Sport Flyers Simple Stick EP User manual

1

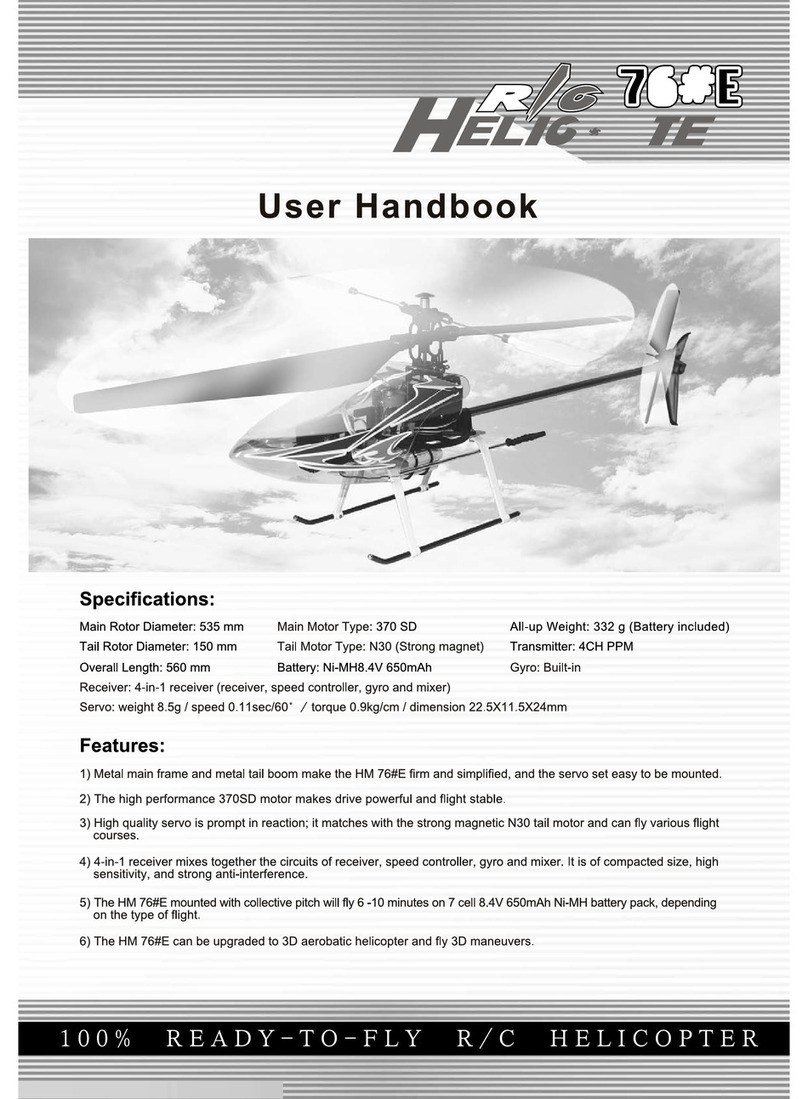

Simple Stick EP Specifications:

ASSEMBLY INSTRUCTIONS

Kit Product Number 160522

The Simple Stick EP is what we have nick named the A-ARF. This is an airplane with many things done for you, but it is not quite

an ARF. Why? You still have to put the color on the foam, so the finish is up to you! You can leave it bare foam or you can apply

the included colored tape as your finish (which makes the airplane very strong, too). You can use different colored rolls of tape to

achieve the color scheme you want, or you can even cover it with low-temperature covering material like Econokote!

The Simple Stick EP is built to be easy and versatile. It is quick to finish, can use a wide selection of mini and micro radio gear,

and will fly on many power systems ranging from a 370 geared motor to the KMS 31/21 brushless motor and 18 amp ESC.

Regardless of the power system you choose, we recommend using a lightweight LiPO battery. In this size range, LiPO batteries

and chargers are affordable and reliable.

In the air, the Simple Stick EP is simply a pleasure to fly. The light wing loading, thick airfoil and 4-channel controls make it

suitable for both new pilots who want to learn to fly aileron airplanes and sport flyers who love aerobatics. Because of its size,

large parks, school yards and other small outdoor areas are perfectly suited for the Simple Stick EP. No matter your skill level is,

this is a fun plane you're going to enjoy flying!

●Functions: Ailerons, Elevator, Rudder and Throttle

●Motor & Battery Required: See Suggestions on Page # 4

●Radio Required: 4 Channel or More w/4 Micro Servos & Micro Rx

●ESC Required: Dependent on Motor and Battery. See Page # 4

●Wing Span: 42.9 Inches (1090mm)

●Wing Area: 378 Square Inches (24.41dm2)

●Length: 31.8 Inches (808mm)

●Weight RTF: 20 - 25 Ounces (566 - 710gr)

●Wing Loading: 7.6 - 9.5 Ounces/Square Foot (23 - 29 g/sqdm)

2

Thank you for purchasing the Simple Stick EP. We're confident that the quality of your new airplane meets and even

exceeds your expectations. Before completing the final assembly of your new airplane, please carefully read through

this instruction manual in its entirety. Doing so will ensure your success the first time around!

SIMPLE STICK EP FEATURES

●Full-Function, 4-Channel, Electric-Powered R/C Aircraft

●Accepts a Wide Range of Affordable Power Systems

●Factory-Assembled Fuselage with Laser-Cut, Light-Plywood Parts

●Two-Piece Molded Foam Wing for Easy Transportation

●Durable Prebent Main Landing Gear Wire with Lightweight Wheels

●Dual Aileron Servos for Solid Control Response

●Complete Hardware Package

●Fast and Easy Assembly - 70 High-Resolution Digital Photos to Guide You

This instruction manual is designed to guide you through the entire assembly process of your new airplane in the least amount of

time possible. Along the way you'll learn how to properly assemble your new airplane and also learn tips that will help you in the

future. We have listed some of our recommendations below. Please read through them before beginning assembly.

●Please read through each step before beginning assembly.

You should find the layout very complete and straightforward.

Our goal is to guide you through assembly without any of the

headaches and hassles that you might expect.

●There are check boxes next to each procedure. After you

complete a procedure, check off the box. This will help prevent

you from losing your place.

●Cover your work table with brown paper or a soft cloth, both

to protect the table and to protect the parts.

●Keep a couple of small bowls or jars handy to put the small

parts in after you open the accessory bags.

●We're all excited to get a new airplane in the air, but take your

time. This will ensure you build a straight, strong and great

flying airplane.

●If you come across this symbol ☞, it means that this is an

important point or an assembly hint.

