10

enough force to cause the tool to cycle.

Keep hands and body away from the discharge area of the tool.•

The tool may bounce from the recoil of driving a fastener and

an unwanted second fastener may be driven possibly causing

injury.

When loading tool, never place a hand or any part of body in•

fastener discharge area of tool, never point tool at anyone,

do not pull the safety trigger or depress the ram/actuator as

accidental actuaon may occur, possibly causing injury.

Always disconnect the air supply before making adjustments,•

when servicing the tool, when clearing a jam, when tool is not

in use, or when moving to a different work area, as accidental

actuaon may occur, possibly causing injury.

Check operaon of the safety mechanism frequently. Do not•

use the tool if the safety is not working correctly as accidental

driving of a fastener may result. Do not interfere with the

proper operaon of the safety mechanism.

The safety trigger is a safety device and should only be pulled•

when the tool is in proper posion on the work surface and

before the ram/actuator is struck with the mallet. Do not e

or tape down the safety trigger as the tool could discharge if

dropped on the plunger. The tool will not fire unless the trigger

is pulled before striking the ram/actuator with the mallet.

Do not use the safety as a disabling mechanism for the ram/•

actuator in order to use the tool to rack the wood. This will

severely damage the mechanism and the tool. This abuse and

damage is not covered by the warranty. Use the mallet to rack

the flooring, not the tool.

Do not strike the ram/actuator without pulling the safety•

trigger! Hing the tool repeatedly with the safety engaged will

damage the safety mechanism and the tool.

Do not drive fasteners on top of other fasteners or with the•

tool at an overly steep angle as this may cause deflecon of

fasteners which could cause injury.

Do not strike the ram/actuator or any part of the tool with the•

metal poron of the mallet. Use the rubber capped end only to

prevent possible injury and/or damage to the tool.

Do not drive fasteners close to the end of the work piece as the•

wood may split, allowing the fastener to be deflected possibly

23

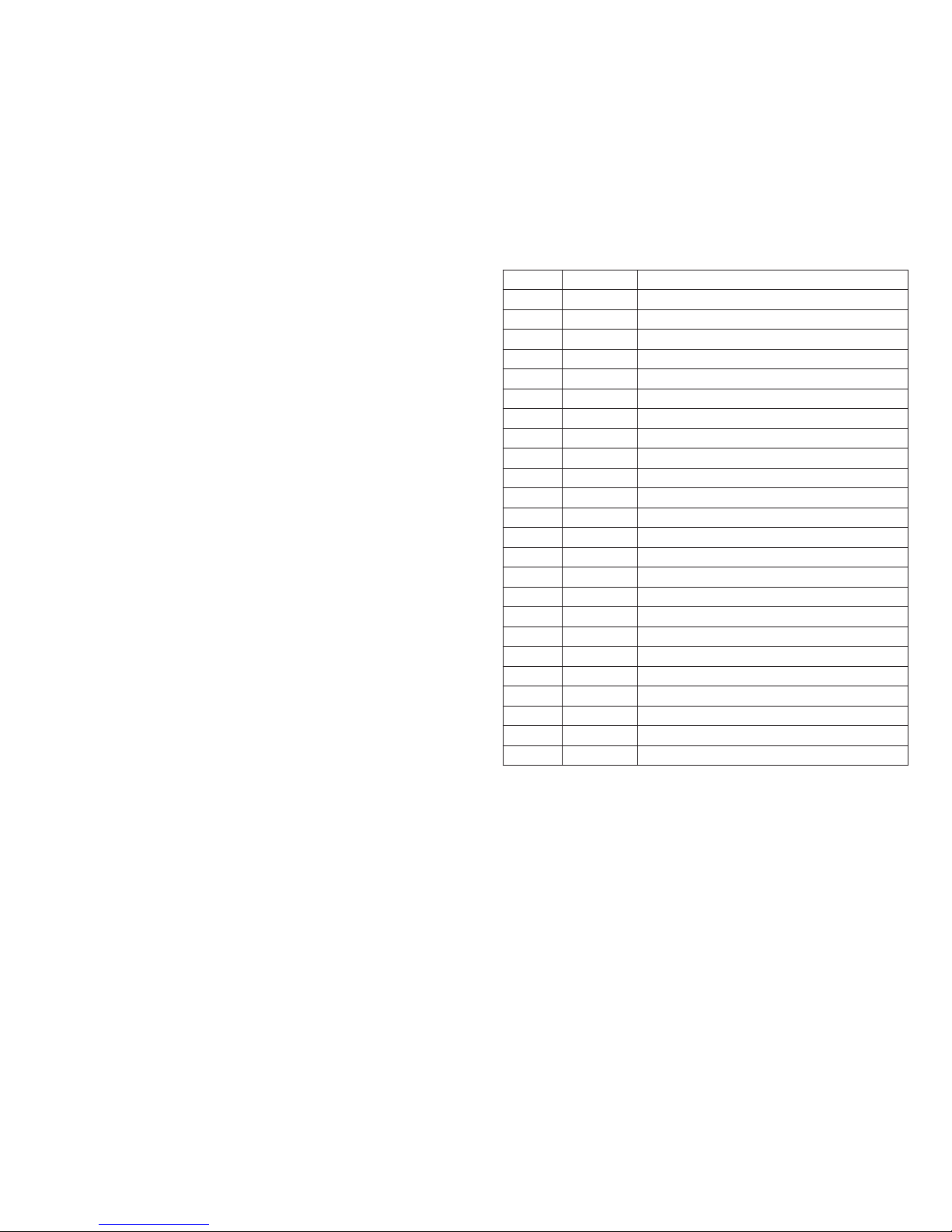

33 47074 SCREW – HANDLE CAP

34 47036 SCREW – MAGAZINE STAND-OFF

35 47048 ROLLER – SPRING

36 47044 CONSTANT FORCE SPRING

37 47037 MAGAZINE SPACER / STAND-OFF

38 47043 ROLLER WHEEL

39 47042 SCREW – CONSTANT FORCE SPRING

40 47041 PUSHER FINGER

41 47057 SPRING– COMPRESSION

42 47039 PUSHER BRACKET

43 47056 O-RING– PUSHER PIVOT PIN

44 47055 PUSHER PIVOT PIN

45, 45A 47028 SCREWS – FOOT / MAGAZINE

46 47029 FOOT

47 47032 SPRINGPIN – FOOT / DRIVER GUIDE PLATE

48 47031 DRIVER GUIDE PLATE

49 47033 NOSE – 470 – T/L

50 47034 MAGAZINE – 470 – T/L

51 47038 NUT – MAGAZINE / STANDOFF SCREWS

52 47027 SHOE

53 47025 SHOE BASE PAD

54 47024 SCREW – SHOE BASE

55, 55A 47026 SCREWS – SHOE / FOOT / BODY

56* 47047 LOCK NUT – SHOE BASE

57* 47075 HAMMER ASSY – GRAPHITE

*NOT SHOWN IN ILLUSTRATION