spinflo S~OH70000Y Operating instructions

PCC 1265Y

–

Issue 2

FOR USE IN USA & CANADA

USER AND INSTALLATION INSTRUCTIONS

READ AND RETAIN FOR FUTURE REFERENCE

MODELS

S~OH70000Y - TRIPLEX

S~OH71000Y – TRIPLEX DUAL FUEL

SPINFLO LIMITED, 19 Oakham Drive, Parkwood Industrial Estate

Rutland Road, Sheffield S3 9QY, ENGLAND.

TEL: + 44 (0) 114 273 8157 FAX: + 44 (0) 114 275 3094

BUILD IN APPLIANCES

FOR USE WITH LIQUIFIED PETROLEUM GAS

C

O

U

N

T

R

Y

L E I S U R E

- Do not store or use gasoline or other

flammable vapors and liquids in the vicinity

of this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS

•Do not try to light any appliance

•Do not touch any electrical switch

•Do not use any phone in your recreational

vehicle

•Clear the recreational vehicle of all

occupants.

•Turn off the gas supply tank valve(s) or

main gas supply.

•Immediately call your gas supplier for

instructions.

•If you cannot reach your gas supplier, call

the fire department.

- Have the gas system checked and leakage

source corrected by a qualified installer,

service agency, manufacturer or dealer or

the gas supplier.

WARNING:

If the information in this manual is not

followed exactly, a fire or explosion may

result causing property damage, personal

in

j

ur

y

or death.

2

3

4

5

6

7

SPECIFICATION

Gas:

TRIPLEX TRIPLEX

PROPANE gas only 11 ins wc ( 27.4mbar )

TRIPLEX TRIPLEX TRIPLEX

Model S~OH70000Y S~OH71000YRange S~OH70000Y S~OH70000Y S~OH70000Y

External

Dimension

(HxWxD)

468 x 456 x 500mm

18.43 x17.95 x19.70in 468 x 456 x 500mm

18.43 x17.95 x19.70in

mm

Inches

468 x 456 x 500mm

18.43 x 17.95 x 19.70in 468 x 456 x 500mm

18.43 x17.95 x19.70in 468 x 456 x 500mm

18.43 x17.95 x19.70in

Oven

Capacity 36

2200 36

2200

Litres

Cubic ins 36

2200 36

2200 36

2200

No. of tra Grill 2, Oven 4 Grill 2, Oven 4

y positions Grill 2, Oven 4 Grill 2, Oven 4 Grill 2, Oven 4

Heat input

Total heat input

Hotplate Burners (LPG) 2 x 5350 Btu/hr

1 x 7850 Btu/hr 2 x 5350 Btu/hr3 x 5350 Btu/hr

2 x 5350 Btu/hr

AUX 1 x 3450 Btu/hr 2 x 4400 Btu/hr

AUX 1 x 3450 Btu/hr

Electric Hot

(110V ~ 60Hz) N/A 1 x 1000W Maxplate N/A N/A N/A

Grill burner heat input 4900 Btu/hr 4900 Btu/hr4900 Btu/hr 4900 Btu/hr 4900 Btu/hr

Oven burner heat input 5700 Btu/hr 5700 Btu/hr5700 Btu/hr 5700 Btu/hr 5700 Btu/hr

Injector size,

mm

Hotplate Burners Sabaf 2x0.67, 1x0.81 Sabaf 2x0.67Sabaf 0.67 Sabaf 2x0.67, 1x0.53 Sabaf 2x0.62, 1x0.53

Grill burner Sabaf 0.62 Sabaf 0.62Sabaf 0.62 Sabaf 0.62 Sabaf 0.62

Oven burner Sabaf 0.65 Sabaf 0.65Sabaf 0.65 Sabaf 0.65 Sabaf 0.65

By

pass size, mm

Hotplate Controls Sabaf 0.34 Sabaf 0.34Sabaf 0.34 Sabaf 0.34 Sabaf 0.34

Grill control N/A N/AN/A N/A N/A

Oven contro Sabaf 0.35 Sabaf 0.35l Sabaf 0.35 Sabaf 0.35 Sabaf 0.35

Spark ignition 12V 12V(If fitted) 12V 12V 12V

Weight

21.5Kg

47.4lbs 23.1Kg

50.9lbs

Kg

Pounds 21.5Kg

47.4lbs 21.5Kg

47.4lbs 21.5Kg

47.4lbs

IMPORTANT

•THIS APPLIANCE IS SUITABLE FOR USE WITH PROPANE AND

SHOULD NOT BE USED ON ANY OTHER GAS.

•USE ONLY THE GAS PRESSURES SPECIFIED ABOVE

•THIS APPLIANCE MUST BE EARTHED.

