IM-P795-04 CH Issue 4 7

3. Installation

3.1 Equipment provided

3.1.1 Unpack individual packages in the area where the installation is to take place. This

avoids the possible loss or damage to parts in transit over the site.

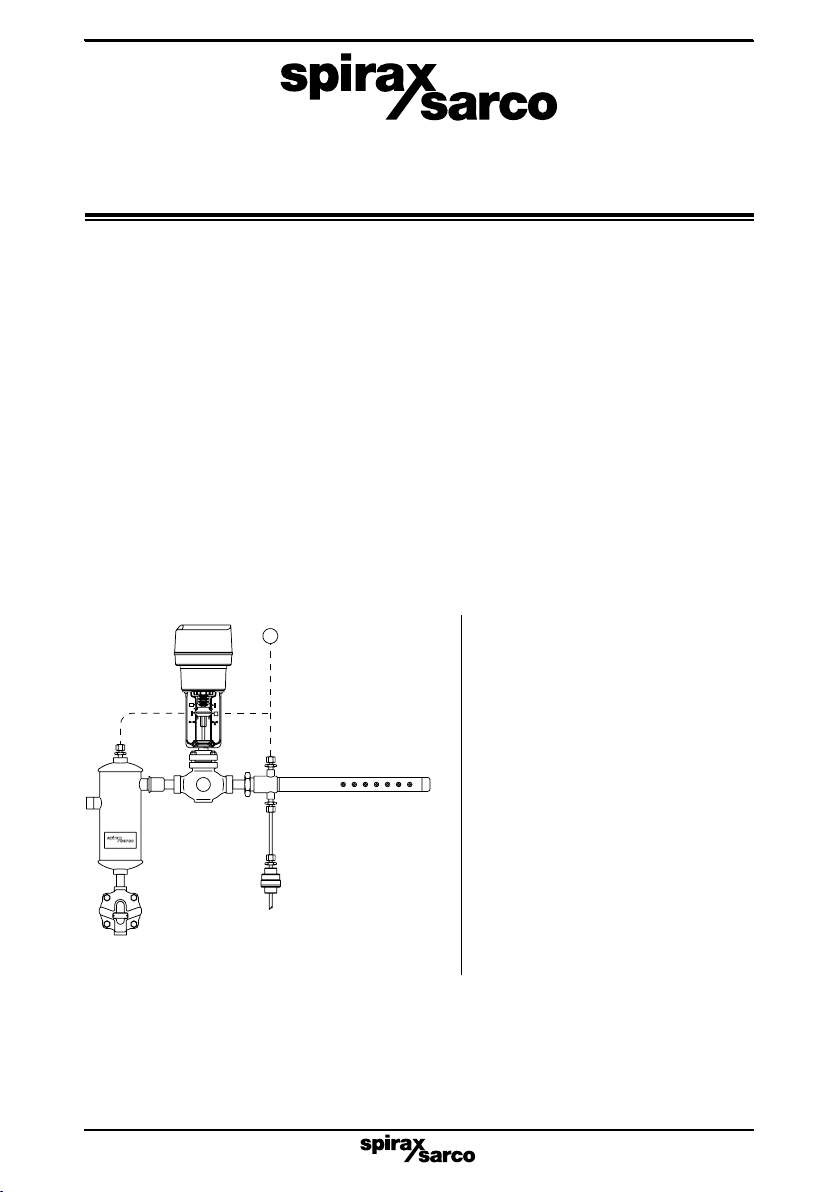

3.1.2 Items shown dotted are to be supplied by the installer.

3.1.3 Two ¼" BSP x 8 mm compression fittings (16 - see Figure 1) are supplied with each

separator, and two with each lance. These support the tracer heating pipework

between the steam supply (separator or separate source) and the lance(s), and the

discharge from the tracer heating circuit to the trap.

3.1.4 If escutcheon plates are to be used (see Figure 6, page 11).

3.1.5 The installer is responsible for the main lance steam supply / supporting pipework.

3.1.6 As the tracer heating circuit is parallel to, but independent from, the main lance steam

supply, it can be run in any acceptable material. Spirax Sarco are able to supply

8 mm annealed copper for this purpose.

3.2 Lance, tracer and pre-heating circuit

3.2.1 The main inlet connection on the lance is: Type 20 - ¾" screwed.

Type 40 - 1½" screwed.

The two tracer connections on each lance are ¼" BSP.

3.2.2 A single lance can be connected directly to the outlet of the valve using the piping

components provided (see Figures 7 to 10, page 12). These are supplied to match

the flanged or screwed connections of the valve to be installed, when the valve is

ordered.

