SPIT AGP 125AV Guide

GB

F

D

I

NL

E

P

S

DK

N

Operator’s manual and 1

maintenance instructions

Notice d’emploi et 14

d’entretien

Bedienungs- und 28

Wartungsanleitungen

Manuale d’uso e 43

manutenzione

Operatorhandleiding en 58

onderhoudsinstructies

Instrucciones del manual de usuario 72

y de mantenimiento

Manual de utilização e 86

manutenção

Bruksanvisning och 100

anvisningar för underhåll

Brugsvejledning og 113

vedligeholdelsesanvisninger

Brukerhåndbok og 126

vedlikeholdsanvisninger

AGP 125AV

AGP125AV_part1.indd 1 27/02/09 16:02

1. On/Off switch 7. Protection guard

2. Auxiliary handle 8. Adjustment screw

3. Thread for auxiliary 9. Clamping lever

handle 10. Diamond disc

4. Spindle lock button 11. Abrasive disc

5. Spindle 12. Clamping nut

6. Mounting ange

with O-ring

GB

1

2

3

4

5

8

7

6

9

11

10

13

AGP125AV_part1.indd 2 27/02/09 16:02

1. Interrupteur marche/arrêt

2. Poignée auxiliaire

3. Filetage pour poignée

auxiliaire

4. Bouton de verrouillage

de la asque

5. Flasque

6. Bride de xation avec

joint torique

7. Protection

8. Vis de réglage

9. Levier de serrage

10. Disque diamant

11. Disque abrasif

12. Écrou de serrage

1. Aan/Uit-schakelaar

2. Extra handgreep

3. Schroefdraad voor

extra handgreep

4. Blokkeerknop as

5. As

6. Bevestigingsens met O-ring

7. Afschermkap

8. Stelschroef

9. Spangreep

10. Diamantschijf

11. Slijpschijf

12. Klemmoer

1. Strömbrytare på/av

2. Sidohandtag

3. Gängor för sidohandtag

4. Låsningsknapp för spindel

5. Spindel

6. Monteringsäns med O-ring

7. Skyddskåpa

8. Justeringsskruv

9. Låsspak

10. Diamantbelagd cirkelsågsklinga

11. Slipskiva

12. Mutter för låsspak

1. Ein/Aus-Schalter

2. Zusatzhandgriff

3. Schraubanschluss für

Zusatzhandgriff

4. Spindelarretiertaste

5. Antriebsspindel

6. Montageansch mit O-Ring

7. Schutzhaube

8. Stellschraube

9. Spannhebel

10. Diamanttrennscheibe

11. Trennscheibe

12. Spannmutter

1. Interruptor de encendido

2. Empuñadura auxiliar

3. Rosca para la empuñadura

auxiliar

4. Botón de bloqueo del husillo

5. Husillo

6. Brida de montaje con

junta tórica

7. Carcasa protectora

8. Tornillo de jación

9. Palanca de jación

10. Disco de diamante

11. Disco abrasivo

12. Tuerca de jación

1. Tænd/Sluk-knap

2. Ekstragreb

3. Gevind til ekstragreb

4. Spindellåsknap

5. Spindel

6. Monteringsange med O-ring

7. Afskærmning

8. Justeringsskrue

9. Klemmegreb

10. Diamantskive

11. Slibeskive

12. Fastspændingsskive

1. Spegnimento

2. Impugnatura ausiliaria

3. Filettatura di montaggio

impugnatura ausiliaria

4. Tasto di blocco mandrino

5. Mandrino

6. O-ring della angia di ssaggio

7. Maschera di protezione

8. Vite di regolazione

9. Leva di arresto

10. Disco al diamante

11. Disco abrasivo

12. Vite di ssaggio

1. Interruptor Ligar/Desligar

2. Manípulo auxiliar

3. Rosca para manípulo auxiliar

4. Botão de bloqueio do veio

5. Veio

6. Flange de montagem com

O-ring

7. Protecção

8. Parafuso de ajuste

9. Alavanca de xação

10. Disco de diamante

11. Disco abrasivo

12. Porca de xação

FNL S

DEDK

IP1. Av-/på-bryter

2. Hjelpehåndtak

3. Gjenger for hjelpehåndtak

4. Låseknapp for spindel

5. Spindel

6. Festeens med o-ring

7. Beskyttelsesvern

8. Justeringsskrue

9. Festespake

10. Diamantskive

11. Slipeskive

12. Festemutter

N

AGP125AV_part1.indd 3 27/02/09 16:02

1. Strömbrytare på/av

2. Sidohandtag

3. Gängor för sidohandtag

4. Låsningsknapp för spindel

5. Spindel

6. Monteringsäns med O-ring

7. Skyddskåpa

8. Justeringsskruv

9. Låsspak

10. Diamantbelagd cirkelsågsklinga

11. Slipskiva

12. Mutter för låsspak

1. Tænd/Sluk-knap

2. Ekstragreb

3. Gevind til ekstragreb

4. Spindellåsknap

5. Spindel

6. Monteringsange med O-ring

7. Afskærmning

8. Justeringsskrue

9. Klemmegreb

10. Diamantskive

11. Slibeskive

12. Fastspændingsskive

SERVICE

SPIT FRANCE SPIT ESPAÑA

Route de Lyon 150 Calle Murcia 36

B.P. 150 P.I. Les Salines

26501 Bourg-Les-Valence Cedex 08830 Sant Boi de Llobregat

FRANCE ESPAÑA

tel. 475 82 20 20 tel. 93 652 59 52

fax 475 82 21 54 fax 93 652 53 59

SPIT BELGIUM SPIT DEUTSCHLAND

Rue Bollinckxstraat 205 Gütenbergstrasse 4

1070 Bruxelles - Brussel 91522 Ansbach

BELGIQUE - BELGIË DEUTSCHLAND

tel. 02 524 10 60 tel. 0981 95 09 0

fax 02 520 25 58 fax 0981 95 09160

SPIT HOLLAND SPIT AUSTRIA

Rendementsweg 1 Wasserfeldstrasse 22

P.B. 41 Postfach 31

3641 SK Mijdrecht 5022 Salzburg

NEDERLAND ÖSTERREICH

tel. 0297 230 260 tel. 0662 452 056

fax 0297 230 270 fax 0662 451 879

SPIT ITALIA SPIT NORDIC

Via Reiss Romoli 265/12 Gl. Banegaardsvej 25

10148 Torino 5500 Middelfart

ITALIA DANMARK

tel. 011 2975 601 tel. 244 912 710

fax 011 2975 666 fax 244 912 580

SPIT CZECH REPUBLIC SPIT GREECE

Videnska ul., Horny Dvory Voutsina 72

148 00 Praha 4 15561 Holargos-Attiki

CZECH REPUBLIC GREECE

tel. 244 912 719 tel. 210 6564 530