INTRODUCTION

TABLE OF CONTENTS

Introduction ............................................................................................ 2

Customer Service Information .............................................................. 3

Section 1: Our Recommendations ....................................................... 3

Section 2: Lithium Polymer Battery Warnings - Please Read ............ 4

Section 3: Tools and Supplies Required ............................................. 5

Section 4: A Warning About Working with Foam................................. 5

Section 5: Finishing Options ................................................................ 5

Section 6: Kit Contents ........................................................................ 6

Section 7: Horizontal and Vertical Stabilizer Installation .................... 7

Section 8: Elevator and Rudder Control Systems Installation .......... 10

Section 9: Motor Installation .............................................................. 13

Section 10: Landing Gear Installation ............................................... 14

Section 11: Wing Assembly ............................................................... 16

Section 12: Wing Mounting ................................................................ 19

Section 13: Final Assembly ................................................................ 20

Section 14: Balancing the Simple Stick EP ....................................... 22

Section 15: Control Throws ................................................................ 22

Section 16: Preflight Check and Safety ............................................. 23

3

This section describes our recommendations to help you in deciding which types of accessories to purchase for your new Simple

Stick EP. Please read through this entire section carefully. We have provided you with recommendations that, if followed,

will result in a great flying airplane. Failure to follow our recommendations may result in a poor flying airplane.

SECTION 1: OUR RECOMMENDATIONS

What Motor, Speed Control and Battery Should I Use?

The Simple Stick EP is designed to be flown with a wide range of power

systems. Anything from an SP400 Direct Drive to a 370 Gear Drive to an

Outrigger Brushless can be used. No matter which power system you

choose though, we recommend using a LiPO battery. A 2 cell 1250mAH

LiPO would be a perfect choice for any of the power systems recommended.

QTY. 1 Hitec Laser 4 FM Transmitter

QTY. 1 443534 Cirrus MRX-4II FM Micro Receiver

QTY. 1 446216 Cirrus Crystal for MRX-4II

QTY. 1 109111 Phase3 370 Motor and Gear Box

QTY. 1 107112 Phase3 10x4.7 Slow Flyer Propeller

QTY. 1 109109 Phase3 10 Amp ESC for 2 Cell LiPO

QTY. 4 440301 Cirrus CS301 Micro Servos

QTY. 1 128755 WattAge 2 Cell 1250mAH LiPO Flight Battery

QTY. 1 444728 Cirrus Y-Harness

QTY. 1 158370 Pro-Peak Quattro LiPO Charger

QTY. 1 869020 Dubro Double-Sided Tape

QTY. 1 131151 WattAge Male BEC Plug

Here's a List of What We Used in Our Simple Stick EP for These Instructions

✦✦

✦✦

✦IMPORTANT✦✦

✦✦

✦The part number for the Cirrus servos is compatible with all name-brand radio control systems. These servos use a universal

connector. The Cirrus receiver is compatible with all connector types and is auto-shift capable. The part number for the Cirrus Y-Harness is

compatible with S/JR connectors.

WHEN CHOOSING YOUR POWER SYSTEM, MAKE SURE TO CHOOSE AN ESC THAT IS RATED

FOR THE AMOUNT OF AMPERAGE YOUR MOTOR, PROPELLER AND FLIGHT BATTERY WILL DRAW.

TO CHARGE YOUR LIPO FLIGHT BATTERY, YOU MUST USE A LIPO-COMPATIBLE CHARGER.

WE SUGGEST USING THE PRO-PEAK QUATTRO LIPO CHARGER. NEVER ATTEMPT TO CHARGE

A LIPO BATTERY WITH ANY OTHER TYPE OF CHARGER.

IF YOU USE A BRUSHLESS MOTOR, YOU MUST USE AN ESC DESIGNED SPECIFICALLY FOR BRUSHLESS MOTORS.

ESC'S DESIGNED FOR USE WITH BRUSHED MOTORS WILL NOT WORK WITH BRUSHLESS MOTORS.

Speed 400 Brushed Power System:

●Global 6V Speed 400 Direct Drive Motor

●Phase3 10 Amp ESC for 2 Cell LiPO

●WattAge 2 Cell 1250 LiPO Battery

●APC 6 x 3E Propeller

370 Gear Drive Power System:

●Phase3 370 Motor and Gear Box

●Phase3 10 Amp ESC for 2 Cell LiPO

●WattAge 2 Cell 1250 LiPO Battery

●Phase3 10 x 4.7 Slow Flyer Propeller

Direct Drive Brushless Power System:

●KMS 31/21 Brushless Motor

●KMS 18 Amp Brushless ESC

●KMS Stick Motor Mount Adapter

●WattAge 2 Cell 1250 LiPO Battery

●Phase3 10 x 4.7 Slow Flyer Propeller

What Radio, Receiver and Servos Should I Use?

You will need to use a 4 or more channel transmitter with a 4 or more channel

micro receiver. The receiver should be as light as possible, preferably 1/2oz. or

less. We suggest using the Cirrus MRX-4II FM Micro receiver.

The servos you use should be the lightest available, yet still have an adequate

amount of torque. We suggest using servos that weigh no more than 9-10

grams and have a torque rating of no less than 11 ounces per square inch.

Cirrus CS201 or CS301 Micro servos or Hitec HS-55 Micro servos would be a perfect choice.

✦✦

✦✦

✦IMPORTANT✦✦

✦✦

✦The MRX-4II receiver has a range of approximately 500 yards (~1/4 mile). Keep this in mind when flying the

airplane while using this receiver.

4

Please read and understand the warnings listed in this section. Make sure to read any and all warnings

included in the packaging with your battery, too. If used improperly, lithium polymer batteries can be very

dangerous, so please follow these warnings and suggestions at all times.

WARNINGS AND SAFETY PRECAUTIONS FOR ALL BRANDS OF LITHIUM POLYMER BATTERIES

●This product may explode or catch fire. Serious injury can result from misuse. Serious injury, loss of property, fire and death

can result from misuse of this product.

●All instructions, warnings and cautions must be followed at all times. Failure to do so can lead to serious injury or fire.

●Do NOT use this product before reading and understanding all directions and warnings.

●Do NOT overcharge. Maximum voltage for each pack must be followed.

●Do NOT over-discharge. NEVER discharge below minimum volts.

●Do NOT discharge at a rate greater than the maximum continuous discharge.

●Do NOT use or charge if the battery is hot.

●ONLY use a charger made for Lithium Polymer batteries.

●Do NOT charge at a rate higher than 1C. Example: if the battery’s rating is 340mAH, then the charger’s charge rate must be set

at 340mAH or less.

●Do NOT leave in direct sunlight or in a hot car or storage area.

●Do NOT get wet or expose to moisture.

●Do NOT short-circuit the battery.

●ONLY discharge and charge the battery outdoors or in a firesafe container.

●Do NOT charge with reverse polarity.

●Do NOT leave the battery connected when not in use.

●Do NOT operate or charge unattended.

●Do NOT solder to the battery directly and do not get the battery hot in any way.