INTRODIONUCT

In your own interest of safety, gas applianc

Failure to install the appliance correctly coul

This appliance shall be installed in accor

instructions, local and state codes or, in t

Recreational Vehic

es

d

ab

sh

inv

se

oul

alid

nc

d in led by competent persons.

a or liability claims.

e e u o ith the Standard for

, ANSI A119.2.

be

te a

of s

stal

y w

ch c

n arra

de

nty

s, w

dance with the manufacturers installation

h

les

Data label

The data label is locat

oven door. Ensure that the gas supply is Pr

with Propane gas and should not be conv

ed on the right hand si

erted for use with any other gas.

de front of the oven compartment, behind the

opane. This appliance is designed for use

Provision of Ventilation e s o ti f heat and moi e in a

ll ventilated and in accordance

obstruct the flow of combustion or ventilation ir

e adequate ventilation for complete combustion of gas,

mperature mmediate surroundings within safe limits.

The use of a gas cooking applianc

room in which it is installed.

with local and state codes. Do not

general, the appliance should hav

proper flueing and to maintain

Location

t.

This appliance maybe installed in a kitchen/ki

bath or a shower. LP gas appliances must

b

tchen diner but NOT in a room containing a

not be fitte e level. e

as d b low ground

emen .g. in a

result in the pr duc on o

Ensure that the kitchen is we

te of i

stur

a . In

OPERATION

WARNING

•The appliance is NOT intended for use by young children or

infirm persons, without supervision

•Glass lids may shatter when heated. Turn off all burners

efore shutting the lidb

•Spillage on the lid surface should be removed before opening.

Burner operation

The burners on this appliance have fixed aeration and no adjustment is required. The

burners should flame as follows:-

Propane - The flames should burn quietly with a blue/green colour with

no sign of yellow tips.

IMPORTANT

Although each burner will support pans from 4ins (100mm) to

For safe operation burner flames should be adjusted so they do NOT

extend beyond the edge of the pan as this will reduce the efficiency

of the burner.

•Avoid old or misshapen pans as these may cause instability.

•

•8½ins (220mm), care should be taken not to overload the appliance

as reduced performance may result.

•

The lid must be opened fully when using the hotplate burners.

Using the Hob Burners

. Ensure gas cylinder/supply is connected and turned on. In the event of a gas smell turn

off at gas cylinder/mains and contact supplier.

. Flame supervision: Each burner is controlled individually and is monitored by a

thermocouple probe. In the event of the burner flames being accidentally extinguished,

turn off the burner control and do not attempt to re-ignite the burner for at least one

minute.

