Speedway 350-400 User manual

1

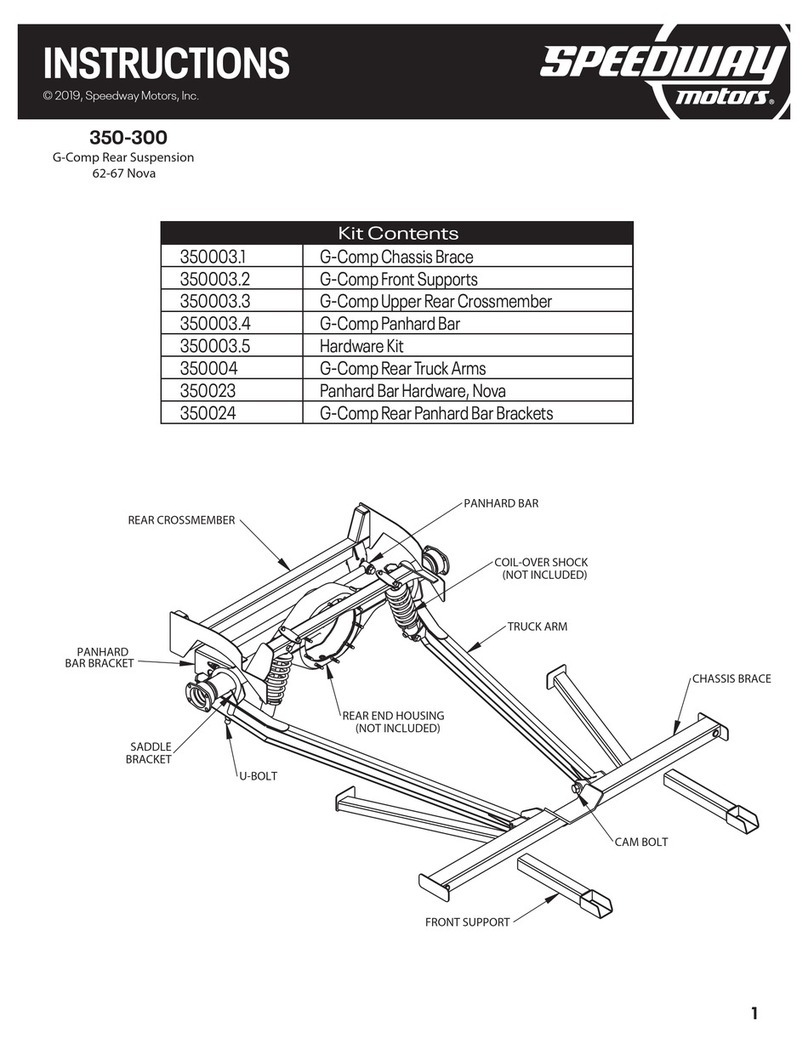

350-400

INSTRUCTIONS

© 2019, Speedway Motors, Inc.

Unser Rear Suspension

62-67 Chevy Nova

350003.1

350003.2

350400.1

350021.1

350009

350029.2

65579031-25.5

65579031-30

350800.4

350029

350402

G-Comp Chassis Brace

G-Comp Front Support

Chevy II Unser Rear Arms (pair)

G-Comp Upper Crossmember

G-Comp 54” Floater Rear Housing

Floater Components

25.5” Double Splined Axle - 31

30” Double Splined Axle - 31

Hardware Kit - Unser Rear

G-Comp Rear Watts Link Package

G-Comp Rear Sway Bar - Nova

Kit Contents

G-COMP TRUCK ARMS - UNSER EDITION

CHASSIS BRACE

FRONT SUPPORT BRACES

ECCENTRIC CAMS

COIL OVERS (NOT INCLUDED)

REAR UPPER CROSSMEMBER

FORD NINE INCH FLOATER

REAR END HOUSING

WATTS LINK PIVOT

WATTS LINK RODS

U-BOLTS

FLOATER

HUBS

SWAY BAR ARMS

2

350-400

INSTRUCTIONS

© 2019, Speedway Motors, Inc.

Unser Rear Suspension

62-67 Chevy Nova

1. Remove Rear Suspension: Raise the car and support it with jack stands or a lift. Remove the exhaust,

drive shaft, rear end, and all rear suspension components including the rubber bump stops. Disconnect

fuel lines and remove fuel tank. Remove fuel lines, brake lines, and E-brake cables from bottom of car.