fax 244 912 580 fax 210 6564 540

1. Av-/på-bryter

2. Hjelpehåndtak

3. Gjenger for hjelpehåndtak

4. Låseknapp for spindel

5. Spindel

6. Festeens med o-ring

7. Beskyttelsesvern

8. Justeringsskrue

9. Festespake

10. Diamantskive

11. Slipeskive

12. Festemutter

AGP125AV_part1.indd 4 27/02/09 16:02

1

GB

EXPLANATION OF SYMBOLS AND PICTOGRAMS

n Rated speed

V Volts

A Amperes

Hz Hertz

W Watts

/min Revolutions or reciprocations per minute

~ Alternating current

Class II construction

Disposal of old electrical & electronic equipment

Wear eye protection

Wear ear protectors

Read all safety warnings and all instructions

Warning

AGP125AV_part1.indd 1 27/02/09 16:02

2

GENERAL POWER TOOL SAFETY WARNINGS

WARNING: Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may result in electric shock, re and/or

serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mains-operated (corded) power

tool.

1) Work area safety

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence

ofammableliquids,gasesordust.

Power tools create sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power tool.

Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in any way.

Do not use any adapter plugs with earthed (grounded) power tools.

Unmodied plugs and matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces, such as pipes,

radiators, ranges and refrigerators.

There is an increased risk of electric shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging

the power tool. Keep cord away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for

outdoor use.

Use of a cord suitable for outdoor use reduces the risk of electric shock.

f) If operating a power tool in a damp location is unavoidable, use a residual

current device (RCD) protected supply.

Use of an RCD reduces the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use common sense when operating

apowertool.Donotuseapowertoolwhileyouaretiredorundertheinuence

of drugs, alcohol or medication.

A moment of inattention while operating power tools may result in serious personal

injury.

b) Usepersonalprotectiveequipment.Alwaysweareyeprotection.

Protective equipment such as dust mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off-position before

connecting the power source, picking up or carrying the tool.

Carrying power tools with your nger on the switch or energising power tools that

have the switch on invites accidents.

AGP125AV_part1.indd 2 27/02/09 16:02

3

GB

d) Remove any adjusting key or wrench before turning the power tool on.

A wrench or a key left attached to a rotating part of the power tool may result in

personal injury.

e) Do not overreach. Keep proper footing and balance at all times.

This enables better control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep you hair, clothing

and gloves away from moving parts.

Loose clothes, jewellery or long hair can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used.

Use of dust collection can reduce dust-related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your application.

The correct power tool will do the job better and safer at the rate for which it was

designed.

b) Do not use the power tool if the switch does not turn it on and off.

Any power tool that cannot be controlled with the switch is dangerous and must

be repaired.

c) Disconnect the plug from the power source from the power tool before making

any adjustments, changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of starting the power tool

accidentally.

d) Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

d) Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tool’s

operation. If damaged, have the power tool repaired before use.

Many accidents are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp cutting edges are less likely to bind and

are easier to control.

g) Use the power tool, accessories and tool bets etc. in accordance with these

instructions, taking into account the working conditions and the work to be

performed.

Use of the power tool for operations different from those intended could result in

a hazardous situation.

5) Service

a) HaveyourpowertoolservicedbyaqualiedSpitrepairserviceusingonly

identical replacement parts.

This will ensure that the safety of the power tool is maintained.

AGP125AV_part1.indd 3 27/02/09 16:02

4

SAFETY INSTRUCTIONS FOR ALL OPERATIONS

Safety warnings common for grinding, sanding, wire brushing, polishing or

abrasive cutting-off operations:

a) This power tool is intended to function as a grinder. Read all safety warnings,

instructions,illustrationsandspecicationsprovidedwiththistool.

Failure to follow all instructions listed below may result in electric shock, re and/or

serious injury.

b) Operations such as sanding, wire brushing, polishing or cutting-off are not

recommended to be performed with this power tool.

