7

REFERENCE INFORMATION

EMISSION-RELATED INSTALLATION INSTRUCTIONS

1

EMISSION-RELATED

INSTALLATION

INSTRUCTIONS

Failing to follow these instructions when

installing a certified engine in a vessel violates

federal law (40 CFR 1068.105 (b)), subject to

fines or other penalties as described in the

Clean Air Act.

Maintenance, replacement, or repair of the emis-

sion control devices and systems may be per-

formed by any marine SI (spark ignition) engine

repair establishment or individual.

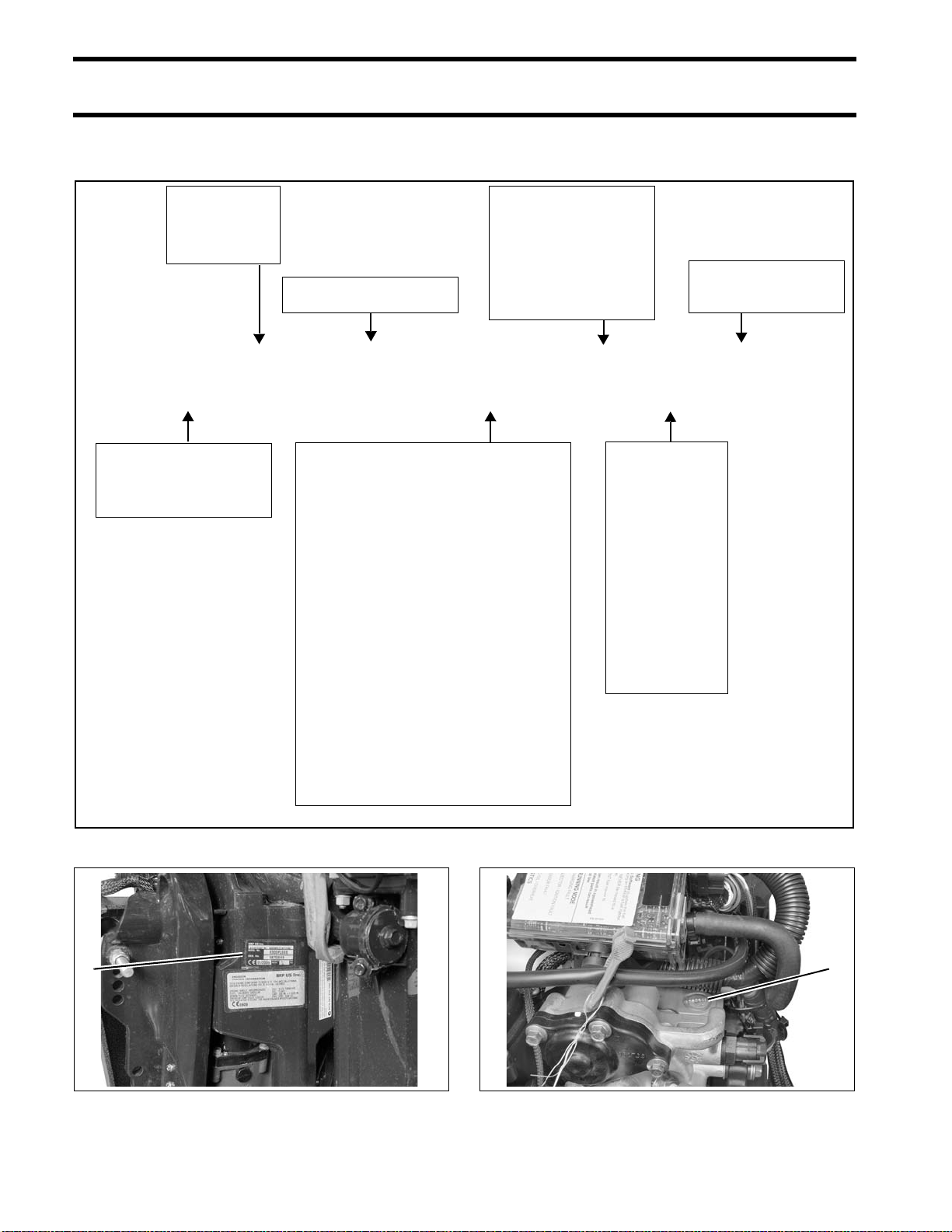

Manufacturer’s Responsibility

Beginning with 1999 model year outboards, man-

ufacturers of marine outboards must determine

the exhaust emission levels for each outboard

horsepower family and certify these outboards

with the United States of America Environmental

Protection Agency (EPA). An emissions control

information label, showing emission levels and

outboard specifications, must be placed on each

outboard at the time of manufacture.

Dealer’s Responsibility

When performing service on all 1999 and more

recent Evinrude/Johnson outboards that carry an

emissions control information label, adjustments

must be kept within published factory specifica-

tions.

Replacement or repair of any emission related

component must be executed in a manner that

maintains emission levels within the prescribed

certification standards.

Dealers are not to modify the outboard in any

manner that would alter the horsepower or allow

emission levels to exceed their predetermined

factory specifications.

Exceptions include manufacturer’s prescribed

changes, such as altitude adjustments, for exam-

ple.

Owner’s Responsibility

The owner/operator is required to have outboard

maintenance performed to maintain emission lev-

els within prescribed certification standards.

The owner/operator is not to, and should not allow

anyone to, modify the outboard in any manner

that would alter the horsepower or allow emis-

sions levels to exceed their predetermined factory

specifications.

Tampering with the fuel system to change horse-

power or modify emission levels beyond factory

settings or specifications will void the product war-

ranty.

EPA Emission Regulations

All new 1999 and more recent Evinrude/Johnson

outboards are certified to the EPA as conforming

to the requirements of the regulations for the con-

trol of air pollution from new watercraft marine

spark ignition outboards. This certification is con-

tingent on certain adjustments being set to factory

standards. For this reason, the factory procedure

for servicing the product must be strictly followed

and, whenever practical, returned to the original

intent of the design. The responsibilities listed

above are general and in no way a complete list-

ing of the rules and regulations pertaining to the

EPA requirements on exhaust emissions for

marine products. For more detailed information on

this subject, you may contact the following loca-

tions:

VIA U.S. POSTAL SERVICE:

Office of Mobile Sources

Engine Programs and Compliance Division

Engine Compliance Programs Group (6403J)

401 M St. NW

Washington, DC 20460

VIA EXPRESS or COURIER MAIL:

Office of Mobile Sources

Engine Programs and Compliance Division

Engine Compliance Programs Group (6403J)

501 3rd St. NW

Washington, DC 20001

EPA INTERNET WEB SITE:

www.epa.gov