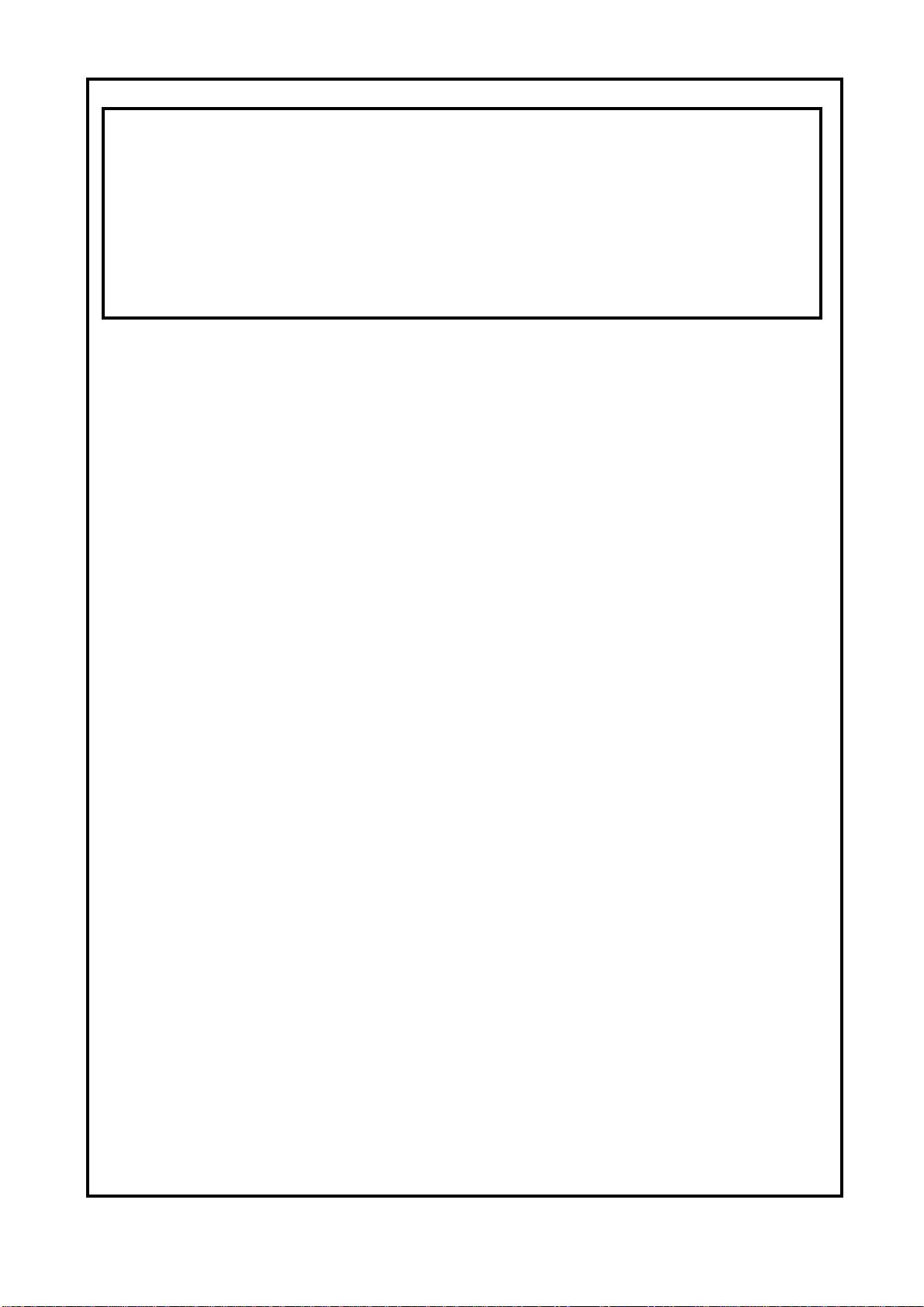

. To light: Push in the control knob and turn to ‘LITE’ position – see Fig.6. Hold a lighted

match or taper to the burner and push the control knob in and hold. It is necessary to

hold the knob depressed after the burner has ignited for approximately 10 - 15

seconds, to allow the thermocouple probe to reach temperature, before releasing the

knob. Should the flame go out when the knob is released, the procedure should be

repeated holding the knob depressed for slightly longer.

. For models fitted with Spark Ignition the procedure is similar except that the burner can

be ignited by depressing the ignition button, which is located on the fascia. If the burner

has not lit within 15 seconds the control knob should be released and the burner left for

at least 1 minute before a further attempt to ignite the burner.

. For simmering, turn the knob further anti-clockwise to the low rate position –see Fig. 7

. To turn off: Turn the control knob until the line on the control knob is aligned with ‘OFF’

on the control panel. Always make sure the control knob is in the ‘OFF’ position when

you have finished using the hotplate burners – see Fig. 5.

1

2

3

4

5

6

10

OPERATION

sing the Electric Hotplate

WARNING

•Glass lids may shatter when heated. Turn off the hotplate and allow it to

re opening.

cool before closing the glass lid.

•Remove all spillage from the surface of the glass lid befo

U

om 1 to 6 – see Fig. 8. To turn it on, rotate the knob

oolest setting.

ho

‘OFF’ on the

T sealed construction and transfers heat through conduction. For maximum

efficien a n size

should be t

Before sin

season .

To prime th

Switch n t the coating.

se a edi uring this

hen season.

me

app

Ensure the electricity is switched on.

he hotplate control is numbered frT

either clockwise or anti-clockwise to the required position. Position 1 is the c

To turn the ob until the line or pointer on the knob lines up withtplate off, rotate the kn

control panel.

he hotplate is a

cy correctly sized pan with a flat heavy gauge base should be used. Pa

he same or slightly larger (up to 1” / 2.5 cm oversize).

u g your hotplate for the first time, we recommend that you prime and then

it

e Hotplate

a ro he hotpl te fo a short period, without a pan, to harden and burn off

m um to high setting for 3 – 5 minutes. A non toxic smoke may occur dU

process. Allow it to cool, t

To season the Hotplate

First heat the hotplate for 30 seconds on a medium setting, then switch off. Pour a minimal

ount of unsalted vegetable oil onto a clean dry cam loth or paper towel, and apply a thin

coat of oil to the hotplate surface. Wipe off any excess oil, then heat the hotplate on a

dium setting for 1 minute. Occasional seasoning will help to maintain the Hotplate’s

earance.

11

OPERATION

IMPORTANT

•

•The grill MUST only be used with the door open.

The control tap on this appliance operates both the Grill and Oven

b

•Tg

the grill. Never adjust the heat deflector position without using hand

protection – ie oven gloves.

burners. To ensure safe operation it is not possible to operate both

urners at the same time.

he heat deflector below the fascia should be pulled out prior to lightin

Using the Grill

. Ensure gas cylinder/supply is conn1

ected and turned on. In the event of a gas smell turn

an

n the fascia. Ignition

nds

ignite the burner.

it should be heated for about 20 minutes to eliminate any

kly, it is recommended that a few minutes preheat

o

y on Butane.

. A reversible grill pan trivet enables the correct grilling height to be achieved.

Fast Toasting trivet in high position

Grilling Sausages trivet in high position

Grilling Steak/Bacon trivet in high position

Grilling Chops, etc trivet in low position

Slow Grilling trivet removed

9. To turn off: turn the control knob until the line on the control knob is aligned with ‘OFF’

on the control panel. Always make sure the control knob is in the off position when you

have finished grilling.

off at gas cylinder/mains and contact supplier.

