SPEX CertiPrep 8000D MIXER/MILL User manual

8000D MIXER/MILL®

OPERATING

MANUAL

8000D Mixer/Mill

Page 2of 21 SPEX CertiPrep 8.21.03

SN and Higher

TABLE OF CONTENTS

SECTION

DESCRIPTION

PAGE

1. Introduction ...............................................................................................................................3

2. Specifications ............................................................................................................................4

3. Unpacking..................................................................................................................................5

4. Setting Up..................................................................................................................................6

5. Operation...................................................................................................................................8

6. Maintenance ............................................................................................................................10

7. Accessories..............................................................................................................................11

8. Parts List & Item Locator........................................................................................................15

9. Assembly Diagrams & Parts ........................................................................................... 17 -19

10. Trouble Shooting.....................................................................................................................20

11. Warranty..................................................................................................................................21

8000D Mixer/Mill

Page 3of 21 SPEX CertiPrep 8.21.03

SN and Higher

1. INTRODUCTION

SPEX CertiPrep Mixer/Mills are a variant of the ball mill or jar mill, which grinds samples by

placing them in a container along with one or more grinding elements, and imparting motion to

the container. Generally the containers and grinding elements are made from the same material.

As the container is swung, the inertia of the grinding elements causes them to move

independently, into each other and against the container wall, grinding the sample.

The 8000D Dual Mixer/Mill is an efficient two-clamp laboratory mill. The 8000-series

Mixer/Mills have been used for pulverizing rocks, minerals, sand, cement, slag, ceramics,

catalyst supports, and hundreds of other brittle, often hard samples in the 10-gram range.

Functionally described as a shaker mill or a high-energy ball mill, the 8000D Dual Mixer/Mill is

capable of rapidly shaking containers back and forth several thousand times a minute. This

multi-purpose mill is capable of rapidly reducing hard, brittle samples to analytical fineness,

blending powders, or making emulsions. It is also very effective for mechanical alloying.

With two clamps for increased throughput, the 8000D also features a variable-range electronic

timer, sleek modern design, forced-air cooling, a safety interlock, and a choice of steel, tungsten

carbide, agate, zirconia, silicon nitride, alumina, and plastic vials which are purchased separately.

This mill duplicates the pulverizing, blending, and alloying action of the proven, reliable 8000

Mixer/Mill. The vial, containing the sample and a ball or balls is secured in the clamp and swung

energetically back and forth. The back-and-forth shaking motion is combined with lateral

movements of the ends of the vial, so that the vial appears to be describing a figure-8 or infinity

sign as it moves. The length of that swing is the same as the internal length of the vial, about two

inches. With each swing of the vial the ball impacts against the sample and the end of the vial,

both milling and mixing the sample. Because of the amplitude and velocity of the clamp’s swing,

each ball develops fairly high G-forces, enough to pulverize the toughest rocks, slag and

ceramics.

The dual clamps of the 8000D Mixer/Mill not only allow twice as many samples to be ground in

a given time, but they also move in balance, reducing vibration and extending the life of the

mill’s components. A fan keeps the motor and clamp mechanisms cool during operation.

For assistance in choosing the SPEX CertiPrep grinding or blending containers which would be

best for your application, please call SPEX CertiPrep Sample Preparation at 1-800-522-7739 or

732-549-7144.

8000D Mixer/Mill

Page 4of 21 SPEX CertiPrep 8.21.03

SN and Higher

2. SPECIFICATIONS

Type of mill: High-Energy shaker mill

Grinding container: Canister with balls

Weight (empty, without vial): 68 lbs. (31 Kg)

Dimensions: 22 in (56 cm) x 15 1/4 in (39 cm) x 11 in (28 cm)

Grinding Vials Available (see pages 16-19):

8001 Hardened Steel Vial Set.

8003 Alumina Ceramic Vial Set

8004 Tungsten Carbide Vial Set

8005 Zirconia Ceramic Vial Set

8006 Methacrylate Vial Set

8007 Stainless Steel Vial Set

8008 Silicon Nitride Vial Set

8009 Round-Ended Hardened Steel Vial Set

8014 Agate Vial Set

Smaller Vials also available:

3114 Stainless Steel Vial Set

3117 Hardened Tool Steel Vial Set

3127 Hardened Tool Steel Vial Set

3118 Agate Vial Set

5004 Tungsten Carbide-Lined Vial Set

NOTE: Smaller vials are to be run in Multiple-Sample Adapters (see page 13 & 14)

Electrical: available in 115V 60Hz (8 amp fuse) or 230V 50Hz (5 amp fuse).

Cord: 115V 60HZ version, 3-prong grounded cord supplied.

230V 50HZ version, with European two-prong plug supplied.

NOTE: Operator is responsible for supplying alternate line cord/plug if required.

Fuses:115V 60HZ version, 8-amp slow-blow fuse in inlet module,

230V 50HZ version, 5-amp slow-blow fuse in inlet module.

Motor: 1/3 Hp

Clamp Movement: 2¼ in. back-and-forth, 1 in. side-to-side

Clamp Speed: 1060 back-and-forth cycles at 115V/60Hz or 875 at 230V/50Hz

Safety Features: Lid Interlock prevents mill from running if lid is not closed. The latch also

prevents the lid from being opened until the clamps come to a stop.

Controls: start, stop/pause, and stop buttons; programmable timer with digital display, factory-

set for 100 minute range but adjustable to 10, 100, 1000, 10,000 minute ranges.

8000D Mixer/Mill

Page 5of 21 SPEX CertiPrep 8.21.03

SN and Higher

3. UNPACKING

Any visible damage to the shipping container should immediately be reported to the carrier. If

there is no visible damage, remove all packing documents from the exterior of the box, and after

completion of your inspection, file with your records.

Open the top of the shipping box. Remove the foamed-in-place packing material. Carefully grasp

the straps on the mill from both sides, exercising caution while using proper lifting techniques to

remove the unit from the carton (the unit weighs 68 lbs). Place the mill on the bench top where it

will likely stay, and open the lid. Look for any hidden damage that may have occurred during

shipping.

