SR X250 User manual

X250tm Assembly Instructions, Page 1

Introduction

You are in for a real treat. You’re going to find that your new

X250 is one of the fastest building and best flying aircraft you’ve ever

owned. Nothing has been taken for granted. If you follow our

instructions, you’ll be amazed at how fast you’ll have your X250 in

the air.

We’ve photographed just about every step in completing the

X250. The notes that accompany each photograph will give you a

“heads up” about any tricks or possible problems you could run into

while completing that particularstep. Please read the instructions!

We used thin, fast setting, CA glue in assembling all of the X250

prototypes. If we recommend a different glue for a particular step,

we’ll mention it in the notes.

Although any small radio system can be used, we’ve specifically

set up the X250 for the very popular Hitec HS-60 servos and the

Hitec “555” or “Super Slim” Series sub micro receivers. These servos

and receivers will work with any brand of transmitter and we strongly

recommend them. If you can’t find them locally, we always keep

them in stock at SR.

Finally, you’ll find that a 5/64” Ball Driver and a Higley

Trimmer will really speed things up. Both are available from SR if

you don’t already have them.

On the following page you’ll find detailed technical

specifications and power system recommendations.

X250tm Assembly Instructions©1999

Preparing the parts...

We’ve included a master parts sheet that identifies each part in

the kit and tells you where the part is located. We’ve deliberately left

all of the MicroLaser Cut parts for the X250 in their sheets to protect

them. Use your modeler’s knife and a straight edge to finish the cuts

and release the parts. Just about all of the cuts will be with the grain

to make it easier for you. You can either cut out all of the parts before

you begin or leave them in their sheets until you’re ready for them.

It’s up to you, but you’ll be less likely to lose a part if you leave it in

its sheet until you’re ready for it.

In most cases, the SR MicroLaser Cut process leaves the balsa

parts with a honey colored edge that needs no sanding. Unfortunately,

the glues used in making plywood tend to glaze the edges of the

plywood parts when they are laser cut. We use a special plywood that

is designed for laser cutting, but we recommend that all plywood

parts be lightly sanded along their edges before gluing the part in

place. In addition, like spruce, plywood parts tend to have an oily film

on their surfaces which prevents CA glues from taking a good hold.

For this reason, we recommend that all plywood parts be given a light

sanding on all surfaces before youglue them in place.

X250tm Assembly Instructions, Page 2

Technical Specifications...

In spite of the X250’s small size, it’s probably one of the

most carefully designed model aircraft ever kitted. Literally

hundreds of hours of computer time were spent optimizing the

design. Rather than just designing an aircraft, we designed an

entire system. There’s no point in designing an aircraft that

requires a motor, gear ratio, battery, or prop that doesn’t exist.

Instead we evaluated dozens of combinations of components

to come up with the optimum, complete system.

We know that some of you will be tempted to change

some of the components in the power system. We suggest that

you don’t. Our target was an aerobatic aircraft that would

easily do consecutive loops yet still give you 7 to 9 minutes of

aerobatic flight and 12 to 15 minutes of sport flying. The

X250 fulfills this goal. If you change any of the components,

you may gain a small advantage in one area of performance,

but you’ll definitely be losing performance in another area.

Here is our definition of Optimum Performance:

