Spinner BN 741650 User manual

Sliding Load

2.4 mm (50 ohms)

BN 741650

BN 741651

Data subject to change without notice│M36082│Issue B│2020-02-21

www.spinner-group.com

2 / 10

Dear Customer,

Thank you for the trust you have placed in us by buying a SPINNER sliding load. Each SPINNER sliding load is

carefully tested and subject to strict quality controls by Spinner’s quality assurance. Nevertheless, the service life

of a sliding load depends to a great extent on you. Observe the information contained in these instructions and

the enclosed documentation. The more carefully you treat your sliding load, the longer it will provide dependable

service.

Certification

Spinner GmbH certifies that this product met its published specifications at the time of shipment from the factory.

Spinner GmbH further certifies that all measurements are traceable to national or international standards and to

natural physical constants or mathematical models.

Data subject to change without notice│M36082│Issue B│2020-02-21

www.spinner-group.com

3 / 10

Content

1.General Safety Information ......................................................................................................................... 4

2.Product Identification .................................................................................................................................. 6

3.Intended Use ............................................................................................................................................... 6

4.Improper Use .............................................................................................................................................. 6

5.Product Description and Scope of Delivery ................................................................................................ 6

6. Data Sheet .................................................................................................................................................. 6

7.Use and Preventive Maintenance ............................................................................................................... 6

7.1 Cleaning Connectors .................................................................................................................................. 7

7.2 Connection and Disconnection ................................................................................................................... 8

8.Handling and Storage ................................................................................................................................. 9

9.Recalibration ............................................................................................................................................... 9

10. Accessories ......................................................................................................................................... 10

11. Disposal ............................................................................................................................................... 10

12. Warranty .............................................................................................................................................. 10

13. Contacts .............................................................................................................................................. 10

Data subject to change without notice│M36082│Issue B│2020-02-21

www.spinner-group.com

4 / 10

1. General Safety Information

The following instructions and safety instructions are to be carefully read and followed!

The Spinner group makes every effort to keep the safety standard of our products up to date to be able to

offer our customers the highest possible degree of safety. Our products are designed and tested in

accordance with the relevant safety standards. Compliance with these standards is continuously monitored

by our quality assurance system. The product described here has been designed and tested in accordance

with the respective EU guidelines and has left the manufacturer’s plant in a condition fully complying with

safety standards. To maintain this condition and to ensure safe operation, observe all instructions and

warnings provided. If you have any questions regarding these safety instructions, the Spinner group will be

happy to answer them.

The operator is responsible for using the product in an appropriate manner. This product must not be used in

any way that may cause personal injury or property damage. The operator is responsible if the product is

used for an intention other than its designated purpose or in disregard of the manufacturer's instructions. The

manufacturer shall assume no responsibility for such use of the product.

The product is used for its designated purpose if it is used according to the specifications listed in the

product’s documentation within its performance limits (see data sheet, performance specifications, circuit

diagram and the following safety instructions).

Putting the product into operation requires special technical skills and must be executed by qualified

personnel with reference to “Start up information” in the product documentation. Keep the basic safety

instructions and the product documentation in a safe place and pass them on to the subsequent users.

Symbols and safety markings

Observe basic

safety instructions

-

Observe product

documentation

Danger of

electric shock Warning! Non

ionised

electro magnetic

radiation

Ground

Observing the safety instructions will help prevent personal injury or damage of any kind caused by

dangerous situations. Therefore, carefully read through and adhere to the following safety instructions before

putting the product into operation. It is also absolutely essential to observe the additional safety instructions

on personal safety that appear in relevant parts of the product documentation.

Tags and their meaning

DANGER Indicates a hazardous situation conveying great risk which, if not avoided, will result in death

or serious injury.

WARNING Indicates a hazardous situation conveying moderate risk which, if not avoided, could result in

death or serious injury.

CAUTION Indicates a hazardous situation conveying minor risk which, if not avoided, may result in minor

or moderate injury.

ATTENTION Indicates the possibility of faulty operation that can damage the product.