These can be re-routed through the holes in the chassis brace after installation.

2. Prep for Welding by raising the chassis brace into its approximate position and mark all areas that will

be welded. These areas should be ground down to bare metal to provide the proper conditions for

welding. (Any carpet or padding installed on back side of weld areas should be removed at this time.) To

position the chassis brace, the rear flanges of the chassis brace should be clamped tight against the leaf

spring boxes while the chassis brace is pushed up against the bottom of the car and centered left to right.

5/16-18 X 3/4" BOLTS

(THREAD INTO FACTORY SHOCK BOLT HOLES)

CLAMP THESE FLANGES TIGHT

AGAINST THE FRONTLEAF SPRING BOXES

TO LOCATE THE CROSSMEMBER.

SLIP OVER FACTORY FLOOR SUPPORTS

FRONT SUPPORT TUBES SHOULD FIT TIGHT

AGAINST CROSSMEMBER FOR WELDING

FIT BETWEEN ROCKERS

FIT BETWEEN FRAME RAILS

3. Repeat step two with the rear cross member and front supports. Depending on the car, minor

trimming/fitting may be required. Bolt the upper rear crossmember to the car using the four supplied

5/16”-18 x 3/4” bolts. These bolts will go into the factory shock bolt holes. This will locate the

crossmember in the proper location.

3

350-400

INSTRUCTIONS

© 2019, Speedway Motors, Inc.

Unser Rear Suspension

62-67 Chevy Nova

4. Tack-Weld Crossmembers: Once all areas that will be welded are prepped and cleaned, then the

cross member, chassis brace, and front supports can be tack welded into place. (Some grinding and

trimming may be necessary to provide proper fit up.) Note: Do not fully weld the crossmembers at

this time! Only weld enough to securely hold the parts in place during mock up. Hint: Weld in places

that can be easily accessed with a grinder in case it becomes necessary to move or adjust the parts.

5. Assemble Truck Arms and Rear End Housing: Install the truck arms onto the front cross member

using the supplied 3/4"-16 X 5-1/2” cam bolts and spacers. Note: Install the cam bolts in the center

of adjustment as shown. The flat side of the bolt should be facing upwards. Tighten the nut until it just

touches the cam spacer, but do not fully tighten it yet.

Raise the rear end housing into its approximate location.

Using the supplied U-bolts and nuts, attach the

truck arms to the rear end housing. The U-bolts

only need to be snug at this time. There is no

need to fully tighten them yet. With the rear

end housing connected to the truck arms,

and raised up to ride height, you can now

tighten the cam bolts.

6. Install the Watts Link Pivot: Once the truck arms have been connected to the rear end housing, it’s

time to mock up the watts link. Start by installing the center pivot to the rear end housing. Use the

supplied 3/4-16 x 3” bolt and washer to attach the pivot to the housing as shown. For initial mock up,

use the second hole from the top on the rear end housing.

3/4-16 X 3" BOLT

3/4" WASHER

5/8-18 X 5" BOLT

5/8-18 X 4 1/2" BOLT

5/8-18 THIN

LOCK NUT

5/8-18 THIN

LOCK NUT

(2X) 5/8-18 X 1 3/4"

BOLT

(2X) 5/8-18 THIN

LOCK NUT

4

350-400

INSTRUCTIONS

© 2019, Speedway Motors, Inc.

Unser Rear Suspension

62-67 Chevy Nova

7. Install the Link Rods: Start by assembling the link rods. Install the lower/drivers side link rod first. Install

one end of the link into the lower location on the pivot using the 5/8-18 x 1 3/4" bolt and lock nut.

Install the other end of the link to the chassis. Use the center hole location and a 5/8-18 x 4-1/2” bolt

and lock nut. Once the link is installed, adjust the length of the link by spinning the tube until the pivot is

at a 90° angle with the ground. Note: The link should be level with the ground at this time. The rear end

housing may need to be raised or lowered to achieve this. Once the link is level with the ground, and the

pivot is at a 90° angle, the jam nuts can be tightened. With the first link installed, it is now time to install

the upper/passenger side link. Start by using the 5/8-18 x 1 3/4" bolt and lock nut to connect one

end of the link to the center pivot. Now, hold the link up in its approximate position and adjust the link

until the outer rod end lines up with the center hole location on the chassis. Use the 5/8-18 x 5” bolt

and lock nut to connect the link to the chassis. Now you can tighten the jam nuts on this link. Be sure to

keep the rod ends adjusted evenly on either side of the tube. Note: The center pivot bolts must be installed

as shown, with the nut towards the rear of the car. Installing them in the other direction may result in

interference between the bolt and the rear end housing. With the links adjusted properly and the rear end

at ride height, both links should be parallel to the ground and the pivot should be at a 90° angle.