2. To light: Open door, push in the control knob and turn to ‘LITE’ position – see Fig 9.

Hold a lighted match or taper to the burner and push the control knob in and hold. The

burner should ignite and the control knob should be held in for 10 -15 seconds before

release. If the burner goes out, repeat procedure holding control knob for slightly

longer.

3. For models fitted with Spark Ignition the procedure is similar except that the burner c

be ignited by depressing the ignition button, which is located o

must be carried out with the door open, and if the burner has not lit within 15 seco

the control knob should be released and the grill left for at least 1 minute before a

further attempt to

4. On first use of the grill,

residual factory lubricants that might impart unpleasant smells to the food being

cooked. A non-toxic smoke may occur when using for the first time so open any

windows and turn on mechanical ventilators to help remove the smoke.

5. Although the grill does heat up quic

be allowed.

6. Flame Failure Device (FFD): the grill burner is fitted with a flame sensing probe, which

will automatically cut off the gas supply in the event of the flame going out. In the event

of the burner flames being accidentally extinguished, turn off the burner control and d

not attempt to re-ignite the burner for at least one minute.

7. It is normal for the flames on this burner to develop yellow tips as it heats up,

particularl

8

IMPORTANT

•The pan supplied is multi functional, for use whilst grilling or when using

the oven. The handle design allows removal or insertion whilst the pan is

in use. Always remove the handle when the pan is in use.

12

OPERATION

WARNING

•When cooking always ensure young children are kept away.

•Never cover slots, holes or passages in the oven bottom or cover an

uch as aluminium foil. Doing so blocksentire shelf with materials s

airflow through the oven and may cause carbon monoxide poisoning.

Aluminium foil linings may also trap heat, causing a fire hazard.

Using the Oven

ual

A

turn

f the

1. Ensure gas cylinder/supply is connected and turned on. In the event of a gas smell turn

off at gas cylinder/mains and contact supplier.

2. To light: Open door, push in the control knob and turn to ‘LITE’ position – see Fig. 9.

Hold a lighted match or taper to the burner and push the control knob in and hold. The

burner should ignite and the control knob should be held in for 10 -15 seconds before

release. If the burner goes out, repeat procedure holding control knob for slightly

longer.

For mod3. els fitted with Spark Ignition the procedure is similar except that the burner can

be ignited by depressing the ignition button, which is located on the fascia. Ignition

must be carried out with the door open, and if the burner has not lit within 15 seconds

the control knob should be released and the oven left for at least 1 minute before a

further attempt to ignite the burner.

4. Place the oven shelf in the required position and close the door. Set control knob to

approximately 3500F and heat the oven for about 30 minutes to eliminate any resid

factory lubricants that might impart unpleasant smells to the meals being cooked.

non-toxic smoke may occur when using for the first time so open any windows and

on mechanical ventilators to help remove the smoke.

5. Although the oven does heat up quickly, it is recommended that a 10 minutes preheat

be allowed. The oven should be up to full temperature in about 15-20mins.

6. To turn off: turn the control knob until the line on the control knob is aligned with ‘OFF’

on the control panel.

7. Shelf: the shelf has been designed to allow good circulation at the rear of the oven and

includes a raised bar to prevent trays or dishes making contact with the back o

oven. To remove a shelf, pull forward until it stops, raise at front and remove.

Oven Temperature Control

T the oven is controlled b

th r 65 F (130°C to 240°C). Approximate temperature

th c shown in the table be

he temperature in y a thermostatic gas tap and is variable over

e ange 2660F to 4 s for the settings on

e ontrol knob are low. The temperatures indicated refer to the

fferent temperatures may be cooked at the same time. In this

way maximum benefit can be obtained from the gas used to heat the oven. Care should be

taken not to overload the oven, adequate spacing being used to allow free circulation for

heat.

0

centre of the oven and at any particular setting the oven will be hotter at the top and cooler

towards the base. The variation between top and centre, and centre to bottom is

approximately equivalent to 300F. Good use can be made of the temperature variation in

several dishes requiring di

13

OPERATION

Cooking Guidelines

Best r

page. s oven

is capable

Most cook

recipe. If n find a

imilar dish in our guide and use our shelf position and gas mark setting recommendation.

from the top down. When roasting with aluminium foil care must be

ken that the foil does not impair circulation or block the oven flue outlet.

Do

esults will be obtained by the shelf positions in this guide – please see chart on next

It i not necessary to preheat the oven but advisable for a range of dishes. The

of full temperature in 15-20 minutes.

ery books give details of the shelf positions and gas mark settings for each

in doubt about a recipe you intend to use, study the recipe carefully the

s

Shelf positions are

ta

's And Don'ts

DO read the instructions carefully before first use of the appliance

pliance regularly.