These tags are in accordance with the standard definition for civil applications in the European Economic

Area. Definitions that deviate from the standard definition may also exist in other economic areas or military

applications. It is therefore essential to make sure that the tags described here are always used only in

connection with the related product documentation and the related product. The use of tags in connection

with unrelated products or documentation can result in misinterpretation and thus contribute to personal

injury or material damage.

Data subject to change without notice│M36082│Issue B│2020-02-21

www.spinner-group.com

5 / 10

Basic Safety Instructions

1. These products must be operated only under the operating conditions specified in this product

documentation. Observe all instructions for start up, operation and servicing listed in the product

documentation.

2. Applicable local or national safety regulations and rules for the prevention of accidents must be

observed in all work performed and only by authorized specially trained personnel.

3. Dangerous voltage must not reach the outer conductor / waveguide of the product.

4. Before applying RF-power to the product, ensure proper connection and matching (load, line, etc.) of

all RF-connectors. Ensure sufficient mechanical rigidity of the RF-Connections. If the product is

equipped with an interlock loop, it must be connected to the transmitter’s interlock system and tested

for function.

5. Unless expressly permitted, never remove the cover or any part of the housing while the product is in

operation. Doing so will expose circuits and components and can lead to injuries, fire or damage to

the product.

6. Repair must be carried out only by the manufacturer or technical personnel authorized by the

manufacturer.

7. Unless otherwise specified, Spinner products are not protected against penetration of liquids, gases,

steam, etc. If this is not taken into account, there exists the danger of electric shock for the user or

damage to the product, which can also lead to personal injury.

8. Spinner products are not explosion-proof. They must not be operated in explosion-prone areas.

9. Never use the product under conditions in which condensation has formed or can form in or on the

product, unless otherwise specified.

10. Please be aware that in the event of a fire, toxic substances (gases, liquids etc.) that may be

hazardous to your health may escape from the product.

11. Do not place the product on heat-generating devices such as radiators or fan heaters. The

temperature of the environment must not exceed the maximum temperature specified in the data

sheet.

12. Improper use of the product can produce an elevated level of electromagnetic radiation. The

employer/operator is required to assess workplaces where there is a special risk of exposure to

radiation and, if necessary, take measures to avert the danger.

13. The operator is responsible for disposing of the product according to national waste disposal

regulations. Improper disassembly or disposal may be hazardous.

14. Use suitable overvoltage protection to ensure that no overvoltage (such as that caused by a

thunderstorm) can reach the product. Otherwise the operating personnel will be endangered by

electric shocks.

