Speedway G-Comp 350-500 User manual

1

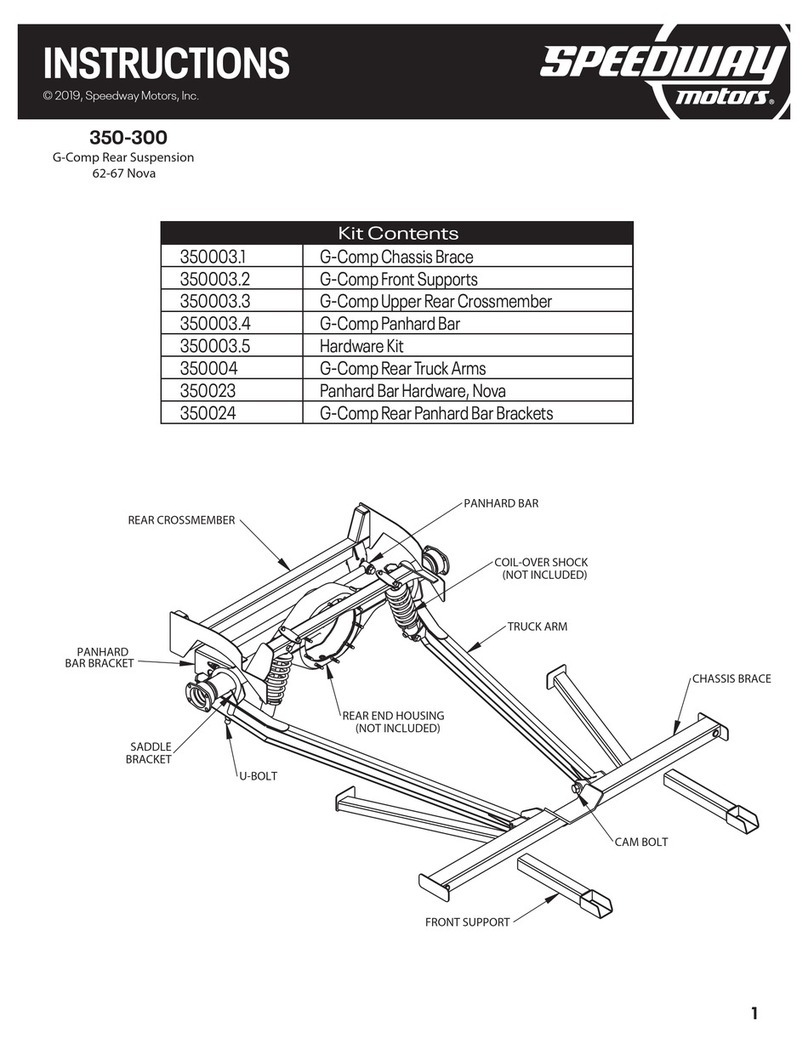

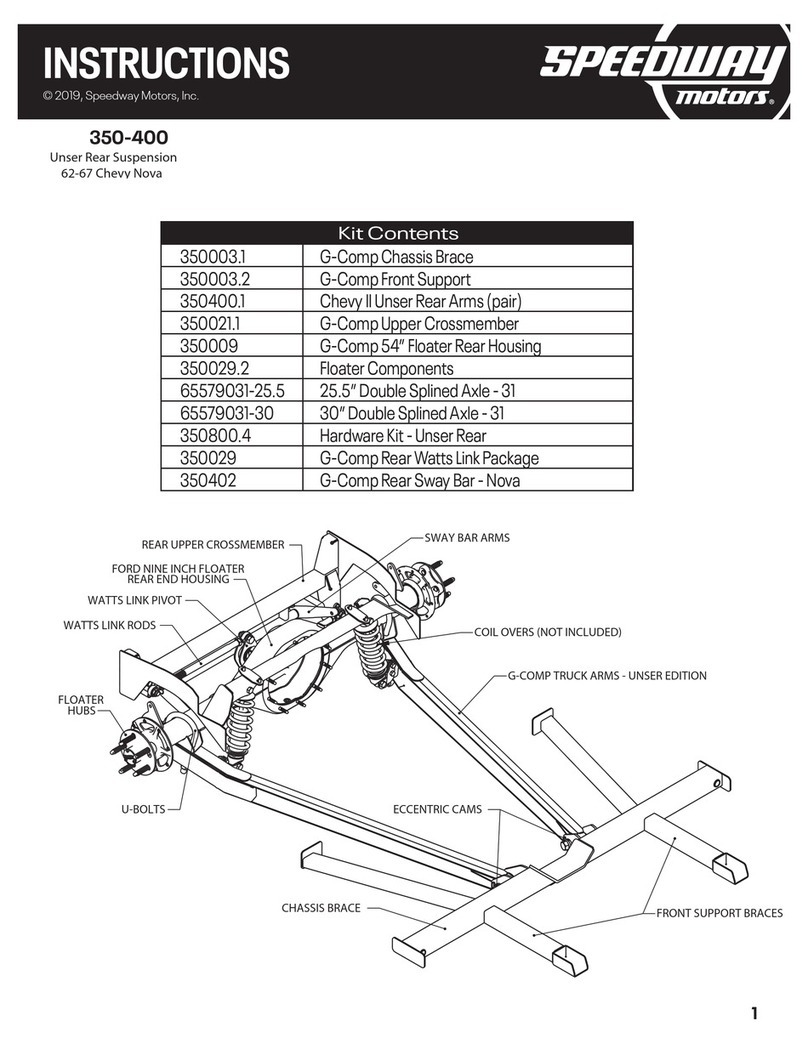

350-500

70-81 Chevy Camaro

G-Comp Front Suspension

INSTRUCTIONS

© 2019, Speedway Motors, Inc.

Kit Contents:

350-100.2

350-500.1

350-500.2

350-500.3

350-503

910-35000

910-35010

910-35341

910-35500

910-35600

G-Comp Camber Shim Kit

G-Comp Subframe, Camaro

G-Comp Sway Bar Kit, Camaro

Hardware Kit, G-Comp Camaro

G-Comp 34'' Sway Bar

G-Comp Spindles

G-Comp Steering Arms

T-Bird Power Steering Rack

G-Comp Upper Control Arms

G-Comp Lower Control Arms

1. Support the car on jack stands or hoist. The front

stands must be located on the main floor just behind

the firewall. Do not support the car on the front sub-

frame.

2. Remove the hood and inner fenders. Remove the

radiator, front bumper, fenders, and core support.

Disconnect all electrical components from the firewall

forward. Retain all hardware to be used during re-

assembly. Remove the engine, transmission, and

accessories. Support the subframe with a floor jack.

Unbolt the subframe from the body and lower it down

until the weight is supported by the front tires. The sub-

frame can now be rolled out of the way.