8. Check Alignment and Clearances: On most cars, a portion of the trunk floor will need to be raised to clear

the center pivot and upper link at full compression. The affected area is the passenger side trunk floor just

in front of the fuel tank (shown below). Note: It is a good idea to leave room to clear the pivot and link rod

even in the upper most position.

Cycle the suspension

completely though its

travel and check for

any clearance issues

with the truck, floor,

etc…

24"

4"

RAISED TRUNK FLOOR

TOP VIEW OF REAR CROSSMEMBER

TOWARDS FRONT OF CAR

9. Weld: If there are no clearance issues, it is time to fully weld in the crossmembers. Start by removing

the rear end, watts link, and truck arms from the car. Take note which link rod goes on which side. Fully

weld the cross member, chassis brace, and front supports to the car. Note: It is a good idea to only weld a

small bead at a time, then move to a new area and allow the first area to cool completely before welding

further in that area. This will greatly reduce the risk of warping.

5

350-400

INSTRUCTIONS

© 2019, Speedway Motors, Inc.

Unser Rear Suspension

62-67 Chevy Nova

10. Final-Assembly: Once all of the welding is complete, the suspension can be assembled.

11. Now is a good time to fully assemble the rear end by installing gears, hubs, axles, and brakes.

Note: This can also be done after installing the housing into the car. Assemble the hub as shown below.

Be sure to pack the wheel bearings with high quality grease. Do not over torque the axle nut! The hub

should spin freely with zero endplay. To achieve this, assemble the hub as shown. Tighten the axle nut

and spin the hub a dozen or so rotations. Now back

the axle nut off 2 full turns. Then tighten the

axle nut until it just starts to get snug. At

this point the hub should spin freely

with little to no resistance, and

there should be no

endplay in the

bearing. Bend

the tab on the

lock ring into the

groove on the axle nut. This

will prevent the axle

nut from loosening.

HUB

OUTER WHEEL BEARING RACE

OUTER WHEEL BEARING

AXLE NUT RETAINING RING

AXLE NUT

DRIVE FLANGE SEAL

DUST CAP SEAL

DRIVE FLANGE BOLTS (2X)

DUST CAP

DUST CAP BOLTS

INNER WHEEL BEARING RACE

INNER WHEEL BEARING

HUB SEAL

HUB SEAL RETAINING RING

INNER AXLE SEAL

AXLE TUBE

DRIVE FLANGE

12. Secure the truck arms to the chassis brace using the cam bolts and cam spacers as shown in step 5.

13. Raise the complete rear end into position. Attach the rear end to the truck arms using the supplied

u-bolts, washers, and nuts.

14. Install the Watts link center pivot as described in step 6.

6

350-400

INSTRUCTIONS

© 2019, Speedway Motors, Inc.

Unser Rear Suspension

62-67 Chevy Nova

15. Install the link rods back into their previous locations and tighten.

16. Install the sway bar as shown. Press the sway bar bushings into the sway bar housing on the

crossmember by lightly tapping them into place with a rubber mallet (be sure the bushings are going

in straight). With the bushings in place, slide the sway bar into the housing. Slide one of the torsion

arms onto the splined portion of the sway bar so it sits flush with the end of the bar. Install the

5/16-24 x 2” bolt and lock nut onto the arm and tighten. Install one of the male rod ends onto the

outside of the arm using a 3/8-16 x 1-1/4" bolt. Now thread the jam nut and female rod end onto the

male rod end leaving roughly 1/4” of threads showing. Attach the female rod end to the rearend

housing using 3/8-24 x 1-1/4" bolt and lock nut. Assemble the opposite side in the same manner. The

arms will need to be “clocked” about 45° relative to one another, with the passenger

side at a downward slope and the driver side at an upward slope. Note: Once

the vehicle is fully assembled and sitting on level ground, it is a good

idea to disconnect one side of the sway bar links

and adjust the length of the rod ends until

there is no pre-load and the holes line

up perfectly.