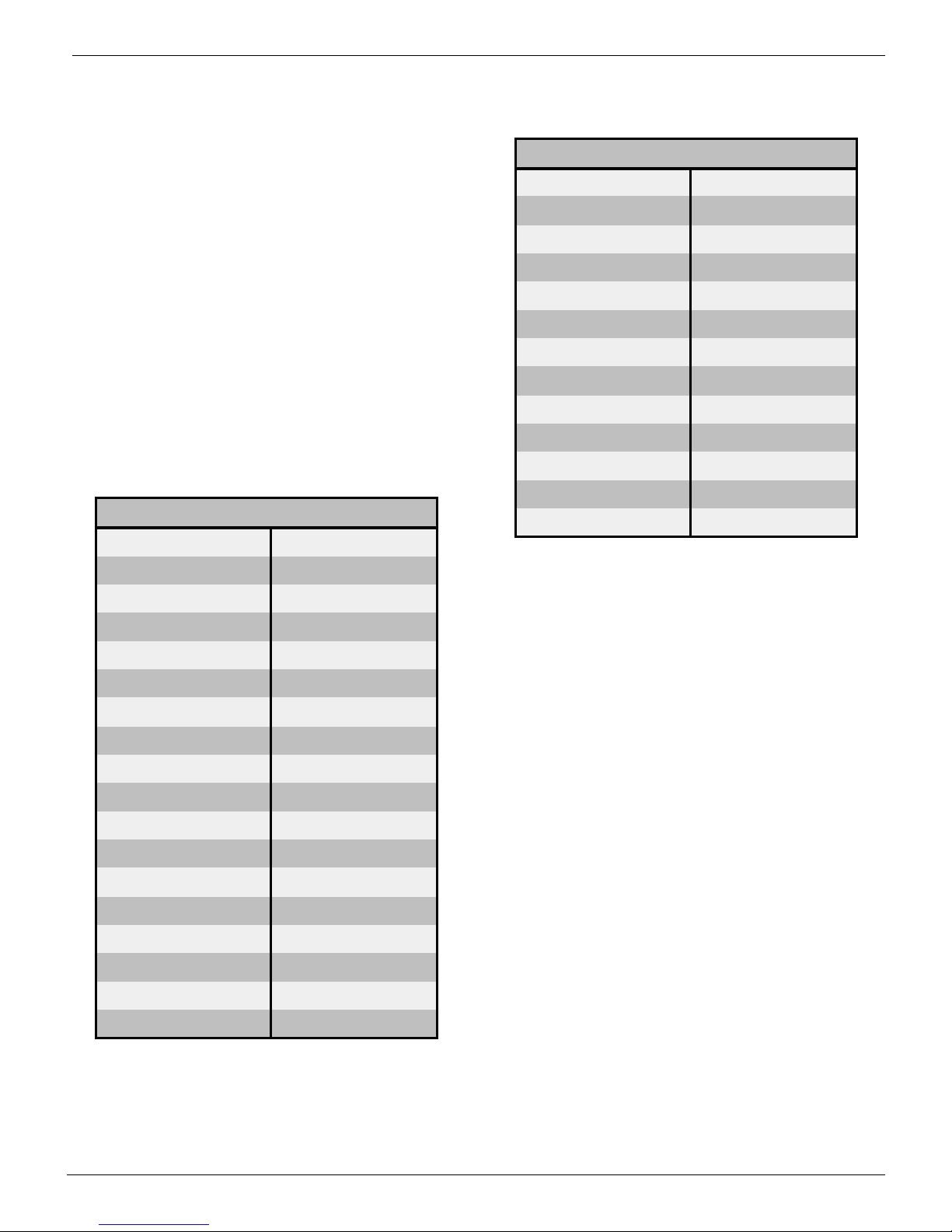

The following table lists the specific equipment we’ve

evaluated and tested to yield the above performance data. You

Aircraft SR X250 (aileron version)

Wing area 266 square inches

WingSpan 36”

Aspect Ratio 4.3:1

CG Limits 2” to 2.75”

Airfoil Computer Optimized by SR

Typical Wt. w/ 10 cell pack 24 oz.

Typical Wing Loading 13 oz. / sq. ft.

StallSpeed 13 MPH

Max. Speed 40 MPH

10 Cell Current Draw 10 Amps

Thrust 18 oz.

Climb Rate 900’/min. @ 23 MPH

Flight Time, Aerobatic 7 to 9 min.

Flight Time, Sport 12 to 15 min.

Minimum Sink Rate 2.761 ft./sec.

Maximum Glide Ratio (L/D) 11.595

Best L/D Speed 25.157 MPH

Optimized Performance

can purchase these items locally, or SR has several packages

available which will save you time and money.

Why the Jeti 350 Speed Control?

The Jeti 350 is overkill as far as current draw goes.

However, it has one feature we really like. Its BEC circuit is

designed to handle up to 4 servos rather than the usual 3. As

we’re using 3 servos, we liked the extra safety margin. In

addition, it’s one of the few speed controls that will allow you

to turn off the Brake function.

Why the SR 500 Max Series cell?

With a capacity of almost 600 mah, yet still having a very

low internal impedance, this cell is optimum for Speed 400

applications. At only .7 oz per cell it’s hard to beat.

Which prop, folding or fixed?

Originally, we recommended the CAM 9x5 folding prop.

The advantage of the folding prop was that it would fold back

rather than break if it hit the ground. However, after over

1,000 flights on our various test aircraft, we’ve come to the

conclusion that the fixed Slim prop gives a slight performance

edge for aerobatic flight. You wouldn’t be wrong if you

decided to use the CAM folding prop, but our first choice

would be the Graupner 9x5 Slim prop. If you do decide to use

a folding prop, be sure you turn off your speed control’s brake

so that the prop blades won’t fold back when you shut down

the motor in a stall turn.

Aircraft SR X250 (aileron version)