Operations for which the power tool was not designed may create a hazard and

cause personal injury.

c) Donotuseaccessorieswhicharenotspecicallydesignedandrecommended

by the tool manufacturer.

Just because the accessory can be attached to your power tool, it does not assure

safe operation.

d) Theratedspeedoftheaccessorymustbeatleastequaltothemaximumspeed

marked on the power tool.

Accessories running faster than their rated speed can break and y apart.

e) The outside diameter and thickness of your accessory must be within the

capacity rating of your power tool.

Incorrectly sized accessories cannot be adequately guarded or controlled.

f) Thearboursizeofwheels,angesoranyotheraccessorymustproperlytthe

spindle of the power tool.

Accessories with arbour holes that do not match the mounting hardware of the power

tool will run out of balance, vibrate excessively and my cause loss of control.

g) Do not use a damaged accessory. Before each use inspect the accessory

such as abrasive wheels for chips and cracks, tear or excess wear. If the power

tool or accessories are dropped, inspect for damage or install an undamaged

accessory. After inspecting and installing an accessory, position yourself

and bystanders away from the plane of the rotating accessory and run the

power tool at maximum no-load speed for one minute.

Damaged accessories will normally break apart during this test time.

h) Wearpersonalprotectiveequipment.Dependingontheapplication,use

face shield, safety goggles or safety glasses. As appropriate, wear dust mask,

hearing protectors, gloves and workshop apron capable of stopping small

abrasive or workpiece fragments.

The eye protection must be capable of stopping ying debris generated y various

operations. The dust mask or respirator must be capable of ltrating particles

generated by your operation. Prolonged exposure to high intensity noise may cause

hearing loss.

i) Keep bystanders a safe distance away from work area. Anyone entering

theworkareamustwearpersonalprotectiveequipment.

Fragments of workpiece or of a broken accessory may y away and cause injury

beyond immediate area of operation.

j) Hold power tool by insulated gripping surfaces only, when performing an

operation where the cutting accessory may contact hidden wiring or its own

cord.

Cutting accessory contacting a “live” wire may make exposed metal parts of the

power tool “live” and shock the operator.

k) Position the cord clear of the spinning accessory.

If you lose control, the cord may be cut or snagged and your hand or arm may be

pulled into the spinning accessory.

AGP125AV_part1.indd 4 27/02/09 16:02

5

GB

l) Never lay the power tool down until the accessory has come to complete stop.

The spinning accessory may grab the surface and pull the power tool out of your

control.

m) Do not run the power tool while carrying it at your side.

Accidental contact with the spinning accessory could snag your clothing, pulling the

accessory into your body.

n) Regularly clean the power tool’s air vents.

The motor’s fan will draw the dust inside the housing and excessive accumulation of

powdered metal may cause electrical hazards.

o) Donotoperatethepowertoolnearammablematerials.

Sparks could ignite these materials.

p) Donotuseaccessoriesthatrequireliquidcoolants.

Using water or other liquid coolants may result in electrocution or shock.

FURTHER SAFETY INSTRUCTIONS FOR ALL OPERATIONS

Kickback and Related Warnings

Kickback is a sudden reaction to a pinched or snagged rotating wheel or any other

accessory. Pinching or snagging causes rapid stalling of the rotating accessory which

in turn causes the uncontrolled power tool to be forced in the direction opposite of the

accessory’s rotation at the point of the binding.

For example, if an abrasive wheel is snagged or pinched y the workpiece, the edge

of the wheel that is entering into the pinch point can dig into the surface of the material

causing the wheel to climb out or kick out. The wheel may either jump toward or away

from the operator, depending on direction of the wheel’s movement at the point of

pinching. Abrasive wheels may also break under these conditions.

Kickback is the result of power tool misuse and/or incorrect operating procedures or

conditions that can be avoided by taking proper precautions as given below.

a) Maintainarmgriponthepowertoolandpositionyourbodyandarmto

allow you to resist kickback forces. Always use auxiliary handle, if provided,

formaximumcontroloverkickbackortorquereactionduringstart-up.

The operation can control torque reactions or kickback forces, if proper precautions

are taken.

b) Never place your hand near the rotating accessory.

Accessory may kickback over your hand.

c) Do not position your body in the area where power tool will move if kickback

occurs.

Kickback will propel the tool in direction opposite to the wheel’s movement at the

point of snagging.

d) Use special care when working corners, sharp edges etc.

Avoid bouncing and snagging the accessory.

Corners, sharp edges or bouncing have a tendency to snag the rotating accessory

and cause loss of control or kickback.

e) Do not attach a saw chain woodcarving blade or toothed saw blade.

Such blades create frequent kickback and loss of control.

AGP125AV_part1.indd 5 27/02/09 16:02

6

ADDITIONAL SAFETY INSTRUCTIONS FOR GRINDING AND CTTING-OFF OPERATIONS

SafetyWarningsSpecicforGrindingandAbrasiveCutting-OffOperations:

a) Use only wheel types that are recommended for your power tool and the

specicguarddesignedfortheselectedwheel.

Wheels for which the power tool was not designed cannot be adequately guarded

and are unsafe.

b) The guard must be securely attached to the power tool and positioned for

maximum safety, so the least amount of wheel is exposed towards the

operator.