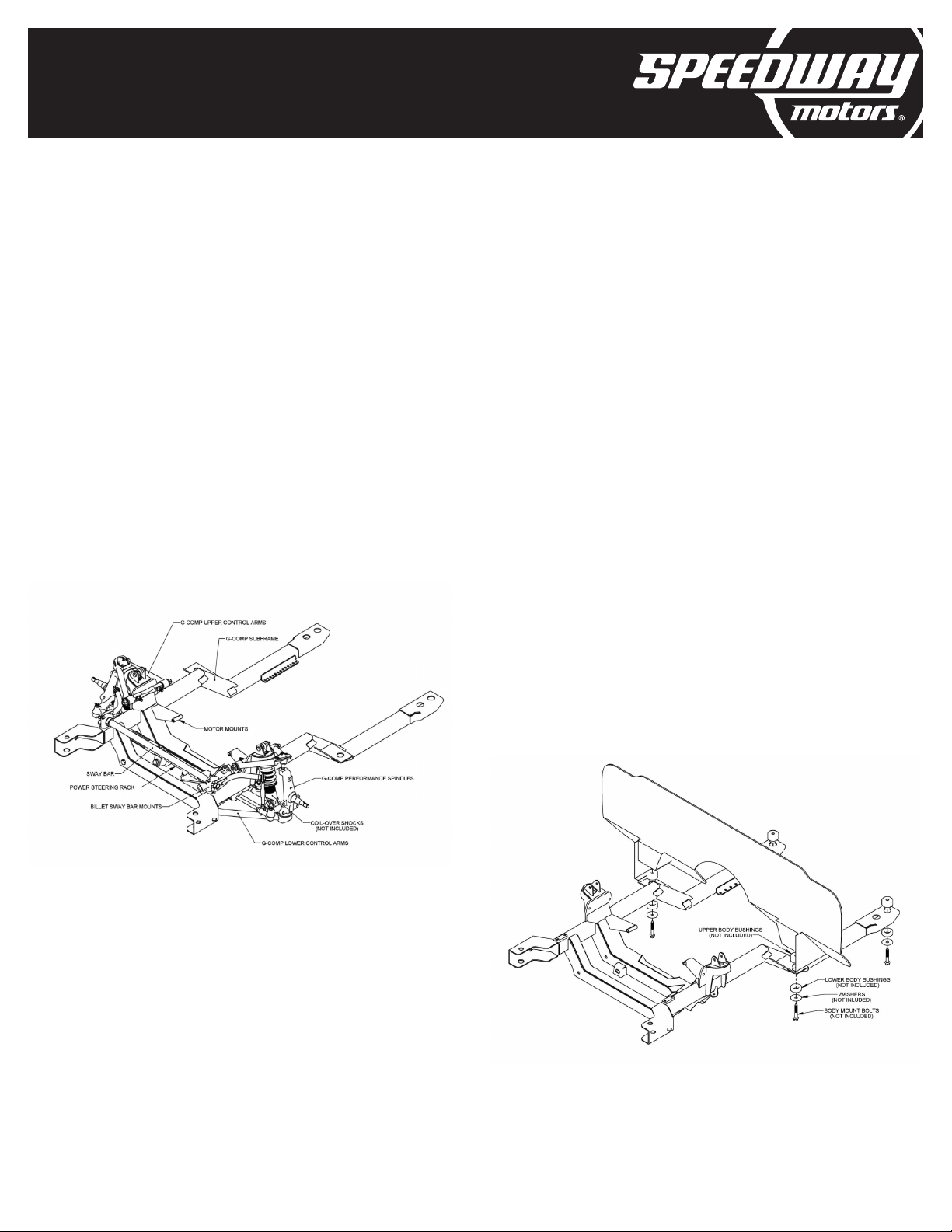

3. Install the G-Comp subframe. Now is a good time

to replace your old worn out body mount bushings.

Place the new upper bushing halves into their locations

on the subframe. The rear portion of the subframe

includes body mount locations for both early and later

style Camaros. Be sure to install the bushings into the

appropriate locations for your car. Using a floor jack,

raise the new G-Comp sub-frame into position while

lining up the holes in the sub-frame with the body.

Install new or re-use your OEM body mount bolts along

with the lower body mount bushings and washers.

Note: Start all of the body bolts before tightening

any of them completely. Once all of the bolts have

been started, make sure the subframe is aligned with

the car, and tighten the bolts. With the subframe in

place, you can now move the jack stands to the front

crossmember. This will make the vehicle more stable

while installing the rest of the kit.

2

350-500

70-81 Chevy Camaro

G-Comp Front Suspension

INSTRUCTIONS

© 2019, Speedway Motors, Inc.

