Kleinn JEEPKIT-1 User manual

Bolt-

on Air Horn & Compressor Kit for Jeep Wrangler JK

SAVE THIS MANUAL FOR FUTURE REFERENCE

It is essential that y

operator of this product read and

understand the contents of this manual

before installing and using this product.

odel JEEPKIT-1

on Air Horn & Compressor Kit for Jeep Wrangler JK

SAVE THIS MANUAL FOR FUTURE REFERENCE

USER ANUAL

I PORTANT:

It is essential that y

ou and any other

operator of this product read and

understand the contents of this manual

before installing and using this product.

on Air Horn & Compressor Kit for Jeep Wrangler JK

odel

JEEPKIT-1

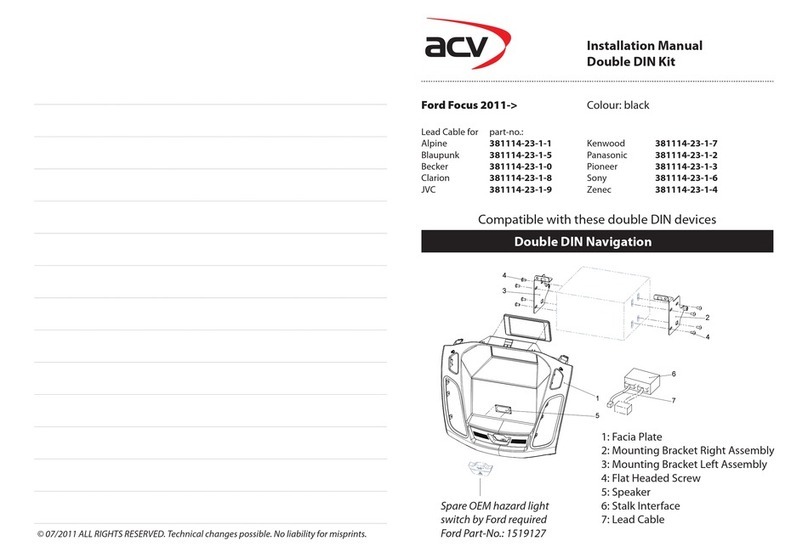

Components:

1 2.5 Liter, 4-port air tan

1 Model 6250RC compressor

1 Dual trumpet air horn

1 Installation wiring & connector it

1 Compressor installation hardware (Pac age #1 - inside compressor box)

1 JEEPKIT mounting hardware (Pac age #2)

1 Compressor/Tan mounting brac et

1 Horn mounting brac et

1 12’ length air tubing

PARTS PACKAGES

Package #1 – Compressor Installation Hardware

Qty 4 13/64” Nuts, bolts, washers & loc ing washers

(Compressor mounting hardware)

Qty 1 Remote Mount Air Filter Assembly

Qty 1 Remote mount air filter fitting for air filter connection

Qty 1 Replacement air filters

Qty 1 Leader Hose Brac et Clip

Qty 1 Air line for remote mounting air filter

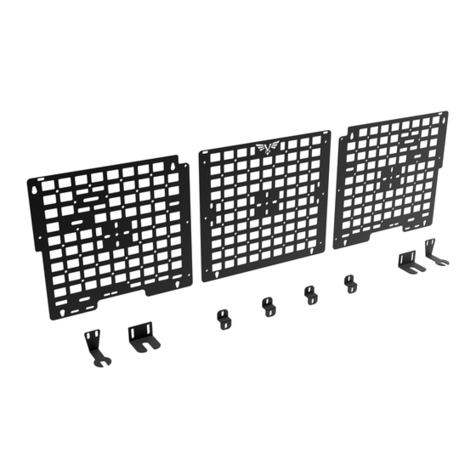

Package #2 – Jeep Kit bracket and tank hardware

Qty 6 5” bolts

Qty 6 Nyloc nuts

Qty 3 Rear mount plates

Qty 4 Nuts, bolts, and washers – (Air tan mounting hardware)

Compressor/Tank – General Information

Your Jeep Kit comes complete with a model 6250RC, 9% duty cycle compressor and a 2.5 liter

air tan . Please follow the installation instructions that follow in order to enjoy the best use of

your air horn it.

CAUTION - To reduce ris of electrical shoc or electrocution:

• Do not disassemble the compressor. Do not attempt repairs or modifications. Refer to

qualified service agencies for all service and repairs.