The guard helps to protect operator from broken wheel fragments and accidental

contact with wheel.

c) Wheels must be used only for recommended applications.

For example: do not grind with he side of cut-off wheel.

Abrasive cut-off wheels are intended for peripheral grinding, side forces applied to

these wheels may cause them to shatter.

d) Alwaysuseundamagedwheelangesthatareofcorrectsizeandshapefor

your selected wheel.

Proper wheel anges support the wheel thus reducing the possibility of wheel

breakage. Flanges fot cut-off wheels may be different from grinding wheel anges.

e) Do not use worn down wheels from larger power tools.

Wheel intended for larger power tool is not suitable for the higher speed of a smaller

tool and may burst.

ADDITIONAL SAFETY INSTRUCTIONS FOR CUTTING-OFF OPERATIONS

a) Do not “jam” the cut-off wheel or apply excessive pressure. Do not attempt

to make an excessive depth of cut.

Overstressing the wheel increases the loading and susceptibility to twisting or binding

of the wheel in the cut and the possibility of kickback or wheel breakage.

b) Do not position your body in line with and behind the rotating wheel.

When the wheel, at the point of operation, is moving away from your body, the

possible kickback may propel the spinning wheel and the power tool directly at you.

c) When wheel is binding or when interrupting a cut for any reason, switch off

the power tool and hold the power tool motionless until the wheel comes to

a complete stop. Never attempt to remove the cut-off wheel from the cut while

the wheel is in motion otherwise kickback may occur.

Investigate and take corrective action to eliminate the cause of wheel binding.

d) Do not restart the cutting operation in the workpiece. Let the wheel reach full

speed and carefully re-enter the cut.

The wheel may bind, walk up or kickback if the power tool is restarted in

the workpiece.

e) Support panels or any oversized workpiece to minimize the risk of wheel

pinching and kickback.

Large workpieces tend to sag under their own weight. Supports must be placed under

the workpiece near the line of cut and near the edge of the workpiece on both sides

of the wheel.

f) Use extra caution when making a “pocket cut” into existing walls or other blind

areas.

The protruding wheel may cut gas or water pipes, electrical wiring or objects that can

cause kickback.

AGP125AV_part1.indd 6 27/02/09 16:02

7

GB

ADDITIONAL SAFETY INSTUCTIONS FOR POLISHING OPERATIONS

a) Do not allow any loose portion of the polishing bonnet or its attachment

strings to spin freely. Tuck away or trim any loose attachment strings.

Loose and spinning attachment strings can entangle your ngers or snag on

the workpiece.

SPECIFIC SAFETY RULES

It is extremely important that you do not forget to read the safety requirements before

using the device for the rst time.

SafetyRequirementsspecictotheAGP125AVandAGS230M:

• Check that the speed marked on the blade is equal to or greater than the speed

indicated on the angle grinder.

• Verify that the dimensions of the blade are compatible with those of the angle grinder.

• Maintain abrasive blades with care and handle them in accordance with the

instructions provided by the manufacturer.

• Before use, carefully check to see that no cracking, chipping, or other defects are

present on the blade. Never use a damaged blade with the device.

• Ensure that the abrasive wheel is correctly mounted and assembled in accordance

with the instructions provided by the manufacturer.

• Utilise disc anges supplied with the abrasive tool if necessary.

• Before using the grinder, check to see that the abrasive wheel is correctly mounted

and allow the device run unimpeded for 30 seconds in a safe position. In the case of

excessive vibration, turn the angle grinder off immediately and examine it thoroughly

to determine the cause.

• If a safety-guard is provided with the tool, be sure to use it at all times while

operating the angle grinder.

• Never use bushings or large-hole adaptors for the abrasive tools that were not

provided by the manufacturer.

• Ensure that any wire wheel is compatible with the size of the axis, if the tool is to be

used with a wire wheel.

• Ensure that the work piece is supported sufciently and held rmly in place before

using the angle grinder.

• Take extra care that sparks given off during the work do not cause any undue risk,

in particular that no one is injured and that no ammable substances are ignited.

• Make sure that the air-slits of the ventilator are kept open when working in a dusty

or dirty environment. Should it become necessary to using the angle grinder, clear

material from the openings, rst separate the work tools from machine (use only

non-metal objects) and take extra care to avoid damaging any internal components.

• Always use safety glasses and ear protectors. Other personal safety items such as

full-face visors, work gloves, helmet and aprons are highly recommended.

• Be aware that the saw continues to rotate after the device is switched off.

AGP125AV_part1.indd 7 27/02/09 16:02

8

TECHNICAL SPECIFICATIONS

Rated input 1400 W

Rated output 750 W

Voltage 230 V~

Current 6,4 A

Frequency 50 Hz

Rated speed n 11000 min-1

Full rated speed n 9200 min-1

Grinding disc Ø 125 mm

Spindle thread M14

Thread length 17 mm

Protection class class II

Weight 2 kg

Dimensions (L x H x W) 300 x 107 x 142 mm

Cable 4 m

Noise/vibration information

Noise (Lpa) 91 dB

Noise (Kpa) 3 dB

Noise (Lwa) 102 dB

Wear ear-protection!

Hand-arm vibrations surface grinding 5,5 m/s²

Hand-arm vibrations surface grinding (K) 2,0 m/s²

Hand-arm vibrations disc sanding 2,5 m/s²

Hand-arm vibrations disc sanding (K) 1,5 m/s²

Conrmationdeclaration

We declare in sole responsibility that the product types Spit AGP 125AV referred to in

this declaration conforms to the following standards and further normative documents.