Data subject to change without notice│M36082│Issue B│2020-02-21

www.spinner-group.com

6 / 10

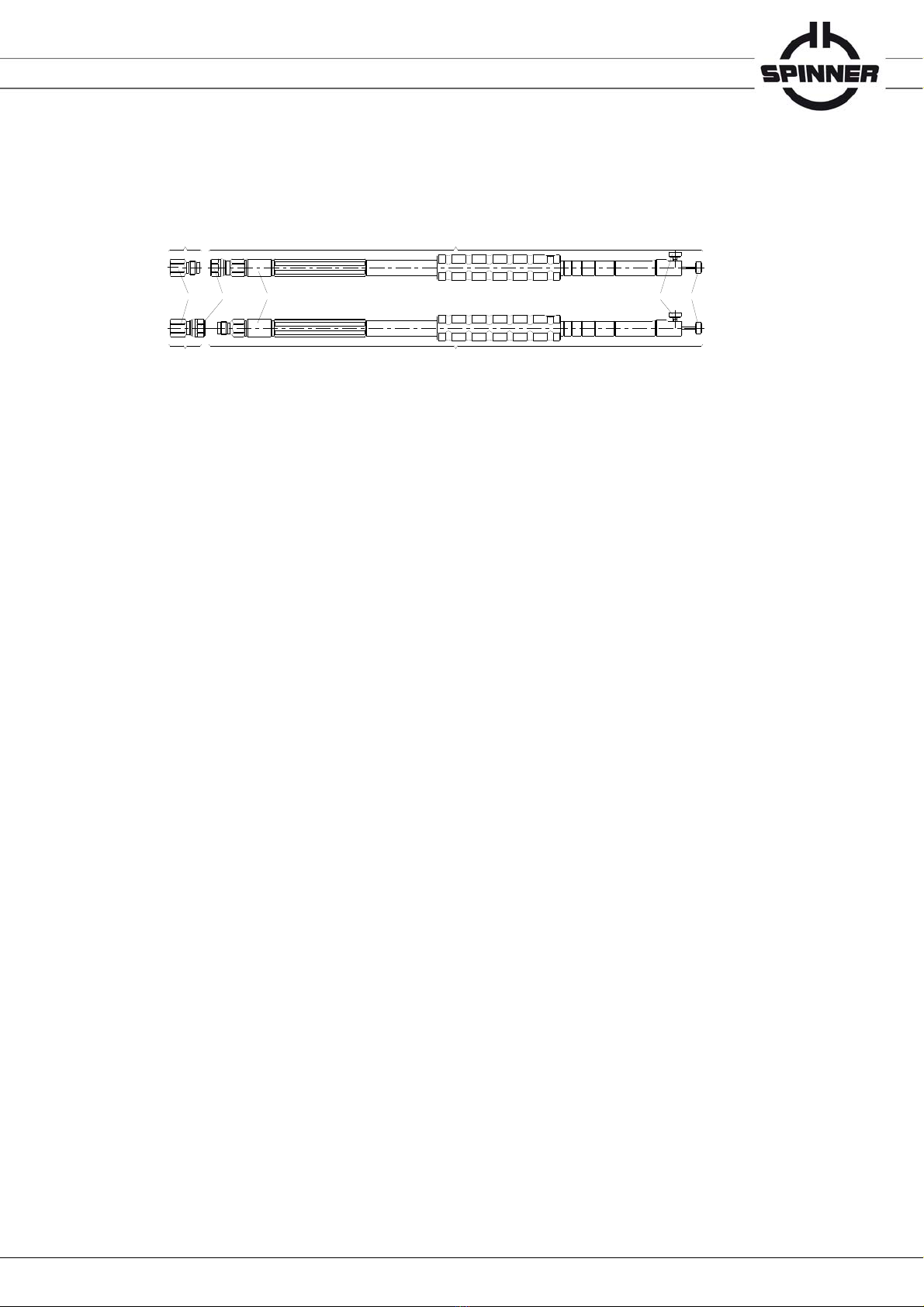

2. Product Identification

The SPINNER 2.4 mm sliding loads type BN 741650 (male) and type BN 741651 (female) are

marked with the following information for product identification:

BN 741650 or BN 741651 (SPINNER part number)

Ser. No: XXX (Serial number)

3. Intended Use

The intended use of the sliding loads BN 741650 and BN 741651 is to calibrate vector network

analyzers (VNAs) from 4 GHz up to 50 GHz for measurements of components with 2.4 mm

connectors.

Details and other limits are given in the data sheets “741650-BE” or “741651-BE”.

The products may only be operated within the specifications given in

the data sheets “741650-BE”or “741651-BE”.

Failure to observe could result in death or serious injury.

4. Improper Use

The products are not intended for any other purpose than indicated above.

If the sliding loads are not used as intended, safe operation of these products cannot be guaranteed.

The user is responsible for all personal injury and property damage resulting from improper use.

Reading the manual as well as adhering to all the information provided - particularly the safety

instructions - is considered mandatory to comply with the intended use.

5. Product Description and Scope of Delivery

The sliding loads are 50 Ω terminations optimized for best performance from 4 GHz up to 50 GHz.

The high-strength internal structure provides very repeatable connections. A precise resistor element

provides excellent stability and return loss.