Prop Graupner 9x5 Slim, Fixed

Motor Graupner Speed 400, 7.2V

Gear Ratio 2.33:1

Speed Control Jeti 350

Cell SR 500 Max Series

Cell Count 10

Pack Shape Rectangular, 5x2

Connector Sermos

Alternative Prop Graupner CAM 9x5, Folding

Receiver Hitec, 555

Servo Hitec, HS-60

Covering Material Goldberg, UltraCote Lite

Optimized Components

X250tm Assembly Instructions, Page 3

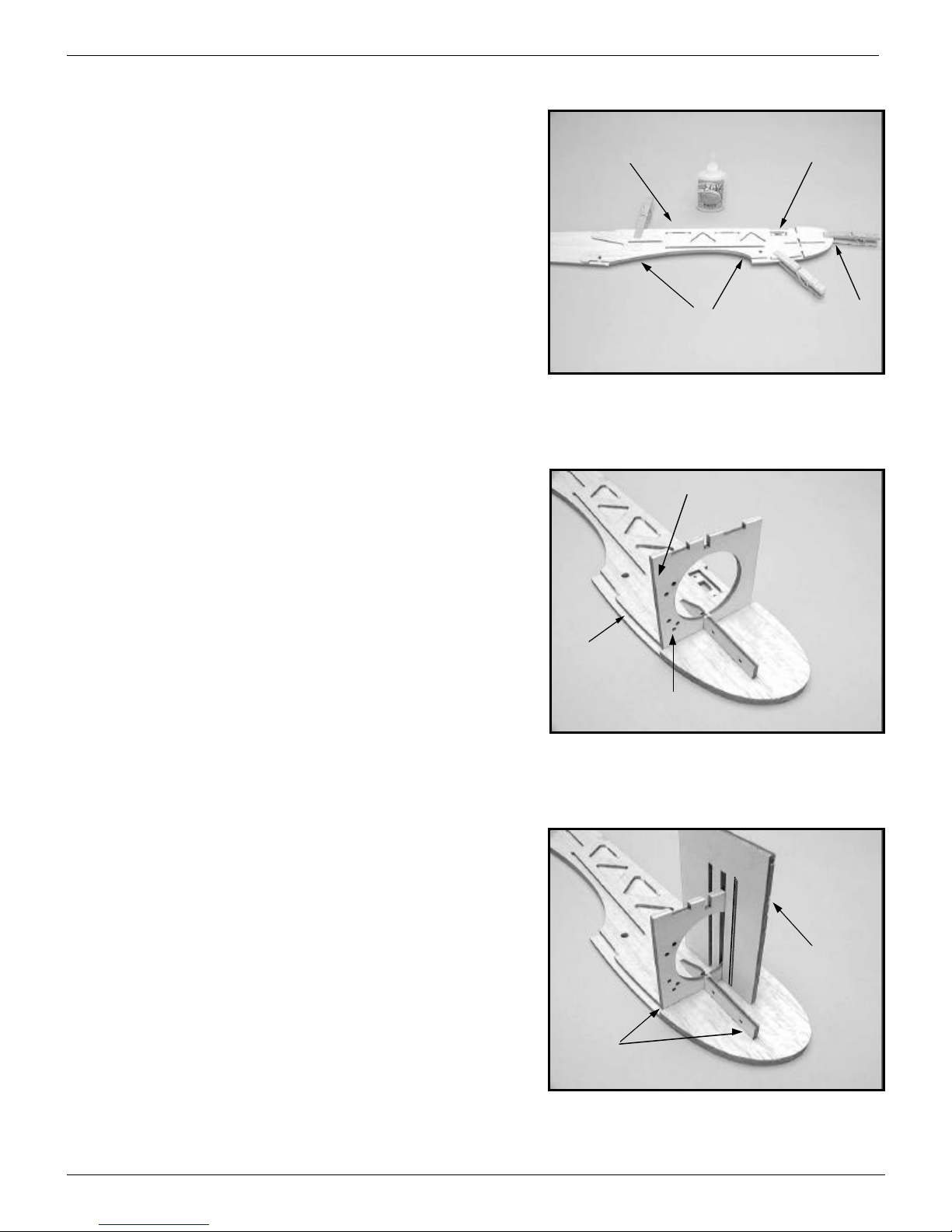

Warning, Warning, Warning!!!

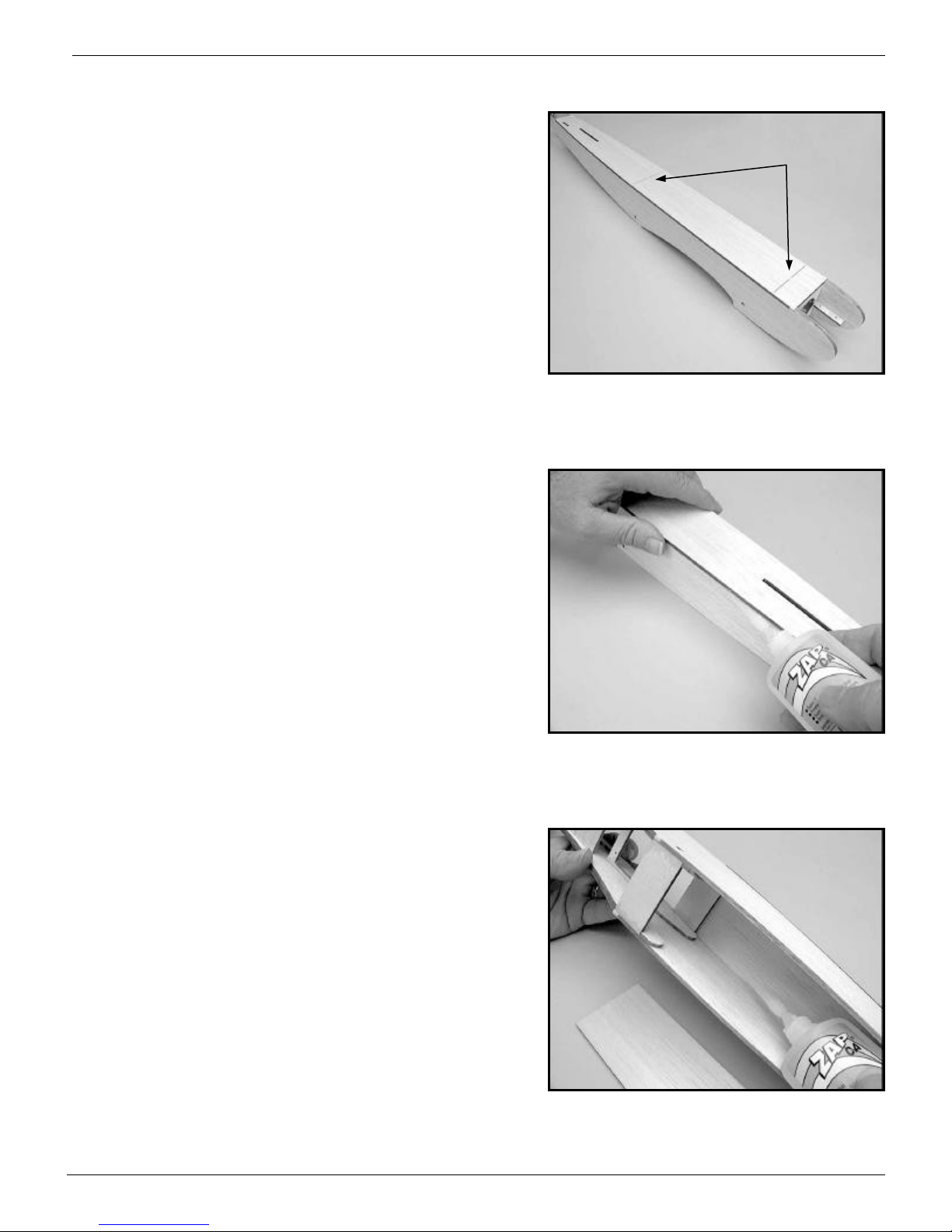

This is the single most important step in building your X250. The

entire trueness of the fuselage depends on you properly aligning the

fuselage doublers to the sides of the fuselage before you glue them to

each other. Take your time and don’t rush this step even though it

may seem very simple. DON’T MAKE TWO LEFTS!!!

There is a right and left fuselage side and a right and left doubler.