We declare under our sole responsibility that this product is in conformity with the

following standards or standardization documents:

EN 60745-1, EN 60745-2-3

EN 55014-1, EN 55014-2, EN 61000-3-2, EN 61000-3-3(Category II)

2006/42/EC, 2004/108/EC

Paul van Beek Ruben Bernaert

General Manager Product Manager

ITW Heger

Industriepark

Cardijnlaan 3

BE-8600 Diksmuide

Belgium

AGP125AV_part1.indd 8 27/02/09 16:02

9

GB

1

3

INTENDED USE

The AGP 125AV is intended for cutting metal and stone materials and for roughing

stone materials without using water.

FUNCTIONAL DESCRIPTION

Before use

The network voltage must conform to the voltage indicated on the nameplate of the tool.

Because the tool falls into Class II category, under normal usage it does not need to be

specially earthed.

Under no circumstances should the tool be used when the power supply cable is

damaged. The use of a damaged power cables can lead to an electric shock.

Check, and if necessary, clear the air-slots for proper ventilation.

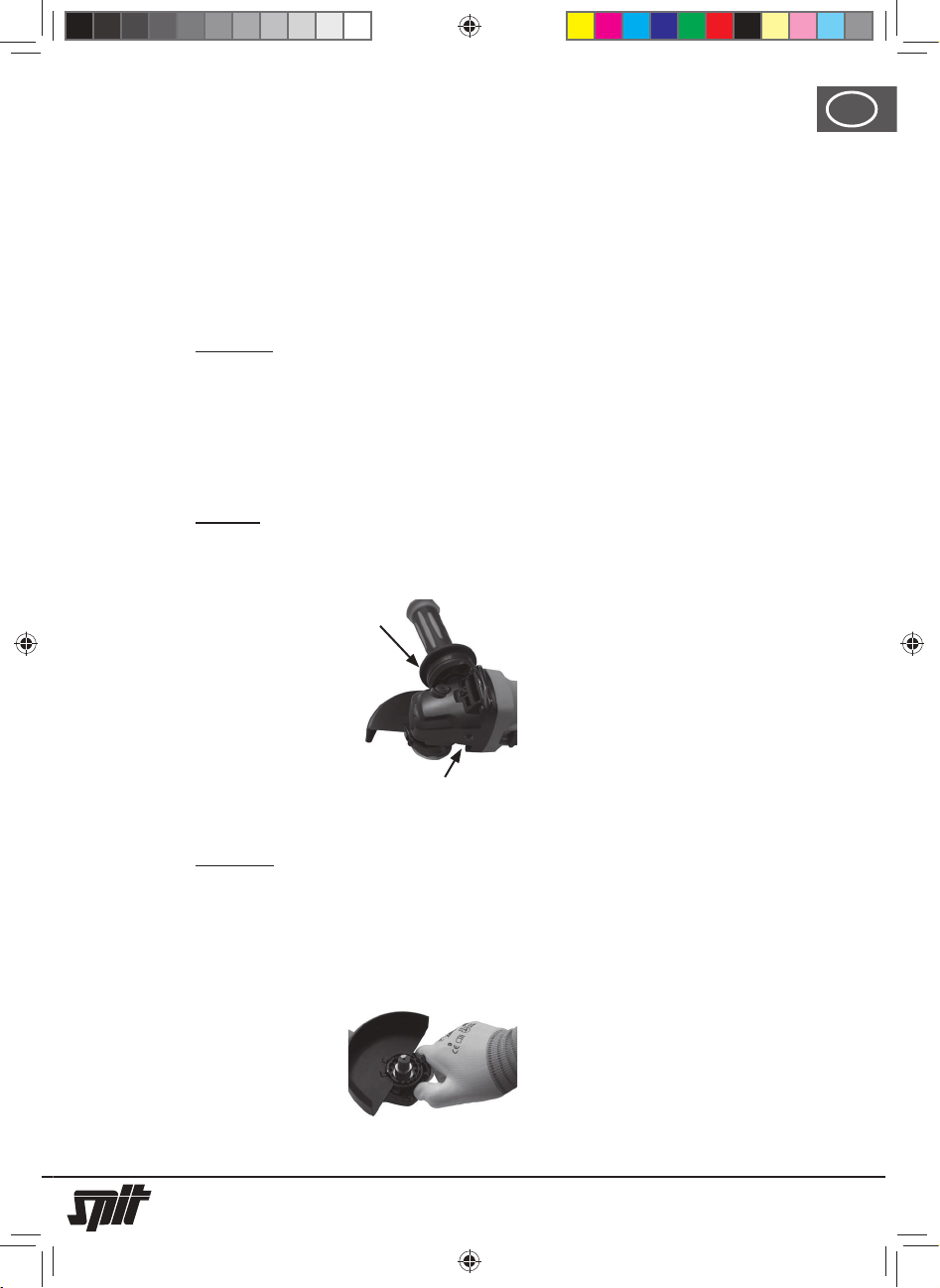

Handgrip

For safety purposes, the machine must always be used with the side handgrip placed in

one of the 2 xed positions (1).