The sliding loads BN 741650 and BN 741651 include the following items:

Sliding load BN 741650 or BN 741651

This manual

Certificate of Calibration

Product data sheet “741650-BE" or "741651-BE”

6. Data Sheet

The electrical, mechanical and environmental specifications of the sliding loads are given in the data

sheets “741650-BE” or "741651-BE".

ATTENTION Temperature changes may have an impact on electrical characteristics. Therefore,

the operating temperature is a critical performance factor. During a calibration

sequence, the temperature of the sliding load must be stable and within the

specified operating temperature range. Avoid unnecessary touching of the sliding

load during the calibration sequence; your fingers apply heat to them.

7. Use and Preventive Maintenance

The best measures for maintaining the accuracy of the sliding load include:

careful handling with the inner conductor

routine visual inspection

cleaning

Data subject to change without notice│M36082│Issue B│2020-02-21

www.spinner-group.com

7 / 10

proper gauging

proper connecting techniques

Failure to detect and remove dirt or metallic particles on a mating plane surface can degrade

repeatability and accuracy and can damage any connector mated to it. Improper connections,

resulting from bad connection techniques, can also damage these devices.

7.1 Cleaning Connectors

A sufficient cleaning of the connectors is essential to ensure the integrity of the RF connections.

Connector interfaces, especially the outer conductor, should be kept clean and free of dirt and other

debris.

Use only denatured alcohol as a solvent.

Use the proper size of cotton swab. Tweezers and a small piece of

cotton can also be used.

Only dampen the swab. Do NOT saturate it.

Gently rotate the swab around the inner conductor being careful not to

stress or bend the pin.

Never put lateral pressure on the connector’s inner conductor. The inner

conductor does not require cleaning.

Verify that no extraneous material remains in the connector after

cleaning.

Verify that the inner conductor has not been bended or damaged.

ATTENTION

Do NOT use other cleaning fluids or solvents. Do NOT use water.

Do NOT put cotton swabs in at an angle. Otherwise you will damage the

connectors.

Do NOT use too large cotton swabs. Otherwise you will damage the

connectors.

Standard cotton swabs are too large to fit in the smaller connector

types. Appropriately sized swabs can be purchased through a medical-

lab-type supply centre.