• Do not use this product in an area where it can fall or be pulled into water or liquids.

• Do not reach for this product if it has fallen into liquid.

• Use this compressor with 12-volt DC systems only.

•

This product should never be left unattended during use.

IMPORTANT:

• Tan is rated for 120 PSI maximum wor ing pressure.

• Tan is not to be used as a breathing device.

• Bleed pressure from tan before servicing or adding attachments.

• Use only attachments or tools rated for 120 PSI wor ing pressure or less.

• Apply sealant or Teflon tape to threads of fittings prior to assembly and tighten each part

with a wrench.

• Do not over tighten, since brass threads can be stripped.

• Always release air from tan before servicing.

• To remove accumulated condensation inside the tan , disconnect power from the compressor

and release the pressurized air by sounding the horns. Unbolt the air tan , then drain water

by removing the drain plug at the bottom of the tan . Once the water is drained, replace the

plug and re-mount the tan . Use Teflon thread tape to ensure a good seal.

CAUTION:

DO NOT PRESSURIZE YOUR TANK UNTIL YOU HAVE INSTALLED ALL

NECESSARY PORT FITTINGS AND ACCESSORIES.

FAILURE TO DRAIN TANK AND RE OVE CONDENSATION WILL CAUSE TANK

TO RUST PRE ATURELY.RUSTED TANKS CAN FAIL CAUSING EXPLOSIONS OR

FATAL INJURIES. DISCARD TANK I EDIATELY IF IT IS RUSTED.

Compressor/Tank Installation

Included in your it is a vehicle-specific mounting brac et for the compressor and air tan . The

brac et clamps around the horizontal beam located above the rear differential.