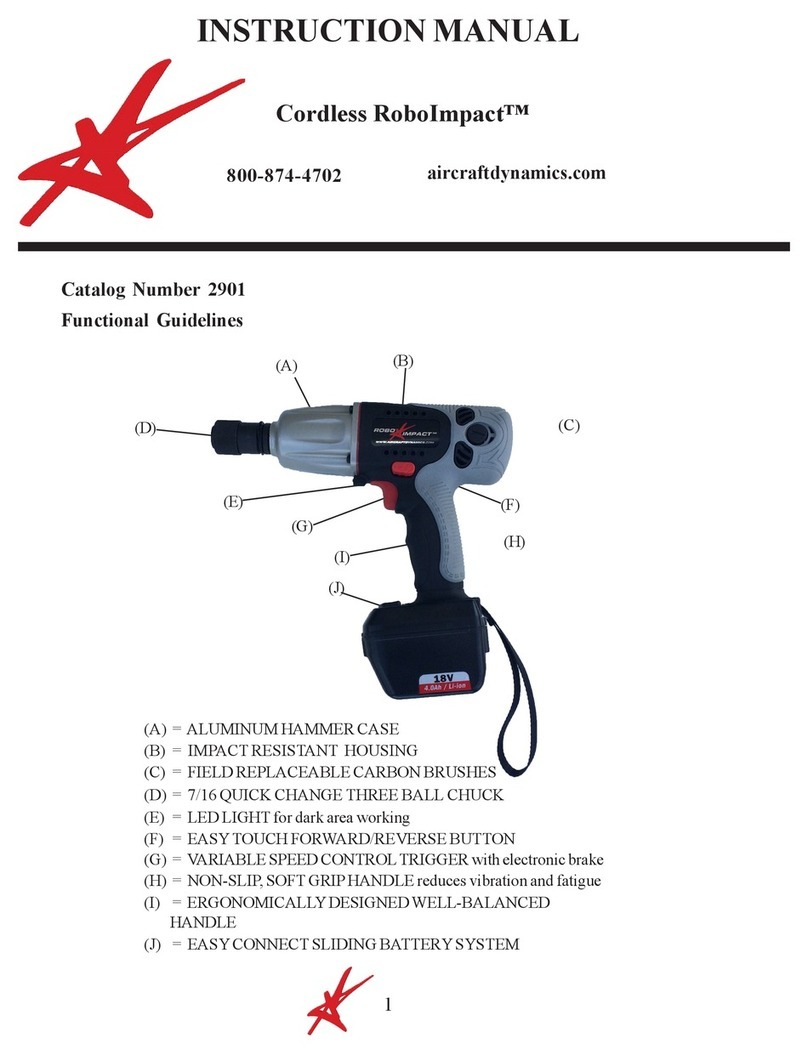

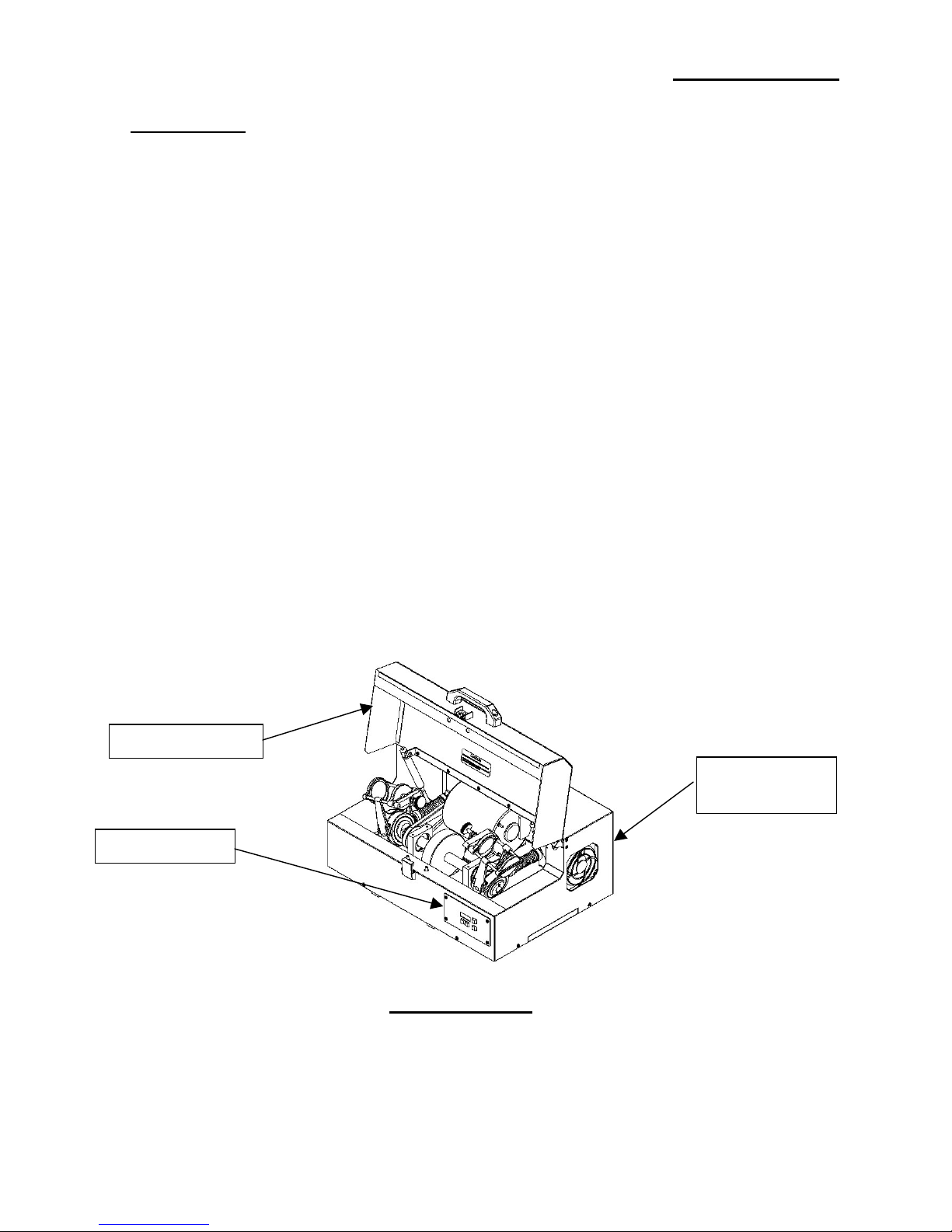

Follow a logical sequence of steps as you inspect the unit (see Figure 2). For example:

1. Inspect the outside of the cabinet for any visible damage.

2. Are any of the switches damaged?

3. Is the latch mechanism damaged?

4. Inspect the interior of the mixer.

5. Is the motor damaged?

6. Do all the springs and mounting points seem okay?

7. Inspect the accessory pack. Compare with the packing list.

If everything seems to be okay, proceed to the section, “ SETTING UP,” on page 11

Lid Assembly

Control Panel

Electrical Inlet

Module at back

(Figure 2)

8000D Mixer/Mill

8000D Mixer/Mill

Page 6of 21 SPEX CertiPrep 8.21.03

SN and Higher

4. SETTING UP

Remove the plastic bag containing the instructions and spare fuses. Then loosen the locking tab

on the clamps, and unscrew the clamps a few turns. Cut and remove the tie holding the clamps

together.