SECTION 2: LITHIUM POLYMER BATTERY WARNINGS - PLEASE READ

CHARGING PRECAUTIONS FOR ALL BRANDS OF LITHIUM POLYMER BATTERIES

●Do NOT use the product if you do not understand the warnings and proper use of the product.

●Always let the battery cool and "rest" between uses and charging.

●To avoid over-discharging, only use a speed control that is made for LiPO batteries.

●We recommend the use of a firesafe container when charging or storing.

●Do NOT charge inside your car or inside your house.

●Inspect the battery before each use for swelling or other malformation. If the cell has ballooned, it MUST be discarded.

●Set the charger to 1C (charge at 1/2C or less for the first 5 cycles).

●Check polarity and then connect battery to charger.

●In use, do not over-discharge or exceed maximum discharge.

●When handling the battery, remember not to poke, bend or damage the cell. The cell outer casing is soft and can be damaged.

●Remember, the cells must never exceed 160 degrees Fahrenheit for any reason.

5

SECTION 3: TOOLS AND SUPPLIES REQUIRED

The tools and supplies listed below will be necessary to finish the assembly of your Simple Stick EP. We suggest having these items

on hand before beginning assembly.

❑Kwik Bond 5 Minute Epoxy # 887560

❑Pacer Zap-O C/A+ # 338995

❑Pacer Aerosol Zip-Kicker # 338772

❑#1 Phillips Head Screwdriver

❑Wire Cutters

❑Needle Nose Pliers

❑Magnum Z-Bend Pliers # 237473

❑Adjustable Wrench

❑Excel Modeling Knife # 692801

❑Scissors

❑Electric or Hand Drill

❑Assorted Drill Bits

❑Ernst Airplane Stand # 223977

❑Ruler

❑Pencil

❑Dubro T-Pins # 567677

❑Builder's Triangle

❑220 Grit Sandpaper w/Sanding Block

❑Masking Tape

❑Paper Towels

❑Rubbing Alcohol

❑NHP Epoxy Mixing Sticks # 864204

❑NHP Epoxy Mixing Cups # 864205

❑K&S 30 Watt Soldering Iron # 598120*

❑Solder*

❑Heat-Shrink Tubing (Assorted Sizes)*

*These items may be necessary for the installation of your power system.

SECTION 4: A WARNING ABOUT WORKING WITH FOAM

The majority of the Simple Stick EP is constructed of foam. While we suggest using 5 minute epoxy for the majority of the assembly,

you can use foam-friendly C/A to make building time quicker. If you use C/A, you MUST USE FOAM-FRIENDLY C/A AND

FOAM-FRIENDLY C/A "KICKER." If you use C/A and C/A "Kicker" that is not foam-friendly, the C/A will melt the foam and destroy

the parts. No parts will covered by the warranty should this occur.

If you use the Pacer Aerosol Zip-Kicker that is recommended, it is very important that you use it properly to prevent

melting the foam. Always spray a very light "mist" from no less than 12" from the surfaces to be glued. After spraying the

surfaces, immediately wipe off any excess with a soft towel. If you spray too much on one area or leave it on too long, it

will melt the foam.

Since the Simple Stick is an A-ARF, the finishing options are left up to you. The airplane can be finished several different ways or it

can simply be flown "bare." Most customers will probably want to add a finish to their airplane. The easiest way to do this is by using

the included roll of colored tape. The colored tape is applied in strips directly to the foam surfaces. The kit includes one color of

tape, but different colors can be purchased separately and used to create the color scheme of your choice. A big advantage of

covering the airplane using this method is that it also strengthens the airplane, making it even stronger and more durable.

The Simple Stick EP comes with a single roll of colored tape. This roll provides enough tape to cover the entire airplane. To liven

up your color scheme, you might want to apply a second or even third contrasting color to the airplane. Multiple colors are

available separately:

Black Colored Tape ............... P/N 300555

White Colored Tape ...............P/N 300554

Yellow Colored Tape ..............P/N 300551

Purple Colored Tape .............. P/N 300561

Blue Colored Tape .................P/N 300550

If you don't want to use colored tape to finish the airplane, the airplane can be covered in a more traditional style using low-temperature

covering material like Econokote. This results in a very nice finish, although it tends to add more weight than if you used the

supplied colored tape, and it also doesn't add as much to the durability of the airframe.

SECTION 5: FINISHING OPTIONS

6

We have organized the parts as they come out of the box for easier identification during assembly. Before you begin assembly,

group the parts as we list them below. This will ensure that you have all of the parts before you begin assembly and it will also help

you become familiar with each part.

If you find any parts missing or damaged, please contact us as soon as possible,

using the Separate Customer Service Information Sheet Provided with Your Kit.

SECTION 6: KIT CONTENTS

AIRFRAME ASSEMBLIES

❑(1) Fuselage

❑(1) Left Wing Panel w/Aileron

❑(1) Right Wing Panel w/Aileron

❑(1) Horizontal Stabilizer w/Elevator

❑(1) Vertical Stabilizer w/Rudder

LANDING GEAR ASSEMBLY

❑(1) Prebent Landing Gear Wire

❑(2) Main Gear Wheels

❑(1) Plywood Triangle-Shaped Landing Gear Retainer

❑(2) Plywood Wheel Retainers

AILERON CONTROL SYSTEM

❑(1) 1.5mm Plain Pushrod Wire

❑(2) Nylon Control Horns w/Backplates

❑(2) Nylon Clevises

❑(6) M2 x 20mm Wood Screws

❑(8) C/A-Style Hinges

ELEVATOR AND RUDDER CONTROL SYSTEMS

❑(2) 1.5mm Plain Pushrod Wires

❑(2) Nylon Control Horns w/Backplates

❑(2) Nylon Clevises

❑(6) M2 x 10mm Wood Screws

❑(2) Carbon Fiber Wing Hold-Down Dowels

❑(4) Plywood Wing Mounting Support Plates

❑(4) Rubber Bands

MISCELLANEOUS WING PARTS

MISCELLANEOUS FUSELAGE PARTS

❑(1) Foam Front Cover

❑(1) Plywood Motor Mount for Direct Drive Motor

❑(1) Plywood Motor Mount for "Stick Mount" Motor

❑(1) Plywood Battery Tray

❑(2) Plywood Servo Mounting Rails

❑(1) Rubber Band

❑(4) M2 x 10mm Machine Screws

❑(4) M2 Hex Nuts

❑(1) Colored Tape

7

❑Kwik Bond 5 Minute Epoxy

❑Excel Modeling Knife

❑Ruler

❑Pencil

❑Builder's Triangle

❑220 Grit Sandpaper w/Sanding Block

❑(1) Fuselage

❑(1) Horizontal Stabilizer w/Elevator

❑(1) Vertical Stabilizer w/Rudder

❑(1) Colored Tape

❑Masking Tape

❑Paper Towels

❑Rubbing Alcohol

❑NHP Epoxy Mixing Sticks

❑NHP Epoxy Mixing Cups

YOU'LL NEED THE FOLLOWING PARTS FROM THE KIT:

YOU'LL NEED THE FOLLOWING TOOLS AND SUPPLIES:

SECTION 7: HORIZONTAL AND VERTICAL STABILIZER INSTALLATION

STEP 1: TAPING THE VERTICAL STABILIZER AND RUDDER

❑Sand a 45º bevel into the right side of the leading edge of the rudder.