Data subject to change without notice│M36082│Issue B│2020-02-21

www.spinner-group.com

8 / 10

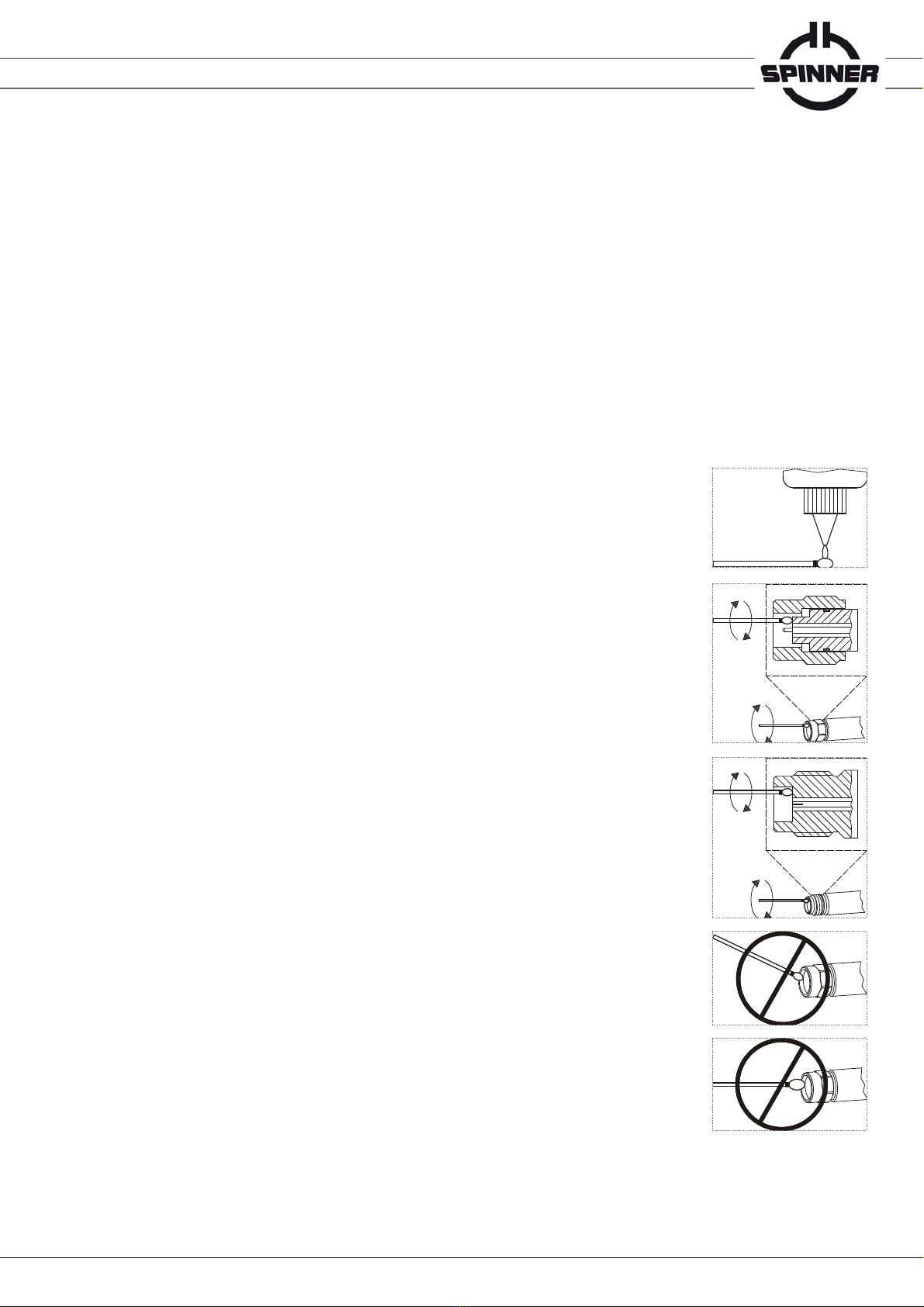

7.2 Connection and Disconnection

This chapter describes the process of achieving proper connections.

Connection

Ground yourself and all components to prevent electrostatic discharge from the measurement

assembly.

Hold on the protection cap body (4) and turn the coupling nut only (5) to remove the protection

cap (1) of the sliding load (2). Do not turn the protection cap body (4) or sliding load body (6).

Perform visual inspection of test port and sliding load connector.

Clean both connectors sufficiently.

Loose lateral locking screw (3) at the end of the sliding load.

Push inner conductor (7) carefully further into the sliding load until it sticks out at the connector.

Align sliding load (2) and test port connectors carefully. The plug inner conductor has to intrude

concentrically into the bushing of the socket connector.

Push sliding load inner conductor (7) very carefully into test port inner conductor until stop.

Push the connectors straight together and tighten the coupling nut (5) hand-tight until the mating

plane surfaces have contact. Do not turn the sliding load body (6). Only turn the coupling nut

(5). Do not overstrain the connection.

ATTENTION Damage to the inner conductor may occur, if the body of the sliding load (6) is turned.

Support the connectors properly. Relieve the connections from any bending torque.

Tighten connection by means of a torque wrench to 90 Ncm ± 10 %.

Torque wrench with unalterable setting to 90 Ncm ± 10 % recommended (SPINNER part

number BN 15 41 41).

Tighten lateral locking screw (3) at the end of the sliding load hand-tight.

Disconnection

Support the connectors properly to relieve the connections from any bending torques and

forces.

Unfasten the coupling nut (5) with open-end wrench. Do not turn the sliding load body(6). Only

turn the coupling nut (5).

ATTENTION Damage to the inner conductor may occur, if the body of the sliding load (6) is turned.

Unplug the sliding load straight, avoid any bending, twisting or rocking.