Tilt the cabinet about 45 degrees, and note the four bolts on the underside of the cabinet. They

hold the floating base plate to the cabinet for shipping. Remove these bolts, the rear ones first,

and save them in case you have to re-ship the mill. NOTE: Never ship or transport the 8000D

Mixer/Mill without the shipping bolts.

4.1 Electrical Hookup

The power inlet, a fuse tray, and the On/Off switch (controlling power to the motor and timer),

are located at the back of the unit. The On/Off switch is a rocker switch marked with a circle (0)

and a bar (-). To turn on the power, press down the bar (-) side of the switch. Before plugging in

the mill, set the power to Off by pressing down the zero (0) side of the On/Off switch, then plug

the power cord into the mill’s power inlet. Plug the mill into a standard 3-prong grounded

electrical outlet; we recommend that it be a fused 20-amp circuit for the 115V/60 HZ version.

The mill uses 8-amp “slow-blow” fuses. The 230 V 50 HZ model uses 5-amp “slow-blow” fuses

and comes with a European-style polarized plug; outside of Europe the cord should be adapted to

local requirements.

The fuse tray is next to the power inlet and includes two fuses in parallel. It can be opened with

a knife-blade or small screwdriver.

4.2 Standard Safety Features

Manual Lid Latch - The lid has a manual latch, just below the lid handle, which should be

closed whenever the mill is run. To close the latch, pull the tab up and out, engage it with the lid,

and push the tab down. To open the latch, pull the tab up and out.

Pneumatic Cylinders -When you raise the lid all the way, the pneumatic cylinders brace the lid

open, and keep it from being closed accidentally or abruptly. However, when you raise or lower

the lid you should always keep your hand on the handle.

Clamp Locking Tab - The clamp is opened and closed by a knob on the end of its threaded

shaft. Whenever the clamp is closed on a vial, lock the clamp by tightening the locking tab

clockwise against the clamp crossbar (The locking tab is on the shaft between the knob and the

clamp crossbar.) When opening the clamp, first loosen the locking tab.

8000D Mixer/Mill

Page 7of 21 SPEX CertiPrep 8.21.03

SN and Higher

4.3 CE Safety Features

CE directives require that electricity to the motor and timer be interrupted whenever the lid is

open, and that the clamp arm must have stopped completely before the lid can open.

Safety Interlock - The Safety Interlock cuts off power when the lid is opened; the switch is

under the lid on the upper right-hand side. Do not disconnect or damage this switch!

Time-Delay Latch - The Time-Delay Latch keeps the lid latched while the mill is running, and

until the clamp stops moving. The Time-Delay Latch consists of two pins, one on either side of

the manual lid latch, powered by a solenoid, to engage two holes in the lid. When the mill is

started the Time-Delay Latch locks the lid immediately, and there is a delay before the motor

starts. When the timer has cycled to zero, and the motor stops, the latch stays locked for about

ten seconds so the clamp will stop moving before the lid can be opened. The latch locks and

unlocks with an audible click. After a run always wait for the click before undoing the manual lid

latch and opening the lid.

NOTE: Never try to force open the lid before the Time-Delay Latch unlocks.

4.4 Control Panel

The four-digit timer is used to set the exact running time of the mill. The 8000D timer’s factory-

set range is 00:01 (one second) to 99:59 (99 minutes and 59 seconds). The default setting, which

always appears when the power is first switched on, is 01:00, or one minute and no seconds.

Electronic Timer - the two buttons underneath the display change the timer setting. The left-

hand button advances the minutes and the right-hand button advances the seconds. To advance a

setting one digit at a time, push a button and release it. If you hold a button down the setting will

advance slowly for a few seconds, then rapidly. The minutes setting will advance from 00 to 99

to 00 again, and the seconds setting from 00 to 59 to 00 again. Any setting other than the default

setting will be retained only as long as the power is switched on. While the mill is running the

timer counts down and displays the minutes and seconds left in a run.

Start Button - Once the timer is set (and the vial is clamped and locked in place, and the lid is

shut and latched) the mill can be started by pushing the Start button. The timer counts down as

the mill begins its run, so that the timer displays the time left to run in a grinding cycle. When

the timer reaches zero (00:00) the motor stops. After a ten-second delay for the clamp to stop

moving, the time-delay latch opens and releases the lid and the timer also re-sets.

Stop/Pause Button - To interrupt (not cancel) a cycle, push the Stop/Pause button once. The

motor will stop, and the display will flash the time left in the cycle; this is the Pause Condition.

During a Pause Condition the lid cannot be opened. This Pause Condition is indefinite, but the

run cycle can once again be resumed at the point where it was stopped, by once again pressing

the Start button. To cancel a cycle in progress, press the Stop/Pause button twice. This will stop

the motor and re-set the timer, and after ten seconds the Time-Delay latch will disengage,

allowing the lid to be opened.

8000D Mixer/Mill

Page 8of 21 SPEX CertiPrep 8.21.03

SN and Higher

5. OPERATION

Plug the power cord into the mill’s electrical inlet, and then into an approved grounded outlet.

Ensure that the On/Off switch (next to the power inlet) is in the off position, before plugging the

unit in. After the unit is plugged in, switch the power on by means of the rocker switch.

After loading each vial with the sample to be mixed or ground, place it in a clamp. Tighten each

clamp with the knob, and lock each clamp with the locking tab. Close the lid and fasten down the

lid with the manual latch.

NOTE: Two vials of the same material must be loaded onto the clamps, in order to assure

proper balance of the grinding mechanism.

Adjust the timer setting as described above under Electronic Timer.

Start the mill sample run by pushing the Start button. To stop the mill during a run (e.g., an

emergency stop), push the Stop/Pause button twice, or cut off power by pressing the power

switch on the back of the mill to 0. If you want to interrupt a run but keep the current position in

the timer sequence, push the Stop/Pause button once only, and the mill will stop. After a pause,

the milling cycle can be resumed by pushing the Start button. It is important to note that the lid

latch will not release when the mill is in the Pause Condition.

NOTE: When the 8000D timer cycle has ended and the motor stops, wait until the lid latch

releases before opening the lid.