❑Apply colored tape to each side of both the vertical stabilizer and the

rudder. To do this, begin by applying one strip of colored tape vertically

from top to bottom, parallel with the trailing edge (leading edge when

taping the rudder), and rub it down firmly.

✦✦

✦✦

✦PRO TIP✦✦

✦✦

✦If any air bubbles form under the colored tape, prick the

bubble(s) with a T-Pin and rub the colored tape back down.

❑Apply more strips of colored tape to cover the remainder of the

stabilizer and the rudder, making sure to overlap each piece about 1/8".

❑Use a sharp modeling knife to carefully cut the colored tape flush

with the edges.

❑While holding the rudder tight against the stabilizer, apply a strip of

clear tape (not included) to the top of the parts to hinge the rudder

into place.

☞You can use the supplied colored tape as your hinge material, but

we prefer using 3/4" 3M Clear Plastic tape (3M No. 190). It's stronger

and easier to work with. It works great for hinging control surfaces.

Continued On Next Page

STEP 2: HINGING THE RUDDER

8

❑Deflect the rudder to the left approximately 45º. While holding the

rudder at a 45º angle, apply a strip of clear tape to the right side of the

hinge line.

❑Push the clear tape gently into the hinge line, then pivot the rudder

right and left several times to ensure free hinge movement in both

directions.

STEP 3: TAPING AND HINGING THE HORIZONTAL STABILIZER AND ELEVATOR

❑If it's not already loose, cut out the scrap material from the mounting

slot in the middle of the stabilizer.

❑Sand a 45º bevel into the bottom of the leading edge of the elevator.

✦✦

✦✦

✦IMPORTANT✦✦

✦✦

✦Make sure to sand the bevel into the leading edge

of the elevator and not the trailing edge. The leading edge is shorter

than the trailing edge.

❑Apply colored tape to the top and bottom of both the horizontal

stabilizer and the elevator, using the same techniques that you used to

apply the colored tape to the vertical stabilizer and the rudder. Apply the

colored tape horizontally from tip to tip, parallel with the trailing edge

(leading edge when taping the elevator).

❑Use a sharp modeling knife to carefully cut the colored tape flush

with the edges.

❑While holding the elevator tight against the stabilizer, apply a strip of

clear tape to the top of the parts to hinge the elevator into place.

❑Deflect the elevator up approximately 45º. While holding the

elevator up at a 45º angle, apply a strip of clear tape to the bottom of the

hinge line.

❑Push the clear tape gently into the hinge line, then pivot the elevator

up and down several times to ensure free hinge movement in both

directions.

Continued On Next Page

9

STEP 4: TAPING THE FUSELAGE AND INSTALLING THE STABILIZER ASSEMBLY

❑Begin by applying one strip of colored tape to the bottom of the

fuselage, making sure to rub it down firmly.

☞The strip of colored tape won't be quite wide enough at the front of

the fuselage, so just center it between the fuselage sides.

❑Carefully cut the colored tape flush with the fuselage sides.

Continued On Next Page

❑Apply colored tape to the rest of the fuselage. Do the right and left

sides first, making sure to overlap the tape onto the bottom of the

fuselage about 1/4". Next, do the top, making sure that the top pieces

overlap the fuselage sides about 1/4".

☞For the color scheme on this airplane, we taped the bottom and

added one strip down each side. We left the top white.

❑Cut away the colored tape from over the top and bottom of the

mounting slot in the horizontal stabilizer.

❑Set the vertical stabilizer into place on top of the horizontal stabilizer.

The mounting tab in the base of the vertical stabilizer should fit into the

mounting slot in the horizontal stabilizer.

❑While holding the vertical stabilizer in place, draw an outline around

the base of the vertical stabilizer onto the horizontal stabilizer.

❑Remove the vertical stabilizer and carefully cut away the colored

tape from within the outline you drew. Cut away the colored tape from

the sides of the vertical stabilizer mounting tab, too.

✦✦

✦✦

✦IMPORTANT✦✦

✦✦

✦Removing the colored tape will ensure a strong glue

joint. Do not glue directly to the colored tape or the glue joint may fail.

❑Glue the vertical stabilizer to the top of the horizontal stabilizer,

using 5 minute epoxy. Remove any excess epoxy before it sets up,

using a paper towel and rubbing alcohol.

✦✦

✦✦

✦IMPORTANT✦✦

✦✦

✦Use a builder's triangle to ensure that the vertical

stabilizer is aligned 90º to the horizontal stabilizer.

10

❑Slide the stabilizer assembly onto the fuselage and align it. The

stabilizer assembly is basically self-aligning. Just make sure that the

leading edge of the horizontal stabilizer is pushed up against the front of

the stabilizer mounting platform.

❑When satisfied with the alignment, hold the stabilizer assembly in

place and draw a line on each side of the top of the horizontal stabilizer

where it meets the fuselage sides, and on each side of the vertical

stabilizer where it meets the top of the fuselage.

❑Remove the stabilizer assembly and carefully cut away the colored

tape from inside the lines you drew.

✦✦

✦✦

✦WARNING✦✦

✦✦

✦When cutting through the colored tape to remove it,

cut with only enough pressure to cut through only the colored tape

itself. Cutting down into the foam could weaken the stabilizer

assembly and cause it to fail during flight.

❑Apply a generous amount of 5 minute epoxy to the gluing surfaces of the stabilizer assembly and the fuselage.

❑Slide the stabilizer assembly back into place and realign it. Quickly remove any excess epoxy, using a paper towel and rubbing

alcohol, and hold the stabilizer assembly in place until the epoxy sets up.

❑Pacer Zap-O C/A+

❑Pacer Aerosol Zip-Kicker

❑# 1 Phillips Head Screwdriver

❑Wire Cutters

❑Needle Nose Pliers

❑Magnum Z-Bend Pliers

❑(2) 1.5mm Plain Pushrod Wires

❑(2) Nylon Control Horns w/Backplates

❑(2) Nylon Clevises

❑(6) M2 x 10mm Wood Screws

❑(2) Plywood Servo Mounting Rails

❑Excel Modeling Knife

❑Electric or Hand Drill

❑1/16" & 5/64" Drill Bits

❑Ruler

❑Pencil

❑Masking Tape

YOU'LL NEED THE FOLLOWING PARTS FROM THE KIT:

YOU'LL NEED THE FOLLOWING TOOLS AND SUPPLIES:

SECTION 8: ELEVATOR AND RUDDER CONTROL SYSTEMS INSTALLATION

STEP 1: INSTALLING THE ELEVATOR AND RUDDER SERVOS

❑Install the rubber grommets and brass collets onto the elevator and rudder servos, making sure to install the collets with the flanges

toward the bottom of the servos.