Dust guard

Attaching the safety-guard before use is obligatory, and ensures a higher degree of

safety for the user. The direction of the safety guard is adjustable.

No tools are necessary, you can use the clamping lever (3) and place the dust guard in

10 different positions.

AGP125AV_part1.indd 9 27/02/09 16:02

10

Starting limiter

Thanks to the electronic safety system, the machine starts slowly (because of a starting

limiter). This makes the machine more safe, which is especially useful in a limited

working area due to the absence of the starting revolutionary movements.

WARNING:Undernocircumstances,uctuationscanoccurinhenumberof

revolutions as a result of electromagnetic disruptions.

Extension cord

When an extension cord is used, use an approved cable that is suitable for the capacity

of the machine (see the table below). This is very important for maintaining the capacity

of the motor.

Length

extension

Nominal current at full power (A)

0,2 2,1 – 3,4 3,5 – 5 5,1 – 7 7,1 – 10 10,1 – 16

7,5 1,5 1,5 1,5 2,5 2,5 4,0

15,0 1,5 1,5 1,5 2,5 2,5 4,0

22,5 1,5 1,5 1,5 2,5 2,5 4,0

30,0 1,5 1,5 1,5 2,5 2,5 6,0

60,0 1,5 1,5 1,5 2,5 4,0 6,0

90,0 1,5 2,5 2,5 4,0 4,0 8,0

Table 1 Cutaway conductor - cable 2 x mm²

Unpacking

Carefully remove the tool and all loose items from the shipping container.

Retain all packing materials until after you have inspected and satisfactorily operated

the machine.

Carton contents

AGP125AV

1. Angle grinder AGP 125AV

2. Auxiliary handle

3. Dust guard

4. Double pin wrench

DO NOT OPERATE THESE TOOLS UNTIL YOU READ AND UNDERSTAND

THE ENTIRE INSTRUCTION MANUAL!

AGP125AV_part1.indd 10 27/02/09 16:02

11

GB

1 2 3

1 2 3 4

Mounting the dust guard

Never use the machine without rst having attached the safety-guard.

Unplug the machine (1)

Place the tool on its back, with the spindle facing upwards (2)

Open the safety guard clamping lever and place the dust guard in the correct position

and close the spring clip (3)