Loosen the locking tabs, then open the clamps and remove the vials.

5.1 MIXING AND GRINDING

Mixing is usually done in a plastic vial with plastic balls. Depending on the nature and amount of

material to be mixed, one or several balls may be used. With a small amount of material and

more than one or two balls, the impact may break the bottom of the plastic vial, so keep the

number of balls to a minimum. Plastic vials and balls can also be used to grind soft metals (e.g.

antimony), carbon, and other easily friable materials.

For samples that cake during mixing, a slurry with water or alcohol may be helpful. Water may

be dried out afterwards by heating plastic vials in a very low oven. If caking is due to static

charges, a small amount of graphite can added to the vial.

Grinding is done in the metallic and ceramic containers: steel, tungsten carbide, alumina,

zirconia, agate, and silicon nitride. Dry grinding is the simplest approach and is most often used.

The criteria for container selection are usually those of grinding efficiency vs: contamination;

steel and tungsten carbide grind more rapidly than ceramics or agate, but contaminate more.

Most 8000-series vials accept 3 to 10 ml of sample for grinding.

8000D Mixer/Mill

Page 9of 21 SPEX CertiPrep 8.21.03

SN and Higher

5. OPERATION

(Continued)

A typical mixing load is up to 25 ml, or about 40% of the vial’s volume.

If a sample is not being ground fine enough, one can decrease the amount of sample, increase

grinding time, use a denser grinding medium, and/or add a grinding aid or a liquid. Wet grinding

keeps the sample from caking and will give a smaller final particle size, but there are handicaps:

an extra drying step is required, the fluid used for wet grinding must be chosen carefully not to

alter the sample or attack the container, and not all the vials are leak-proof. The steel, tungsten

carbide, and plastic vials have screw tops, and are more or less watertight. The alumina vial

(8003) has optional clamps (8014) for slurry grinding. Other 8000-series grinding containers are

not suitable for use with liquids.

Avoid grinding small loads (less than 3 grams) in brittle containers such as alumina and agate. If

there is not enough material to cushion the impact of the balls, they will generate excess

contamination and can in extreme cases chip the container.

Caution: always use grinding balls that match the material of the container, e.g. steel balls for a

steel container, agate balls for an agate container, etc. This will limit contamination. An

inappropriate choice of balls, such as tungsten carbide balls in an alumina container, can damage

the container.

Two balls are standard for most grinding containers, though some users feel that only one ball

should be used in the most brittle containers (alumina and agate). Three balls can hasten grinding

in the strongest containers, the steel ones.

When using grinding containers with threaded aluminum caps (steel and tungsten carbide), be

careful to keep the threads clean. Over time, if care is not exercised to maintain the threads clean,

as sample accumulates in the threads it can jam the caps. Also be careful not to drop these caps

on edge, as if they are knocked out of round they can be very difficult to use.

8000D Mixer/Mill

Page 10 of 21 SPEX CertiPrep 8.21.03

SN and Higher

6. MAINTENANCE

The 8000D Mixer/Mill has been designed to provide trouble-free operation over a long period of

time. To assure proper performance, perhaps an important factor is overall cleanliness. Any spilled

powders or liquids should be wiped up immediately. This should minimize the buildup of any

powders, mold/mildew, or unsightly gunk.

To maintain the exterior of the unit, first disconnect the 8000D Mixer/Mill, then spray it with a mild

window cleaner or similar product, and wipe it down. REMINDER: unplug the Mixer/Mill before

any cleanup or maintenance work.

The threads of the clamp screw should be kept clean. The foam pads in the clamp should be

replaced when damaged, worn, or missing.

If the drive belt becomes loose, tighten it by moving the motor back: loosen the motor mounting

bolts, move the motor, and tighten the bolts. If the drive belt breaks or becomes heavily worn,

replace it. A properly tensioned drive belt can be depressed about ½” midway between the

sprockets.

The flywheel and motor sprockets should be checked from time to time to make sure that they

are tight on their shafts; if either sprocket loosens it must be realigned with the other, and the set

screws tightened.

The sealed ball bearings in the clamp and pillow block assemblies are lubricated for life and

require no maintenance. The shaft bearings of the motor are lubricated for ten years of

intermittent use or one year of heavy use.

The clamp retaining spring assembly includes two open ball-and-socket joints that are lubricated

with heavy-duty automotive-type lithium grease. If these bearings dry out they should be taken

apart and re-greased.

The 8000D Mixer/Mill is intended for intermittent use with running times that are typically 5 to

20 minutes long. Under those conditions it should run for many years without maintenance other

than that described above. Prolonged periods (over 100 min.) of continuous running, as when

the mill is used for mechanical alloying, require extra maintenance

The 8000D Mixer/Mill is warranted against defects of materials and workmanship for a period of

one year from date of shipment. Extreme uses of the mill, such as mechanical alloying, may

modify or void the warranty. Contact us for further information about operating your mill under

unusual circumstances.

Tungsten carbide, ceramic, and agate vials cannot be warranted against breakage.

If you have any questions about the operation and maintenance of your 8000D Mixer/Mill,

please contact our specialists by phone at 1-800 LAB-SPEX (522-7739) or 732-549-7144, or by

e-mail at sampleprep@spexcsp.com

8000D Mixer/Mill

Page 11 of 21 SPEX CertiPrep 8.21.03

SN and Higher

7.0 Accessories: Grinding/Mixing Vials

(If not included in your order, they are available for purchase at additional cost)