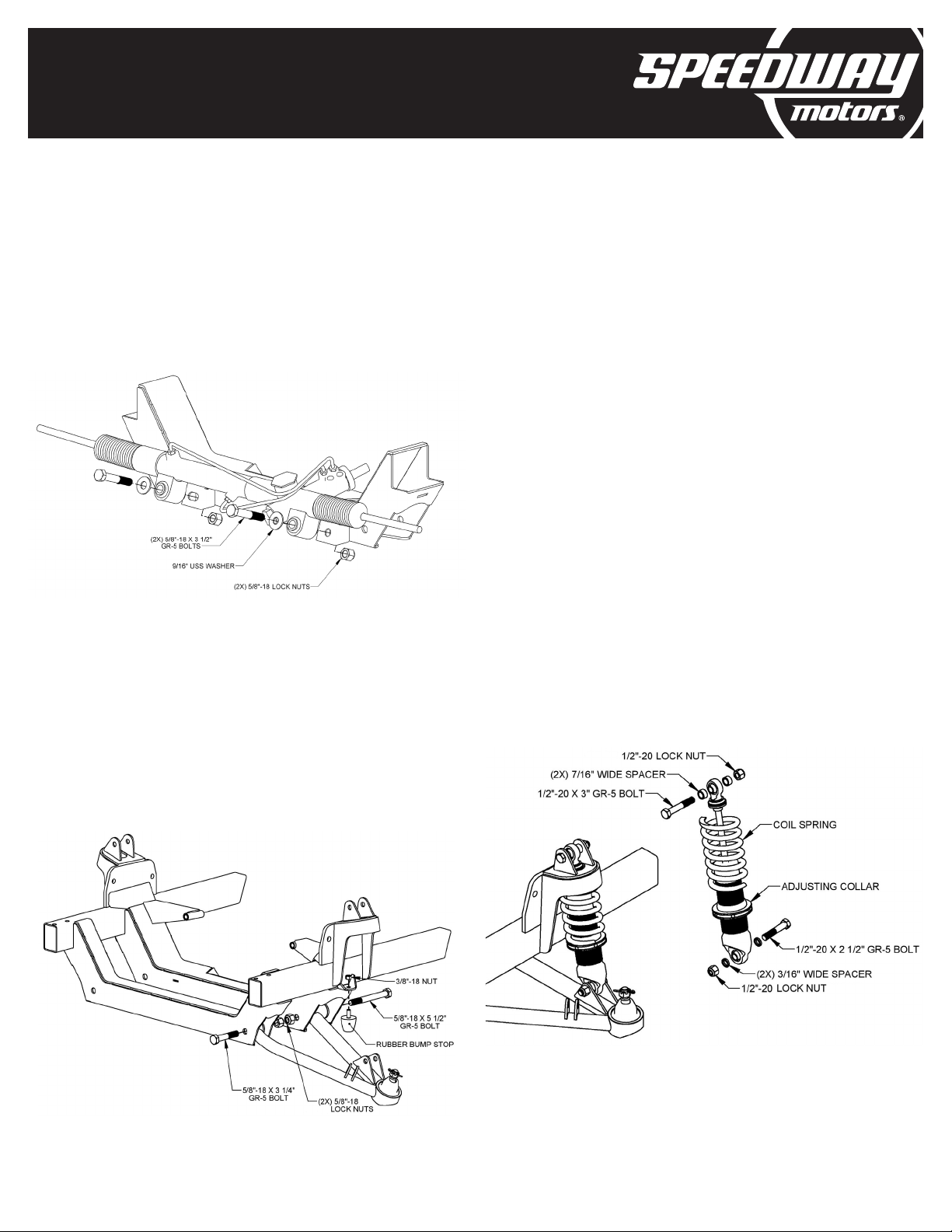

4. Steering Rack. This G-comp front suspension kit

is designed to use a thunderbird style power steering

rack. Install the steering rack as shown, using the two

5/8”-18 x 3 ½” grade 5 bolts and lock nuts. Torque to

65 ft lbs

5. Install the lower control arms into the cross

member. Align the control arm bushings with the lower

control arm holes in the cross-member. The front bolts,

5/8”-18 x 3-1/4” Grade 5, are to be installed from the

front side. The rear bolts are 5/8”-18 x 5-1/2” Grade

5, are to be installed from the rear. Install the 5/8”-

18 lock nuts and torque to 100 ft-lbs. Install the lower

control arm bumps stops to the sub-frame using the

supplied 3/8” nuts as shown.

6. Install the shocks. This procedure may vary slightly

depending on the shocks used. Spin the adjusting

collar onto the threaded shock body. Adjust the collar

all the way to the bottom of the threads. Install the

spring over the shock body. NOTE: The G-Comp

sub-frame has the upper spring retainer built into the

sub-frame so the upper coil-over shock spring retainer

is not used. Using the 1/2”-20 x 2-1/2” Grade 5 bolt and

two 3/16” wide spacers, install the shock into the lower

mount on the control arm. Secure it with a 1/2”-20

Grade 5 lock nut. Fully extend the shock and raise the

lower arm so the upper shock mount and spring align

with the shock mount and spring pocket on the sub-

frame. Install the 1/2”- 20 x 3” Grade 5 upper shock

bolts and 7/16” wide spacers. Secure it with a 1/2”-20

Grade 5 lock nut. Torque to 65 ft-lbs. Note: This kit

is designed to use shocks with a compressed length

of 10” and an extended length of 14”. Shock ends

should be ½” bearings with a mounting width of 1”. For

recommended part numbers please visit our website

or contact one of our tech experts.