SWAY BAR HOUSING

SWAY BAR BUSHING

SWAY BAR

SWAY BAR ARM

5/16-24 LOCK NUT

MALE ROD END

3/8-16 X 1-1/4"

FEMALE ROD END

3/8-24 JAM NUT

5/16-24 X 2"

BOLT

3/8-24 X 1 1/4" BOLT

3/8-24 LOCK NUT

1 7. Install the brakes as per the instructions included with your brake kit. Note: For recommended part

numbers please visit our website or contact one of our tech experts.

7

350-400

INSTRUCTIONS

© 2019, Speedway Motors, Inc.

Unser Rear Suspension

62-67 Chevy Nova

1/2"-20 X 2-1/4"

BOLT

1/2"-20 LOCK NUT

1/2"-20 X 3"

BOLT

1/2"-20

LOCK NUT

(2X) 5/16" WIDE SPACER

(2X) 7/16"-20

LOCK NUT

(2X) 7/16"-20 X 1-1/4"

BOLTS

COIL-OVER SHOCK

(NOT INCLUDED)

SHOCK MOUNT

ON TRUCK ARM

18. Install the coil-over shocks. The

Unser Edition G-Comp rear

suspension features an adjustable

lower shock mount. To install the

shock, first use the two 7/16”-20 x 1 -1/4”

bolts and lock nuts to install the shock

brackets to the shock mount on the truck

arm. Then use a 1/2”-20 x 2-1/4” bolt and

lock nut to secure the lower end of the

shock to the truck arm as shown. The

remaining 1/2”-20 x 3” bolts and lock

nuts are used along with two 5/16” spacers

to install the top of the shocks into the

rear crossmember. Note: This kit is

designed to use 4” stroke shocks with

a compressed length of 10”-11” and an

extended length of 14”-15”. Shock ends

should be 1/2” bearings with a mounting

width of 1”. For recommended part numbers,

please visit our website or contact one of our

tech experts.

19. Re-install the drive shaft, fuel tank, fuel lines, brake lines, exhaust, etc... Bleed the brakes. Fill the rear

end with fluid. Install wheels and tires.

20. Alignment:

Lower the car onto the ground and check for desired ride height. Adjust ride height if necessary by raising

the car and spinning the adjusting collar on the coil-over. Once the ride height has been set, lower the car

onto the ground and make sure the rear end is centered in the car body. Adjust the watts link rods if

necessary. For optimum handling and performance, both rods should be parallel with the ground and

the center pivot should be at a 90° angle. This kit provides multiple mounting locations for the watts link

to allow for different ride heights. Now that the ride height is set and the rear end is centered perfectly in

the car, the rear end can be aligned by adjusting the cam bolts on the front of the truck arms. Note: This is

difficult to do accurately and a professional alignment is recommended. This method will get you close

enough to drive the car to an alignment shop.

SpeedwayMotors.com/Info/FAQ

DISCLAIMER In an effort to offer our customers low prices, quick service

and great value, Speedway Motors reserves the right to change suppliers,

specifications, colors, prices, materials without notice. Prices and policies that

were current and in effect at the time of printing are also subject to change

without notice. Quantities are limited on some items. Any unauthorized use of

this catalog including words, photos or drawings is prohibited. Speedway is not

responsible for any typographical errors, printing errors or misinterpretations

WARRANTY DISCLAIMER Purchasers understand and recognize that racing

parts, specialized street rod equipment, and all other parts and services sold

by Speedway Motors, Inc. are exposed to many and varied conditions due

to the manner in which they are installed and used. Except for certain limited

warranties, if any, set forth in Speedway Motors, Inc.’s current catalog with

respect to the products and/or parts thereof identified on your invoice, each

product,andeachpartthereof,issold“asis”,and“withallfaults”andSpeedway

Motors, Inc. makes no warranties either expressed or implied, writtenor

oral, with regard such products and services including, without limitation,

any warranty of merchantability or fitness for a particular purpose. Without

limiting the foregoing, there is no warranty expressed or implied as to whether

the goods sold hereby will protect purchasers or ultimate end-users of such

products and parts from injury or death. In no event shall Speedway Motors,

Inc. be liable for any special, incidental or consequential damages, or any other