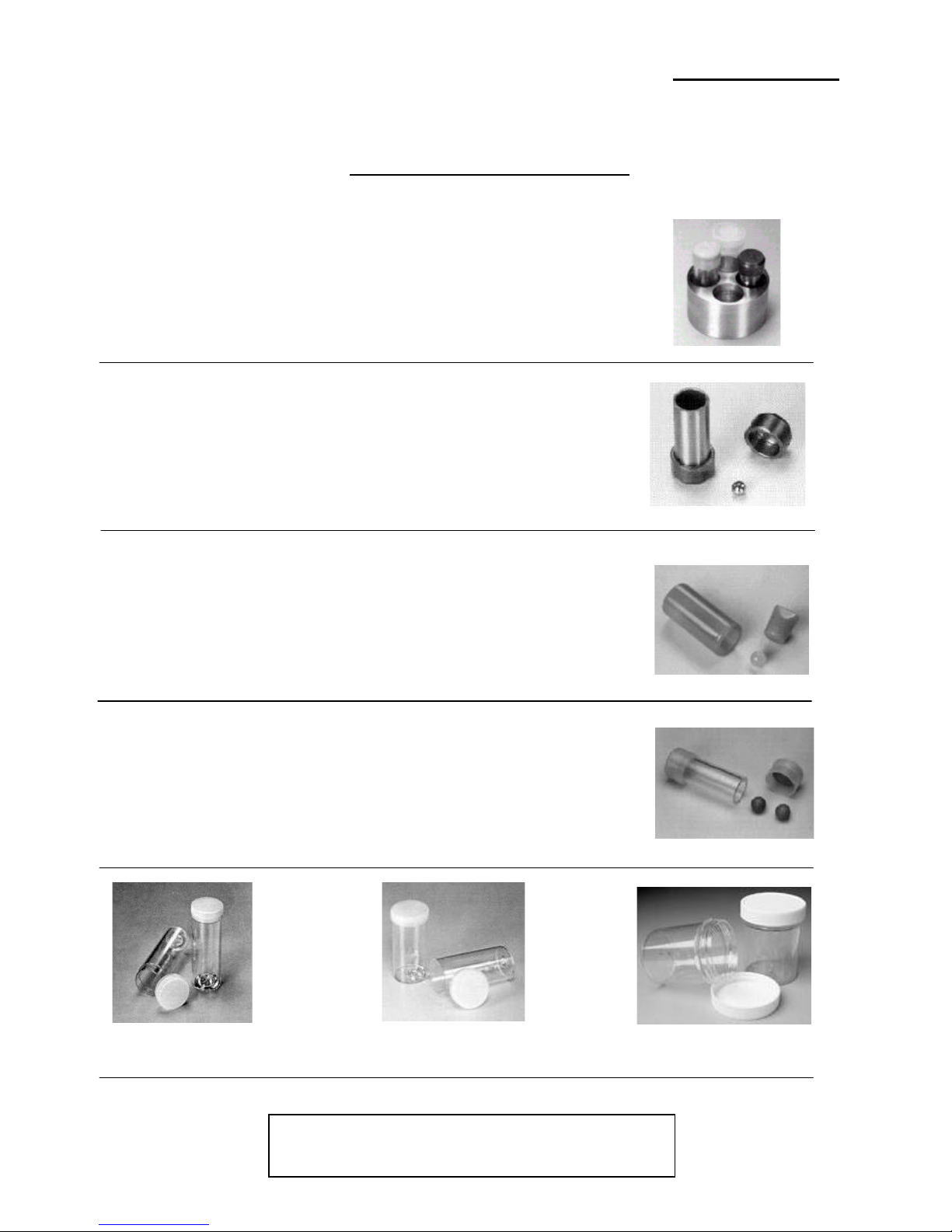

8001 Hardened Steel Vial Set

Vial size 2 ¼n. dia. x 3 in. Vial body and cap liner of

hardened tool steel. Set includes screw-on cap with O-ring

to allow wet or dry grinding/ mixing, two ½in. and four ¼

in. steel balls. Grinding load 3–10 ml; mixing load approx.

25 ml.

8003 Alumina Ceramic Vial Set

For dry grinding/mixing. Vial size 2¼in. diameter x 2¾

in. High purity 99.5% alumina ceramic vial body and two

slip-on caps with one ½in. ball; set includes eight

corprene gaskets. Grinding load 2–8 ml; mixing load

approximately 20 ml.

Note: Although the various accessory packages are Shown for your information, your unit will

arrive only with the accessory package that you have ordered.

8015 Clamp for 8003

Clamps permit slurry grinding in 8003 vials; sold in pairs.

One pair required for each 8003.

8004 Tungsten Carbide Vial Set

For wet or dry grinding/mixing. Vial size 2¼in. diameter

x 2½in. Tungsten carbide-lined body, two screw-on

tungsten carbide-lined caps, two 7/16 in. tungsten carbide

balls, eight corprene gaskets. Grinding load 3-10 ml,

mixing load approximately 25 ml.

8000D Mixer/Mill

Page 12 of 21 SPEX CertiPrep 8.21.03

SN and Higher

7.0 Accessories: Grinding/Mixing Vials

(If not included in your Order, they are Available for Purchase at Additional Cost)

8005 Zirconia Ceramic Vial Set

Vial size 2 ½in. diameter x 2-11/16 in. Solid zirconia ceramic

vial, cap, and two 1/2 in. balls; seven corprene gaskets. Grinding

load approximately 2-8ml; mixing load approximately 20 ml.

8007 Stainless Steel Vial Set

Vial size 2 ¼in. diameter x 3 in. Vial body and cap liner

made of hardened 440C stainless steel. Two ½in. and four

¼in. stainless steel balls are included. Set includes screw-on

cap with O-ring to permit wet or dry grinding/mixing.

Grinding load 3–10 ml; mixing load approx. 25 ml.

8008 Silicon Nitride Vial Set

Vial size 2 ½in. diameter x 2-11/16 in. solid silicon nitride

vial, cap, and two ½in. balls; seven corprene gaskets.

Grinding load approximately 2-8ml; mixing load

approximately 20 ml.

8009 Round-Ended Hardened Steel Vial Set

Vial size 2-3/8 in. diameter x 3 in. Hardened steel vial body

has grinding chamber with rounded ends for more efficient

grinding/mixing. Includes screw-on cap and O-ring for wet

or dry use, two ½in. and four ¼in. steel balls. Grinding

load 3-10 ml; mixing load approximately 25 ml.

To Order any of these

accessories, call Customer

Service at 800-522-7739

8000D Mixer/Mill

Page 13 of 21 SPEX CertiPrep 8.21.03

SN and Higher

7.0 Accessories: Grinding/Mixing Vials

(If not included in your Order, they are Available for Purchase at Additional Cost)

8014 Agate Vial Set

For dry grinding and mixing. Vial size 2 ¼xin. diameter x 2

¾in. All-agate vial body, two slip-on caps, two ½ in. agate

balls, and eight corprene gaskets. Grinding load 3-8 ml;

mixing load approximately 20 ml.

8006 Methacrylate Vial Set

2 ¼in. diameter x 2-5/8 in. Vial body of heavy-gauge

methacrylate with methacrylate-lined aluminum screw-on

cap. Set includes corprene gasket, two 8006A (½in.) and

four 3112 (3/8) in. plastic balls. Allows grinding of soft

materials without metallic contamination. Grinding load 3-8

ml; mixing load approximately 20 ml.

3114 Stainless Steel Vial Set

½ in. diameter x 1 in. long. Made of 303 stainless steel;

includes slip-on cap and ¼in. steel ball; grinding load 0.2-

0.6 ml, mixing load 1ml.