3

350-500

70-81 Chevy Camaro

G-Comp Front Suspension

INSTRUCTIONS

© 2019, Speedway Motors, Inc.

7. Mount the upper control arms to the sub-frame

using the 1/2”-20 x 3” grade 8 bolts and lock nuts.

Rotate the cross shafts so the caster shim pockets are

facing toward the center of the vehicle. Install the bolts

through the caster shims, cross shafts, and the sub-

frame as shown. Then secure with the

1/2”-20 Grade 5 lock nuts. Torque to 72 ft-lbs.

8. Install the spindles and steering arms. Place the ball

joint boots over the ball joints and install the spindle

onto the lower ball joint. Install and tighten the supplied

castle nut. Repeat with the upper ball joints and install

the cotter pins. Bolt the steering arms to the spindles

using the 1/2”-20 x 1-3/4” Grade 8 bolts. NOTE: Make

sure to use Loctite on the threads and torque to 100

ft-lbs.

9. Install the outer tie rod ends and jam nuts onto the

inner tie rods of the rack. Thread both tie rod ends on

equally. Attach the tie rod ends to the steering arms

using the castle nuts supplied with the tie rod ends.

Tighten and install the cotter pins. Final alignment to be

done at a later time.

10. Sway bar assembly: Press the bushings into the

aluminum pillow-blocks and install the pillow-blocks

to the front crossmember with the bushing shoulder

to the inside. Use the four 3/8”-16 x 2-1/4” Grade 8

socket head cap screws to secure the pillow block to

the subframe. Before fully tightening the bolts, slide

the sway bar through the bushings, installing the

two clamp collars to the inside of both pillow blocks.

Now, torque the 3/8” socket cap screws to 42 ft-lbs.

Center the sway bar between the pillow blocks. Slide

one clamp collar up against the bushing shoulder in

the pillow block and tighten the set screw. Slide the

second clamp collar up to the opposite bushing in

the pillow block leaving about .075” of side clearance

between the clamp collar and the bushing. Tighten the

set screw. NOTE: A nickel is about .075” thick and can

be used as a spacer between the clamp collar and the

bushing to provide the proper side clearance. Slide

the sway bar arms onto the splined ends of the sway

bar aligning them flush with the end of the bar. Make

4

350-500

70-81 Chevy Camaro

G-Comp Front Suspension

INSTRUCTIONS

© 2019, Speedway Motors, Inc.

sure they are parallel or “clocked” to one another then

tighten the 3/8”-24 x 2-1/2” pinch bolts and lock nuts.

Assemble the sway bar links as shown, leaving roughly

¼” of threads showing on either heim joint. Use the

1/2”-20 x 1-1/4” grade 5 bolts to secure the sway bar

link to the sway bar arm. Mount one of the lower links

into the bracket on the lower control arm using a 1/2”-

20 x 2-1/4” grade 5 bolt and secure it with the 1/2”-20

lock nut. Leave the bolt out of the lower link on one

side at this time. The second bolt/nut will be installed

after the ride height is set and the car is setting on level

ground. This will ensure that there is no preload on the

sway bar at ride height.

11. Install the brake kit to the spindle per the

instructions included with your brake kit. Note: For

recommended part numbers please visit our website

or contact one of our tech experts.

12. Align the subframe: Before installing the front

sheet metal, you must first make sure the subframe is

aligned with the body. Start by setting the toe to zero

and making sure the tires are perfectly straight. Note:

this is easily accomplished with the tires removed and

a 2’-3’ long piece of angle iron clamped to the brake

rotor. Measure the distance between two pieces, both

in the front, and in the rear. Adjust the tie rod length

until the distance is the same. Now measure the wheel

base on both sides of the car. If they are different,

you must loosen the body bolts and slightly adjust the

subframe as needed.