Preparation

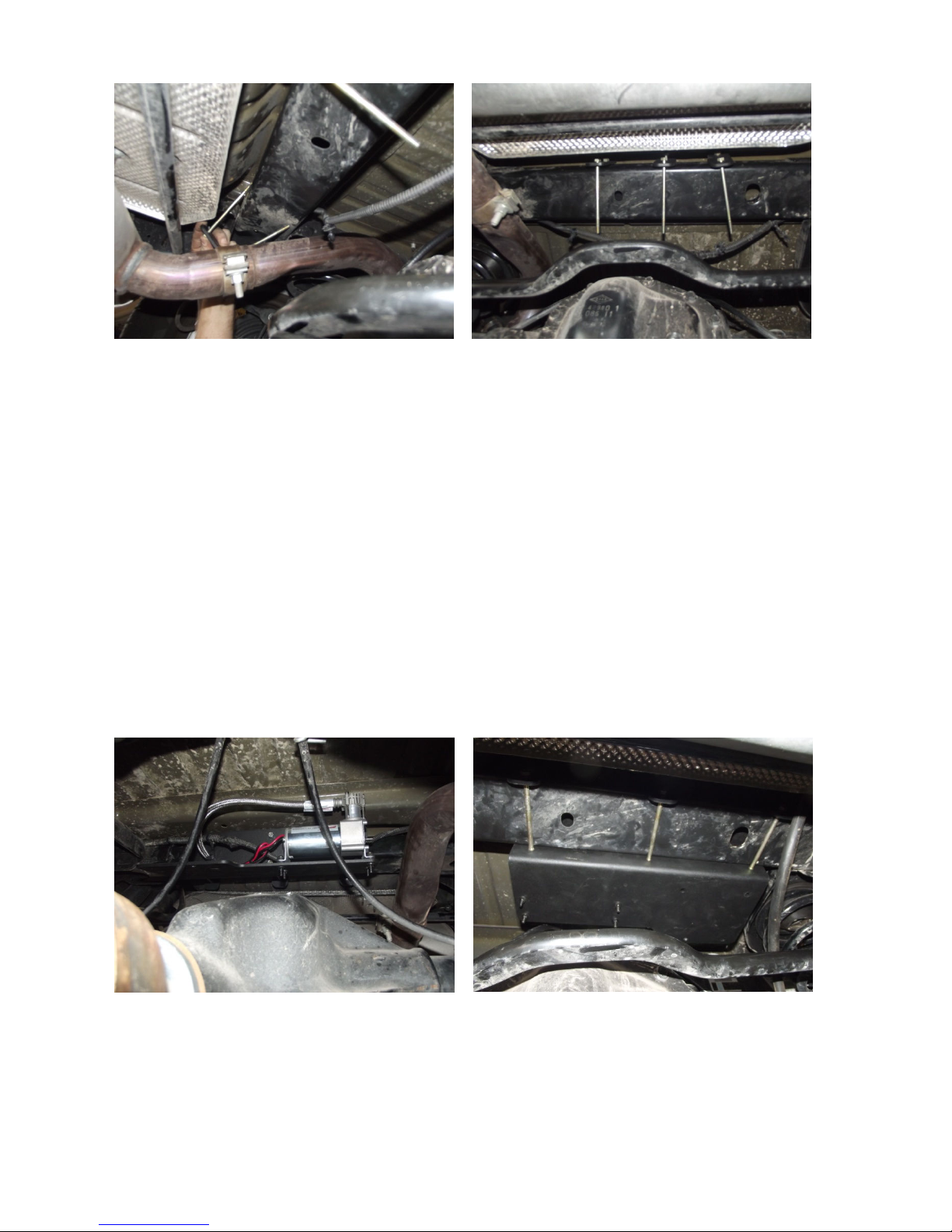

1. Locate the horizontal beam above the rear differential. There is a small wiring harness,

attached to the top of the support with two plastic clips. Remove the clips to allow free

movement of the wiring harness. It is not necessary to salvage the clips – they will not

be re-used (see photo 1).

2. Attach the compressor to the vehicle-specific mounting brac et using the bolts in

Pac age 2. The compressor should be mounted with the piston on the driver’s side of

the vehicle, facing away from the tan mounting location. Bring the bolts up through the

bottom of the mounting plate and have the nuts on the top. Do not mount the tank yet.

3. Insert two 5” mounting bolts into each rear mount plate (see photo 2).

Photo 1 – Horizontal beam with wiring harness clips

removed

Photo 2 – Rear Mount Plates with bolts inserted

Mounting the compressor/tan brac et

1. Wor from the driver’s side of the vehicle and slide all three rear mount plate/mounting

bolt sub-assemblies onto the horizontal beam. The rear mount plates should be towards

the rear of the vehicle, the bolts should be extending over and below the beam, pointing

toward the front of the vehicle (see photo 3). As each sub-assembly is positioned over

the beam, slide it towards the passenger side of the vehicle so that the three sub-

assemblies are spaced at roughly the same intervals as the three sets of mounting holes on

the brac et (see photo 4). Ma e sure the wiring harness you detached from the beam

earlier is lying on TOP of the bolts and not running under the bolts! Helpful Tip: Using

electrical tape to temporarily hold the bolts on the rear mount plates will make this task

easier.

Photo 3 – Slide the rear mount plate/bolt assemblies

over the beam. Wor from the driver’s side and slide

the assemblies towards the passenger’s side

Photo 4 – All three rear mount plate/bolt assemblies in

place.