DO turn pan handles away from the front to avoid accidents

ar the cooker when in use.

O NOT allow fats or oils to build up in the oven trays or base.

DO allow the oven to heat before first use, to expel smells

DO clean the ap

DO remove spills as soon as they occur.

DO always use oven gloves when removing food shelves and trays.

DO check that controls are in the ‘OFF’ position when finished.

DO NOT allow children ne

D

DO NOT use abrasive cleaners or powders to clean the surfaces of the appliance.

DO NOT under any circumstances use the oven as a space heater.

DO NOT put heavy objects onto open grill and oven doors.

DO NOT reach over a lit appliance to gain access to overhead storage cabinets

Temperature

oF oC

¼ - ½ 255-275 120-135 Very cool Meringues

1 285 140 Cool Stewed fruit

2 300 150 Cool Rich fruit cake

3 330 165 Warm Baked custard

4 355 180 Moderate Victoria sandwich

5 385 195 Fairly hot Whisked sponges

6 410 210 Hot Short crust pastry

7 430 220 Hot Bread, scones

8 445 230 Very hot Puff pastry

9 465/480Max 240/260Max Very hot Quick browning

Shelf Cooking Time

Dish Pos

Scones 7 2 8-15mins

Small cakes 5 2 15-25mins

Victoria sandwich 4 2 20-30mins

Very rich fruit cake 2 2 Approx. 60mins per 500g

Puff pastry 8 2 15-30mins

Flaky pastry 7 2 15-30mins

Shortcrust pastry 6 2 15-55mins

Shortbread fingers 3 2 25-30mins

Ginger nuts 5 2 12-16mins

Rice pudding 2 3 100-120mins

Baked custard 3 3 50-60mins

Fruit crumble 5 3 30-40mins

Beef 3

7 3

3 25min per 500g plus 25min

15min per 500g plus 20min

Pork 3

7 3

3 30min per 500g plus 35

25min per 500g plus 25min

min

WARNING

•Never use this appliance as a space heater to heat or warm the room.

Doing so may result in carbon monoxide poisoning and overheating of

the oven

•Never use the oven as storage space. Doing so may result in a fire

and/or cause incomplete combustion.

14

OPERATION

Leaks

a smell of gas becomIf es apparent, the supply should be turned off at the cylinder

IMMEDIATELY. Extinguish naked lights including cigarettes and pipes. Do not operate

electrical switches. Open all doors and windows to disperse any gas. Propane gas is

heavier than air; any escaping gas will therefore collect at a low level. The strong that

bnormal Operation

unpleasant smell of gas will enable the general area of the leak to be detected. Check

the gas is not escaping from an unlighted appliance. Never check for leaks with a naked

flame, leak investigation should be conducted according to the following instructions.

A

of the are onside ed to be

•Yellow tipping of burner flame.

Burners not igniting properly.

B er h

Burners exting upb

a t to

Any following c r abnormal operation and may require servicing.

•Sooting of cooking utensils.

•

•urn s failing to remain alig t

•uished by c oard doors.

•Gas valves th t are difficul turn

W

O

he

Owhile it is in operation.

Ens

or motor homes.

•NEVER check for leaks with an open flame

ARNINGS

•D NOT store or use gasoline or other flammable vapours, liquids or items in

t vicinity of this or any other appliance.

•D NOT spray aerosols in the vicinity of this appliance

•N VER use the appliance as a space heater, either in marine craft, carava

15

INSTALLATION

Regulations and Standards

own interest of safety, gas appliances should be installed by competent persons.

ms.

for

In your

Failure to install the appliance correctly could invalidate any warranty or liability clai

This appliance shall be installed in accordance with the manufacturers installation

instructions, local and state codes or, in the absence of such codes, with the Standard

Recreational Vehicles, ANSI A119.2.

Data label.

The data label is located on the right hand side front of the oven compartment, behind the

ven door. Ensure that the gas supply is Propane. This appliance is designed for use

ith Propane gas and should not be converted for use with any other gas.

o

w

Ventilation

This appliance is suitable for installation into Holiday Homes, Touring Caravans and Boats.

In all cases the national standards with regard to ventilation for the particular vehicle into

which the appliance is to be

The appliance Mosure having the following ventilation:-

•A g esc eneath the appliance and positioned

at t rea T vent to the outside and have a cross-

sectional ar 2 ) and should be baffled to

pre nt di

•A h h lev liance in either the worktop or direct to

the outside – see ×Fig. 1 & 2, with a cross sectional area of minimum 4in2

(2400mm2). If vented to the outside a baffle should be attached to prevent direct

draught to the appliance.

Location of Appliance

installed must be adhered to.

UST be installed into an encl

as ape hole in the floor, directly b

he r – see ¯Fig. 2. The hole MUS

2 2

ea between 3in and 6in (1965 to 3850mm

ve rect draught to the appliance.

ig el rear vent, directly behind the app

This appliance maybe installed in a kitchen/kitchen diner but NOT in a room containing a

bath or a shower. LP gas appliances must not be fitted below ground level. e.g. basement.

