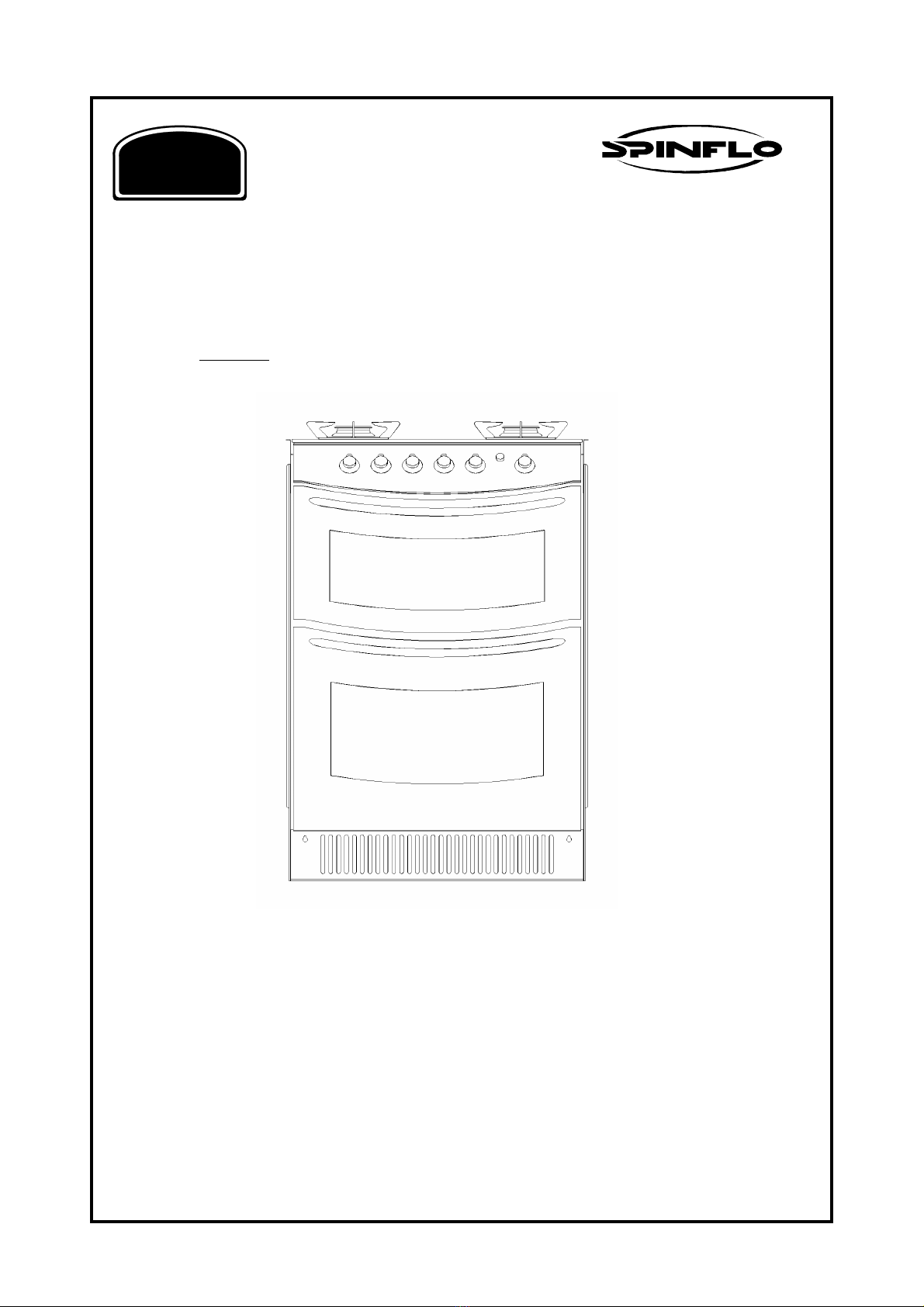

spinflo PRODIGY 600 OH88000 Operating instructions

GAS APPLIANCES

PCC1293 – Issue 2

C

O

U

N

T

R

Y

L E I S U R E

BUILD IN APPLIANCES

FOR USE WITH LIQUIFIED PETROLEUM GAS

CAUTION – ALL OUTER SURFACES WILL GET HOT WHEN IN USE

MODEL:- OH88000 PRODIGY 600

USER AND INSTALLATIO

N INSTRUCTIONS

SPINFLO LIMITED,

UNIT 19, Oakham Drive

, Parkwood Industrial

Estate,

Rutland Road, Sheffield S3 9QY, ENGLAND.