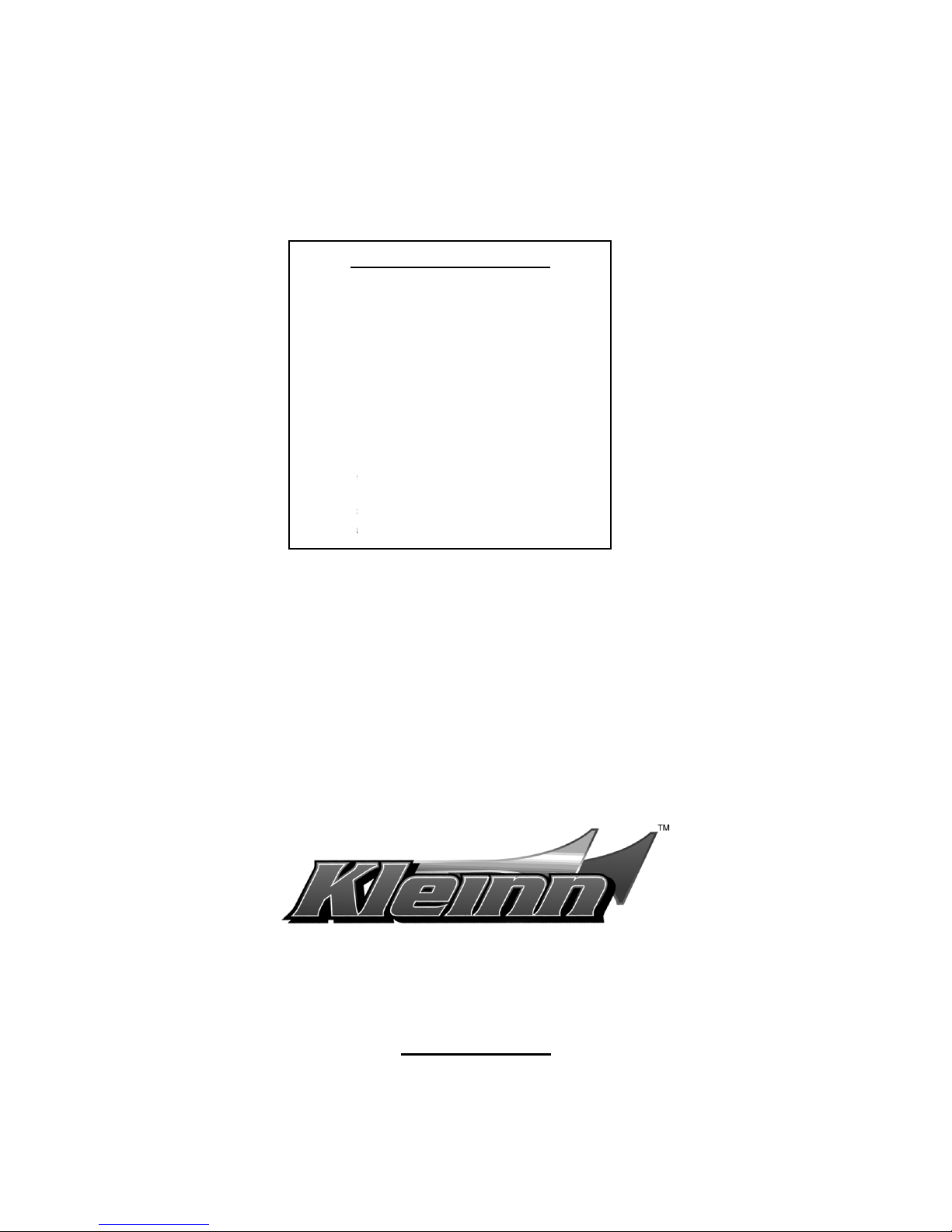

2. Position the brac et in front of the beam, then align the rear mount/bolt assemblies so that

the bolts pass through the mounting holes in the brac et. Hand tighten the six Nyloc nuts

onto the bolts.

3. Position the entire brac et assembly towards the passenger side of the beam. There is a

welded joint at the end of the beam – the brac et should be butted up against that weld.

Do not try to attach the bracket over the weld (see photos 5 & 6)

4. Using an 11mm gear wrench or a ratchet with a 6” extension, tighten the six Nyloc nuts.

Alternate between top and bottom so that the rear mount plates sit flush against the bac

of the beam and the bolts sit flush on the top and bottom of the beam. Use a wrench to

hold the bolt heads while tightening.

5. Attach a short section (approx 12-18”) of the blac tubing in the compressor accessory

pac age to the air inta e on the front of the compressor. Route the other end into the

existing opening in the floor brace just above the compressor.

Photo 5 – Compressor on mounting brac et, as seen

from the front of the vehicle.

Photo 6 – Mounting brac et, as seen from underneath.