Continued On Next Page

✦✦

✦✦

✦IMPORTANT✦✦

✦✦

✦You may need to cut the mounting slot in the top of the fuselage slightly longer so that you can push the

stabilizer assembly far enough forward.

11

❑Glue the two plywood servo mounting rails into the fuselage. The

front edge of the forward mounting rail should be 2-3/4" in front of the

rear bulkhead and the rear mounting rail should be spaced to fit the

width of your particular servos.

❑Install the servos onto the servo mounting rails, making sure to

drill 1/16" diameter pilot holes for the mounting screws.

✦✦

✦✦

✦IMPORTANT✦✦

✦✦

✦When installed, the servo output shafts should be

toward the front of the fuselage. Each servo should be pushed up

against the sides of the fuselage, too.

STEP 2: INSTALLING THE ELEVATOR PUSHROD ASSEMBLY

❑Install one control horn onto the top, left side of the elevator, 1/2" out

from the side of the fuselage, using three M2 x 10mm wood screws.

☞Be careful not to overtighten the screws. You don't want to crush

the foam.

❑Carefully glue one clevis to the end of one pushrod wire.

✦✦

✦✦

✦IMPORTANT✦✦

✦✦

✦So that the glue sticks to the wire, we suggest

roughening the gluing surface of the wire with 220 grit sandpaper.

Also, make sure that the pushrod wire is pushed completely through

the clevis.

❑So that you can center the elevator after the pushrod is installed,

carefully make a V-Shaped bend in the pushrod, 1" in front of the clevis.

✦✦

✦✦

✦PRO TIP✦✦

✦✦

✦The pushrod is designed to use a Z-Bend to attach to

the servo arm. As an option, you can use a Dubro Mini EZ-Connector

(Dubro P/N 915) to attach the pushrod to the servo arm. If you do

this, it's not necessary to make a V-Shaped bend in the pushrod wire.

❑Drill a 5/64" diameter hole through the left side of the fuselage for

the pushrod wire. Position the hole 5-3/4" in front of the back edge of

the fuselage and 1/2" down from the top of the fuselage.

✦✦

✦✦

✦IMPORTANT✦✦

✦✦

✦When you drill the hole, make sure to drill it at an

angle, so that the pushrod wire lines up as close as possible with the

control horn. This will prevent binding where the pushrod wire exits

the fuselage.

Continued On Next Page

12

❑Slide the plain end of the pushrod wire through the fuselage and

snap the clevis into the outermost hole in the control horn.

✦✦

✦✦

✦IMPORTANT✦✦

✦✦

✦Slide the end of the pushrod wire through the square

hole in the left side of the rear bulkhead, so that it will line up properly

with the elevator servo (left-side servo).

❑Enlarge the hole in a servo arm that is 3/8" out from the center of the

servo arm, using a 1/16" diameter drill bit.

❑Connect your radio system and plug the elevator servo (left-side servo) into the receiver. Center the servo by double-

checking that the elevator trim lever on your transmitter is centered, then use a couple of pieces of masking tape to hold the

elevator centered.

❑Install the servo horn onto the servo, making sure that the servo

horn is centered and points toward the middle of the fuselage.

❑With both the elevator and the servo horn centered, draw a mark on

the pushrod wire where it crosses the enlarged hole in the servo arm.

❑Use Z-Bend pliers to make a Z-Bend in the pushrod wire at the mark

you drew.

☞To make it easier, unsnap the clevis and pull the pushrod as far

forward as possible.

❑Cut off the excess pushrod wire, then connect the Z-Bend to the

servo arm and snap the clevis back into the control horn.

STEP 3: INSTALLING THE RUDDER PUSHROD ASSEMBLY

✦✦

✦✦

✦IMPORTANT✦✦

✦✦

✦ The rudder pushrod assembly is installed using the same techniques that you used to install the elevator

pushrod assembly.

❑Install one control horn onto the right side of the rudder, 1/2" up from

the bottom of the rudder, using three M2 x 10mm wood screws.

☞Be careful not to overtighten the screws. You don't want to crush

the foam.

❑Glue one clevis onto the end of one pushrod wire, then make a V-Shaped bend in the pushrod wire, 1" in front of the clevis. Use

the same techniques that you used to install the clevis and make the V-Shaped bend in the elevator pushrod wire.

Continued On Next Page

13

❑Drill a 5/64" diameter hole through the top, right side of the fuselage

for the pushrod wire. Position the hole 4-1/2" in front of the back edge

of the fuselage and 7/16" out from the side of the vertical stabilizer.

✦✦

✦✦

✦IMPORTANT✦✦

✦✦

✦When you drill the hole, make sure to drill it at an

angle so that the pushrod wire lines up as straight as possible with

the control horn.

❑Slide the plain end of the pushrod wire through the fuselage and

snap the clevis into the outermost hole in the control horn.

✦✦

✦✦

✦IMPORTANT✦✦

✦✦

✦Make sure to slide the end of the pushrod wire

through the square hole in the right side of the rear bulkhead, so that

it will line up with the rudder servo.

❑Connect your radio system and plug the rudder servo into the receiver. Center the servo by double-checking that the rudder trim

lever on your transmitter is centered, then use a couple of pieces of masking tape to hold the rudder centered.

❑Connect the rudder pushrod wire to the servo arm, using the same

techniques that you used to connect the elevator pushrod wire to the

servo arm.

☞As with the elevator pushrod wire, the rudder pushrod wire should

be installed into the hole that is 3/8" out from the center of the servo arm.

❑With the servo arms centered, double-check that the elevator and rudder are centered. If they are not centered, use needle nose

pliers to bend the V-Shape open or closed to center them. Move the elevator up and down, and the rudder right and left several

times to ensure that the linkage assemblies do not bind. They should operate smoothly in both directions.

❑# 1 Phillips Head Screwdriver

❑Adjustable Wrench

❑(1) Plywood Motor Mount for Direct Drive Motor

❑(1) Plywood Motor Mount for "Stick Mount" Motor

❑(4) M2 x 10mm Machine Screws

❑(4) M2 Hex Nuts

❑Electric or Hand Drill (for Stick Mount Only)

❑1/16" Drill Bit (for Stick Mount Only)

YOU'LL NEED THE FOLLOWING PARTS FROM THE KIT:

YOU'LL NEED THE FOLLOWING TOOLS AND SUPPLIES:

SECTION 9: MOTOR INSTALLATION

STEP 1A: INSTALLING A SPEED 400 DIRECT DRIVE MOTOR

❑Install the direct drive motor mount onto the fuselage, using four

M2 x 10mm machine screws and four M2 hex nuts.

Continued On Next Page

14

❑Set your motor into the motor mount and line up the holes in the front

of the motor with the matching holes in the motor mount.

❑Secure your motor into place, using two machine screws (not included).

STEP 1B: INSTALLING A 370 GEAR DRIVE MOTOR WITH STICK MOUNT

❑Push your motor and gear box assembly firmly onto the end of the

stick-style motor mount and secure it into place using one wood screw

(not included) installed through the top of the gear box mount.

✦✦

✦✦

✦IMPORTANT✦✦

✦✦

✦Notice the orientation of the motor and gear box

assembly on the motor mount.

You may need to sand the width and/or height of the stick portion of

the motor mout to fit your particular motor and gear box assembly.

❑Install the stick-style motor mount assembly onto the fuselage,

using four M2 x 10mm machine screws and four M2 hex nuts.

❑Kwik Bond 5 Minute Epoxy

❑Wire Cutters

❑Needle Nose Pliers

❑Excel Modeling Knife

❑Ernst Airplane Stand

❑Ruler

❑(1) Prebent Landing Gear Wire

❑(2) Main Gear Wheels

❑(1) Plywood Triangle-Shaped Landing Gear Retainer

❑(2) Plywood Wheel Retainers

❑Pencil

❑220 Grit Sandpaper w/Sanding Block

❑Paper Towels

❑Rubbing Alcohol

❑NHP Epoxy Mixing Sticks

❑NHP Epoxy Mixing Cups

YOU'LL NEED THE FOLLOWING PARTS FROM THE KIT:

YOU'LL NEED THE FOLLOWING TOOLS AND SUPPLIES:

SECTION 10: LANDING GEAR INSTALLATION

STEP 1: INSTALLING THE MAIN LANDING GEAR ASSEMBLY

❑Cut away the colored tape from over the landing gear mounting slot

in the bottom of the fuselage. The slot is located 4-1/2" behind the front

of the fuselage.

Continued On Next Page

15

❑Push the landing gear wire firmly down into the mounting slot,

making sure that the landing gear wire is straight when viewed from

the front.

❑Apply a generous amount of 5 minute epoxy to the plywood landing

gear retainer, then push the landing gear retainer firmly down into the

mounting slot to wedge the landing gear wire firmly in place. Remove

any excess epoxy, using a paper towel and rubbing alcohol, before the

epoxy sets up.

✦✦

✦✦

✦IMPORTANT✦✦

✦✦

✦Before the epoxy sets up, double-check that the

landing gear wire is straight when viewed from the front.

❑Slide one main gear wheel onto each axle and secure the wheels

into place, using the two plywood wheel retainers.

☞The plywood wheel retainers should fit firmly on the axles, but you

may want to apply a drop of C/A to each one to lock them into place. If

you do this, be careful not to glue the wheels to the axles.

STEP 2: INSTALLING THE TAIL SKID

❑Cut a 4-1/2" long piece of wire from the remaining pushrod wire.

❑Bend the 4-1/2" long pushrod wire into the shape shown and cut off

the excess.

❑Cut a shallow groove in the bottom of the vertical stabilizer mounting

tab for the tail skid to mount into.

❑Push the end of the tail skid up into the vertical stabilizer mounting

tab and glue it into place, using 5 minute epoxy.

✦✦

✦✦

✦IMPORTANT✦✦

✦✦

✦Roughen the gluing surfaces of the wire first so that

the epoxy will stick to it. This will make the glue joint much stronger.

16

❑Kwik Bond 5 Minute Epoxy

❑# 1 Phillips Head Screwdriver

❑Wire Cutters

❑Needle Nose Pliers

❑Magnum Z-Bend Pliers

❑Excel Modeling Knife

❑Electric or Hand Drill

❑1/16" Drill Bit

❑(1) Left Wing Panel w/Aileron

❑(1) Right Wing Panel w/Aileron

❑(1) 1.5mm Plain Pushrod Wire

❑(2) Nylon Control Horns w/Backplates

❑(2) Nylon Clevises

❑(6) M2 x 20mm Wood Screws

❑(8) C/A-Style Hinges

❑(1) Colored Tape

YOU'LL NEED THE FOLLOWING PARTS FROM THE KIT:

YOU'LL NEED THE FOLLOWING TOOLS AND SUPPLIES:

SECTION 11: WING ASSEMBLY

STEP 1: CUTTING OUT THE AILERONS

❑Using a straight edge and a sharp modeling knife, carefully cut out

the aileron from each wing panel, using the molded outlines as a guide.

❑Carefully sand the leading edge of both ailerons round, then sand

the edges of both the ailerons and the wing panels smooth and straight.

STEP 2: INSTALLING THE AILERON SERVOS

❑Install a long servo horn onto the servo, making sure that the servo

horn is centered, then install the servo horn retaining screw to secure

the servo horn to the servo.

Continued On Next Page

❑Ruler

❑Pencil

❑220 Grit Sandpaper w/Sanding Block

❑Masking Tape

❑Paper Towels

❑Rubbing Alcohol

❑NHP Epoxy Mixing Sticks

❑NHP Epoxy Mixing Cups

❑Connect your radio system and plug one aileron servo into the aileron slot in your receiver. Center the servo by double-checking

that the aileron trim lever on your transmitter is centered.

✦✦

✦✦

✦IMPORTANT✦✦

✦✦

✦You must install the servo horn and make sure that it's centered before installing the servo into the wing panel.

Once the servo is installed, it will be difficult to adjust the servo horn.

17

STEP 3: TAPING THE WING PANELS

❑Cut away the tape from over the top of the aileron servo arm.

❑Turn the wing over and apply colored tape to the top of the wing.

☞Make sure to wrap the colored tape completely around the leading

edge of the wing, so that it doesn't peel up during flight.

STEP 4: HINGING THE AILERONS

❑Working with one wing panel and aileron for now, carefully cut four

hinge slots in the leading edge of the aileron and the corresponding

locations in the trailing edge of the wing panel. Position the two outer

hinges 1" in from the ends of the aileron and space the two inner hinges

equally apart.

✦✦

✦✦

✦IMPORTANT✦✦

✦✦

✦Make sure that you cut the hinge slots on the

centerline.

❑Apply a thin layer of 5 minute epoxy to one half of each hinge, then

slide the hinges halfway into the aileron, making sure that the hinges

are centered and straight.

☞Allow the epoxy to set up before continuing.

❑Install the servo into the molded servo bay in one wing panel, using

a small piece of double-sided foam tape (not included).

☞The servo wire should lay flush in the molded channel in the wing.

❑Repeat the previous procedures to install the second aileron servo

into the other wing panel.

✦✦

✦✦

✦IMPORTANT✦✦

✦✦

✦Even though C/A-style hinges are included, because they're being glued directly into foam, we've found that

using 5 minute epoxy to glue them into place works better than foam-friendly C/A.

