force is

applied to the brake shoes by a pre-streesed compression spring.

The shoe press on the rotating brake drum retarding its speed and

finally stopping it. Other release device like pneumatics /hydraulic

cylinder or manual release arrangements can be offered on request.

To insert the brake in position, the brake shoes are to be

taken apart to clear the drum diameter. To don this,

slacken the spring settling nut and the tie-rod nut in the 14 9

side arm and pull it slightly. This increase the distance between

the brake shoes. Insert the brake on the foundation bolts.

Adjust shoes by setting screws and position them on brake17

drum. Re-tighten the setting bolt and the tie-rod nut.9

Tighten the foundation bolt 18 .

The thruster tank is to be filled with sufficient quantity of oil

as mentioned in the Thruster dimension Table. To mount the

thruster on the brake, remove one side splits pins on the

thruster hinge pins. in the base frame of brake and lever .15 12

Remove both pins and re-insert them after positioning the

thruster on the pin holes in the base and the lever of the base

Replace both split pins. Check that the thruster movement is

unobstructed when the crane lever is pulled manually and

the thrust rod of the thruster is free to move. Open the terminal

box cover of the thruster and connect power supply cables to

the three terminals on the terminal plate inside the terminal box.

Terminate the earthing lead on the earth terminal plate inside

the te rmi nal pr ovi ded on the thruster or br ake .

Replace the terminal box cover on the terminal box.The thruster

is ready for operation.

ALIGNING AND SETTING OF BRAKE

TECHNICAL DATA

Next, align the brake shoes with the diameter and the surface of

the brake drum and adjust the lock nuts 9 on the tie-rod such

that shoes grip the brake drum equally. Energize the power

cables, this will cause the thrust rod of the thruster to move up

and the shoes release th brake drum. Adjust the gap between

the drum and shoes to 0.3 to 0.5mm (with feeler gauge) equally

by adjusting the setting bolts 17 on both arms. For equal and

uniform liner wear it is necessary that the shoes and the arms

move equally. Ensure the brake drum is free to rotate when the

brake is released.

ADJUSTING BRAKING TORQUE

To adjust the braking torque to the desired value, the

pre-loadingof the compression spring is to be done by top 13

nuts on the spring tie rod. To increase torque, turn nut 14

clockwise. For most applications, braking torque of about

150 to 250% of rated torque of the drive motor is sufficient.

Colour RAL 7021

POWDER COATING

Asbestos Free Liner

Lining Wear Indicator

Open Brake Limit Switch

Manual Opening & Locking

System

LAF

OL

LWI

MS

A thruster shoe brake has a pair of shoes which are lined up with1

friction pads 2 the shoes are hinged on main arm and side arm 3 4

of the brake, each of them have hinge pin fitted in the base. Both5

arms are connected to each other on top by a tie rod .A hinge in 6 7

the main arm and the swivel block lock nut in the side arm, and8 9

the other end is fixed on top clevis of the thruster by a hinge pin11

.A brake spring ,is fixed on the main arm and is pre - loaded 12 13

by a locknut on the lever. The pre-tension in this spring decides14

the braking torque The thruster is fitted on the base by a hinge pin.

When the thruster is not energized, the brake shoes are pressed on

the brake drum 16 fitted on the drive motor shaft and is braked

under the effect of braking force provided by spring. In such

condition, the brake is applied, and the drum cannot rotate. When

the thruster motor is energized , the lifting force provided by thruster

lifts up the crank lever causing the arms and the shoe to move

away and the brake is released. The spring is compressed and

braking energy is stored for the next cycle.

OPTIONAL

Visit us at :

www.speedocontrols.com

www.socremote.com

H. O. Unit -I : C-15/16, Nand Jyot

Industrial Estate, Andheri-Kurla

Road, Mumbai - 400072 ,

Tel : (022) 42469700/730

E-mail : [email protected]

Unit - II: Plot No. 4912, G. I. D. C.,

Phase IV, Vatva,

Ahmedabad - 382445

Tel.

:

(079) 68169700/702/712

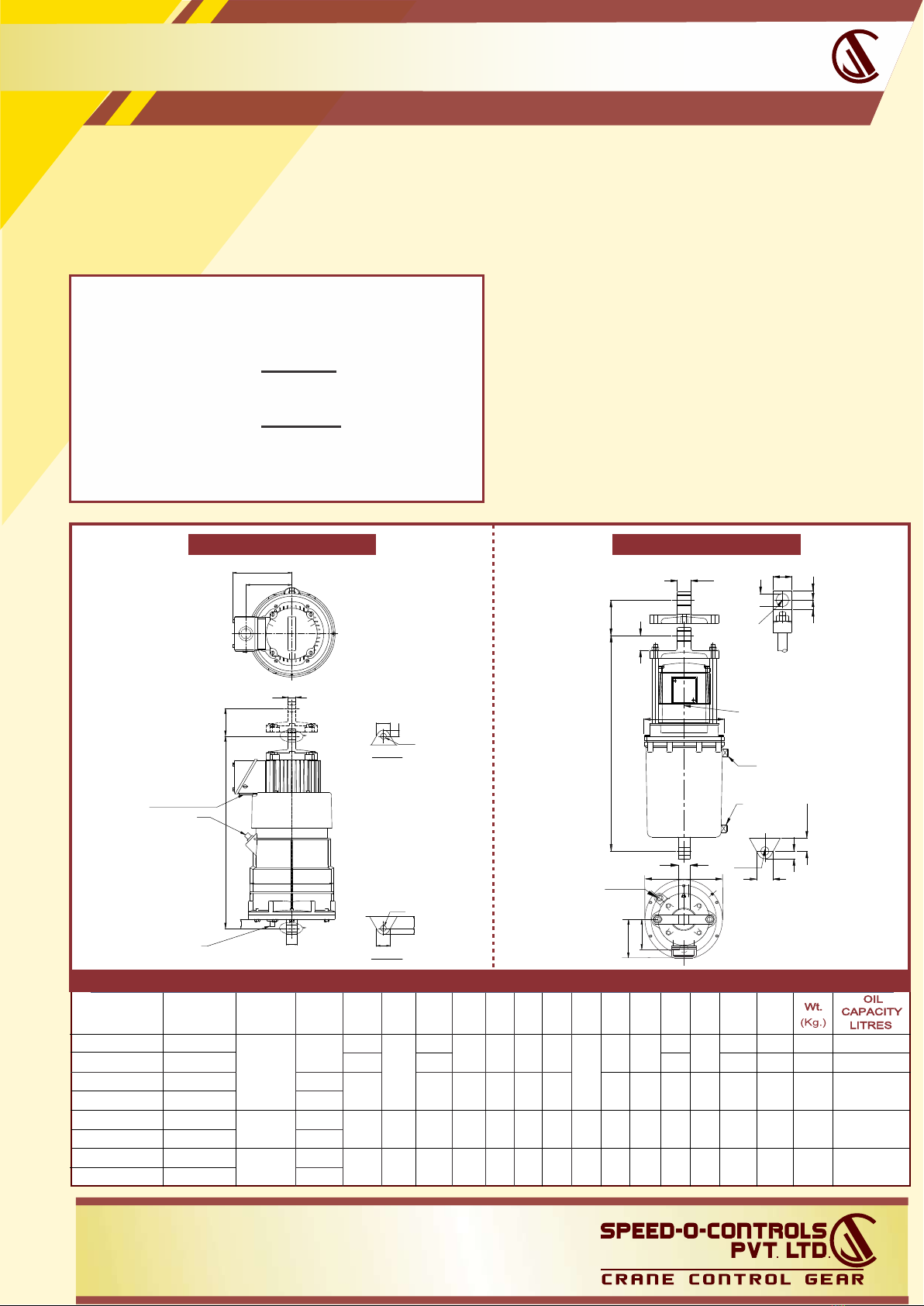

MILL DUTY THRUSTER BRAKES

DIMENSIONS :

DIMENSIONS :

MSHOE

WIDTH

K LJ

7013

7013

130 100

130 100

385

435

433

385

445

108

88

18160

160 125

120 635

580

HhGEA B

350100 125

406100 125

160

235

265

110

145

160

350 146

148

Break Model

MDT - 150 - 15

MDT - 100 - 15

MDT - 160 - 15

563

508170

225

200

320

360

480

450

240

215

MDT - 250 - 18

MDT - 200 - 18

MDT - 150 - 18

MDT - 100 - 18

MDT - 160 - 18

14020205 145 780548250 275480525 270

MDT - 300 - 18

14

360

170

Thruster Brake MDT

( Drum Diameter100 to 250 mm. )

TECHNICAL DATA :

TECHNICAL DATA :

B

QN PC

Mass kg.

(S)

Thruster DetailsBrake Torque

(N)

N-m kg-m Model

Dia. mm

Force

Force

kg.

Brake Model

rake Drum

Stroke

50

150

5

100

606100

150

757.5

MDT - 100 - 15

MDT - 150 - 15

MDT - 100 - 18

MDT - 150 - 18

MDT - 160 - 15

350

200

250 35

20200MDT - 200 - 18

MDT - 250 - 18

90

MDT - 160 - 18 9

160

160

420300 42

MDT - 300 - 18

85

85

280135

349

51

160 110

10515015

ST 515

18018ST 520

14

17

11

12

22

18

30

QP

80

124

124

112

180

180

30

132

95

70

Mass kg.

C

Thruster Details

215

215

174

51

76

76

46

68

68

ST 545

ST 870

ST 870

460

680

680

kg.