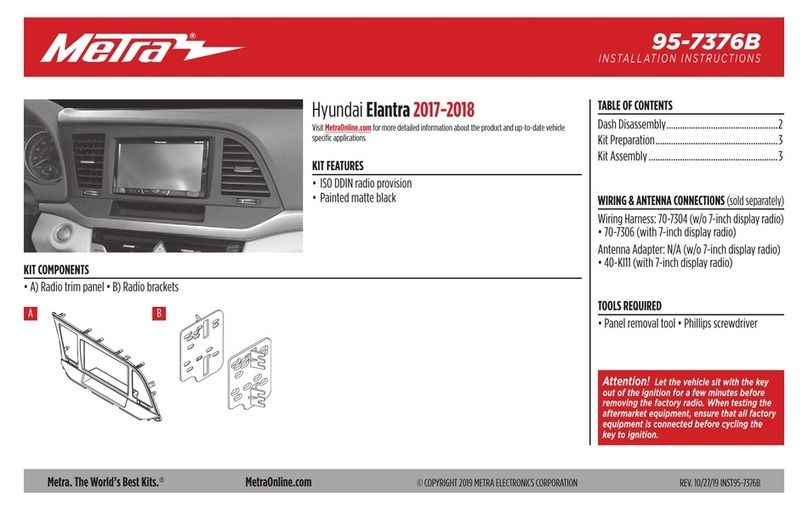

Ma ing the air connections

1. Temporarily slip the emergency bra e cables out of their support to allow room for

installing the air tan . Position the air tan on top of the mounting brac et with the

fittings facing the driver’s side of the vehicle and the compressor. Do not attach the tan

to the brac et yet (see photo 7).

2. Remove the red rubber plug from the end of the steel braided leader hose on the

compressor and apply Teflon thread tape to the threads on the chec valve at the end of

the leader hose.

3. Ma e a loop with the leader hose and position the hose between the compressor body and

the bac of the brac et (see photo 8).

4. Thread the leader hose into the tan and tighten with a wrench. It is important that the

connection is snug, but not over tightened. When the brass female adapter on the tan

starts turning, you’ve tightened the leader hose enough.

5. Connect the air tube to the compression fitting on the tan . For best results, ma e sure the

end of the tube is cut clean and square. Route the tube over the top of the brac et that

holds the Jeep EVAP canister.

Photo 7 – Emergency bra e cable support Photo 8 – Air tan positioned on mounting brac et.

Note how the braided steel leader hose is looped

between the compressor body and the mounting brac et.

Mounting the air horn

1. Locate the EVAP canister under the vehicle. It is towards the driver’s side, just forward

of the rear axle (see photo 9).

2. Remove the two 5/8” bolts for the EVAP canister mounting brac et.

3. Use the mounting bolts found inside the horn box to attach the horns to the horn

mounting brac et

4. Cut your tubing to length, ma ing sure the end is clean and square. Connect the air line

to the solenoid valve, then slip the horn mounting brac et UNDER the EVAP canister

brac et and align the holes. Re-install the 5/8” bolts through the EVAP canister mount

and the horn brac et (see photo 10)

Photo 9 – EVAP canister. Note the two 5/8” mounting

bolts

Photo 10 – Air horn brac et mounted under EVAP unit

brac et

Pre-wiring

1. Disconnect ground cable from vehicle’s battery.

2. Ground the compressor blac wire. The nut that secures the emergency bra e cable

support just forward and above the rear differential is a good grounding point.

3. Your wiring it includes red, yellow, purple and blac wires that will need to be run the

length of the vehicle. Run the red and yellow wires from the battery area (passenger

side), across the engine compartment, and bac to the compressor/tan .

4. Run the blac and purple wires to the bac from the area of the ignition switch harness

(under the steering column). The blac wire will terminate at the air horns, the purple

wire will run all the way bac to the compressor/tan .

Be sure to keep your wiring away from heat sources such as the exhaust!

Wiring Connections

1. Use the relay including in your wiring pac age to supply power to the compressor.

Mount the relay near the battery and wire as follows:

• Pin 30 – to the 10 gauge red wire that runs the length of the vehicle and attaches to

the red wire on the compressor

• Pin 85 – to the yellow wire runs the length of the vehicle to one side of the pressure

switch (it does not matter which terminal)*

• Pin 86 – to ground

• Pin 87 – to one end of the fuse holder (cut the loop)

* before attaching spade connectors to the ends of the wires that connect to the

pressure switch, pass the wires through the opening in the black rubber pressure

switch cover. Slide the cover over the pressure switch once the connections have

been completed.

2. Connect the end of the purple wire at the compressor/tan to the open terminal on the

pressure switch. Connect the other end of the purple wire to the 12v+ ignition wire in the

ignition switch harness.

3. The blac wire will be your horn trigger. If you want to activate your horn using the

pushbutton supplied with the it, connect one side of the pushbutton to ground and the

other side of the pushbutton to the blac wire. If you want to use your factory horn

switch instead of the pushbutton, connect the blac wire to the vehicle (-) horn wire,

located in the ignition switch harness. In either scenario, the other end of the blac wire

should be connected to one of the wires (it doesn’t matter which) coming out of the

solenoid valve on the air horn.