TEL: + 44 (0)114 273 8157 FAX: + 44 (0)114 275 3094

2

3

CONTENTS

User’s Section

Specification ………………………………………………… 3

Introduction ………………………………………………… 4

Using the Hotplate ………………………………………………… 5

Using the Grill ………………………………………………… 6

Using the Oven ………………………………………………… 7

Installation and Servicing

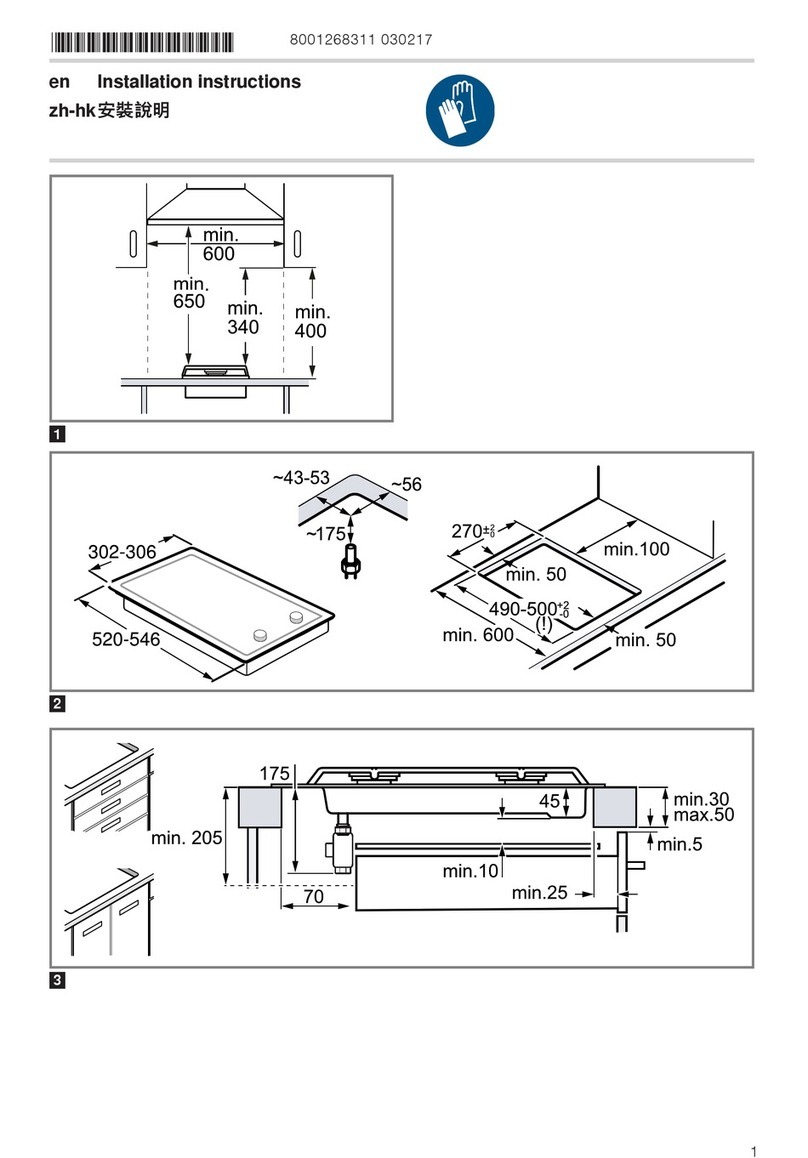

Installation Dimensions ………………………………………………… 2

Specification ………………………………………………… 3

Installation Instructions ………………………………………………… 9

Maintenance & Servicing ………………………………………………… 11

SPECIFICATION

Gas Category

CAT I

3

+ (28-30/37) CAT I

3

B/P (30)

BUTANE (G30) 28-30 mbar BUTANE (G30) 30 mbar

PROPANE (G31) 37 mbar PROPANE (G31) 30 mbar

OH88000

External Dimensions, mm (HxWxD) 936x614x617

Oven Capacity, litres (HxWxD) 60 (335x505x358)

No. of tray positions Grill 2, Oven 5

Heat input, kW

Total heat input 9.35

Hotplate burners heat input 4 x 1.5

Grill burner heat input 1.55

Oven burner heat input 1.80

Injector size, mm

Hotplate burners Sabaf 0.62

Grill burner Sabaf 0.62

Oven burner Sabaf 0.65

Bypass size, mm

Hotplate controls Sabaf 0.34

Grill control Sabaf 0.45

Oven control Sabaf 0.35

Spark ignition (where fitted) 230V ~ 50Hz

IMPORTANT

•This appliance is suitable for use with Liquefied Petroleum

Gas (LPG) and should not be used on any other gas.