❑Apply colored tape to the bottom of both wing panels. Apply the colored tape horizontally from tip to tip. Start at the trailing edge

and work your way to the leading edge, making sure to overlap each strip of colored tape about 1/8".

Continued On Next Page

18

STEP 5: INSTALLING THE AILERON PUSHROD ASSEMBLIES

❑Install one control horn onto the bottom of one aileron, using three

M2 x 20mm wood screws. Position the control horn even with the

aileron servo arm (approximately 1-1/2" out from the inside edge of

the aileron).

☞Be careful not to overtighten the screws. You don't want to crush

the foam.

❑Connect your radio system and plug the aileron servo into the receiver. Center the servo by double-checking that the aileron trim

lever on your transmitter is centered, then use a couple of pieces of masking tape to hold the aileron centered.

❑Double-check that both the servo arm and the aileron are still centered. If the aileron is not centered, adjust the V-Shaped bend

to center it. Move the aileron up and down several times to ensure that the linkage assembly does not bind. It should operate

smoothly in both directions.

❑Repeat the previous procedures to install the second aileron pushrod assembly on the other wing panel.

❑Cut the remaining length of pushrod wire in half, then make a Z-Bend

in one end of one pushrod wire.

❑Make a V-Shaped bend in the pushrod wire, 1" behind the Z-Bend.

Use the same techniques that you used to make the V-Shaped bend in

the elevator and rudder pushrod wires.

❑Install the Z-Bend into the outermost hole in the servo arm.

❑Cut the pushrod wire to length and slide one clevis over the end of

the pushrod wire.

❑Snap the clevis into the outermost hole in the control horn, then

glue the clevis to the pushrod wire.

✦✦

✦✦

✦IMPORTANT✦✦

✦✦

✦Remember to roughen the gluing surface of the

wire with 220 grit sandpaper.

❑After the epoxy sets up, apply a thin layer of 5 minute epoxy to the

exposed half of each hinge, then hinge the aileron to the wing panel.

Push the aileron firmly up against the trailing edge and use masking

tape to hold the aileron in place until the epoxy sets up.

❑After the epoxy sets up, pivot the aileron up and down several times

to ensure free hinge movement.

❑Repeat the previous procedures to hinge the second aileron to the other wing panel.

19

❑Kwik Bond 5 Minute Epoxy

❑Excel Modeling Knife

❑Pencil

❑Paper Towels

❑(2) Carbon Fiber Wing Hold-Down Dowels

❑(4) Plywood Wing Mounting Support Plates

❑(4) Rubber Bands

❑(1) Colored Tape

❑Rubbing Alcohol

❑NHP Epoxy Mixing Sticks

❑NHP Epoxy Mixing Cups

YOU'LL NEED THE FOLLOWING PARTS FROM THE KIT:

YOU'LL NEED THE FOLLOWING TOOLS AND SUPPLIES:

SECTION 12: WING MOUNTING

STEP 1: JOINING THE WING PANELS

❑Glue two of the plywood wing mounting support plates to the top of

each wing panel. The rear support plate should be mounted even with

the trailing edge and the forward support plate should be mounted just

behind the leading edge. The edges of the support plates should be

even with the inside edge of the wing panels.

✦✦

✦✦

✦IMPORTANT✦✦

✦✦

✦Don't forget to cut away the colored tape from the

gluing surfaces first.

❑Apply colored tape to the top of each of the four plywood wing mounting support plates.

❑Carefully push the two wing panels firmly together.

❑With the wing panels pushed firmly together, line up both the leading

and trailing edges and apply a strip of clear tape over the top and

bottom of the wing joint, to hold the wing panels together.

✦✦

✦✦

✦IMPORTANT✦✦

✦✦

✦The wing panels are not glued together. They are

designed to be removed for easy transport, so remember to apply a

strip of clear tape to the top and bottom of the wing joint before flying.

STEP 2: MOUNTING THE WING

❑Glue one carbon fiber wing hold-down dowel through the two holes

in front of the wing saddle, making sure that the dowel is centered.

❑Repeat the previous procedures to glue the second carbon fiber wing hold-down dowel through the two holes behind the wing saddle.

Continued On Next Page

20

❑Set the wing onto the fuselage and center it at both the leading and

the trailing edges.

☞Check to make sure that the aileron servo leads don't get pinched

between the wing and the fuselage.

❑Secure the wing to the fuselage, using four rubber bands.

❑Pacer Zap-O C/A+

❑Pacer Aerosol Zip-Kicker

❑Wire Cutters

❑Adjustable Wrench

❑Excel Modeling Knife

❑(1) Foam Front Deck

❑(1) Plywood Battery Tray

YOU'LL NEED THE FOLLOWING PARTS FROM THE KIT:

YOU'LL NEED THE FOLLOWING TOOLS AND SUPPLIES:

SECTION 13: FINAL ASSEMBLY

STEP 1: INSTALLING THE ELECTRONIC SPEED CONTROL

STEP 2: INSTALLING THE RECEIVER

✦✦

✦✦

✦IMPORTANT✦✦

✦✦

✦The mounting locations shown in this section are based on our particular setup. The mounting locations of

these items for your setup may differ. The final mounting locations will depend on where your airplane balances. In most cases,

you'll want to mount the ESC near the front of the airplane, the receiver near the servos and the battery either in the forward

compartment or right behind the forward bulkhead.

Continued On Next Page

✦✦

✦✦

✦IMPORTANT✦✦

✦✦

✦After installing the wing, look from the front of the fuselage at both the wing and the horizontal stabilizer. The

wing should be parallel to the horizontal stabilizer. If it's not, either glue a shim to the low side of the wing saddle or carefully sand

down the high side of the wing saddle to correct any misalignment.

❑(1) Rubber Band

❑Scissors

❑Paper Towels

❑K&S 30 Watt Soldering Iron

❑Solder

❑Heat-Shrink Tubing (Assorted Sizes)

❑Connect your ESC to your motor. Make sure to use heat-shrink

tubing to insulate any solder joints.

❑Mount your ESC to the fuselage floor in the forward compartment,

using a piece of double-sided foam tape (not included).

❑If your ESC features an on/off switch, mount it in a convenient place

on the side of the fuselage.

❑Plug the elevator, rudder and ESC leads into their proper slots in

your receiver.

❑Mount your receiver to the fuselage floor in front of the servos, using

a piece of double-sided foam tape (not included).

❑Run the antenna out the bottom of the fuselage and secure it to the

bottom of the horizontal stabilizer, using a piece of clear tape (not included).