4. Use a leftover section of your blac wire to connect the remaining wire on the air horn

solenoid valve to +12v ignition. You can use the +12v ignition you already have

running to the bac of the vehicle via the purple wire.

5. Connect the remaining end of the fuse holder to the + terminal of the battery or the

‘power point’ on the corner of the fuse box, in front of the battery.

6. Insert the fuse in the fuse holder to complete your wiring

7. Use the wire loom supplied with the it to protect your wiring!

8. Use the supplied wire ties to secure the factory wiring harness that was detached earlier

to the holes on the compressor mounting brac et.

Mounting the air tan

1. After all electrical connections have been completed, pressure test the tan before bolting

it to the brac et. To pressure test the tan , complete your wiring and turn on the ignition

to run the compressor. Once the pressure switch shuts the compressor off, spray soapy

water on all the air connections at the tan . If you see bubbles, tighten the connection

slightly or add more Teflon tape.

2. Once you have pressure tested the system, the tan can be mounted to the brac et. Use

the four nuts, bolts and washers included in hardware pac age #1. Install the bolts from

the top downward. Helpful Tip: The passenger side rear bolt will be difficult to access.

Use a piece of electrical tape to temporarily hold the bolt into the tank s foot when doing

your final positioning of the tank on the bracket.

CO PRESSOR OPERATING INSTRUCTIONS

I PORTANT: The compressor has a maximum wor ing pressure of 120 PSI and is capable of

9% duty cycle. It is designed for use with air horns, air bags and other accessories that utilize the

compressed air stored in the tan . Always operate the compressor at or below the MAXIMUM

PRESSURE RATING of the compressor. Operation exceeding maximum pressure ratings and or

duty cycle will result in damage to air compressor.

1. Your air compressor is equipped with an AUTOMATIC THERMAL OVERLOAD

PROTECTOR. This feature is designed to protect the air compressor from overheating and

causing permanent damage to your air compressor. The thermal overload protector will

automatically cut off power to your air compressor should the internal operating temperature

of the air compressor rise above safe levels during excessive use.

2. Should your air compressor automatically shut off while in use; do not attempt to restart the

air compressor. Turn power switch to the air compressor to the OFF position. The automatic

thermal overload protector will automatically reset when internal temperature of the air

compressor drops below safe level. After allowing air compressor to cool off for about 30

minutes, you can safely resume use of the air compressor by turning on the air compressor.

3. To prevent discharge of your vehicle’s battery and to provide pea performance, we strongly

recommend that you eep the vehicle’s engine running while using the air compressor.

4. ONLY OPERATE THE AIR COMPRESSOR IN WELL-VENTILATED AREAS.

Compressor Maintenance & Repairs

1. Periodically chec all electrical and fitting connections. Clean and tighten as needed.

2. Periodically chec all mounting screws. Tighten as needed.

3. Replace air filter element periodically. Replacement frequency depends on operating

frequency and operating environment. For frequent use in dusty environment, you should

replace air filter element more often.

4. Regularly clean dust and dirt from compressor.

5. Your air compressor is equipped with permanently lubricated, maintenance free motor.

Never lubricate compressor.

6. Repairs should be performed by Manufacturer or Manufacturer’s Authorized Service

Agencies only.

CAUTION: Never touch the air compressor or fittings connected to the air compressor with bare

hands during or immediately after use. Leader hose and fittings will become very HOT during

and after use.

Kleinn odel

Kleinn Automotive Accessories

LI ITED WARRANTY

Kleinn Automotive Air Horns warrants this

product, when properly installed and under

normal conditions of use, to be free from

defects in wor manship and materials for a

period of one year from provided date of

purchase. To receive a replacement or for

rep

airs, return the complete unit to retailer from

whom it was purchased along with proof of

purchase.

Returns should be made within the time period

and conditions of the retailer’s policy for

exchanges. If you are unable to contact your

dealer, contact Kl

replacement at our option.