•Use only the gas pressures specified above

•This appliance must be earthed.

4

INTRODUCTION

This appliance must be installed in accordance with the local, national and European

regulations in force. Particular attention shall be given to the requirements regarding

ventilation. Read the instructions before installing or using the appliance

The appliance is designed for either high or low level installations. Failure to install the

appliance correctly could invalidate any warranty or liability claims and lead to prosecution.

Please refer to the methods of installation within this handbook.

Our policy is one of continuous development and improvement. Specifications and

illustrations may change subsequent to publication.

Provision Of Ventilation

The use of a gas cooking appliance results in the production of heat and moisture in a room

in which it is installed. Ensure that the kitchen is well ventilated, keep natural ventilation holes

open or install a mechanical ventilation device (mechanical extractor hood).

Prolonged intensive use of the appliance may call for additional ventilation, for example

opening a window, or more effective ventilation, for example increasing the level of

mechanical ventilation where present. The room containing the appliance should have an air

supply in accordance with local, national and European standards.

Position

This appliance must be positioned free from draughts, which may affect the combustion and

in a manner that will prevent the accumulation of unburnt gas. When in use ensure that air

vents are not inadvertently blocked or shut off.

IMPORTANT

Before using the appliance for the first time, remove all accessories and

packing in the grill and oven, including any surface protection film, ie plastic

coating. Clean all interior surfaces with hot soapy water to remove any residual

protective covering of oil and rinse carefully.

5

OPERATION

Burner operation

The burners on this appliance have fixed aeration and no adjustment is required. Depending

on the gas being used, the burners should flame as follows:-

Propane - The flames should burn quietly with a blue/green colour with no sign of yellow

tips.

Butane - Normally on initial lighting, a small amount of yellow tipping will occur and then

slightly increases as the burner heats up.

Using the Hotplate Burners

1. Ensure gas cylinder/supply is connected and turned on. In the event of a gas smell

turn off at gas cylinder/mains and contact supplier.

2. Flame supervision: Each burner is controlled individually and is monitored by a

thermocouple probe. In the event of the burner flames being accidentally extinguished,

turn off the burner control and do not attempt to re-ignite the burner for at least one

minute.

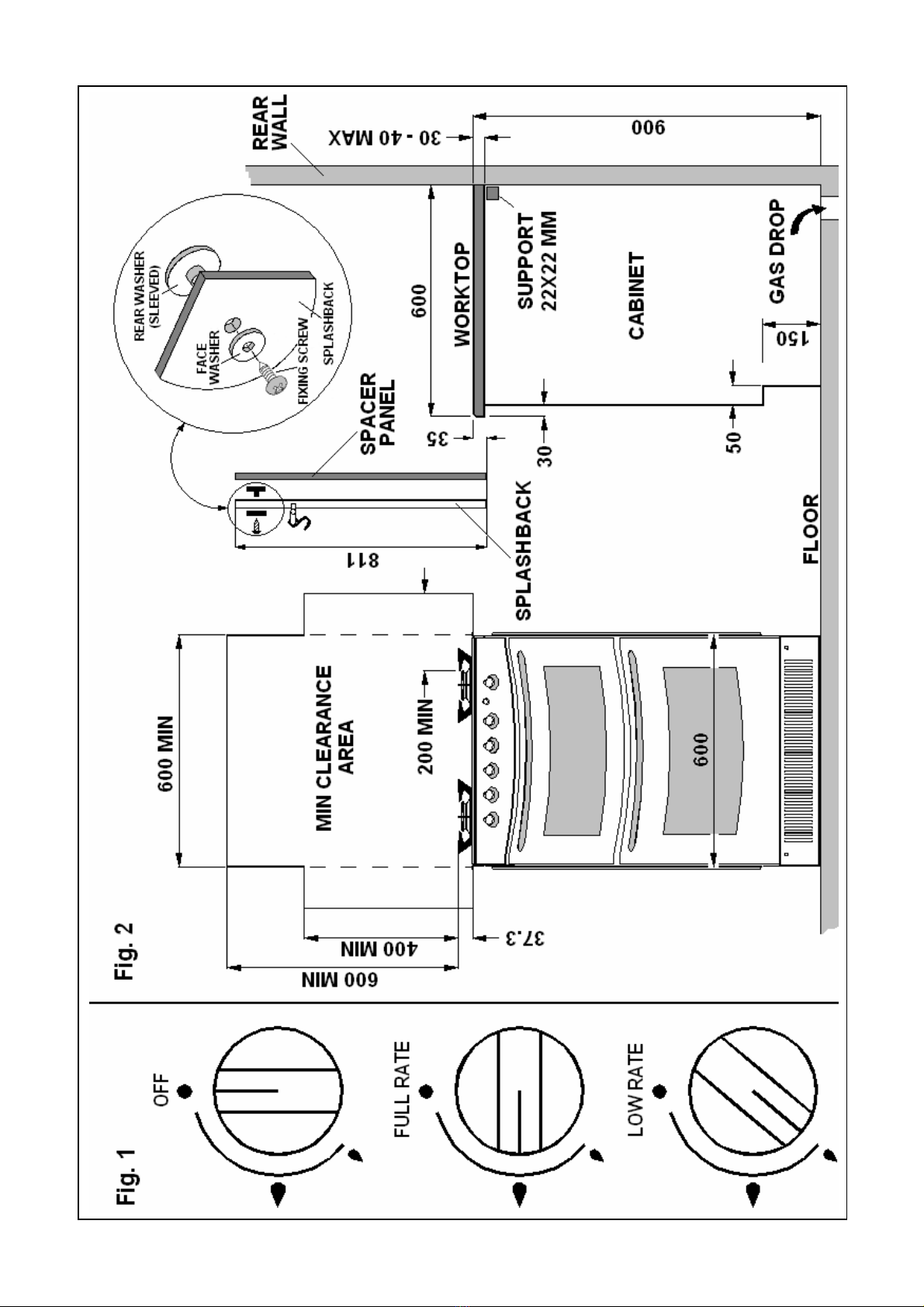

3. To light: Push in the control knob and turn to full rate – see Fig.1. Hold a lighted

match or taper to the burner and push the control knob in and hold. It is necessary to

hold the knob depressed after the burner has ignited for approximately 10 - 15

seconds, to allow the thermocouple probe to reach temperature, before releasing the

knob. Should the flame go out when the knob is released, the procedure should be

repeated holding the knob depressed for slightly longer.

4. For models fitted with Spark Ignition the procedure is similar except that the burner

can be ignited by depressing the ignition button, which is located on the fascia. If the

burner has not lit within 15 seconds the control knob should be released and the

burner left for at least 1 minute before a further attempt to ignite the burner.

5. For simmering, turn the knob further anti-clockwise to the low rate position.

6. To turn off: Turn the control knob until the line on the control knob is aligned with the

dot on the control panel. Always make sure the control knob is in the off position

when you have finished using the hotplate burners.

WARNING

•When cooking, young children should be kept away.

•Glass lids may shatter when heated. Turn off all burners

before shutting the lid

•Spillage on the surface of the lid should be removed

before opening the lid.

IMPOR

TANT

•Although each burner will support pans from 10 to 22cm, care

should be taken not to overload the appliance as reduced

performance may result.

•When using small pans the flames should not spread beyond

the base of the pan as this will reduce the efficiency of the burner.

•Avoid old or misshapen pans as these may cause instability.

•The lid must be opened fully prior to using the hotplate burners.

6

OPERATION

Using the Grill

1. Ensure gas cylinder/supply is connected and turned on. In the event of a gas smell turn

off at gas cylinder/mains and contact supplier.

2. To light: Open door, push in the control knob and turn to full rate – see Fig 1. Hold a

lighted match or taper to the burner and push the control knob in and hold. The burner

should ignite and the control knob should be held in for 10 -15 seconds before release. If

the burner goes out, repeat procedure holding control knob for slightly longer.

3. For models fitted with Spark Ignition the procedure is similar except that the burner can

be ignited by depressing the ignition button, which is located on the fascia. Ignition must

be carried out with the door open, and if the burner has not lit within 15 seconds the

control knob should be released and the grill left for at least 1 minute before a further

attempt to ignite the burner.

4. Note: the grill must only be used with the door open.

5. On first use of the grill, it should be heated for about 20 minutes to eliminate any residual

factory lubricants that might impart unpleasant smells to the food being cooked. A non-

toxic smoke may occur when using for the first time so open any windows and turn on

mechanical ventilators to help remove the smoke.

6. Although the grill does heat up quickly, it is recommended that a few minutes preheat be

allowed.

7. Flame Failure Device (FFD): the grill burner is fitted with a flame sensing probe, which will

automatically cut off the gas supply in the event of the flame going out. In the event of the

burner flames being accidentally extinguished, turn off the burner control and do not

attempt to re-ignite the burner for at least one minute.

8. It is normal for the flames on this burner to develop yellow tips as it heats up, particularly

on Butane.

9. A reversible grill pan trivet enables the correct grilling height to be achieved.

Fast Toasting trivet in high position

Grilling Sausages trivet in high position

Grilling Steak/Bacon trivet in high position

Grilling Chops, etc trivet in low position

Slow Grilling trivet removed

10.To turn off: turn the control knob until the line on the control knob is aligned with the dot

on the control panel. Always make sure the control knob is in the off position when you

have finished grilling.

IMPORTANT

•The pan supplied with the appliance is multi functional, for use in grill or

oven.

•The handle design allows removal or insertion whilst the pan is in use.

•

Always remove the handle when the pan is in use.

7

Operation

Using the Oven

1. Ensure gas cylinder/supply is connected and turned on. In the event of a gas smell turn

off at gas cylinder/mains and contact supplier.

2. To light: Open door, push in the control knob and turn to gas mark 9. Hold a lighted match

or taper to the burner and push the control knob in and hold. The burner should ignite and

the control knob should be held in for 10 -15 seconds before release. If the burner goes

out, repeat procedure holding control knob for slightly longer.

3. For models fitted with Spark Ignition the procedure is similar except that the burner can

be ignited by depressing the ignition button, which is located on the fascia. Ignition must

be carried out with the door open, and if the burner has not lit within 15 seconds the

control knob should be released and the oven left for at least 1 minute before a further

attempt to ignite the burner.

4. Place the oven shelf in the required position and close the door. Set control knob to

approximately gas mark 5 and heat the oven for about 30 minutes to eliminate any

residual factory lubricants that might impart unpleasant smells to the meals being cooked.

A non-toxic smoke may occur when using for the first time so open any windows and turn

on mechanical ventilators to help remove the smoke.

5. Although the oven does heat up quickly, it is recommended that a 10 minutes preheat be

allowed. The oven should be up to full temperature in about 15-20mins.

6. To turn off: turn the control knob until the line on the control knob is aligned with the dot

on the control panel.

7.

Shelf: the shelf has been designed to allow good circulation at the rear of the oven and

are also fitted with a raised bar to prevent trays or dishes making contact with the back of

the oven. To remove a shelf, pull forward until it stops, raise at front and remove.

Oven Temperature Control

The temperature in the oven is controlled by a thermostatic gas tap and is variable over the

range 130°C to 240°C. Approximate temperatures for the settings on the control knob are

shown in the table below. The temperatures indicated refer to the centre of the oven and at

any particular setting the oven will be hotter at the top and cooler towards the base. The

variation between top and centre, and centre to bottom is approximately equivalent to one

gas mark. Good use can be made of the temperature variation in several dishes requiring

different temperatures may be cooked at the same time. In this way maximum benefit can be

obtained from the gas used to heat the oven. Care should be taken not to overload the oven,

adequate spacing being used to allow free circulation for heat.

IMPORTANT

•The pan supplied with the appliance is multi functional, for use in grill or

oven.

•The handle design allows removal or insertion whilst the pan is in use.

•

Always remove the handle when the pan is in use.

8

OPERATION

Cooking Guidelines

Best results will be obtained by the shelf positions in this guide. It is not necessary to preheat

the oven but advisable for a range of dishes. The oven is capable of full temperature in 15-20

minutes.

Most cookery books give details of the shelf positions and gas mark settings for each recipe.

If in doubt about a recipe you intend to use, study the recipe carefully then find a similar dish

in our guide and use our shelf position and gas mark setting recommendation. Shelf

positions are from the top down. When roasting with aluminium foil care must be taken that

the foil does not impair circulation or block the oven flue outlet.

Do's And Don'ts

DO read the user instructions carefully before using the appliance for the first time.

DO allow the oven to heat before using for the first time, in order to expel any smells

before the introduction of food.

DO clean the appliance regularly.

DO remove spills as soon as they occur.

DO always use oven gloves when removing food shelves and trays from the oven.

DO check that controls are in the off position when finished.

DO NOT allow children near the cooker when in use. Turn pan handles away from the

front so that they cannot be caught accidentally.