Choose a location free of draughts, open doors and clear of combustible materials and

other fire hazards. The location should ensure convenience of operation and service. Any

adjoining wall surface situated within 41/2 in (115mm) from the cooker side – see Fig. 3,

must be made from a suitable non-combustible material for a height of 6in (150mm) for

the hotplate.the entire length of

Position

CAUTION: DO NOT LIFT APPLIANCE USING THE DOOR HANDLES

The appliance must be installed in such a

follows

becaus o

tempe u

Temp n Procedure

way that the furniture fitted around the unit

the minimum dimensions as shown in Figs. 1, 2 & 3. If this cannot be adhered to

f design constraints, then the design is deeemed permissible providing that the

rat re rise on the furniture is tested by undertaking following procedure.

erature Verificatio

Pla ate burners and fill up 3/4with

water. Turn on all 3 hotplates and the oven on full. After 45 minutes turn off the

oven and turn on the grill to full. After a further 15mins establish the highest

temperature points on ALL the furniture surfaces in direct line of sight of the

appliance. The temperature rise must not exceed 1490F ( 65oC) above the ambient

temperature, or where applicable, must not exceed the maximum allowable

temperature, to avoid damage, as detailed within the material suppliers

specification.

ce 3 large pans (20-22cm Ø) on top of the hotpl

16

INSTALLATION

All Appliances – The maximum depth of overhead cabinets installed above the cooker

cal

Fixing

must NOT exceed 13ins (330mm). All combustible materials such as curtains and shelves

must be kept well clear of the appliance, and their installation should meet all relevant lo

and state regulations/standards in force.

The

me se appliances can be front or side fixed, holes are provided for either installation

thod. Fixing screw positions are located as follows.

Gas Connection

A ¼ NPT female connection is provided for gas inlet, on the rear of the appliance. It is

on – 27.4mbar)

et to the correct pressure for the type of gas

bei

If th e that

the sooting)

the d

not

The burners on this appliance hav

Appl

recommended that the appliance be connected by copper tubing, a rubber or hose

connection must not be used. After connection the appliance must be tested for

soundness.

This appliance is suitable for use

Propane Gas Only 11 ins wc (

Max regulator inlet pressure ½ ins psi (34.5mbar)

Regulator supply pressure 12 ins wc (30.0mbar)

Manifold working pressure 11 ins wc (27.5mbar)

It is important that the regulator should be s

ng used. Excessive pressure must not be permitted.

e flame on either the top burners or the grill show a tendency to lift, it is probabl

line pressure is too great. Should there be excessive yellow tips (resulting in

n it is probable that the line pressure is too low and, in either case, the burners shoul

be used until the line pressure has been checked.

e fixed aeration and no adjustment is necessary.

iance Front Fixed Appliance Side Fixed Appliance

S~OH&

70000Y 2

S~OH71000Y

front fix holes each side of

Oven opening

s each hotplate side trim

2 side

2 fix hole

fix holes each side of

Oven opening

2 fix holes each hotplate side trim

IMPORTANT

•This appliance must be installed into an aperture, sealed off at either side in

order to prevent draughts from adjoining cupboards/vents. Ensure that air vents

and gas escape holes are kept clear, holes for cables and pipes mu

st be sized to

minimize air leakage between compartments.

r no circumstances should the ventilation hole exceed 3850mm2or other

aled to prevent a gas escape

•Unde

low level ventilation be located in the compartment, including vents in kickboards.

Low level vents in adjacent compartments are permitted.

•Any cupboards beneath the appliance MUST be se

entering the living area.