ATTENTION Do not reconnect the sliding load right after disconnection without repeating the

complete connection sequence described above. Non-compliance will damage

sliding load and test port inner conductors.

(3)

(1) (2)

(1) (2)

(7)(6)(5)(4)

Data subject to change without notice│M36082│Issue B│2020-02-21

www.spinner-group.com

9 / 10

8. Handling and Storage

ATTENTION Sliding loads are sensitive to impact. Do not drop!

Keep dry and avoid exposure to sudden temperature changes to prevent condensation.

Environmental conditions for storage are specified in the data sheets “741650-BE” or "741651-BE".

Loose lateral locking screw (3) at the end of the sliding load.

Push inner conductor (7) carefully further into the sliding load until it sticks out at the connector.

Align sliding load (2) and protection cap (1) carefully. The plug inner conductor has to intrude

concentrically into the bushing of the socket connector.

Push sliding load inner conductor (7) very carefully into protection cap inner conductor until

stop. Hold on the protection cap body (4) and tighten the coupling nut (5) hand-tight until the

mating plane surfaces have contact. Do not turn the protection cap body (4) or sliding load body

(6). Only turn the coupling nut (5).

Do not overstrain the connection.

Tighten lateral locking screw (3) at the end of the sliding load hand-tight.

Store the sliding load in a box when not in use.

Never store the sliding load without the protection cap. This is the most common cause of

damages during storage.

Avoid touching mating plane surfaces with your fingers. Residues on the connector interface

may degrade the performance of the sliding load and can only be removed with difficulty.

Always make sure that the connectors are in a clean condition.

Avoid the contact of the sliding load interface surfaces with any hard material. The plating and

the mating plane surfaces may be damaged if the interface contacts any hard surface

uncontrolled.

After any shock to the sliding load (e.g. drop down on the floor) recalibration is recommended.

9. Recalibration

The suggested initial interval for recalibration is 12 months or 500 matings, whichever comes first.

The actual need for recalibration depends on the use and the maintenance of the sliding load. The

recalibration interval should begin with the day of initial use after recalibration.

The SPINNER recalibration service includes

cleaning of the connector interfaces

electrical testing

(3)

(1) (2)

(1) (2)

(7)(6)(5)(4)

Data subject to change without notice│M36082│Issue B│2020-02-21

www.spinner-group.com

10 / 10

10. Accessories

Ordering Number Component

BN 154141 Torque Wrench 8 mm / 90 Ncm

11. Disposal

WARNING Improper disassembly or disposal may be hazardous.

Some parts are made of copper beryllium. The user is responsible for disposing of the product in

accordance with the national waste disposal regulations.

12. Warranty

Do not disassemble the sliding load. The warranty is void, if the sliding load is modified, improperly

handled or third party intervention or modification has occurred.

13. Contacts

SPINNER GmbH • Headquarters

Erzgiessereistr. 33

80335 München

Germany

tel.: +49 89 12601-0

fax: +49 89 12601-1292

www.spinner-group.com

SPINNER Telecommunication

Devices Co., Ltd.

351 Lian Yang Road

Songjiang Industrial Zone

Shanghai

201613 P.R. China

tel.: +86 21 577 45377

fax: +86 21 577 40962

This manual suits for next models

3

Table of contents

Other Spinner Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Retrotec

Retrotec DM-2 Operation manual

Magnescale

Magnescale DF830SLR instruction manual

Keysight Technologies

Keysight Technologies E8364-60108 Installation note

Vivax Metrotech

Vivax Metrotech VM-540 user guide

WATERS CORPORATION

WATERS CORPORATION TA Instruments DSC 2010 Operator's manual

techem

techem Compact IV c operating instructions

VDO

VDO TU00-0752-5807102 installation instructions

Anritsu

Anritsu MS27101A-IBCM quick start guide

Microsensor

Microsensor MPM380 Operation manual

Emerson

Emerson Rosemount 2051CF series quick start guide

Thermo Scientific

Thermo Scientific ISE user guide

Bosch

Bosch DWM 40 L PROFESSIONAL operating instructions