DO NOT allow fats or oils to build up in the oven trays or base.

DO NOT use abrasive cleaners or powders that will scratch the surfaces of the

appliance.

DO NOT under any circumstances use the oven as a space heater.

DO NOT put heavy objects onto open grill and oven doors.

Leaks

If a smell of gas becomes apparent, the supply should be turned off at the cylinder

IMMEDIATELY. Extinguish naked lights including cigarettes and pipes. Do not operate

electrical switches. Open all doors and windows to disperse any gas escape.

Butane/Propane gas is heavier than air; any escaping gas will therefore collect at a low level.

The strong unpleasant smell of gas will enable the general area of the leak to be detected.

Check that the gas is not escaping from an unlighted appliance. Never check for leaks with a

naked flame, leak investigation should be carried out using a leak detector spray.

Gas

Mark

Temperature

¼ - ½

265-275ºF

130-135ºC

Very cool Meringues

1 285 140 Cool Stewed fruit

2 300 150 Cool Rich fruit cake

3 330 165 Warm Baked custard

4 355 180 Moderate Victoria sandwich

5 385 195 Fairly hot Whisked sponges

6 410 210 Hot Short crust pastry

7 430 220 Hot Bread, scones

8 445 230 Very hot Puff pastry

9 465 240 Very hot Quick browning

Dish Gas

Mark

Shelf

Position

Cooking Time

Scones 7 2 8-15mins

Small cakes 5 2 15-25mins

Victoria sandwich 4 2 20-30mins

Very rich fruit cake 2 2 Approx. 60mins per 500g

Puff pastry 8 2 15-30mins

Flaky pastry 7 2 15-30mins

Shortcrust pastry 6 2 15-55mins

Shortbread fingers 3 2 25-30mins

Ginger nuts 5 2 12-16mins

Rice pudding 2 3 100-120mins

Baked custard 3 3 50-60mins

Fruit crumble 5 3 30-40mins

Beef 3

7 3

3 25mins per 500g plus 25mins

15mins per 500g plus 20mins

Pork 3

7 3

3 30mins per 500g plus 35mins

25mins per 500g plus 25mins

9

INSTALLATION

Regulations and Standards

In your own interest of safety, it is law that all gas appliances are installed and serviced by

competent persons. CORGI (Confederation for the Registration of Gas Installers) registered

installers undertake to work to safe and satisfactory standards.

Failure to install the appliance correctly could invalidate any warranty or liability claims and

lead to prosecution. This appliance shall be installed in accordance with the local and

National/European standards in force. Particular attention shall be given to the requirements

regarding ventilation. Read the instructions before installing or using this appliance.

Ventilation

This appliance is suitable for installation into Holiday Homes, Touring Caravans and Boats.

In all cases the national standards with regard to ventilation for the particular vehicle into

which the appliance is to be installed must be adhered to.

The appliance MUST have a gas escape hole (min size 50mm Ø; max 70mm Ø; or shaped

hole of equivalent area – 1965 to 3850mm

2

) in the floor, directly beneath the appliance and

positioned at the rear as shown in Fig. 2. The hole MUST vent to the outside and should be

baffled to prevent direct draught to the appliance.

Location of Appliance

This appliance maybe installed in a kitchen/kitchen diner but NOT in a room containing a

bath or a shower. LP gas appliances must not be fitted below ground level. e.g. in a

basement.

Position

This appliance must be installed in such a way that the furniture fitted around the unit follows

the minimum dimensions as shown in Fig. 2. If this cannot be adhered to because of design

constraints, then the design is deemed permissible providing that the temperature rise on the

furniture is tested. To establish whether the temperature rise is acceptable, the following test

must be verified.

Place 4 large pans (20-22cm Ø) on top of the hotplate burners and fill up ¾with water.

Turn on all 4 hotplate and the oven on full. After 45 minutes turn the grill on full, then

after a further 15 mins, establish the highest temperature points on all the furniture

surfaces in direct line of sight of this appliance. The temperature rise must not exceed

65ºC above the ambient temperature, or where applicable, must not exceed the

maximum allowable temperature, to avoid damage, as detailed within the supplier’s

material specification.

A horizontal difference of 200mm must exist between the edge of the burner and combustible

material unless protected by a layer of non-combustible material.

All combustible materials such as curtains and shelves must be kept well clear of the

appliance, their installation should meet all relevant local and national/European standards in

force.