damages whatsoever arising out of or connected with the use or misuse of the

products and each part thereof. Purchasers acknowledge and agree that no

person, entity or agent of Speedway Motors, Inc. has any authority to make

any statement contrary to this disclaimer and that any warranty statements

or representations allegedly made on behalf of Speedway Motors, Inc. by any

such person, entity or agent are void. Purchasers are relying solely on their own

skill and judgment to select, purchase and use suitable products and assume

all responsibility and risk with regard thereto. Some local laws prohibit the use

of utility jugs, funnels and barrel pumps for dispensing fuel. Please check your

own state for more information, regulations or further direction in your use of

the utility jugs, funnels and barrel pump described in Speedway’s catalogs or

on Speedway Motors websites. Some parts in this catalog are not legal for sale

or use in California. Items sold in this catalog are for racing vehicles which may

never be used on a highway. The use of manufacturer’s names and symbols

are for reference purposes only.

DAMAGE CLAIMSPlease inspect all packages upon delivery and in the

presence of the delivery driver when possible. The driver must note any visible

damage and provide procedures for handling damage claims. To allow for a

claims process, please retain original box, packing material and damaged

merchandise. Contact Speedway Motors for instructions regarding damage

claim within 5 days of receipt. Speedway Motors assumes no liability after

this period.

SHORTAGES Please check the contents of your delivery to ensure that all

parts ordered are received. Refer to your invoice to cross check all items

received and inspect all packing materials for contents of small items. Retain

original shipping box and packing materials. Orders may be split into multiple

boxes which can be delivered on different days. Contact Speedway Motors

for instructions regarding shortage claim within 5 days of receipt. Speedway

Motors assumes no liability after this 5 day period.

REFUSALS All refused packages will be billed the freight to and from the

destination and refused COD orders will be billed a 15% restocking charge plus

freight to and from destination.

WARRANTY CLAIMS If the item is used or installed and a warranty claim

request is submitted, warranty work is done by the manufacturer and may

take up to 30 days for processing. Speedway Motors will be required to

follow the manufacturer’s warranty instructions to allow for a credit refund or

exchange when specified.

RETURNS We want you to be satisfied with your purchase. If you are not

satisfied, you may return your new, unused item within 60 days for refund or

exchange.

All exchanged or returned merchandise must be in original factory condition

with no modifications or alterations. Returned merchandise must include

original packaging materials, warranty cards, manuals, instructions, etc. If the

returned item requires repackaging, your refund / exchange will be subject

to a repackaging charge.Return/Exchange transactions less than $99 are

excluded from the free shipping offer.

HOW TO RETURN AN ITEM Please re-pack the item in a sturdy box, include

a copy of your invoice and completed return form. Returns must be shipped

prepaid. CODs are not accepted. Shipping costs for exchanged merchandise

will be charged to your credit card.

Items that are returned after 60 days are subject to a 15% restocking charges.

Fiberglass items returned will be subject to a 15% restocking charge. We are

unable to accept returns on electrical parts, video tapes, DVD’s, books, special

order or closeout merchandise.

BRAKE INSTALLATION ALERT The selection and installation of brake

components should only be done by personnel experienced in the proper

installation and operation of braking systems. The installer must use his/

her own discretion to determine the suitability of all brake components

and brake kits for every particular application. Speedway Motors, Inc.

makes no warranties either expressed or implied including any warranty of

merchantability or fitness for a particular purpose, other than those contained

in its current catalog or website with respect to the goods identified on the

face of the invoice. There is no warranty expressed or implied as to whether

the goods sold hereby will protect the purchaser or ultimate user of such

goods from injury of death.

EXHAUST INSTALLATION ALERTExhaust systems and other component

surface finishes are not permanent. Coatings, paint and other factory supplied

cosmetic treatments are only intended to protect from surface corrosion in

an unused state. No returns are allowed after the parts have been installed.

Header flanges must be clean and clear of paint and surface contaminants

prior to mating to exhaust gaskets. Exhaust fasteners must be re-torqued

after the initial heat cycle and regularly thereafter to ensure a proper gasket

seal is maintained. Should you decide to install this exhaust product at your

home, be warned that pleasure car or light duty truck/van “bumper” jacks

are intended for emergency use only. The use of frame contact jack stands

in conjunction with a floor jack as a main support is highly recommended to

minimize accidental dropping of a vehicle while the installation proceeds. We

recommend the use of a shop hoist if possible. Please use caution! Speedway

Motors, Inc. makes no warranties either expressed or implied including any

warranty of merchantability or fitness for a particular purpose, other than

those contain in its current catalog or website with respect to the goods

identified on the face of the invoice. There is no warranty expressed or implied

as to whether the goods sold hereby will protect the purchaser or ultimate user

of such goods from injury or death.