You can identify the left fuselage side and doubler by the cutout for

the speed control switch. Carefully align the doubler with the fuselage

side. Hold them together with clothes pins and check that they are

absolutely lined up with each other in the nose, wing saddle, and

fuselage top areas. When you’re satisfied with their registration, glue

them together. Glue the doubler around its edge and around all of the

cutouts in the doubler.

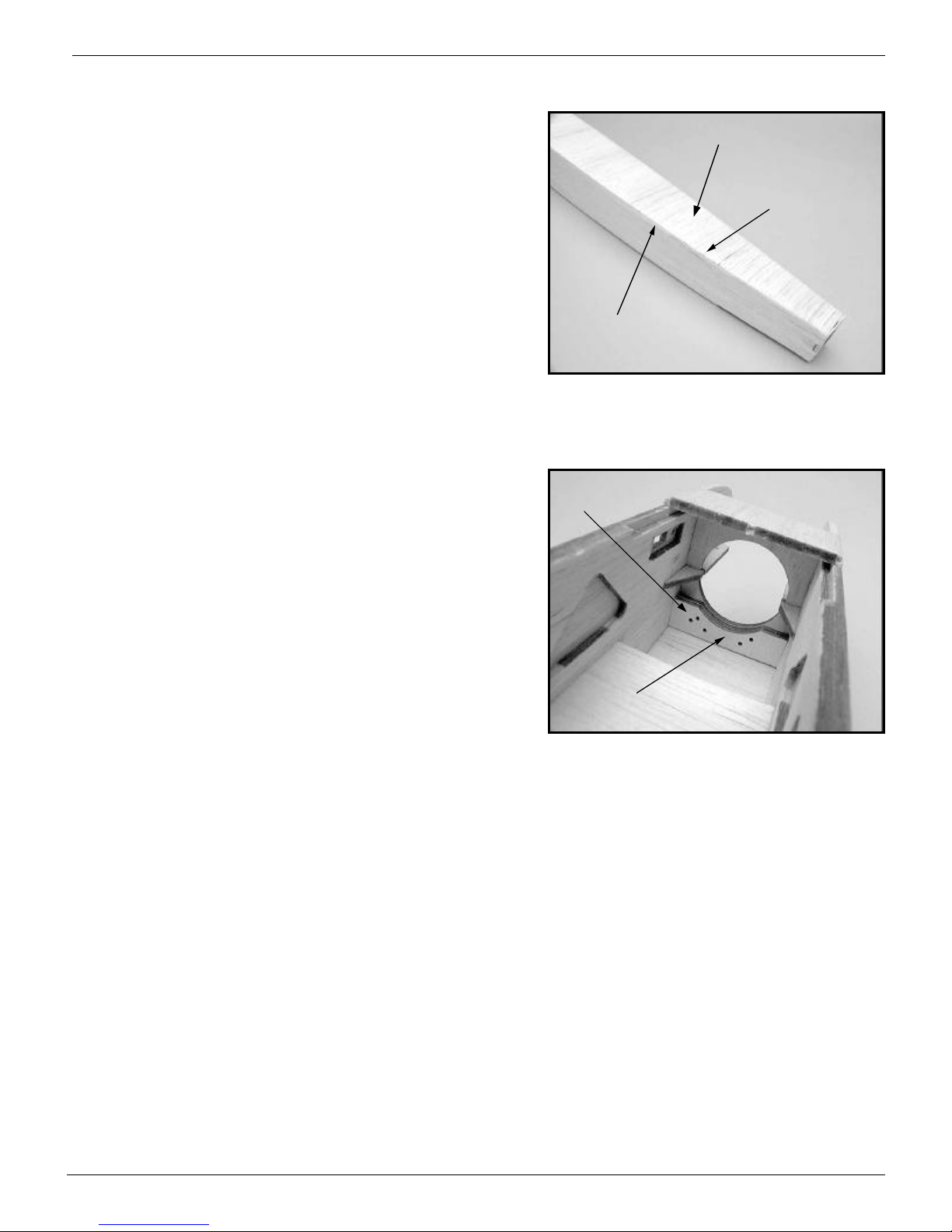

Left doubler and side

have the switch cutouts

Align

Align Align

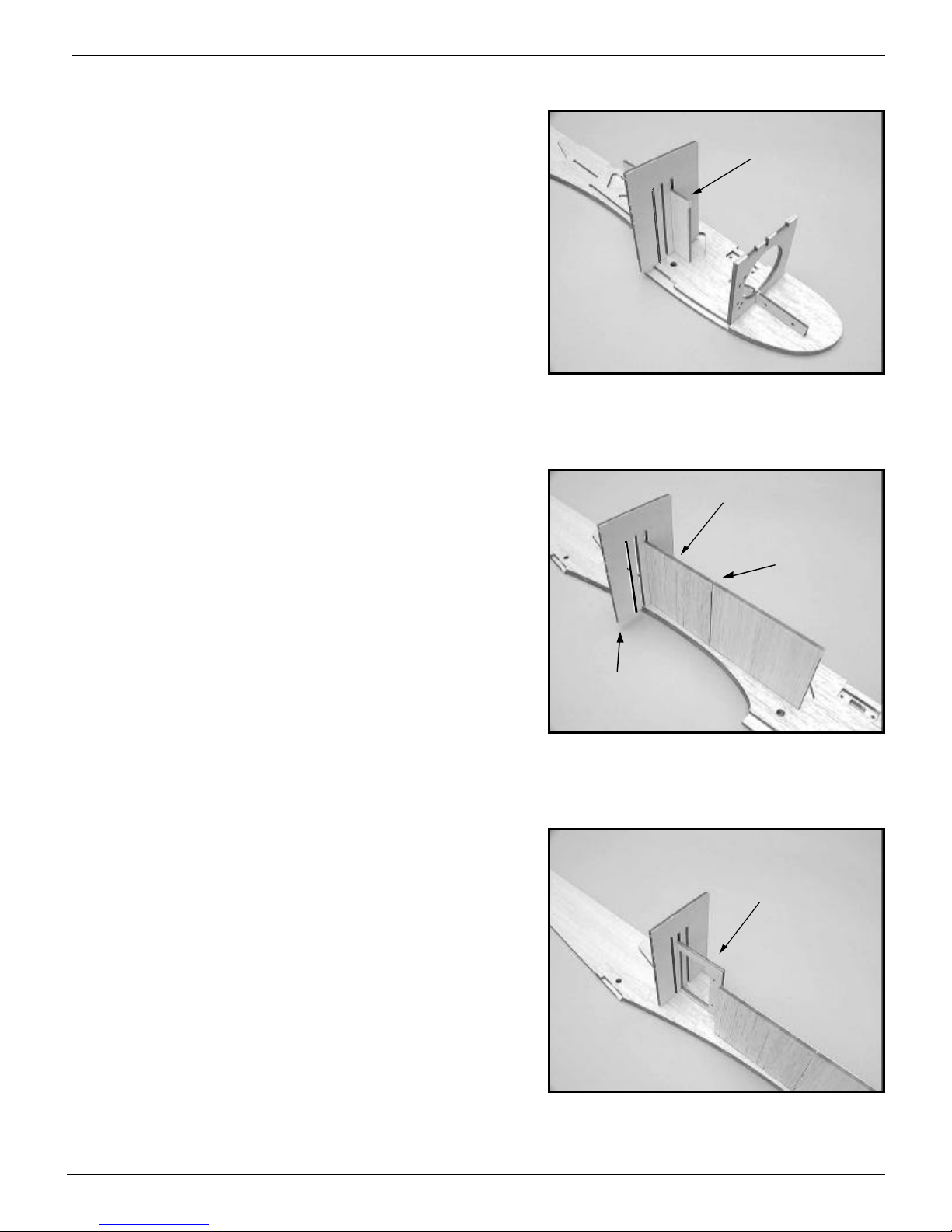

Trial fit the left motor mount and firewall...

Insert, but don’t glue, the left motor mount and firewall into the