WARNING

When installing DO NOT lift appliance using the door handles

10

INSTALLATION

Fixing

There are several fixing screw positions, located in the vertical side trims as follows:

(A) – top of grill opening

(B) – bottom of grill opening

(C) – middle of oven opening.

Only 4 fixing screws are required to fix cooker securely, 2 per side. Make sure the cooker is

fully home in the cabinet/aperture. Open the oven door and use position (C) on the none

hinged side. Open the grill door and use Position (A) on the same side the oven fixing was

put in, and Positions (A) and (B) on the other side of the grill opening. Screw into place using

a flange head Nº 6 woodscrew.

Utensil Rail And Hooks (optional)

The utensil rail is designed to be fitted onto the optional glass splashback. If the hooks are

not already on the rail, they need to be added prior to fitting. The two pillars on the utensil rail

will unscrew using a large flat head screwdriver, only one need be removed to add the hooks.

Slide the hooks onto the rail with the hook point away from the pillars. Screw on the pillar and

fit the utensil rail to the splashback. With the hooks hang downwards and pointing away from

the glass, fit using M4x12 pozi pan-head screws and 2 plastic washers per fixing. The

washers must sandwich the glass from the utensil rail and screw.

Glass Splashback (optional)

The splashback must have a support batton (22x22mm approx.) on which to rest. The

support must be securely fixed to the rear wall, the top surface of the support 35mm below

the worktop surface. A 15-18mm spacer panel must be fitted directly on top of this batton and

secured to the wall. The spacer panel should be slightly narrower than the spashback, but be

the same height i.e. 810x585mm. Finally the splashback can be installed; resting it on the

support batton there are 4 fixing screw positions, one in each corner. Screw into place using

a flange head Nº 6 woodscrew with a 2mm thick plastic washer to protect the glass. Make

sure utensil rail is at top.

IMPORTANT

•This appliance must be installed into an aperture, sealed off at either side in order

to prevent draughts from adjoining cupboards/vents. Ensure that air vents and gas

escape holes are kept clear, holes for cables and pipes must be sized to minimize

air leakage between compartments.

•Under no circumstances should the ventilation hole exceed 3850mm

2

or other low

level ventilation be located in the compartment, including vents in kickboards. Low

level vents in adjacent compartments are permitted.

WARNIN

G

•Do not over tighten the screws when fitting the utensil rail

•Utensil rail and hooks must be fitted prior to Splashback installation.

WARNING

•Do not over tighten the screws when fitting the glass splashback.

•

Splashback must be fitted prior to cooker installation.

11

INSTALLATION

Connection

Gas connection - To an 8mm OD inlet pipe on the underside of the appliance. It is

recommended that the cooker be connected by copper tubing using a compression fitting.

Rubber tubing MUST NOT be used.

Electrical connection - Ensure that all electrical cables and wires are routed well clear of

any heat source, including this appliance. The plug and socket must be accessible after

installation.

IMPORTANT

•This appliance MUST be earthed

•After installation the appliance must be tested for soundness

•

The gas supply input pressure to which this appliance is connected MUST not rise

or fall by more than 2.5mbar (butane/propane) from nominal when ALL appliances

connected to the supply are operated simultaneously. If this appliance is not

installed in accordance with the instructions and tolerances detailed herein, we the

manufacturer can not be held responsible for any problems that occur, or poor

performance that is perceived/witnessed.

12

MAINTENANCE SERVICING

This appliance needs little maintenance other than cleaning. All parts should be cleaned

using warm soapy water. Do not use abrasive cleaners, steel wool or cleansing powders.

When cleaning the burner ring it is essential to ensure that the holes do not become blocked.

The control knobs are a push fit and can be removed for cleaning.

ALL SERVICING MUST BE CARRIED OUT BY AN APPROVED COMPETENT PERSON.

BEFORE ANY SERVICE WORK IS STARTED, THE APPLIANCE SHOULD HAVE BEEN

LEFT TO COOL AND BE DISCONNECTED AT THE MAINS SOCKET. AFTER EACH

SERVICE THE APPLIANCE MUST BE CHECKED FOR GAS SOUNDNESS.

1. Disconnect from gas supply

Loosen the 2 screws securing the bottom trim in keyhole slots. Lift and remove the

bottom trim to gain access, then disconnect the gas supply.

2. Remove the hob surface

Lift off all the panrests and remove the burner caps and spreaders. Unscrew the 2 screws

on either side of each burner. Holding the hob surface by the scalloped section at the

rear (flue outlet) and by the overhang at the front, carefully lift the hob surface vertically

and clear of the burners. The hob surface should be put onto a suitable surface.