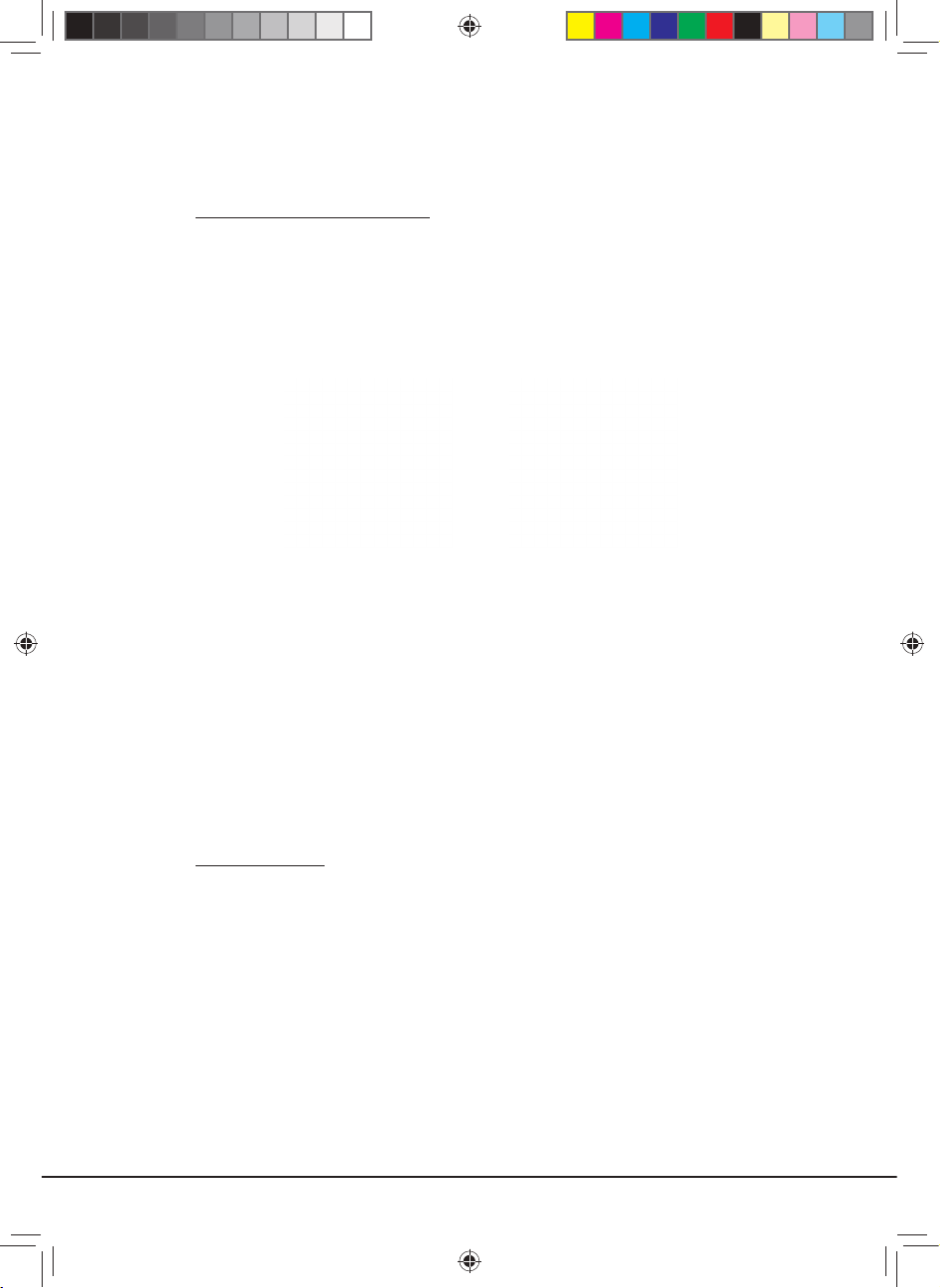

Mounting the grinding discs

Pay attention to the dimensions of the grinding discs. The mounting hole diameter must

t the mounting ange without play. Do not use reducers or adaptors.

When using a diamond cutting disc, take care that the direction of rotation arrow on

the disc and the direction of rotation of the machine (direction of rotation arrow on

the machine head) agree.

Unplug the machine (1)

Place the under ange (2)

Place the diamond disc (3)

Place the upper ange and tighten it with the double pin wrench (4)

Removal is the opposite of assembly.

AGP125AV_part1.indd 11 27/02/09 16:02

12

1 2

After mounting the grinding disc and before switching on the machine, check that

the grinding tool is correctly mounted and that it can run freely.

Switching the machine on and off

To switch on

To start the machine, press the on/off switch forward and then down (1)

To switch off

Release the on/off switch (2)

HOW TO USE THE TOOL

Effective control of this powerful tool requires two-handed operation for maximum safety

and control.

The proper position is to keep one hand on the main handle and the other hand on the

auxiliary handle. It is vitally important to keep stable footing at all times,.

Cutting operations

The machine must be used only for dry cutting!

When cutting, do not press, jam or oscillate the machine. Work with moderate feed,

adapted to the material being cut.

Do not reduce the speed of running down cutting discs by applying sideward pressure.

The direction in which the cutting is performed is important.

The machine must always work in an up-grinding motion. Therefore, never move

the machine in the other direction! Otherwise, the danger exists of it being pushed

uncontrolled out of the cut.

AGP125AV_part1.indd 12 27/02/09 16:02

13

GB

For cutting, especially hard material, the diamond cutting disc can overheat and

become damaged as a result. This is clearly indicated by circular sparking, rotating with

the diamond cutting disc. In this case, interrupt the cutting process and allow the

diamond disc to cool by running freely at no-load speed for a short time.

Noticeable decreasing work progress and circular sparking are indications that

the diamond disc has become dull. Briey cutting into abrasive material can resharpen

the disc.

MAINTENANCE

Keep the tool clean

Periodically blow out all air passages with dry compressed air. All plastic parts should

be cleaned with a soft damp cloth. Never use solvents to clean plastic parts. They could

possibly dissolve or otherwise damage the material.

Wear safety glasses while using compressed air.

The carbon brushes

This machine has self-interrupting carbon brushes whose purpose is to automatically

cut the power when the carbon brushes have reached a certain degree of wear.

If this occurs, replace the two worn-out carbon brushes.

To inspect or replace the carbon brushes, rst unplug the machine.

Loosen the screw completely.

Remove the tail cover to the back, with the help of a screwdriver. Lift the spring and

remove the brushes from the carbon brush holder.

Check the length of the brushes. Replace both brushes when they have less then

10 mm length.

When replacing the carbon brushes, pull the conductors form their position, lift up the

carbon brush via the spring, remove it and replace it with the new brush facing in

the opposite direction.

After checking or replacing the carbon brushes, assemble the tail cover and ensure that

you do not damage the conductors.

Screw in the screw rmly. Before using the machine again, let it run freely for a few

minutes so that the carbon brushes can nd their place.

All other repairs and/or maintenance have to be done by a Spit service centre.

Dispose of your appliance, accessories and packaging in an environment-friendly

manner.

AGP125AV_part1.indd 13 27/02/09 16:02

14

EXPLICATION DES SYMBOLES ET PICTOGRAMMES

n Vitesse nominale

V Volts

A Ampères

Hz Hertz

W Watts

/min Tours ou coups par minute

~ Courant alternatif

Construction de classe II

Mise au rebut des anciens équipements électriques et électroniques

Porter une protection oculaire

Porter une protection auditive

Lire tous les avertissements de sécurité et toutes les instructions

Avertissement

AGP125AV_part1.indd 14 27/02/09 16:02

15

F

AVERTISSEMENTS DE SÉCURITÉ D’ORDRE GÉNÉRAL RELATIFS AUX OUTILS

ÉLECTRIQUES

DANGER: Lire tous les avertissements de sécurité et toutes les instructions.

Le non-respect des avertissements et des instructions risque d’entraîner un choc

électrique, un incendie et/ou une blessure grave.

Conserver tous les avertissements et instructions pour pouvoir les consulter

ultérieurement.

Le terme « outil électrique » auquel il est fait référence dans les avertissements se

réfère à votre outil électrique manuel (à cordon).

1) Sécurité de la zone de travail

a) Maintenir la zone de travail propre et bien éclairée.