left doubler. Note that the lower right corner of the firewall (viewed

from the front) has 3 holes for mounting the nose gear!

The forward, bottom edge of the firewall needs to be reshaped.

When the 1/8” bottom sheeting is added to the fuselage, it will rest on

the bottom of the firewall. If you locate and trial fit the bottom

sheeting, you’ll see how much of the bottom, forward edge of the

firewall will have to be sanded away to form the proper angle.

3 Holes!

Bottom sheeting

will go here

Forward bottom edge has to

be sanded at an angle to

match bottom sheeting

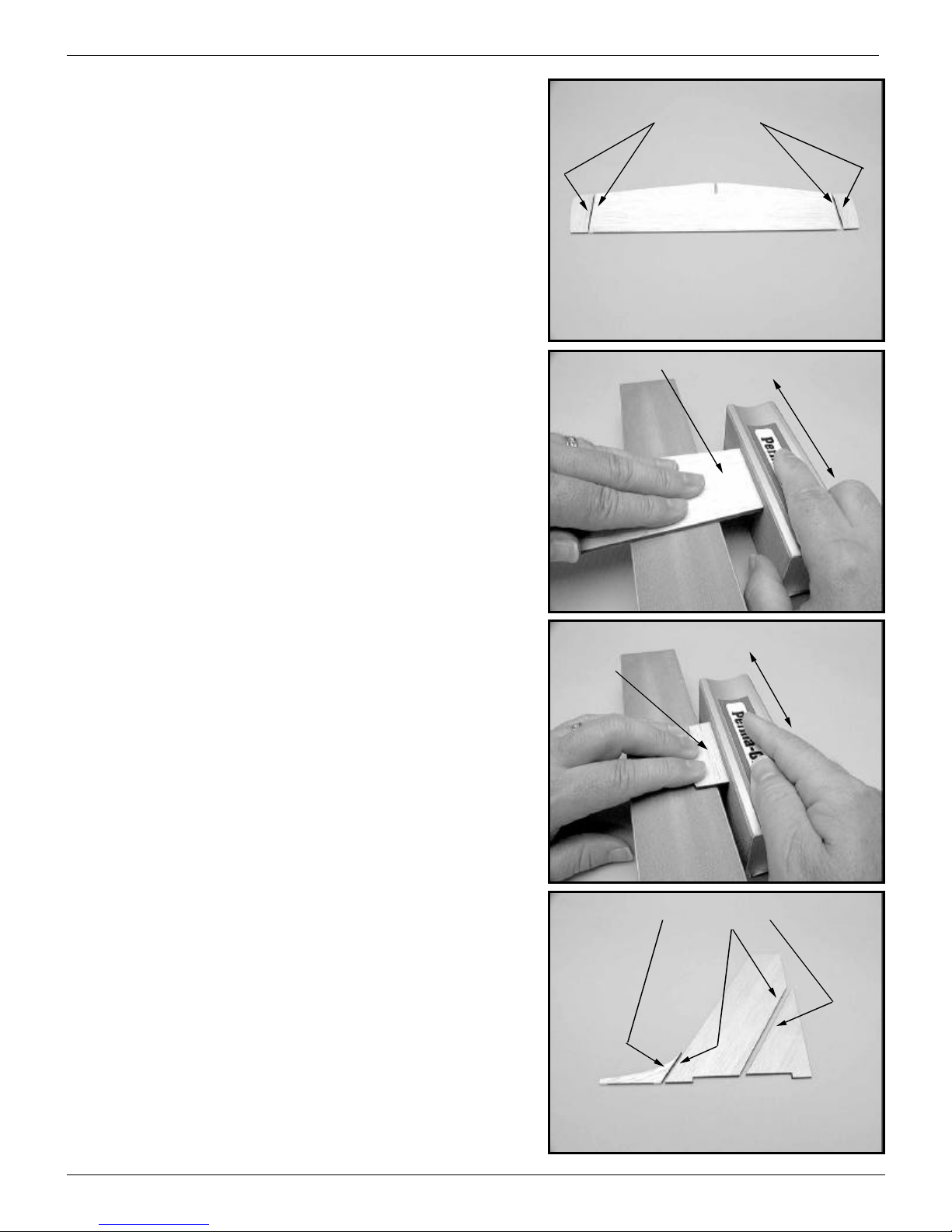

Use the alignment jig...