Kleinn odel

JEEPKIT-1

Kleinn Automotive Accessories

P.2094 N. Dragoon St

Tucson, AZ 85 45

Phone: (520) 5 9-1531

Fax: (520) 5 9-1528

info@kleinn.com

LI ITED WARRANTY

Kleinn Automotive Air Horns warrants this

product, when properly installed and under

normal conditions of use, to be free from

defects in wor manship and materials for a

period of one year from provided date of

purchase. To receive a replacement or for

airs, return the complete unit to retailer from

whom it was purchased along with proof of

purchase.

Returns should be made within the time period

and conditions of the retailer’s policy for

exchanges. If you are unable to contact your

dealer, contact Kl

einn directly for repairs or

replacement at our option.

Table of contents

Other Kleinn Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

Metra Electronics

Metra Electronics 95-7376B installation instructions

Traxxas

Traxxas PRO SCALE 1979 quick start guide

Toro

Toro 07046 installation instructions

Victory 4x4

Victory 4x4 TUNDRA Install instructions

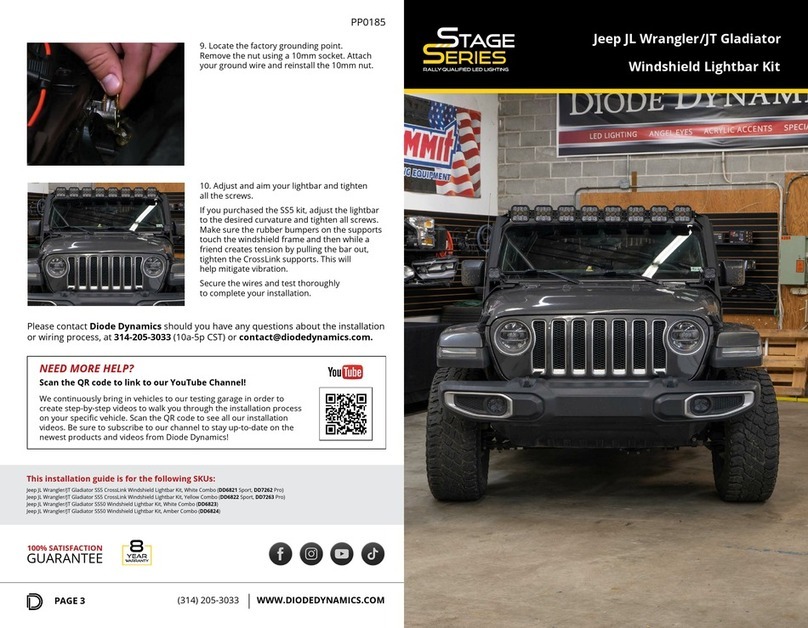

Diode Dynamics

Diode Dynamics STAGE Series quick start guide

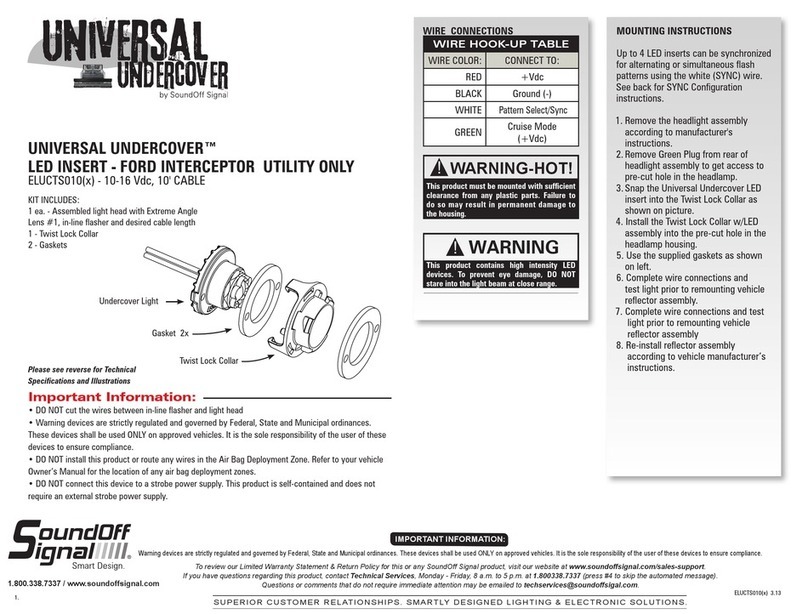

Soundoff Signal

Soundoff Signal UNIVERSAL UNDERCOVER ELUCTS010 Quick installation guide