Model

Force

(S)

(N)

Force

Stroke

444

508

508

N

190

68

114

ST 870

ST 8110

680

1140

ST 8110 114 1140

Brake Model

42

62

250

300

170

290

190500

400

500

MDT - 250 - 34 - 46

MDT - 400 - 68

MDT - 300 - 34 - 46

MDT - 500 - 68

MDT - 500 - 46

kg-m

Dia. mm

Brake Drum

350

580

600

600MDT - 600 - 114

MDT - 600 - 68

485MDT - 500 - 114 500

Brake Torque

1900

3500

5800

2900

4850

420

1700

620

N-m

27

11044451 174 112

34034

320

32200

ST 535

MDT - 200 - 34 - 46

85

90400MDT - 400 - 34 900

MDT - 400 - 46 110 1100 ST 545 46 460

400

132

ML SHOE

WIDTH

955

640

780

20

18

1130

25

180

108

140

J KHhGF

650

563

600

236

160

205

857 302

310

225

275

65

-

100

377

170

250

150 380 215

180

120

145

1300 240

970 322

475

150 485 235

EA B

Break Model

508

320

480

641

523

542

350

250

285

680800 410

MDT - 250 - 34 - 46

MDT - 300 - 34 - 46

MDT - 400 - 68

MDT - 500 - 68

MDT - 500 - 46

765688 215

MDT - 600 - 114

MDT - 600 - 68

MDT - 500 - 114

88

600540 160 125200180350463 215MDT - 200 - 34 - 46

MDT - 400 - 34

417 200

-

MDT - 400 - 46

682

Visit us at :

www.speedocontrols.com

www.socremote.com

H. O. Unit -I : C-15/16, Nand Jyot

Industrial Estate, Andheri-Kurla

Road, Mumbai - 400072 ,

Tel : (022) 42469700/730

E-mail : [email protected]

Unit - II: Plot No. 4912, G. I. D. C.,

Phase IV, Vatva,

Ahmedabad - 382445

Tel.

:

(079) 68169700/702/712

MILL DUTY THRUSTER BRAKES

Rated supply : 400/440 V / 50 Hz / 3 - Phase.

( Thrusters or other voltages ( up to 600 V ) on request.)

Thrusters should be mounted with in ± 10° from vertical.

Working fluid - Transformer oil to BS 148.

ELECTRO HYDRAULIC THRUSTER - (ST)

*

THRUSTER ST-515 / ST 518 / ST 520

1/8” BSP

OIL LEVEL PLUG

3/4" BSP CONDUIT

1/8" BSP

DRAIN

B

H

1/4" BSP.

ØC

PQ

M

SELECTION OF BRAKE SIZE

Electo-hydraulic thruster is a device which develops

linear thrust (or force) required to operate the required

mechanism. The input to the device is three phase

supply.

Where Hp/Kw = motor output & rpm = Rev/minute

T = Torque in Kgm = 716 x Hp

rpm

Kw

T = Torque in Nm

rpm

The brake torque must be than motor full

load as referred with drum. Formula as below:

=

>

=

Electro-hydraulic thruster is a device which develops

linear thrust (or force) required to operate the

required mechanism. The input to the device is

three phase supply. The thrusters are widely used

to actuate Thruster Shoe Brakes, commonly used

in material handling machines. Thrusters in various

models develop 15 kg to 295 kg. In stroke lengths of

51, 76 and 127 mm.

THRUSTER ST-535 . . . ST-13300

9552 x

TYPE THRUST

kgs.(N) STROKE

MM. WATTS ABCDE F GH J KLM P Q

VIEW ‘A’

2

3

6

12

34

ST 515

ST 520

ST 535

ST 545

ST 870

ST 8110

ST 13200

ST 13300

15 (150)

18 (180)

34 (340)

45 (450)

68 (680)

114 (1140)

225 (2250)

295 (2950)

51

76

127

90

150

180

200

250

420

580

280

349

444

508

660

51

76

127 254

215

174

160

130 19 25 13 12.7 19 16 19 30

32 19 110

105 85 62

25

32

38

54

48

41

22 30

85

95

15 19.7 21 27

25 32 16 22.2 40 24 29

25.4 30 27

19

38

32 45 152 132 55 9.0

5

110 85

110

P

Q

D

B

A

H

M

VIEW ’B’

ØC

JK

L

ØG

E

F

ØG

VIEW ‘A’

VIEW ’B’

A

DE

F

F

ØG

K

J

L

ØG

DRAIN PLUG

1/8” BSP

OIL FILLER

PLUG 1/4” BSP

TAPPED HOLE

3/4” BS CONDUIT

Visit us at :

www.speedocontrols.com

www.socremote.com

H. O. Unit -I : C-15/16, Nand Jyot

Industrial Estate, Andheri-Kurla

Road, Mumbai - 400072 ,

Tel : (022) 42469700/730

E-mail : [email protected]

Unit - II: Plot No. 4912, G. I. D. C.,

Phase IV, Vatva,

Ahmedabad - 382445

Tel.

:

(079) 68169700/702/712

This manual suits for next models

7