3117 Hardened Tool Steel Vial Set

½in. diameter x 1 in. long. Made of Worpliss tool steel.

Includes slip-on cap and ¼in. steel ball. Grinding load 0.2-

0.6 ml, mixing load 1ml.

8010 Multiple Sample Adapter

Can be used in 8000D Mixer/Mill with 3116 vials, or with

3111, 3114, and 3117 vials if 8012 adapter is also used.

8000D Mixer/Mill

Page 14 of 21 SPEX CertiPrep 8.21.03

SN and Higher

7.0 Accessories: Grinding/Mixing Vials

(If not included in your Order, they are Available for Purchase at Additional Cost)

8011 Multiple Sample Adapter

Can be used in 8000D Mixer/Mill with 3118, 5004, and

6133 vials. To use 3127 vials in 8000D, 8012 adapter is also

necessary.

3127 Hardened Tool Steel Vial Set

¾in. diameter x 1-7/8 in. long. Made of Worpliss tool steel;

includes center cylinder with two slip-on caps and ¼in. steel

ball. Grinding load 0.5-1.0 ml, mixing load 2 ml.

3118 Agate Vial Set

Handmade from flawless Brazilian agate; must be run inside

cushioned SPEX CertiPrep 6133 vial (included); includes

stopper and ¼in. agate ball. Grinding load 0.2-0.6ml,

mixing load 1 ml.

5004 Tungsten Carbide-Lined Steel Vial Set

¾in. diameter x 2-1/8 in. long. Includes two slip-on Delrin

caps with tungsten carbide inserts, six disposable

methacrylate center cylinders, and two 5/16 in. tungsten

carbide balls. Grinding load 0.5-1.5 ml; mixing load 3ml.

6135 Plastic Vial

8002 Plastic Vial

6134 Plastic Vial

Vial

To Order any additional accessories, call Customer

Service at 800-522-7739

8000D Mixer/Mill

Page 15 of 21 SPEX CertiPrep 8.21.03

SN and Higher

8.0 PARTS LIST & ITEM LOCATOR

Item

Part No.

Description

Location

(Diagram, Page #)

1

37356

Single Clamp Assembly

A, 17

2

50013

Bearing for Clamp (2 required per clamp)

A, 17

3

33297

Clamp Retaining Spring Assembly

A, 17

4

37347

Motor Pulley

A, 17

5

10023

Motor, 1/3 HP, 115/230 volt

A, 17

6

50140

V-Belt

A, 17

7

60226

Bushing for Movable Clamp Face

A, 17

8

37362

Lock Nut

A, 17

9

37501

Clamp Screw

A, 17

10

37360

Tie Bar

A, 17

11

60152

C-Clip for Screw

A, 17

12

37363

Movable Clamp Face

A, 17

13

37361

Rod

A, 17

14

22606

Fixed Clamp Face

A, 17

15

53069

Rubber Pad for Clamp Face

A, 17

16

22604

Clamp Body

A, 17

17

37344

Eccentric

A, 17

18

50014

Bearing for Pillow Block

A, 17

19

50525

Retaining Ring for Bearing

A, 17

20

37348

Shaft

A, 17

21

37345

Flywheel

A, 17

22

37346

Pillow Block

A, 17

23

37350

Shaft Pulley

A, 17

24

92941

Relay (115V)

B, 18

25

92942

Relay (230V)

B, 18

26

96092

Fan

B, 18

27

96004

AC Input

B, 18

8000D Mixer/Mill

Page 16 of 21 SPEX CertiPrep 8.21.03

SN and Higher

8.0 PARTS LIST & ITEM LOCATOR

(Continued)

Item

Part No.

Description

Location

(Diagram, Page #)

28

96005

Fuse Holder

B, 18

29

93850

Fuse, 8 amp (for 115 Volt)

B, 18

30

93840

Fuse, 5 amp (for 230 Volt)

B, 18

31

92703

Rocker Switch

B, 18

32

92912

Hinge Switch

B, 18

33

51208

Handle

B, 18

34

38567

Gas Spring

B, 18

35

92701

Roller Switch

B, 18

36

92965

Solenoid (115V)

B, 18

37

92968

Solenoid (230V)

B, 18

38

37483-D

Display Board

B, 18

39

37483-P

Power Board

B, 18

40

22640

Ball Seat

C, 19

41

60156

Retaining Ring For Ball Seat

C, 19

42

21519

Spring For 33297

C, 19

43

33297R

Pivot Assemblies (1 Pair)

C, 19

50152

Vibration Mount

37349

Rear Spring Bracket

93719

Rubber Feet for Cabinet (4 required)