Table of contents

Other Sport Flyers Toy manuals

Popular Toy manuals by other brands

Hasbro

Hasbro STAR WARS ROGUE ONE NERF IMPERIAL DEATH... quick start guide

GAUGEMASTER

GAUGEMASTER Structures KD1003 manual

Radio Shack

Radio Shack Rockin' PT Cruiser owner's manual

Fisher-Price

Fisher-Price J4419 instruction sheet

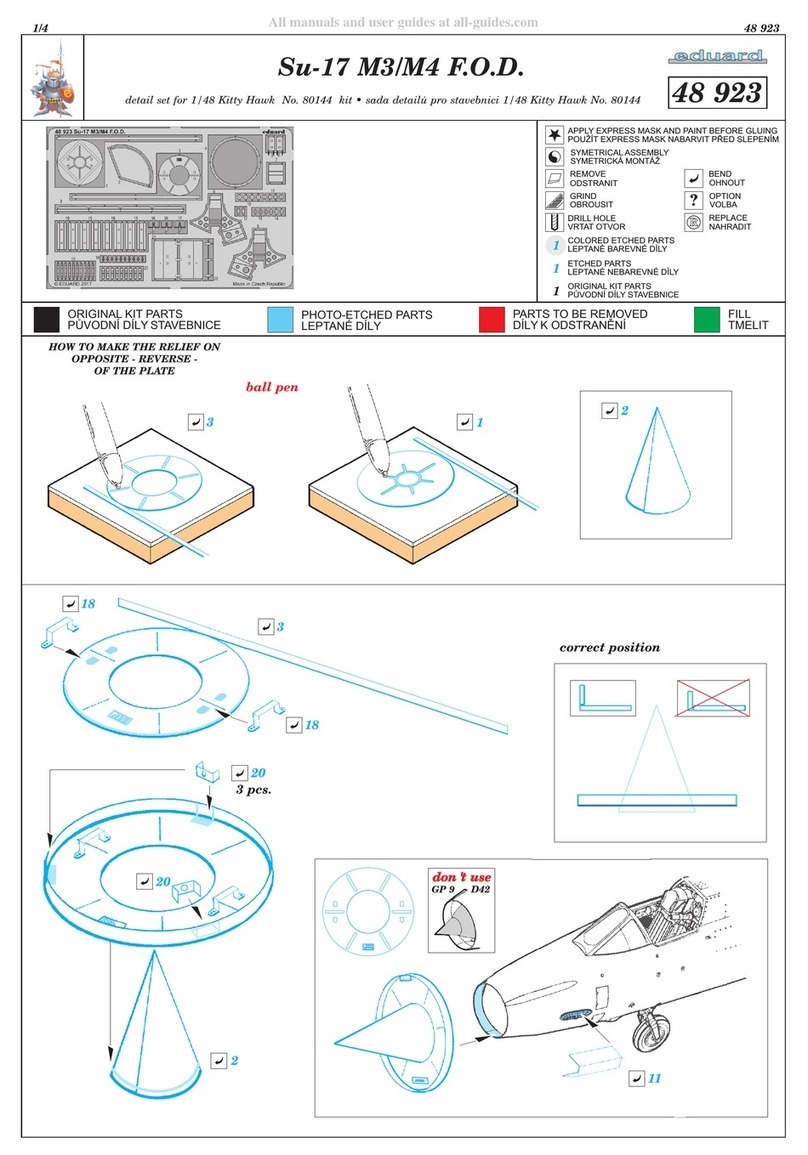

Eduard

Eduard Su-17 M3 F.O.D. Assembly instructions

MegaTech

MegaTech Freedom Flyer Flight manual

Morris

Morris MR-124885 Easy Assembly and operation instructions

Fisher-Price

Fisher-Price THOMAS & FRIENDS TRACK MASTER BUILDER BUCKET instructions

Tomahawk

Tomahawk Viper Jet Building instructions

MTHTrains

MTHTrains Premier Baldwin P-47 Operator's manual

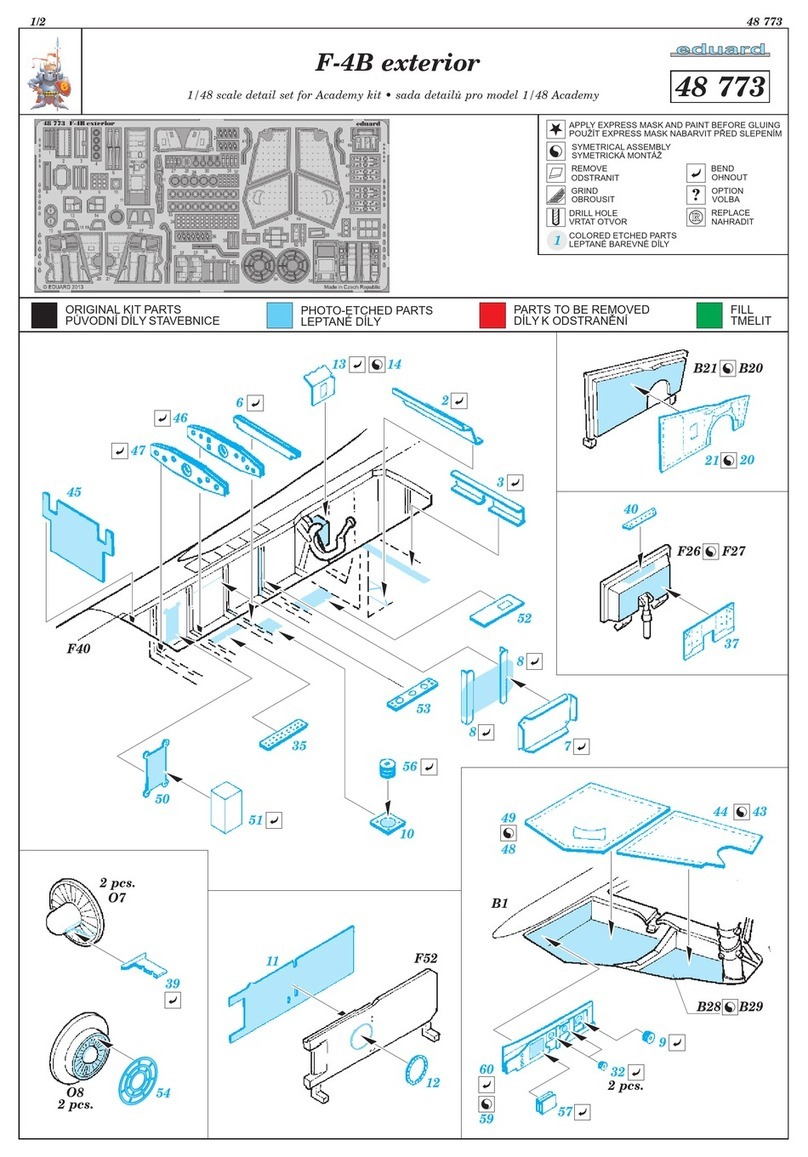

Eduard

Eduard 48 773 quick start guide

Jamara

Jamara Fokker DVII Instruction