13. Install the engine and transmission. The G-Comp

sub-frame was designed to use stock type GM motor

mounts (910-18012) or Speedway’s Prothane mounts

(910-18015).

14. Install the core support, radiator, grill, and fenders.

All accessories and other components can now be

installed.

15. Alignment. The lower control arms should be

level, with all the weight on the car. To adjust the ride

height, take the weight off the suspension and turn

the threaded adjusters on the bottom of the coil over

shocks. Turning the adjusters clockwise will raise the

ride height. Once the ride height has been set, place

the car back down on level ground. Adjust the free

heim end on the sway bar link so that it lines up with the

bracket in the lower control arm. Keep adjusting the

heim end until the remaining 1/2”-20 x 2-1/4” grade 5

bolt

Set the alignment to the following initial settings:

Caster = 5°

Camber = negative .25°-5°

Toe in = 0''-1/8'' Toe Out

16. Caster adjustments are made by changing the

caster inserts. The caster inserts are identified with

numbers indicating the distance of the hole from the

center of the insert in 1/8” increments.

#1 = 1/8” #2 = 1/4” #3 = 3/8”

The inserts can be reversed to move the hole in front of

or behind center for a total range of ¾”.

17. Camber is adjusted using the included A-arm

shim plates. Additional shim plates can be purchased

separately if desired under Speedway Part # 917-

21005. These are available in thicknesses ranging from

1/8” to 1/2".

SpeedwayMotors.com/Info/FAQ

DISCLAIMER In an effort to offer our customers low prices, quick service

and great value, Speedway Motors reserves the right to change suppliers,

specifications, colors, prices, materials without notice. Prices and policies that

were current and in effect at the time of printing are also subject to change

without notice. Quantities are limited on some items. Any unauthorized use of

this catalog including words, photos or drawings is prohibited. Speedway is not

responsible for any typographical errors, printing errors or misinterpretations

WARRANTY DISCLAIMER Purchasers understand and recognize that racing

parts, specialized street rod equipment, and all other parts and services sold

by Speedway Motors, Inc. are exposed to many and varied conditions due

to the manner in which they are installed and used. Except for certain limited

warranties, if any, set forth in Speedway Motors, Inc.’s current catalog with

respect to the products and/or parts thereof identified on your invoice, each

product,andeachpartthereof,issold“asis”,and“withallfaults”andSpeedway

Motors, Inc. makes no warranties either expressed or implied, written or

oral, with regard such products and services including, without limitation,

any warranty of merchantability or fitness for a particular purpose. Without

limiting the foregoing, there is no warranty expressed or implied as to whether

the goods sold hereby will protect purchasers or ultimate end-users of such

products and parts from injury or death. In no event shall Speedway Motors,

Inc. be liable for any special, incidental or consequential damages, or any other

damages whatsoever arising out of or connected with the use or misuse of the

products and each part thereof. Purchasers acknowledge and agree that no

person, entity or agent of Speedway Motors, Inc. has any authority to make

any statement contrary to this disclaimer and that any warranty statements

or representations allegedly made on behalf of Speedway Motors, Inc. by any

such person, entity or agent are void. Purchasers are relying solely on their own

skill and judgment to select, purchase and use suitable products and assume

all responsibility and risk with regard thereto. Some local laws prohibit the use

of utility jugs, funnels and barrel pumps for dispensing fuel. Please check your

own state for more information, regulations or further direction in your use of

the utility jugs, funnels and barrel pump described in Speedway’s catalogs or

on Speedway Motors websites. Some parts in this catalog are not legal for sale

or use in California. Items sold in this catalog are for racing vehicles which may

never be used on a highway. The use of manufacturer’s names and symbols

are for reference purposes only.

DAMAGE CLAIMS Please inspect all packages upon delivery and in the

presence of the delivery driver when possible. The driver must note any visible

damage and provide procedures for handling damage claims. To allow for a

claims process, please retain original box, packing material and damaged

merchandise. Contact Speedway Motors for instructions regarding damage

claim within 5 days of receipt. Speedway Motors assumes no liability after

this period.