We’ve given you a plywood alignment jig to keep everything

aligned properly. The jig has three slots. The center slot is used with

plywood parts. The largest slot is for aligning the vertical stabilizer

after it’s covered and the narrowest slot is used with 3/32” parts. The

outer corners of the jig are cut at exactly 90° which will come in

handy later.

With the firewall and motor mount firmly seated in their recesses

in the doubler, use the alignment jig to make sure the firewall is

square with the doubler. Tack glue the firewall and motor mount to

the doubler in a corner of each and let the glue set. Remove the jig

and then glue the motor mount and firewall in place along their entire

edges. Don’t forget to glue the motor mount to the firewall too.

Tack glue

Alignment

Jig

X250tm Assembly Instructions, Page 4

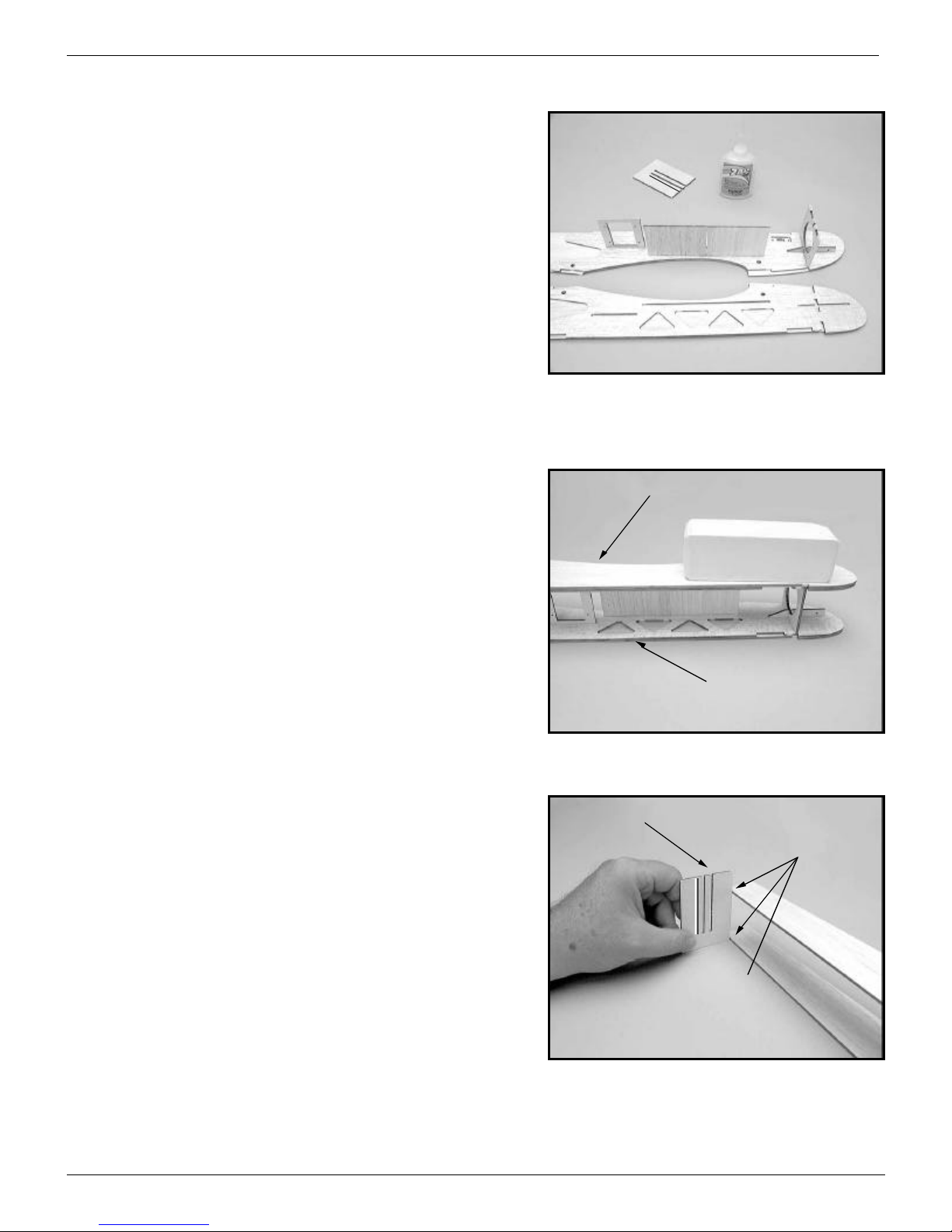

Front battery pack mounting plate...

Use the alignment jig to make sure the front battery pack

mounting plate is square to the side of the fuselage and that it is

firmly seated in the recess in the doubler. Tack glue the mounting

plate in place. When the glue has set, remove the jig and finish gluing

the mounting plate in place.

Front battery pack mount

Rear battery pack mounting plate...

Use the alignment jig to position the rear battery pack mounting

plate in place. You don’t have full support along the bottom of the jig

so be careful. A double check that the alignment is correct is that the

rear motor mounting plate should line up with the front motor

mounting plate.

Rear battery pack mounting plate

The front and

rear plates should

line up with each

other

Be careful! No support

Servo mounting tray...

The servo mounting tray is setup for Hitec HS-60 servos. Check

to see if the cutout is properly sized for the servos you’re going to

use. We’ve left plenty of extra material in the plate so just open up the

hole until it fits the servos you’re going to use.