CHECK LOCAL LAW Some parts are not legal for sale or use in California on

any pollution controlled motor vehicles. These items are legal in California for

racing vehicles only which may never be used upon a highway. Check local

law.

Speedway Motors, Inc.

P.O. Box 81906 • Lincoln, NE 68501

800.979.0122 • SpeedwayMotors.com

Find the above info on our website:

© 2019, Speedway Motors, Inc.

IMPORTANT

Other Speedway Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

TrailFX

TrailFX A1545S quick start guide

Safe Fleet

Safe Fleet Rear View Safety RVS-918718 instruction manual

Metra Electronics

Metra Electronics 99-8223 installation instructions

Safe Fleet

Safe Fleet Prime Design AR1413 manual

TAUBENREUTHER

TAUBENREUTHER 2351-02 manual

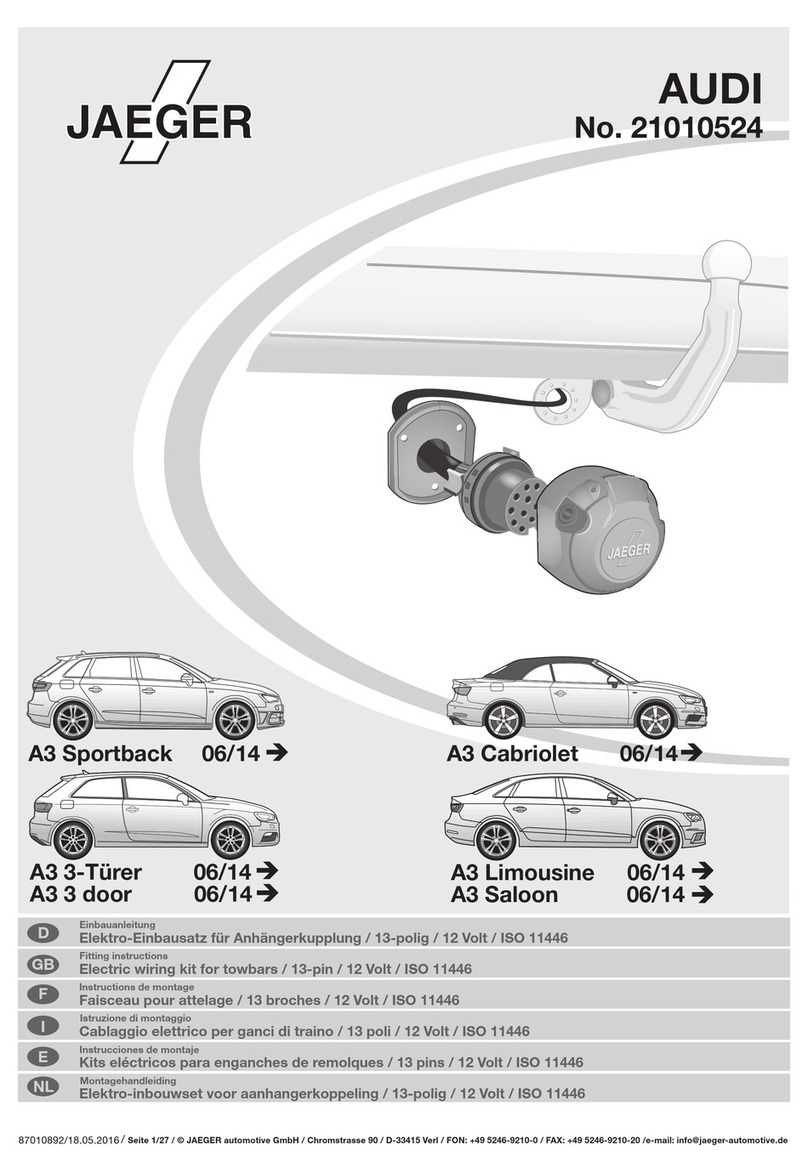

Jaeger

Jaeger 21010524 Fitting instructions