SHORTAGES Please check the contents of your delivery to ensure that all

parts ordered are received. Refer to your invoice to cross check all items

received and inspect all packing materials for contents of small items. Retain

original shipping box and packing materials. Orders may be split into multiple

boxes which can be delivered on different days. Contact Speedway Motors

for instructions regarding shortage claim within 5 days of receipt. Speedway

Motors assumes no liability after this 5 day period.

REFUSALS All refused packages will be billed the freight to and from the

destination and refused COD orders will be billed a 15% restocking charge plus

freight to and from destination.

WARRANTY CLAIMS If the item is used or installed and a warranty claim

request is submitted, warranty work is done by the manufacturer and may

take up to 30 days for processing. Speedway Motors will be required to

follow the manufacturer’s warranty instructions to allow for a credit refund or

exchange when specified.

RETURNS We want you to be satisfied with your purchase. If you are not

satisfied, you may return your new, unused item within 60 days for refund or

exchange.

All exchanged or returned merchandise must be in original factory condition

with no modifications or alterations. Returned merchandise must include

original packaging materials, warranty cards, manuals, instructions, etc. If the

returned item requires repackaging, your refund / exchange will be subject

to a repackaging charge. Return/Exchange transactions less than $99 are

excluded from the free shipping offer.

HOW TO RETURN AN ITEM Please re-pack the item in a sturdy box, include

a copy of your invoice and completed return form. Returns must be shipped

prepaid. CODs are not accepted. Shipping costs for exchanged merchandise

will be charged to your credit card.

Items that are returned after 60 days are subject to a 15% restocking charges.

Fiberglass items returned will be subject to a 15% restocking charge. We are

unable to accept returns on electrical parts, video tapes, DVD’s, books, special

order or closeout merchandise.

BRAKE INSTALLATION ALERT The selection and installation of brake

components should only be done by personnel experienced in the proper

installation and operation of braking systems. The installer must use his/

her own discretion to determine the suitability of all brake components

and brake kits for every particular application. Speedway Motors, Inc.

makes no warranties either expressed or implied including any warranty of

merchantability or fitness for a particular purpose, other than those contained

in its current catalog or website with respect to the goods identified on the

face of the invoice. There is no warranty expressed or implied as to whether

the goods sold hereby will protect the purchaser or ultimate user of such

goods from injury of death.

EXHAUST INSTALLATION ALERT Exhaust systems and other component

surface finishes are not permanent. Coatings, paint and other factory supplied

cosmetic treatments are only intended to protect from surface corrosion in

an unused state. No returns are allowed after the parts have been installed.

Header flanges must be clean and clear of paint and surface contaminants

prior to mating to exhaust gaskets. Exhaust fasteners must be re-torqued

after the initial heat cycle and regularly thereafter to ensure a proper gasket

seal is maintained. Should you decide to install this exhaust product at your

home, be warned that pleasure car or light duty truck/van “bumper” jacks

are intended for emergency use only. The use of frame contact jack stands

in conjunction with a floor jack as a main support is highly recommended to

minimize accidental dropping of a vehicle while the installation proceeds. We

recommend the use of a shop hoist if possible. Please use caution! Speedway

Motors, Inc. makes no warranties either expressed or implied including any

warranty of merchantability or fitness for a particular purpose, other than

those contain in its current catalog or website with respect to the goods

identified on the face of the invoice. There is no warranty expressed or implied

as to whether the goods sold hereby will protect the purchaser or ultimate user

of such goods from injury or death.

CHECK LOCAL LAW Some parts are not legal for sale or use in California on

any pollution controlled motor vehicles. These items are legal in California for

racing vehicles only which may never be used upon a highway. Check local

law.

Speedway Motors, Inc.

P.O. Box 81906 • Lincoln, NE 68501

800.979.0122 • SpeedwayMotors.com

Find the above info on our website:

© 2019, Speedway Motors, Inc.

IMPORTANT

Other Speedway Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 279746 Assembly and Safety Advice

SSV Works

SSV Works DF-F65 manual

ULTIMATE SPEED

ULTIMATE SPEED CARBON Assembly and Safety Advice

Witter

Witter F174 Fitting instructions

WeatherTech

WeatherTech No-Drill installation instructions

TAUBENREUTHER

TAUBENREUTHER 1-336050 Installation instruction