Use the alignment jig to hold the servo mount perpendicular to

the side of the fuselage while the glue sets. Again, tack glue first.

Then remove the jig and complete gluing the servo mount in place.

Servo mounting tray

X250tm Assembly Instructions, Page 5

The left side is done...

Here’s what the left fuselage side should look like at this point.

The left motor mount, firewall, battery pack mounting plate and servo

tray are in place.

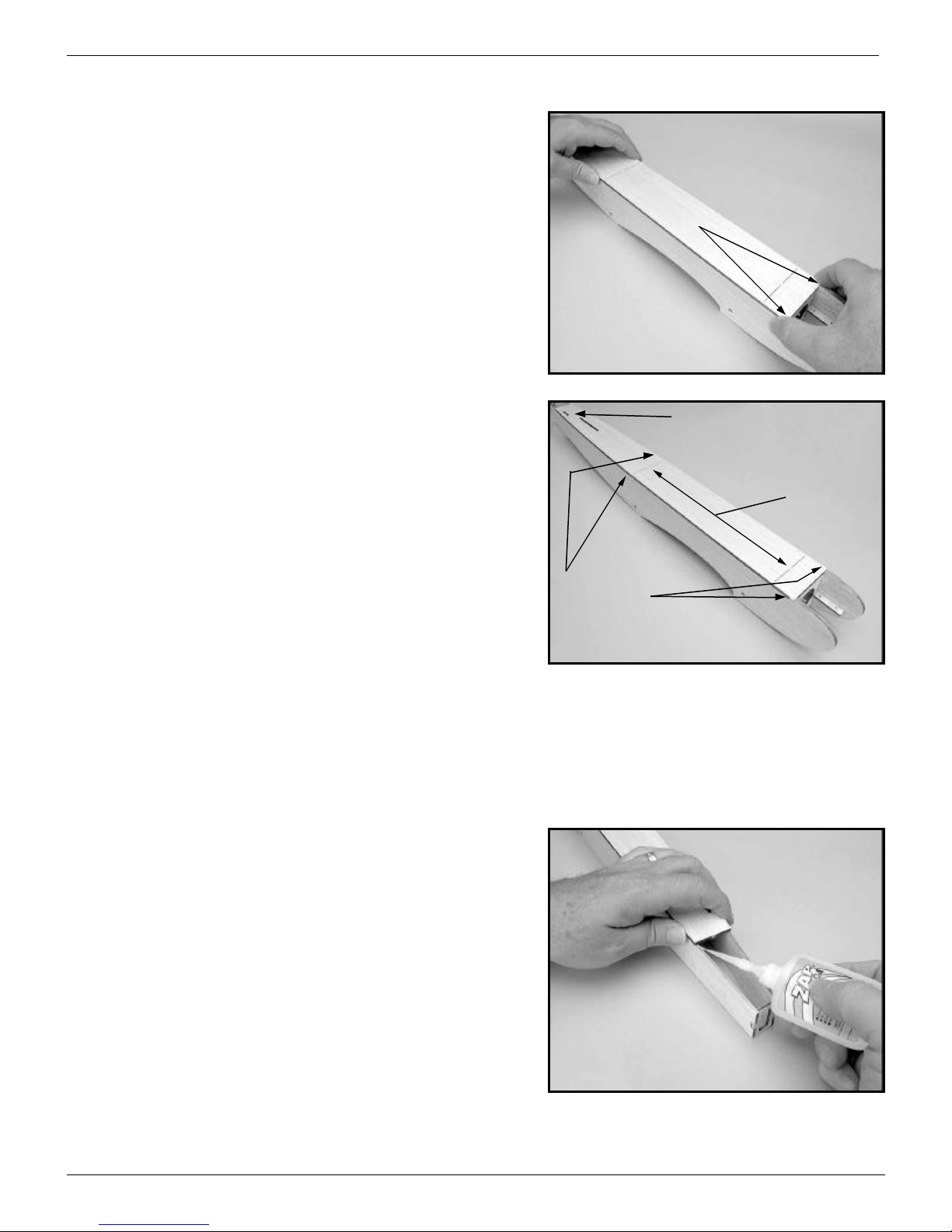

Attach the right fuselage side...

Following these instructions will assure a straight and true

fuselage without any twists.

Dry!!! fit the right side of the fuselage. Insert the right motor

mounting plate, firewall, battery pack support plate, and servo tray

into their corresponding recesses in the right side doubler. Make sure

that the parts are firmly seated in their recesses and that nothing is

preventing them from completely seating.

Before gluing any parts together, use a weight to hold the parts

in place and use the right angle jig to check how closely the two

fuselage sides line up at the tail. Put the jig flat on the building

surface and see how close each of the fuselage sides comes to the jig.

If you were careful about lining up the doublers with the fuselage

sides and all of the parts were firmly seated in their recesses before

you glued them into the left fuselage side, the fuselage sides should

line up very closely with one another.

If the fuselage sides are close to being square (within an 1/8” or

so), go ahead and glue the right side and doubler in place. If the two

are way off (1/4” or more), try to sand and adjust the ends of the parts

and the recesses in the doubler until you can align the two fuselage

sides with one another. They should be within 1/8” of being square.

However, if you’re within an 1/8”, just pull the fuselage sides into

perfect alignment before you glue the right side in place.

Right angle jig

With one fuselage side

flush up against the

right angle jig, the other

fuselage side should be

within 1/8” of the jig.

Weight

Right fuselage side

Leftfuselageside

Don’t Glue Anything Yet!!!