3.2.3 The connection of the lance to the separator with these fittings, allows the correct

orientation of the lance to be achieved, i.e. nozzles facing into the air flow (except

for the installation shown in Figure 15, page 14). This is important to consider as

the lance(s) can be inserted from either the left hand side or the right hand side

of the duct.

3.2.4 If the tracer heating steam is taken from the top connection on the separator, then

the pressure / temperature of the tracer circuit will be as for the main humidifying

steam supply.

Where dry steam is sourced from a separate system for tracer heating, the top

connection on the separator (¼" BSP) should be plugged. The tracer heating circuit

can operate at up to 4 bar g (58 psi g) steam pressure.

3.2.5 Single lance systems should be assembled such that the lance is mid-height in the

duct.

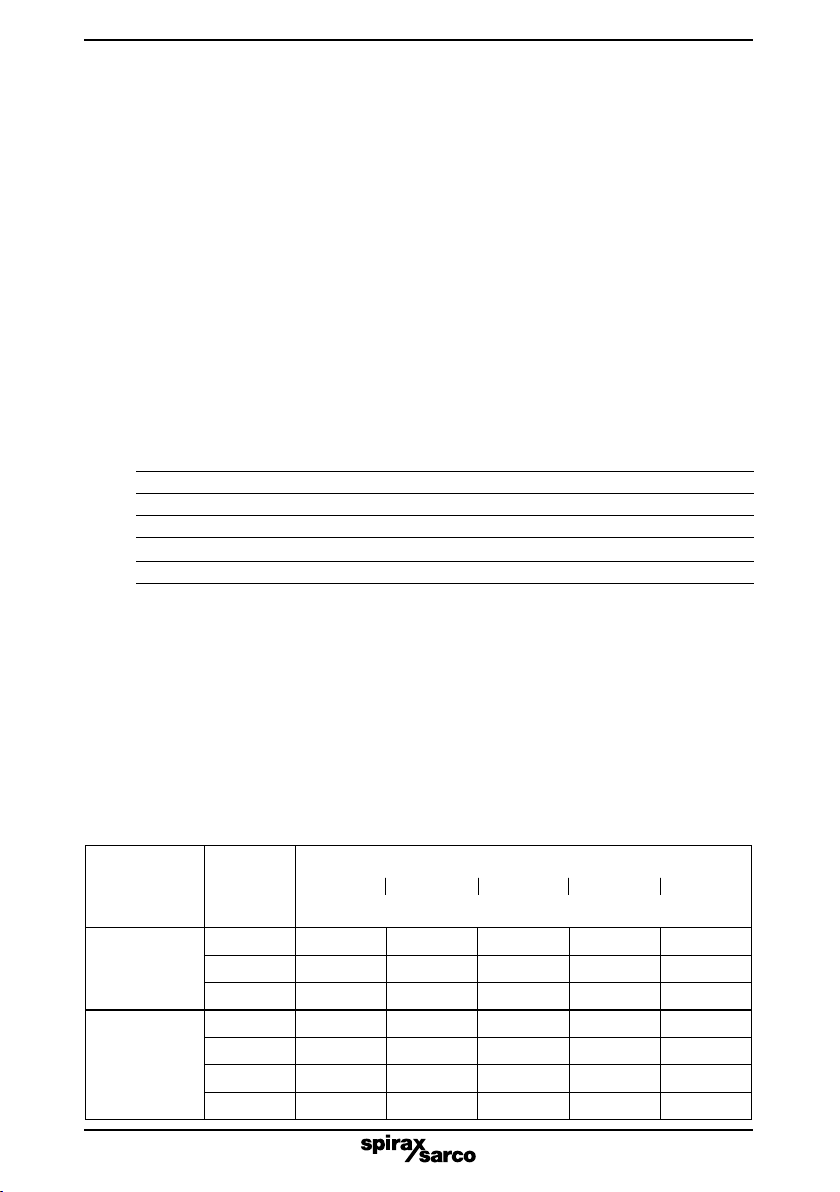

3.2.6 On multi-lance systems, the lances should be assembled such that there is an even

distribution of steam over the duct, as shown in Figure 3, page 10. Particular attention

should be paid to the position of the main steam supply to the interconnecting

pipework - see Figures 5, 11, 12 and 13.

Generally up to 5 lances can be installed horizontally on an application.

Recommendations on lance numbers relative to duct height can be found in

Section 3.3.4.

3.2.7 The outer end of the lance can be supported utilising the M10 thread in the lance

end cap.