Data subject to change without notice │ M36318 │ Issue D │ 2021-02-18

www.spinner-group.com

1.7 Grouped safety instructions for SPINNER broadcast products

Entire or multiple phases of product lifecycle

Unless otherwise specified, these products are not protected against condensation, penetration of

liquids, gases, steam, etc. Failure to comply could result in electric shock or product damage, which

could also lead to serious injury.

Blocking of constructive openings on the product (ventilation slots, fine leaks etc.) must be

prevented, because these are necessary for product operation. Failure to comply could lead to

overheating and could result in burns, fire and electric shock.

Any object that is not designed to be placed in the openings of the housing must not be used for this

purpose. Doing so can cause short circuits inside the product and could result in electric shock, fire

or injury.

Depending on the function, certain products such as RF radio equipment can produce an elevated

level of electromagnetic radiation. Considering that unborn babies require increased protection,

pregnant women must be protected by appropriate measures. Persons with pacemakers may also

be exposed to risks from electromagnetic radiation. The employer/operator must evaluate

workplaces where there is a special risk of exposure to radiation and, if necessary, take measures to

avert the potential danger.

As with all industrially manufactured goods, the use of substances that induce an allergic reaction

(allergens) such as nickel cannot be generally excluded. If you develop an allergic reaction (such as

a skin rash, frequent sneezing, red eyes or respiratory difficulties) when using a SPINNER product,

consult a physician immediately to determine the cause and to prevent health problems or stress.

Should a fire occur, the product may release hazardous substances (gases, fluids, etc.) that can

cause health problems. Therefore, suitable measures must be taken, e.g. protective masks and

protective clothing must be worn.

Transport

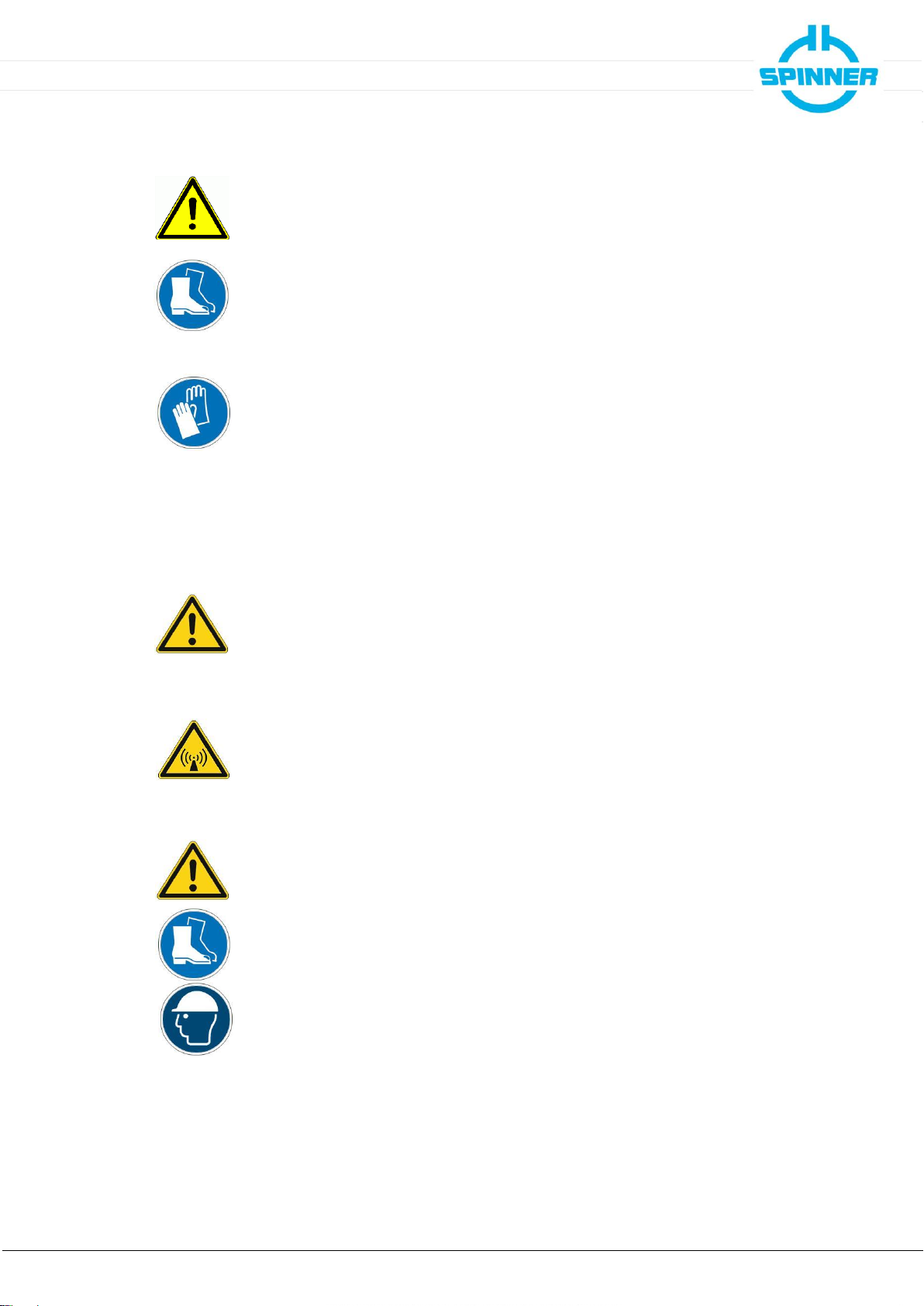

The product may be very heavy. In some cases, the user may require suitable lifting gear and means

of transportation to avoid back or other physical injuries.

If auxiliary objects e.g. lifting tools, trolleys, shelves are required, check their suitability before use.

Failure to comply could result in death or serious injury.

Transport the product only in the original packaging. Do not unpack until immediately prior to

installation. Failure to comply could result in death or serious injury.

Installation

Do not place the product on heat-generating devices such as radiators or fan heaters. The ambient

temperature must not exceed the maximum temperature specified in the product documentation or in

the attached data sheet. Product overheating could result in burns, fire and electric shock.

Do not place the product on surfaces, vehicles, cabinets or tables that for reasons of weight or

stability are unsuitable for this purpose. Always follow the installation instructions of the manufacturer

when installing the product and fastening it to objects or structures (e.g. walls and shelves). An

installation that is not carried out as described in the product documentation could result in death or

serious injury.

Mains driven products must be operated only from a TN power distribution system. The operator is

responsible for using an appropriate and sufficiently dimensioned AC power line. The AC power line

must be externally fused according to the product documentation. Failure to comply could result in

fire or electric shock.

Operation of products with protection class I according to EN 61140 is permitted only with a mains

cable with protective earth connection. The protective conductor continuity must be inspected by an

electrically skilled person. Failure to comply could result in electric shock.

All externally connected circuits for controlling, alerting and signalling have to be fed from ES1

sources acc. to EN 62368-1 only. The current in these circuits has to be externally limited by means