17

INSTALLATION

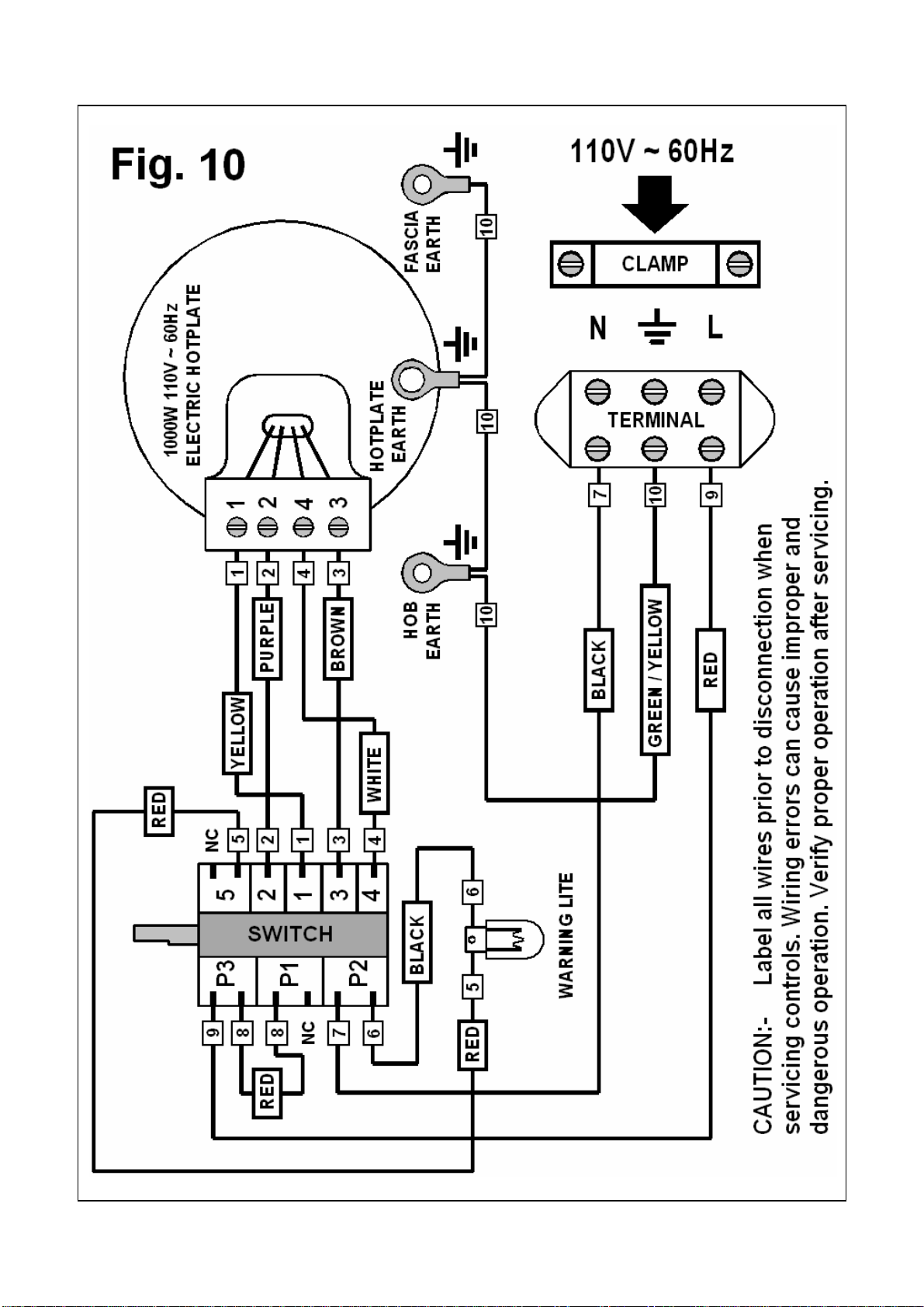

Dual Fuel Appliances - Electrical Connection

This appliance must be connected using a double insulated cord, type 227 IEC 53,

HO5V V-F, which is suitable for use up to 4 amps. See Fig 4 for terminal connection

etails. This should be connected to a double pole switched mains supply, with 3mm

minimum contact separation at all poles. The supply cord must be retained using the

attached cable clamp and routed to the side through the supplied ‘P’ clip. Excess cord

m s n

body

All Mod

d

u t be routed away from the appliance and must not come into contact with the ove

or hang loose into the lower compartment.

els

liance must be electrically grounded in accordaThe a p in

the a e

Models

pnce with state or other codes or,

bs nce of such codes, with the National Electrical Code, ANSI / NFPA 70.

with 12Volt Spark Ignition

Conn c

terminals located on the spark ignition generator. A supply cord terminating in sheathed

spade connectors is recommended. The supply cord should be retained against the rear

upport leg using a ‘P’ clip and routed away from the appliance.

e tion to the 12volt electrical supply of the recreational vehicle is made via the spade

appliance s

All Models – Pressure Testing

The appliance and its individual shutoff valve must be disconnected from the gas sup

piping system during any pressure testing of the system ply

at test pressures in excess of

½ psi (3.5kPa).

vthe

l

e

service provider in your area.

The appliance must b

manual shutoff

ressures equa

e isolated from the gas supply system be closing its individual

alve during any pressure testing of

to or less the ½ psi (3.5kPa). gas supply piping system at test

p

When satisfied with the appliance and after instructing the user on the correct

method of operation, these instructions MUST be left with the appliance. If th

appliance fails to operate correctly after all checks have been made, refer to the

uthoriseda

IMPORTANT

•After installation the appliance MUST be tested for soundness

•Test ALL burners on high and low flame for flame stability.

•The gas supply input pressure MUST NOT rise or fall significantly from

eived/witnessed.

nominal when ALL appliances connected to the supply are operated

simultaneously. If NOT installed to the manufacturers instructions detailed

herein, we the manufacturer can not be held responsible for any problems

that occur, or poor performance that is perc

18

MAINTENANCE & SERVICING

aners, steel wool or cleansing powders.

hen cleaning the burner ring it is essential to ensure that the holes do not become

terchangeable without affecting the sense of operation.