3. Remove appliance from housing

Disconnect from gas supply (1). Open the grill door and remove the screws from each

side trim. Open the oven door and remove the screw from the side trim opposite the door

hingeing side. Carefully slide the appliance out one third and check for any possible

snagging of wires or pipes. If OK, lift appliance out onto a suitable surface.

4. Control replacement

Disconnect from gas supply (1). Remove the hob surface (2). To assist, the trim above

the grill opening may be removed by unscrewing the fixing screw on each side of the

appliance. Unscrew the corresponding pipe and thermocouple and remove from the

control. Pull off the corresponding control knob.

Hob and grill controls - Remove the 2 screws from the mounting bracket and the

locknut from the front of the control panel. Disengage the control from the gas rail and

remove.

Oven thermostat - Remove appliance from housing (3). Open the oven door and

unscrew the 2 screws holding the thermostat probe in position and push the probe back

out through the hole in the oven chamber. Remove the retaining screws from on top and

underneath the control and remove from the gas rail. Remove the fittings off the old

control and fit on the replacement.

5. Remove the grill burner

Remove appliance from housing (1). Remove the hob surface (2). Unscrew the screw on

the bush at the end of the grill burner and disengage the grill pipe. Open the grill

compartment door and unscrew the locknut on the thermocouple (thermocouple at the

rear of the grill tube at the left hand side) and push back through the hole. With a pair of

pliers remove the 2 star locks on top of the grill hood, ease the grill assembly out.

13

MAINTENANCE SERVICING

6. Spark Ignition (where fitted)

Remove the hob surface (2). Unscrew the 4 fixing screws and remove the generator

cover at the rear left of the appliance.

Hotplate burners - Pull off the fixing clip on the burner and remove electrode from the

burner cup. Trace the electrode wire back to the generator and pull off the connector.

Grill burner - Remove the push fit spark ignition wire from the probe in the top of the

burner. Trace the electrode wire back to the generator and pull off the connector.

Oven burner - Remove appliance from housing (3). Trace the electrode wire up the back

of the cooker to the generator and pull off the connector. Unscrew the fixing screw on the

spark electrode inside the oven cavity, then carefully pull the electrode from inside the

oven and remove.

Generator - Remove all electrode wires and pull off all power and earth wires. The

generator is a snap fit into the rear panel; using a flat head screwdriver, push in the 4 tabs

holding the generator in place and carefully remove from panel.

7. Hotplate burner injector (No62)

Lift off the panrest, remove the burner cap and spreader and unscrew the injector.

8. Grill burner injector (No62)

Remove the hob surface (2). To assist, the trim above the grill opening may be removed

by unscrewing the fixing screw on each side of the appliance. Unscrew the locknut on the

injector holder at the tube end of the burner, disengage the grill pipe from the control and

remove the injector.

9. Oven burner injector (No65)

Open the oven door and unscrew the burner retaining screw, slide the burner to the left

and lift out. The injector is exposed to the right hand side of the cut out. Unscrew the

injector.

10.Hob and grill thermocouples

Remove the hob surface (2). Unscrew the thermocouple from the control. Unscrew the

nut at the burner.

11.Oven thermocouple

Remove appliance from housing (3). At the right hand side of the appliance, remove the

side cover by unscrewing the fixing screws at front and rear, then unscrew the

thermocouple from the control. Inside the oven cavity, the thermocouple is found just

above the burner on the rear wall. Unscrew the locknut and pull out the thermocouple

from the rear of the appliance.

12.Removing doors

Grill door - Open the grill door halfway and remove the screw on top of the grill door

hinges. Carefully lower the grill door and remove. To remove the hinges, unscrew the 2

screws in the grill floor on either side at the front of the grill chamber.

Oven door - Open the door and remove the 2 screws retaining the top hinge, tilt the door

slightly forwards at the top and then lift the door off the bottom hinge.

This manual suits for next models

1

Other spinflo Cooker manuals

Popular Cooker manuals by other brands

Moffat

Moffat GSC5062S Operating & installation instructions

Elba

Elba DUAL FUEL COOKERS Instructions for the use - installation advices

Kenwood

Kenwood CK 304 G Instructions for use

AEG

AEG COMPETENCE 521 V operating instructions

Parkinson Cowan

Parkinson Cowan Renowm RG60SS Operating and installation instructions

Bosch

Bosch HGV1F0 50Z Series instruction manual