8000D Mixer/Mill

Page 17 of 21 SPEX CertiPrep 8.21.03

SN and Higher

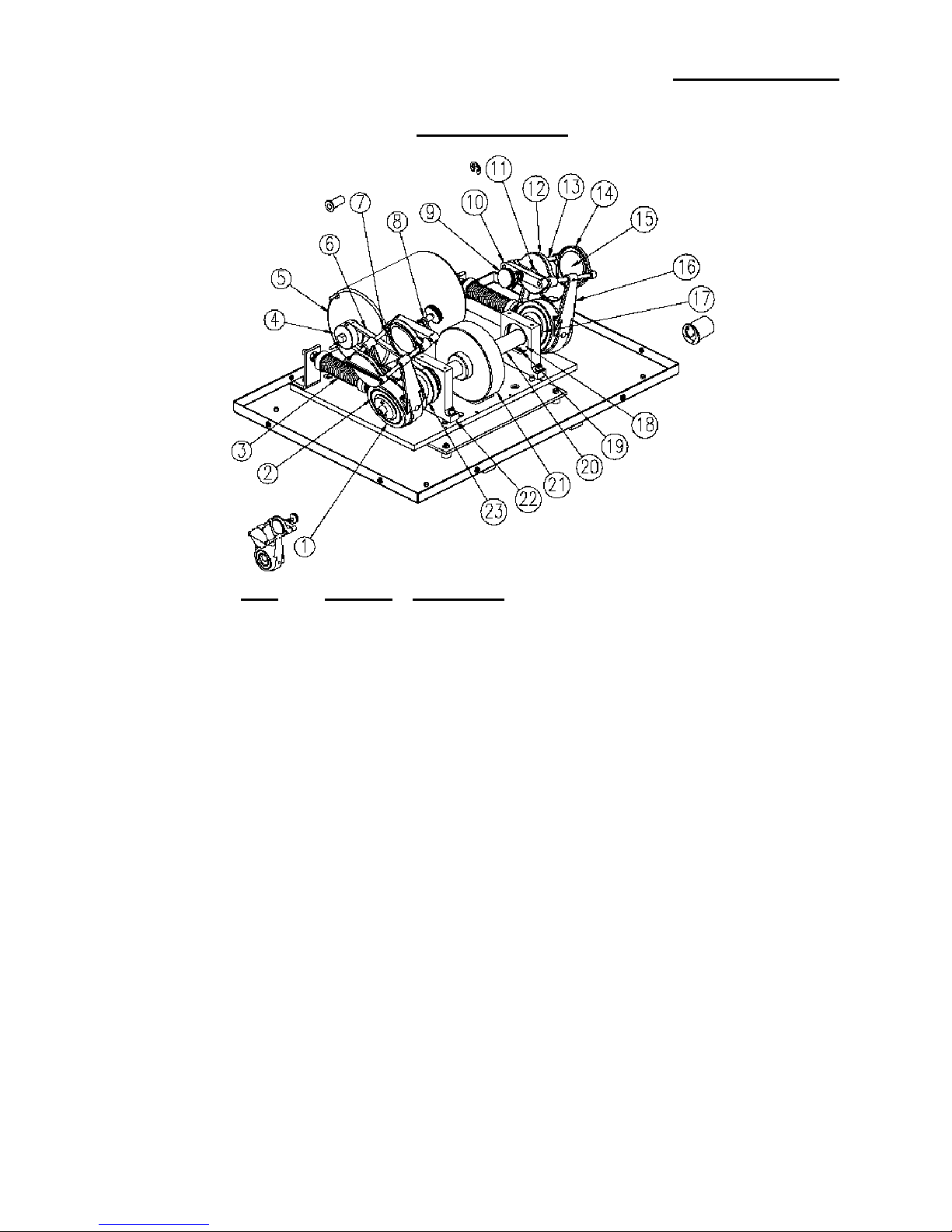

9.0 DIAGRAM “A”

Item

Part No.

Description

1

37356

Single Clamp Assembly

2

50013

Bearing for Clamp (2 required per clamp)

3

33297

Clamp Retaining Spring Assembly

4

37347

Motor Pulley

5

10023

Motor, 1/3 HP, 115/230 volt

6

50140

V-Belt

7

60226

Bushing for Movable Clamp Face

8

37362

Lock Nut

9

37501

Clamp Screw

10

37360

Tie Bar

11

60152

C-Clip for Screw

12

37363

Movable Clamp Face

13

37361

Rod

14

22606

Fixed Clamp Face

15

53069

Rubber Pad for Clamp Face

16

22604

Clamp Body

17

37344

Eccentric

18

50014

Bearing for Pillow Block

19

50525

Retaining Ring for Bearing

20

37348

Shaft

21

37345

Flywheel

22

37346

Pillow Block

23

37350

Shaft Pulley

8000D Mixer/Mill

Page 18 of 21 SPEX CertiPrep 8.21.03

SN and Higher

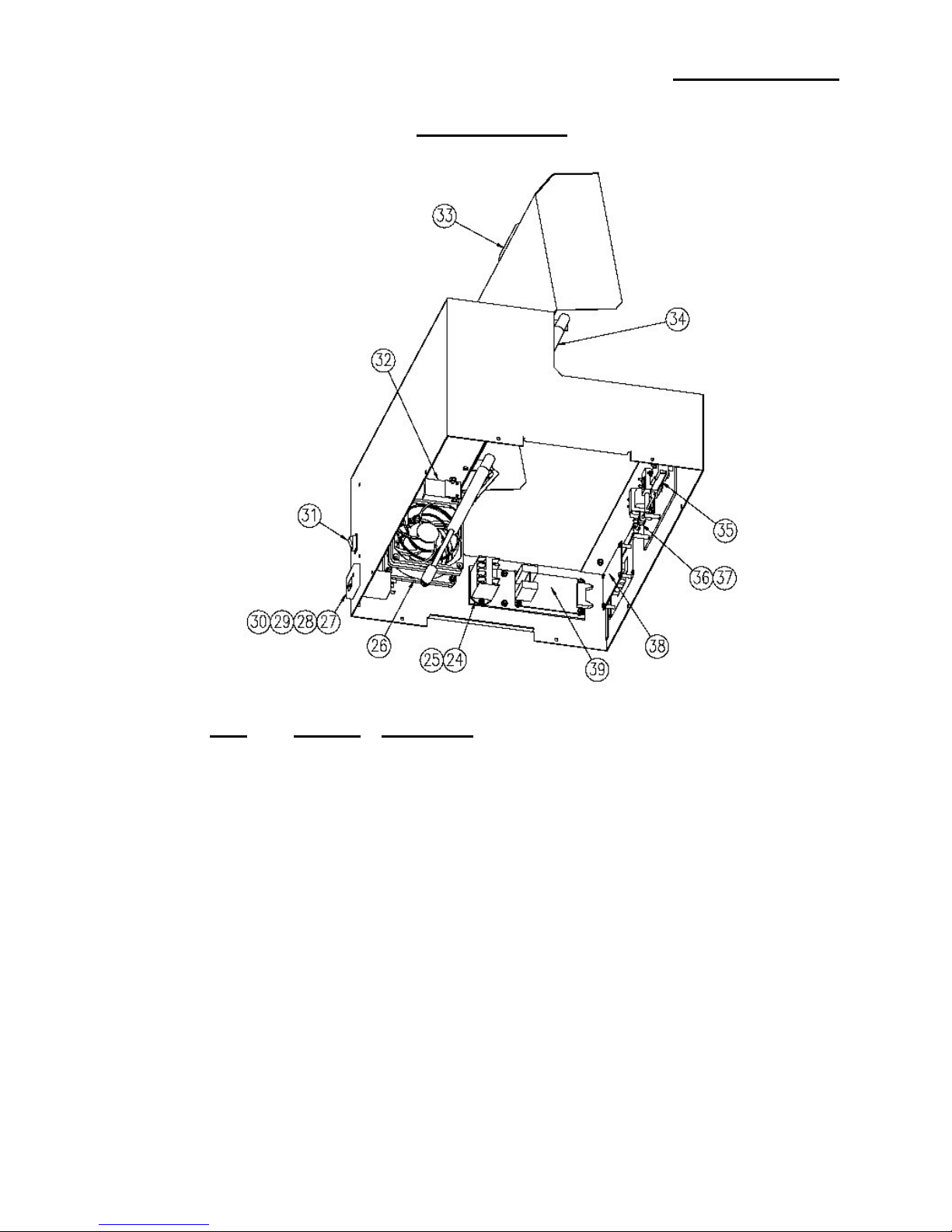

9.1 DIAGRAM “B”

Item

Part No.