This appliance needs little maintenance other than cleaning. All parts should be cleaned

using warm soapy water. Do not use abrasive cle

IMPORTANT

•All servicing must be carried out by an approved competent person.

•After each service the appliance must be checked for gas soundness

W

blocked.

The control knobs are a push fit and can be removed for cleaning. They are

in

Who To Contact

For service, please contact your authorised local Service Agent giving full details of the

model, serial number and date of purchase.

All Models Leak Detection Test Method

following procedures should only be carried out by an

st

the end of the manifold near the gas regulator.

1. Leak testing of manifold f

Turn all control valves to High (max) setting. Pressurize the system – max 60 ins

wc (150mbar). Verify all control valves are gas sound – ie no pressure loss.

m –

rify the control valve and pipework to the

respective burner are gas sound – ie no pressure loss. Repeat for each of the

control valves and gas circuit.

In all cases if a leak is detected its location should be established by using leak detector

spray following which remedial action should be taken.

In your own interest of safety the

approved competent person. Before commencing any leak testing Isolate the appliance

from the gas supply. For each test the system should be pressurized via the pressure te

point located on

Pressurize the system – max 60 ins wc (150mbar). Verify gas soundness o

manifold – ie no pressure loss.

2. Leak testing control valves

3. Leak testing individual control valves and pipe work

Turn on the control valve to be tested to a High setting. Pressurize the syste

max 60 ins wc (150mbar). Temporaily block the respective burner jet and

depress the control valve knob. Ve

19

MAINTENANCE & SERVICING

Service Instructions

1s supply.

the appliance is Dual Fuel, disconnect/isolate the electric supply.

2. emove hob surface

nd

fascia retaining screws. Carefully lift off the fascia and if spark ignition fitted

remove the two spade connectors from the rear of the toggle switch. Remove the

ove the two

ed through the outer slots on

the angled front. Grasp the hob by the angled front face, carefully lift the hob

the front to allow the rear edge to unhook from the rear box section. e

e put onto a suitable surface.

3. Remove appliance from housing n the oven door and remove the 2 screws from

pply lead from rear

nce out onto a suitable surface.

4. Co

Ho emove hob surface (2). Unscrew the

cor

Op rear of oven. Remove

the

pip it on

the

Ov

As above instructions but remove appliance from housing to gain access to the

oven thermostat, grill and oven thermocouples.

ce from housing (3). Remove hob

surface (2). Remove the two screws retaining the heat deflector. Remove the

insulation wrap and lever off the two starlock washers retaining the grill burner. Lift

out the burner assembly.

. isconnect from gas supplyD

Lift and remove the bottom plinth to gain access, then disconnect the ga

If

R

Disconnect from gas supply (1) and electric supply if Dual Fuel. Lift off the Panrest

and remove the two screws securing each burner spreader. Remove front fascia by

removing all push on control knobs and unscrew the two recessed fixed nuts a

both

two central screws securing the pressing to the rear box section. Rem

front retaining screws located each side and access

surface from

Note:- On Dual Fuel appliances, remove the hotplate rear cover and disconnect th

power leads. The hob surface should b

Disconnect from gas supply (1). Ope

each side trim - note the appliance can either be front or side fixed, see under

Fixing, page 17. Open the glass lid and remove the 2 screws from each side trim.

Carefully slide the appliance out one third and check for any possible snagging of

wires or pipes. If the appliance is Dual Fuel, disconnect su

terminal block. If OK, lift applia

ntrol replacement

b controls

Disconnect from gas supply (1). R

responding pipe and thermocouple and remove from the control.

en the oven door and unscrew the 2 screws holding the thermostat probe in

position and push the probe back out through the hole in the

retaining screws from on top and underneath the control. Disconnect the inlet

e and two burner supply pipes. Remove the fittings off the old control and f

replacement.

en and Grill control

5. Remove the grill burner

Disconnect from gas supply (1). Remove applian

20

This manual suits for next models

1

Table of contents

Languages:

Other spinflo Cooker manuals

Popular Cooker manuals by other brands

Beko

Beko DVC665 Installation & operating instructions and cooking guidance

STOVES

STOVES SFG60DOP Users guide & installation handbook

Electrolux

Electrolux EH L20-4 user manual

Bosch

Bosch HXQ38AE5 M Series instruction manual

Tricity Bendix

Tricity Bendix SB432 Operating & installation instructions

Bosch

Bosch HGD4321.0M instruction manual

STOVES

STOVES ELLINGWOOD & BELMONT user manual

Beko

Beko DCC4521 Installation & operating instructions and cooking guidance

Olympia

Olympia GD155 instruction manual

Hotpoint

Hotpoint EW74 Instructions for installation and use

Zanussi Electrolux

Zanussi Electrolux ZCE 640 Instruction booklet

inventum

inventum VFI6042RVS instruction manual