Les zones encombrées ou sombres sont propices aux accidents.

b)Nepasutiliserd’outilsélectriquesdansdesatmosphèresexplosives,en

présencedeliquidesinammables,degazoudepoussièreparexemple.

Les outils électriques créent des étincelles qui peuvent enammer la poussière ou les

vapeurs.

c) Tenir les enfants et toute autre personne à distance lors de l’utilisation d’un

outilélectrique.

Les distractions peuvent entraîner une perte de contrôle de l’outil.

2) Sécurité électrique

a)Lachedel’outilélectriquedoitcorrespondreàlapriseélectrique. Ne jamais

modierlachedequelquefaçonquecesoit.

Nepasutiliserdechesd’adaptationavecdesoutilsélectriquesmisàlaterre.

Les ches non modiées et les prises électriques correspondantes réduiront le risque

de choc électrique.

b)Évitertoutcontactcorporelaveclessurfacesmisesàlaterretellesqueles

tuyaux,lesradiateurs,lescuisinièresetlesréfrigérateurs.

Un risque accru de choc électrique est présent si votre corps est mis à la terre.

c)Nepasexposerlesoutilsélectriquesàlapluieouàdesconditions

d’humidité.

La pénétration d’eau dans un outil électrique augmentera le risque de choc

électrique.

d) Ne pas malmener le cordon. Ne jamais utiliser le cordon pour porter, tirer

suroudébrancherl’outilélectrique.Tenir le cordon à distance de sources de

chaleur,d’huile,d’arêtesvivesoudepiècesmobiles.

Les cordons endommagés ou emmêlés augmentent le risque de choc électrique.

e)Lorsdel’utilisationd’unoutilélectriqueàl’extérieur,utiliserunerallonge

adaptée à un usage en extérieur.

L’utilisation d’un cordon adapté à un usage en extérieur réduit le risque de choc

électrique.

f)Sil’utilisationd’unoutilélectriquedansunendroithumideestinévitable,

utiliser une alimentation protégée par un dispositif à courant résiduel (RCD).

L’utilisation d’un RCD réduit le risque de choc électrique.

AGP125AV_part1.indd 15 27/02/09 16:02

16

3) Sécurité personnelle

a)Restervigilant,faireattentionàcequel’onfaitetfairepreuvedelogique

lorsdel’utilisationd’unoutilélectrique. Nepasutiliserunoutilélectrique

lorsquevousêtesfatiguéouquevousêtessousl’inuencededrogues,

d’alcool ou de médicaments.

Un moment d’inattention lors de la manipulation d’outils électriques risque d’entraîner

de graves blessures corporelles.

b)Utiliserdeséquipementsdeprotectionindividuelle.Toujoursporterune

protection oculaire.

Les équipements de protection tels que les masques antipoussière, les chaussures

de sécurité antidérapantes, les casques ou les protections auditives, utilisés dans

des circonstances adéquates, réduiront le risque de blessure corporelle.

c) Prévenir tout démarrage involontaire. Veilleràcequel’interrupteursoiten

position Arrêt avant de brancher, de prendre ou de porter l’outil.

Le fait de porter des outils électriques en mettant le doigt sur l’interrupteur ou

l’activation d’outils électriques alors que l’interrupteur est sur Marche sont propices

aux accidents.

d)Retirertouteclavettedecalageoucléavantdemettrel’outilélectriquesous

tension.

Une clé ou une clavette qui demeure xée à une pièce rotative de l’outil électrique

risque d’entraîner des blessures corporelles.

e)Nepass’étirer.Veilleràgardersonéquilibreàtoutmoment.

Ceci permet un meilleur contrôle de l’outil électrique dans des circonstances

inattendues.

f) Porter une tenue appropriée. Ne pas porter de vêtements amples ni de bijoux.

Tenirlescheveux,vêtementsetgantsàdistancedespiècesmobiles.

Les vêtements amples, les bijoux et les cheveux longs risquent de se prendre dans

les pièces mobiles.

g)Sidesdispositifssontfournispourlebranchementdesystèmesd’extraction

etderécupérationdepoussière,veilleràcequ’ilssoientconnectésetutilisés

defaçonappropriée.

L’utilisation d’un système de récupération de poussière peut réduire les dangers liés

à la poussière.

4) Utilisation et entretien d’un outil électrique

a)Nepasexercerdeforcesurl’outilélectrique.Utiliserl’outilélectriquequi

convient à votre application.

L’outil électrique approprié fera un meilleur travail de façon plus sûre à la vitesse pour

laquelle il a été conçu.

b)Nepasutiliserl’outilélectriquesil’interrupteurnelemetpassoustensionet

hors tension.

Un outil électrique qui ne peut pas être contrôlé par le biais de l’interrupteur est

dangereux et doit être réparé.

c)Débrancherlachedel’outilélectriqueavantd’effectuerdesréglages,de

changerdesaccessoiresouderangerdesoutilsélectriques.

Ce genre de mesures de sécurité préventive réduisent le risque de démarrer l’outil

électrique accidentellement.

d)Rangerlesoutilsélectriquesaureposhorsdelaportéedesenfantsetne

paslaisserlespersonnespeufamiliariséesavecl’outilélectriqueouces

instructionsmanipulerl’outilélectrique.

Les outils électriques sont dangereux lorsqu’ils sont entre les mains d’utilisateurs non

formés.

AGP125AV_part1.indd 16 27/02/09 16:02

Table of contents

Languages: