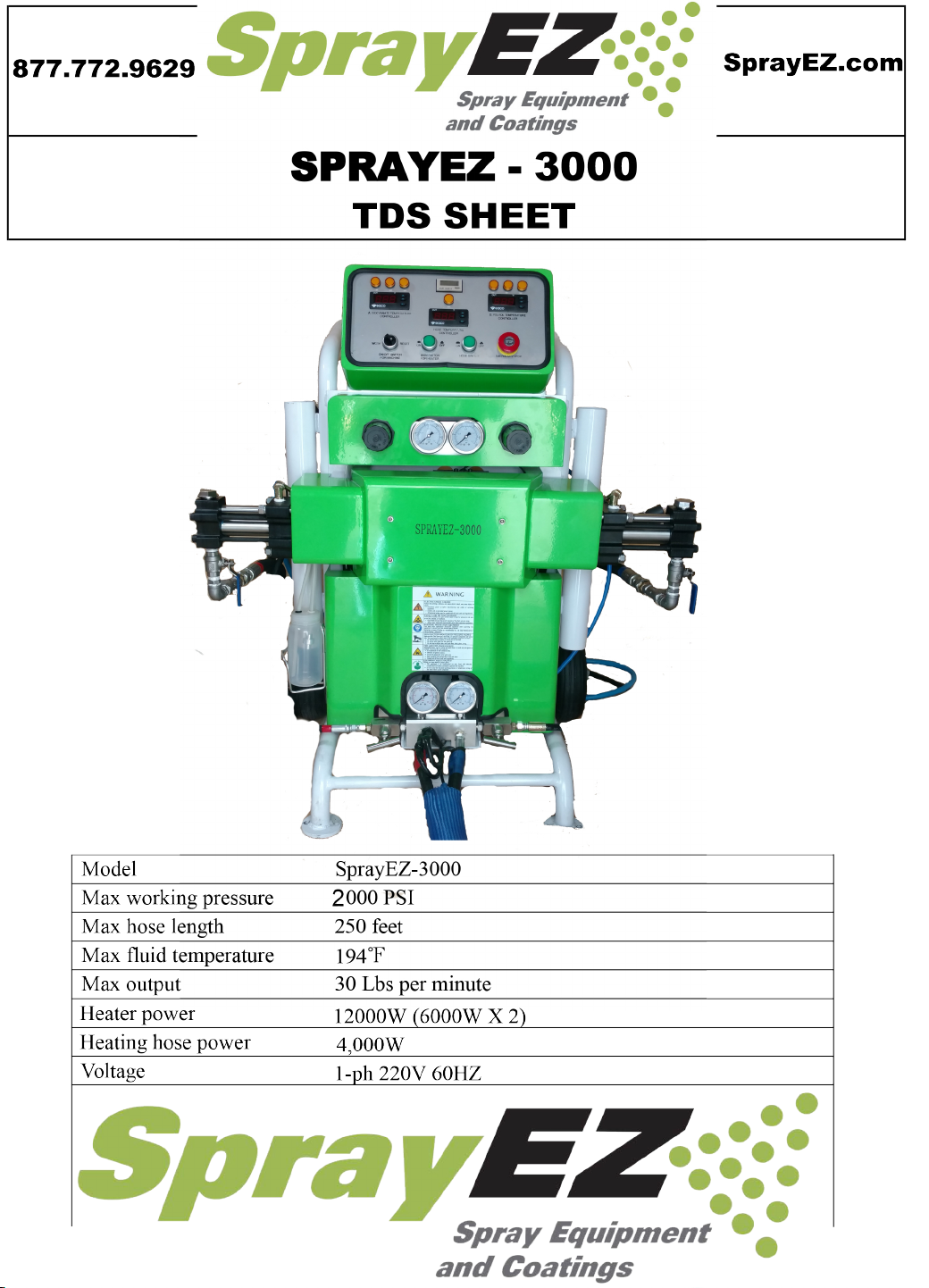

SprayEZ SPRAYEZ-3000 User manual

SPRAYEZ-3000 Polyurethane Proportioner User Manual

SPRAYEZ-3000 POLYURETHANE

SPRAY MACHINE USER MANUAL

Important Safety Instructions

Read all warnings and instructions in this manual. Save these

instructions.

Standard Technical Parameters,

SPRAYEZ-3000 Polyurethane Proportioner User Manual

2

READ ME FRIST, IT IS VERY IMPORTANT:

Never mix ISO and POLY pumps/hoses

Add Throat seal liquid (TSL) into the TSL cup before use, if there is no TSL, you

can not use the machine. Check TSL before each use of the machine;

Circulate the A side fluid weekly if equipment is not used.

Any questions, please contact us. 877.772.9629

SPRAYEZ-3000 Polyurethane Proportioner User Manual

3

Contents

1.

Warnings .............................................................................................. 4

2.

Important Two-Component Material Information ......................... 8

3.

Flow Charts of Raw Material ....................................................... 10

4.

System Installation ........................................................................ 11

5.

System Operation .......................................................................... 18

6.

Check for Fluid Flow System and Equipment Problems .............. 22

7.

Drawings ....................................................................................... 24

SPRAYEZ-3000 Polyurethane Proportioner User Manual

4

1.

Warnings

The following warnings are for setup, use, grounding, maintenance, and repair of this

equipment. The exclamation point symbol alerts you to a general warning and the

hazard symbol refers to procedure-specific risk. Refer back to these

warnings. Additionally, product-specific warnings may be found throughout the body

of this manual where applicable.

WARNING

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or

usage of the system can cause electric shock.

•

Turn off and disconnect power at main switch before

disconnecting any cables and before servicingequipment.

•

Connect only to grounded power source.

•

All electrical wiring must be done by a qualified electrician and

comply with all local codes andregulations.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in

the eyes or on skin, inhaled, or swallowed.

•

Read MSDS to know the specific hazards of the fluids you are

using.

•

Store hazardous fluid in approved containers, and dispose of it

according to applicableguidelines.

•

Always wear chemically impermeable gloves when spraying,

dispensing, or cleaning equipment.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating,

servicing, or when in the operating area of the equipment to help

protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but not limited

to:

•

Protectiveeyewear

•

Clothing and respirator as recommended by the fluid and solvent

manufacturer

•

Gloves

•

Hearing protection

SPRAYEZ-3000 Polyurethane Proportioner User Manual

5

WARNING

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leak, or ruptured components will

pierce skin. This may look like just a cut, but it is a serious injury that

can result in amputation. Get immediate treatment.

•

Engage raw material valve lock when notspraying.

•

Do not point gun at anyone or at any part of the body.

•

Do not put your hand over the spray tip.

•

Do not stop or deflect leaks with your hand, body, glove, or

rag.

•

Turn off the machine when you stop spraying and before

cleaning, checking, or servicing equipment.

•

Tighten all fluid connections before operating theequipment.

•

Check hoses and couplings daily. Replace worn or damaged

parts immediately.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can

ignite or explode. To help prevent fire and explosion:

•

Use equipment in well ventilated only.

•

Eliminate all ignition sources; such as pilot lights, cigarettes;

plastic drop cloths, and portable electriclamps.

•

Keep work area free of debris, including solvent, rags and

gasoline.

•

Do not plug or unplug power cords, or turn power or light switch

on or off when flammable fume arepresent.

•

Ground all equipment in the workarea.

•

Hold gun firmly to side of grounded pail when triggering into

pail.

•

If there is a static sparking or you feel a shock, stop operation

immediately. Do not use equipment until you identify and correct

the problem.

•

Keep a working fire extinguisher in the workarea.

THERMAL EXPANSION HAZARD

Fluid subjected to heat in confined spaces, including hoses, can creat

a rapid rise in pressure due to the thermal expansion. Over-

pressurization can result in equipment rupture and serious injury.

•

Open a valve relieves the fluid expansion duringheating.

•

Replace hosed proactively at regular intervals based on your

operation conditions.

SPRAYEZ-3000 Polyurethane Proportioner User Manual

6

WARNING

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in

pressurized equipment can cause serious chemical reaction and

equipment rupture. Failure to follow this warning can result in

death, serious injury, or property damage.

•

Do not use 1,1,1-trichloroethane, methylene chloride, other

halogenated hydrocarbon solvents for fluids containing such

solvents.

•

Many other fluids may contain chemicals that can react with

aluminum. Contact your material supplier forcompatibility.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

•

This equipment is for Professional use only.

•

Do no leave the work area while the equipment is energized or

under pressure. Turn off all equipment when the equipment is not

in use.

•

Do not operate the unit when fatigued or under the influence of

drugs or alcohol.

•

Do not exceed the maximum working pressure or temperature

rating of the lowest rated system component. See Technical Data

in all equipment manual.

•

Use fluids and solvents that are compatible with equipment wetted

parts. See Technical Date in all equipment manuals. Read fluid and

solvent manufacturer’s warnings. For complete information about

your material, request MSDS forms from distributor or retailer.

•

Check equipment daily. Repair or replace worn or damaged parts

immediately with genuine manufacturer’s replacement parts only.

•

Do not alter or modify equipment.

•

Use equipment only for its intended purpose. Call your distributor

for information.

•

Route hoses and cables away from traffic areas, sharp edges,

moving parts, and hot surfaces.

•

Do not kink or over bend hoses or use hoses to pull equipment.

•

Keep children and animals away from workarea.

•

Comply with all applicable safetyregulations.

SPRAYEZ-3000 Polyurethane Proportioner User Manual

7

WARNING

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

•

Keep clear of moving parts.

•

Do not operate equipment with protective guards or covers

removed.

•

Pressurized equipment can start without warning. Before

checking, moving, or servicing equipment, follow the Pressure

Relief Procedure in this manual. Disconnect power or air supply.

s

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during

operation. To avoid severe burns, do not touch hot fluid or equipment.

Wait until equipment/fluid has cooledcompletely.

SPRAYEZ-3000 Polyurethane Proportioner User Manual

8

2.

Important Two-Component MaterialInformation

Isocyanate Conditions

•

Spraying or dispensing materials containing isocyanates creates

potentially harmful mists, vapors, and atomized particulates.

•

Read material manufacturer’s warnings and material MSDS to

know specific hazards and precautions related to isocyanates.

•

Prevent inhalation of isocyanate mists, vapors, and atomized

particulates by providing sufficient ventilation in the work area. If

sufficient ventilation is not available, a supplied-air respirator is

required for everyone in the work area.

•

To prevent contact with isocyanates, appropriate personal

protective equipment, including chemically impermeable gloves,

boots, aprons, and goggles, is also required for everyone in the

work area.

Material Self-ignition

Some materials may become self-igniting if applied too thickly. Read

material manufacturer’s warnings and material MSDS.

SPRAYEZ-3000 Polyurethane Proportioner User Manual

9

Keep Components A and B Separate

Cross-contamination can result in cured material in fluid lines which

could cause serious injury or damage equipment. To prevent

cross-contamination of the equipment’s wetted parts, never

interchange component A (isocyanate) and component B (resin) parts.

Moisture Sensitivity of Isocyanates

Isocyanates (ISO) are catalysts used in two component foam and polyurethane

coatings. ISO will react with moisture (such as humidity) to form small, hard,

abrasive crystals, which become suspended in the fluid. Eventually a film will form

on the surface and the ISO will begin to gel, increasing in viscosity. If used, this

partially cured ISO will reduce performance and the life of all wetted parts.

The amount of film formation and rate of crystallization varies depending on the

blend of ISO, the humidity, and the temperature.

To prevent exposing ISO to moisture:

•

Always use a sealed container with a desiccant dryer in the vent, or a nitrogen

atmosphere. Never store ISO in an open container.

•

Keep the ISO lube pump reservoir (if installed) filled with DOP. The lubricant

creates a barrier between the ISO and the atmosphere.

•

Use moisture-proof hoses specifically designed for ISO, such as those supplied

with your system.

•

Never use reclaimed solvents, which may contain moisture. Always keep solvent

containers loosed when not in use.

•

Never use solvent on one side if it has been contaminated from the other side.

•

Always lubricate threaded parts with ISO pump oil or grease when reassembling.

Changing Materials

•

When changing materials, flush the equipment multiple times to ensure it is

thoroughly clean.

•

Always clean the fluid inlet strainers after flushing.

•

Check with your material manufacturer for chemical compatibility.

•

Most materials use ISO on the RED drum, and POLY on the BLUE drum.

SPRAYEZ-3000 Polyurethane Proportioner User Manual

10

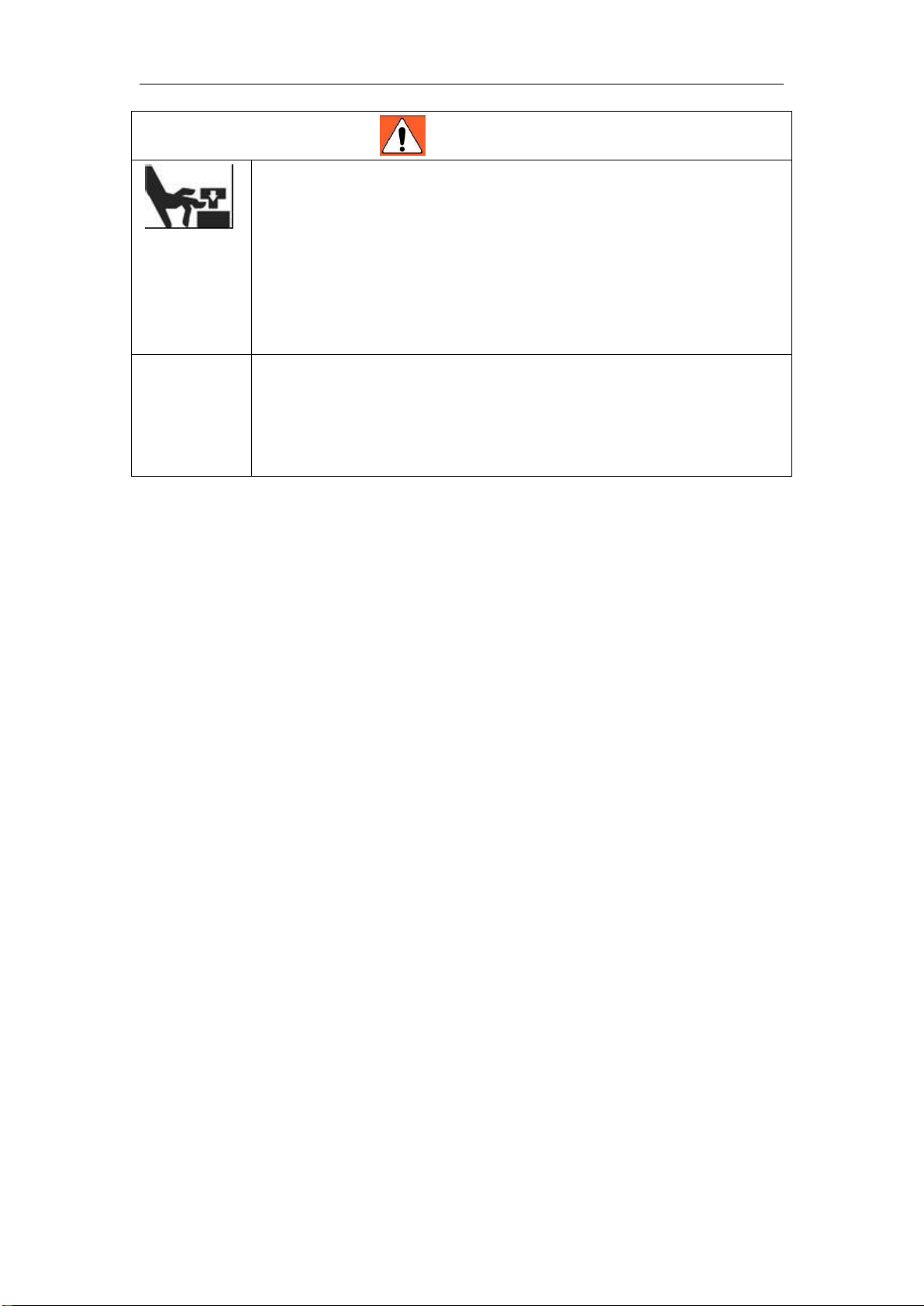

3.

Flow Charts of Raw Material

SPRAYEZ-3000 Polyurethane Proportioner User Manual

11

4.1

Installation of air supplysystem:

1.

Connect main air line from air compressor to the main air inlet,

2.

Connect the air line in heated hose to mainframe,

3.

Connect air lines from mainframe to transfer pumps.

See figure (1) (2).

Figure (1)

Air pressure regulator for mainframe:

Used to adjust the mainframe air pressure, pull the knob to adjust the air pressure, “+”

to increase the air pressure, “-” to reduce the air compressor, press the knob to lock it.

Mainframe air manometer:

Displays the mainframe air pressure, when the mainframe air regulator is adjusted, the

SPRAYEZ-3000 Polyurethane Proportioner User Manual

12

current air pressure is displayed.

Air pressure regulator for transfer pumps:

Used to adjust two transfer pumps air pressure, pull the knob to adjust the air pressure,

“+” to increase the air pressure, “-” to reduce the air compressor, press the knob to lock

it.

Transfer pumps air manometer:

Displays two transfer pumps air pressure, when the transfer pump air regulator is

adjusted, the current air pressure is displayed.

Figure (2)

Mainframe air inlet:

The total air supply inlet of the whole system, the compressed air from the air

compressor enters the system though this connector.

Heated hose air connector:

This connector connects the air line in the heated hose, to provide compressed air as

power to the foam gun.

Transfer pumps air connector:

Connects air lines to A and B transfer pumps separately, to provide compressed air as

power to A and B transfer pumps.

4.2

Installation of raw material transfer system:

Lead the POLY and ISO from material drum to the pump entrance of the mainframe;

connect hoses of chemical material and air to spray gun respectively as the following

steps.

WARNING

Before installing the raw material lines, make sure the equipment is not electrified.

Under ordinary pressure, the foaming agent will expand intensively when the

temperature of raw material is more than 73

degrees Fahrenheit

.

SPRAYEZ-3000 Polyurethane Proportioner User Manual

13

1. Installation of transfer pump system:

Open the drum put in the material transfer pump slowly till to the bottom.

Figure (3)

Connect the transfer pump hose and the booster pump entrance of the mainframe

respectively. As figure (3)

SPRAYEZ-3000 Polyurethane Proportioner User Manual

14

Figure (4)

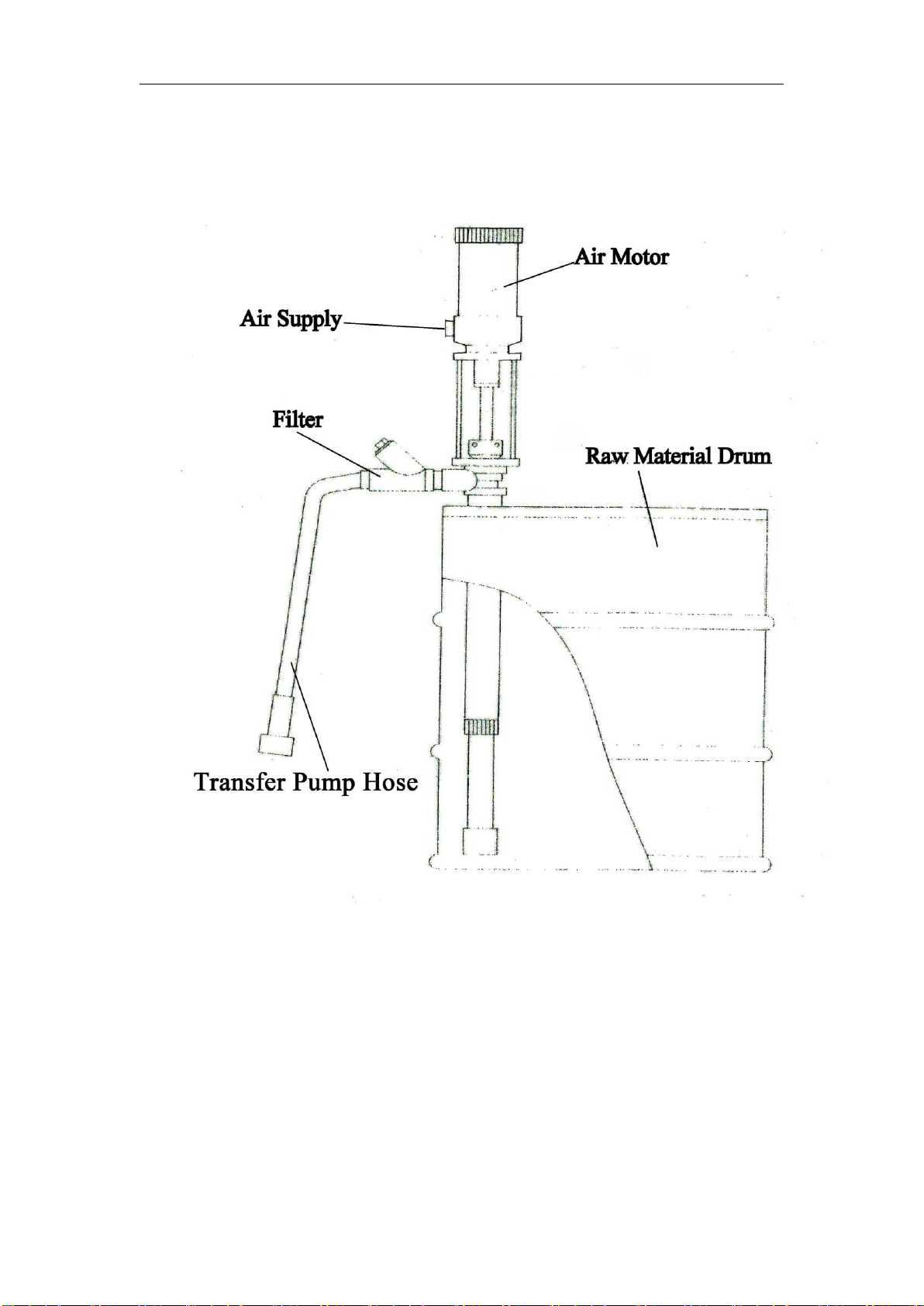

4.3

Installation of heating hose

Connect the heated hose to the mainframe and spray gun respectively. See figure (4).

Connect one of the heated hose power wire to the 0v tap and connect the other wire to

the tap that gives you 40 amps or less on the heated hose. See Figure (5).

5 ft whip

50 ft heated hose

SPRAYEZ-3000 Polyurethane Proportioner User Manual

15

Figure (5)

4.4

The connection and requirement of powersource

Connect the power line from the mainframe to single-phase 220V 50 amp power.

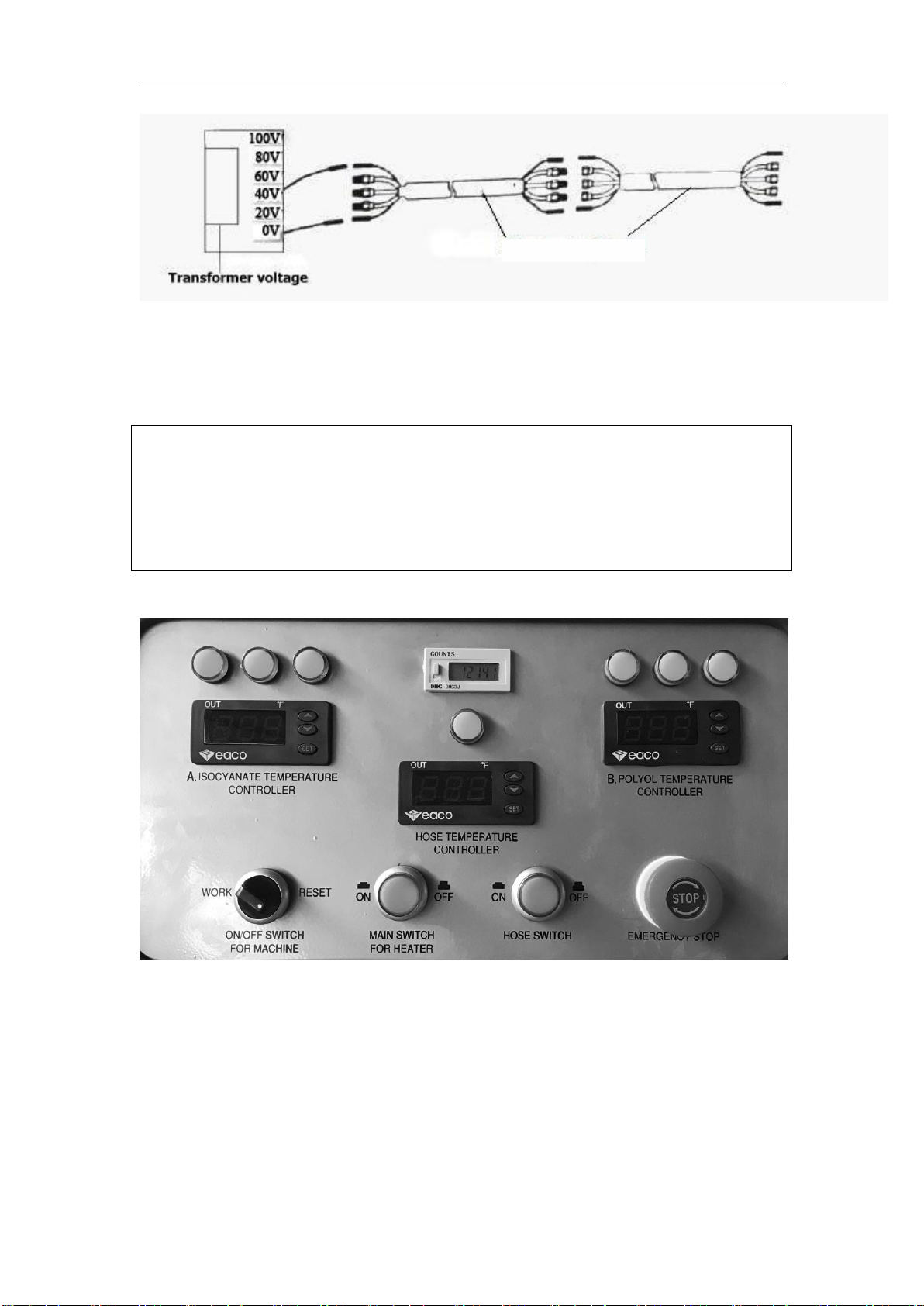

4.5

Instrument panel: as figure (7)

Figure (7)

Emergency Stop:

Press the stop switch in an emergency situation, then the machine will stop working,

but the equipment will still be electrified. Be sure to cut off the main power if you

want to maintain the equipment. After finishing maintenance, turn the knob clockwise

then it will reset, and the equipment recovers to working state.

WARNING

Installing this equipment requires access to parts which may cause electric shock

or other serious injury if work is not performed properly. Be sure your

installation complies with all National, State and Local safety, electrical, and

firecodes.

50 ft heated hose

SPRAYEZ-3000 Polyurethane Proportioner User Manual

16

Main Switch for Heater:

The heater power switch controls the A and B heater power. Press this button and the

A, B temperature controller will display.

Hose Switch:

The hose switch controls the heated hose power. Press this button and the hose

temperature controller will display.

Temperature Controller:

A Isocyanate temperature controller for A side heater temperature display and set,

B Polyol temperature controller for B side heater temperature display and set,

Hose temperature controller for heated hose temperature display and set.

How to set temperature:

1.

Press “MAIN SWITCH FOR HEATER” to “ON” position,

2.

Press “SET” knob on the controller three times, the LED digital Continues

flashing,

3.

Press ▲ or▼ to set the temperature,

4.

Press “SET” one time to finish the setting.

Counts

For recording the booster pump stroke count, press the reset button on counter back to

zero.

ON/OFF Switch for Machine

This switch controls the booster pump movement. It has two positions, “ WORK” and

“ RESET.” In the WORK” position, the air motor drives the booster pump building

pressure on the system, in the “RESET” position, the air motor stops working.

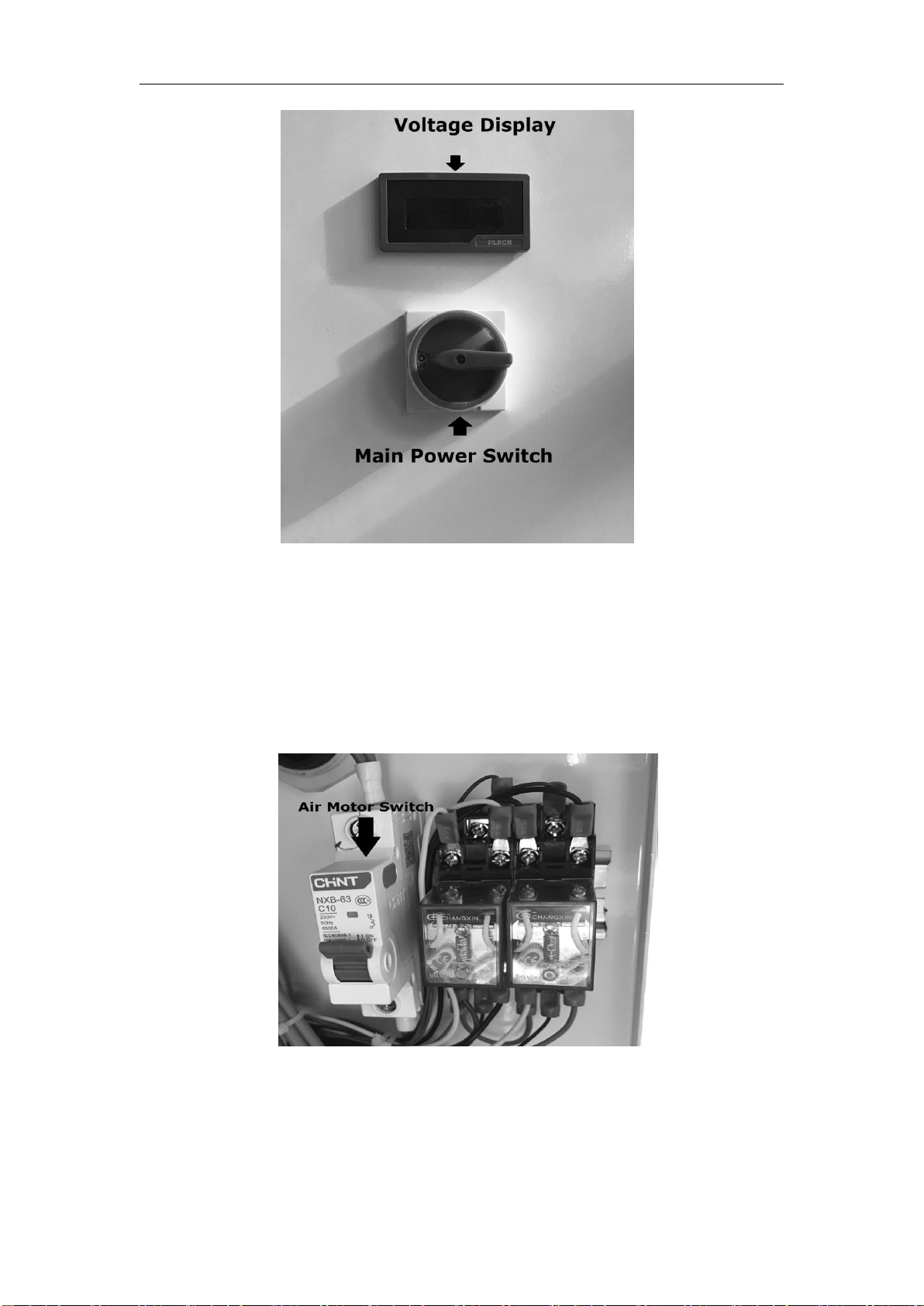

4.6

Main Power Switch and VoltageDisplay

The main power switch (as Figure 8) is the total power switch, controls the heater

power, heated hose power and all electrical parts. Please note that even with this

switch in the off position, portions of the machine are still electrified. Please disconnect

power supply before servicing machine.

The voltage display show the shows the voltage of the currently connected power

supply.

SPRAYEZ-3000 Polyurethane Proportioner User Manual

17

Figure (8)

4.7

Air Motor HeaterSwitch

In order to prevent the air motor from freezing in cold winter, the air motor has a heating

band, the switch for air motor heater is in the electrical box, if do not use air motor

heater, you can turn it off. See Figure (9).

The power supply of the air motor heater is AC40V, from the transformer, never

disconnect the power supply of air motor heater.

Figure (9)

SPRAYEZ-3000 Polyurethane Proportioner User Manual

18

5.

System Operation

5.1 Check these items before operating

1.

Make sure the TSL container is 4/5 full to prevent the ISO chemical in the booster

pump from crystallizing. The supply line (Coarser line) should in the cup 1/3 position,

return line (Finer line) in the bottom of the cup. (Figure 10).

Figure (10)

2.

Check that all connections are tight.

3.

Check the connection of power line and make sure it is properly grounded.

4.

Check that all switches on the control panel are in the OFF position.

5.

Check that the air supply regulator is in the OFF position.

Don’t put any parts of body in the range of spray.

Don’t let the gun point to someone.

Don’t look into the hole of the gun mixing chamber.

Please use proper PPE like mask, gloves, goggles and protective clothing.

5.2 Initial start (the first use of the newmachine)

TSL CUP

SUPPLY LINE

RETURN LINE

SPRAYEZ-3000 Polyurethane Proportioner User Manual

19

Before you operate the system you must make sure all fluid flow lines, air supply lines

and power lines are connected and correct. The operator must fully understand

every part on the control panel.

NOTICE

Proper system setup, startup, and shutdown procedures are critical to electrical

equipment reliability. Failure to follow safety procedures will cause voltage

fluctuations that can damage electrical equipment and void the warranty.

WARNING

Do not operate this machine without all covers and shrouds in place.

Table of contents

Other SprayEZ Paint Sprayer manuals