Description

24

92941

Relay (115V)

25

92942

Relay (230V)

26

96092

Fan

27

96004

AC Input

28

96005

Fuse Holder

29

93850

Fuse, 8 amp (for 115 Volt)

30

93840

Fuse, 5 amp (for 230 Volt)

31

92703

Rocker Switch

32

92912

Hinge Switch

33

51208

Handle

34

38567

Gas Spring

35

92701

Roller Switch

36

92965

Solenoid (115V)

37

92968

Solenoid (230V)

38

37483-D

Display Board

39

37483-P

Power Board

8000D Mixer/Mill

Page 19 of 21 SPEX CertiPrep 8.21.03

SN and Higher

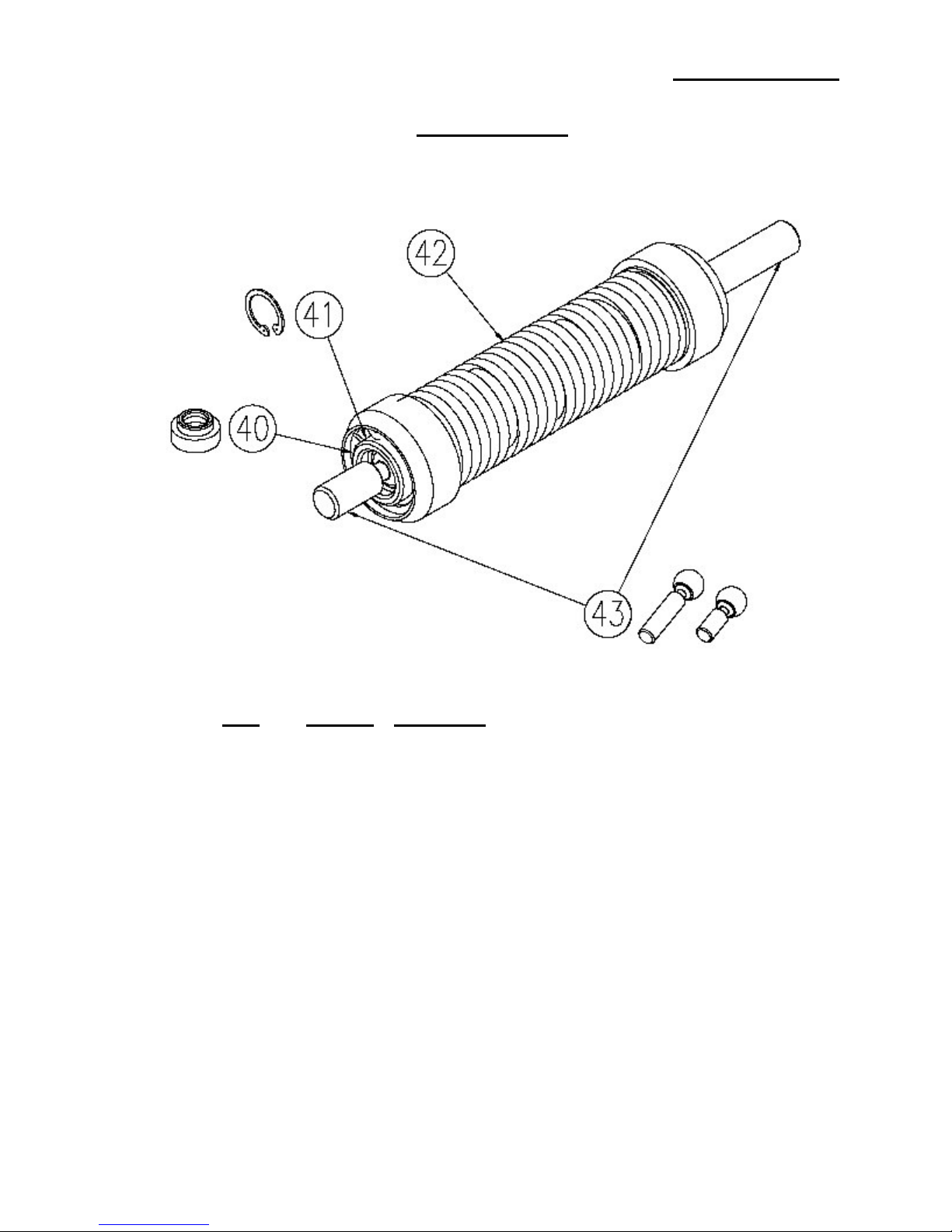

9.2 DIAGRAM “C”

Item

Part No.

Description

40

22640

Ball Seat

41

60156

Retaining Ring For Ball Seat

42

21519

Spring For 33297

43

33297R

Pivot Assemblies (1 Pair)

8000D Mixer/Mill

Page 20 of 21 SPEX CertiPrep 8.21.03

SN and Higher

10.0 TROUBLESHOOTING GUIDE

PROBLEM

CAUSE

SOLUTION

1

The unit does not turn on

No AC power

Make sure power cord is

plugged into outlet and check

outlet for power and correct as

required

2

The unit does not turn on

Blown fuse

Replace fuses

3

The unit does not turn on

Power switch not

turned on

Depress power switch

4

Unit does not run

Lid is open

Close the lid and be sure that

the latch is locked

5

Unit does not run, lid is

closed and timer counts down

Safety interlock switch

Adjust safety interlock switch

6

Unit does not run

Disconnected harness

Re-connect wiring harness to

motor

7

The lid does not open

Unit may be paused

Depress start/stop button

8

The lid does not open

Safety catch has not

released

Depress start/stop button or

turn off unit to open

9

Grinding ball doesn’t shuttle

back and forth

Too much sample is in

the vial or sample

pieces are too large

Remove some sample from the

vial and start again

10

Excessive Vibration

Shipping bolts still in

place

Remove shipping bolts

Table of contents

Popular Power Tools manuals by other brands

jbc

jbc advanced Series manual

Greenlee

Greenlee GATOR CLS60GL instruction manual

CHP

CHP AT-6500 instruction manual

PCB Piezotronics

PCB Piezotronics J353B34 Installation and operating manual

Porta-Nails

Porta-Nails PORTAMATIC 470 owner's manual

Parkside

Parkside 353260 2007 Translation of the original instructions