X250tm Assembly Instructions, Page 6

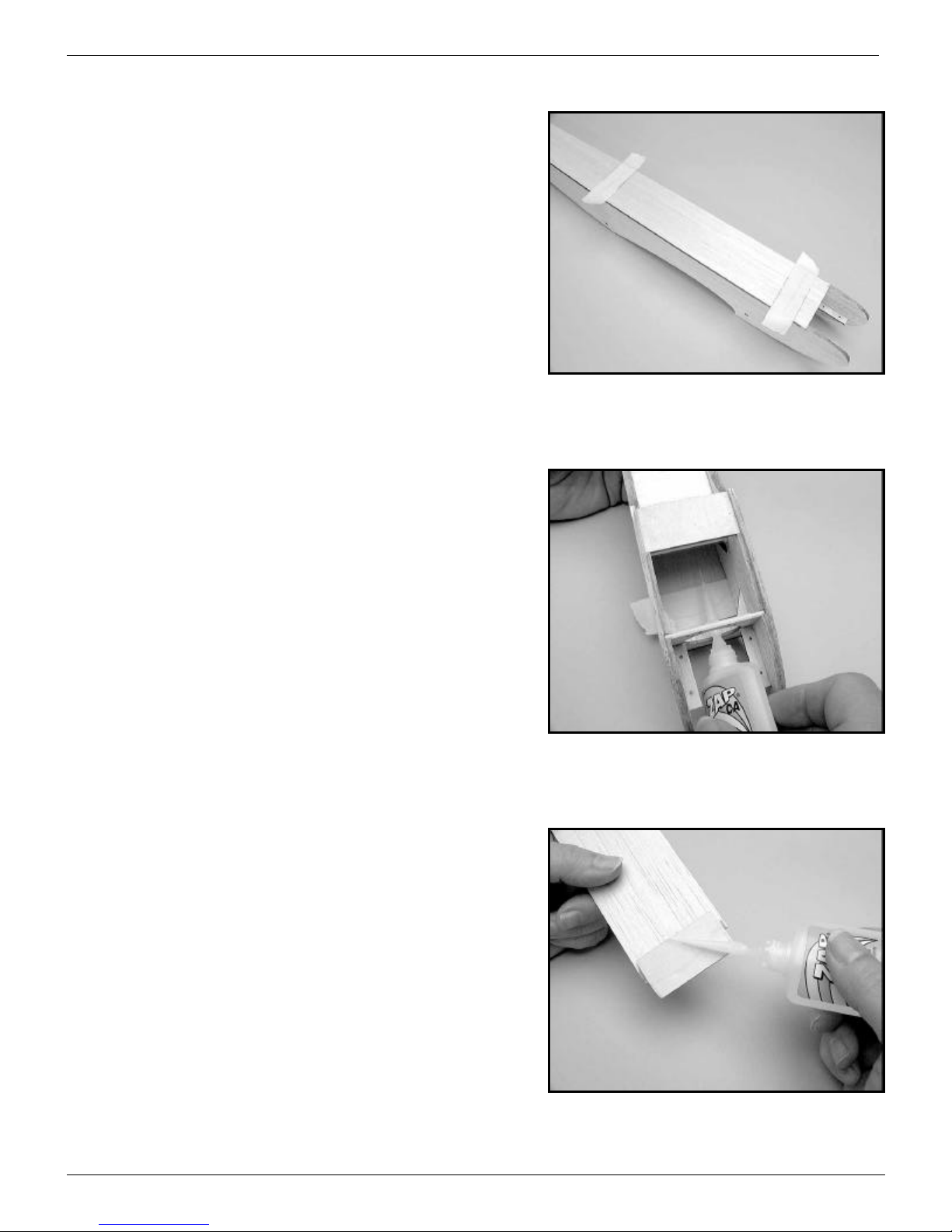

1” Wide ply plates...

There are three, 1” wide plates that you should glue in next.

Before you do, lightly sand them to remove any oil or glazing from

their surfaces.

The upper rear plate is for securing the hatch and the lower two

plates are to reinforce the fuselage and provide mounting points if you

should choose to add floats for flying off of water at a later date. Do

not glue the upper front plate in! It will be glued to the hatch rather

than the fuselage top!

Glue rear hatch mounting

plate into place

Do Not glue this

plate into place!

Glue these two plates

into place.

Glue tail former into place...

Hold the sides of the fuselage together and tape the tail former

into place. Make sure you don’t glue in the tail former upside down

as there’s a right way and a wrong way! If you’ve got it right, the

former will be flush with the top and bottom of the fuselage sides.

With the tape holding the tail together, check the alignment of the

fuselage. Either lay the fuselage over the top view on the plans or

draw three parallel lines on your building board. The tail former

should be centered. If need be, pull it to the right or left to center it

and glue it in place. You’ll be able to correct minor misalignments

when you glue the top and bottom sheeting in place, but that’s no

reason to not make it as right as possible now.

Tail former should be

centered and not

upside down!

X250tm Assembly Instructions, Page 7

Glue the top at the tail...

The fuselage top is straight. The fuselage sides may be off a little

so pull the fuselage sides left or right a little until they line up with the

fuselage top. Tack glue the top to the sides only at the tail at this

point.

Trial fit the fuselage top...

How well does it fit? Notice that there is a right and left side to

the fuselage top! The right side has an exit hole for the rudder

pushrod at the tail.

The fuselage top should fit squarely up against the fuselage sides

where the cheek cowls begin and it should be centered on top of the

fuselage sides at the trailing edge of the wing. Don’t worry about

alignment at the tail. You’ll be able to fix that as long as the fuselage

top is square and centered over the forward partof the fuselage. If the

top doesn’t fit squarely, use a small sanding block to adjust the

fuselage sides at the cowl check notches.

A note before you glue! You do not want to glue the hatch area

of the fuselage top or the rear end of the fuselage top to the fuselage

sides. At this point, you only want to tack glue the fuselage top to the

fuselage sides just in front of and just behind the hatch. Use the

smallest amount of glue so that it doesn’t spread to the hatch area.

Hatch area. Do

Not Glue along

the edges

Only tack glue in

these four places

The rudder pushrod exit hole is on

the right side of the fuselage top

Fit should be flush up

against cheek cowls

X250tm Assembly Instructions, Page 8

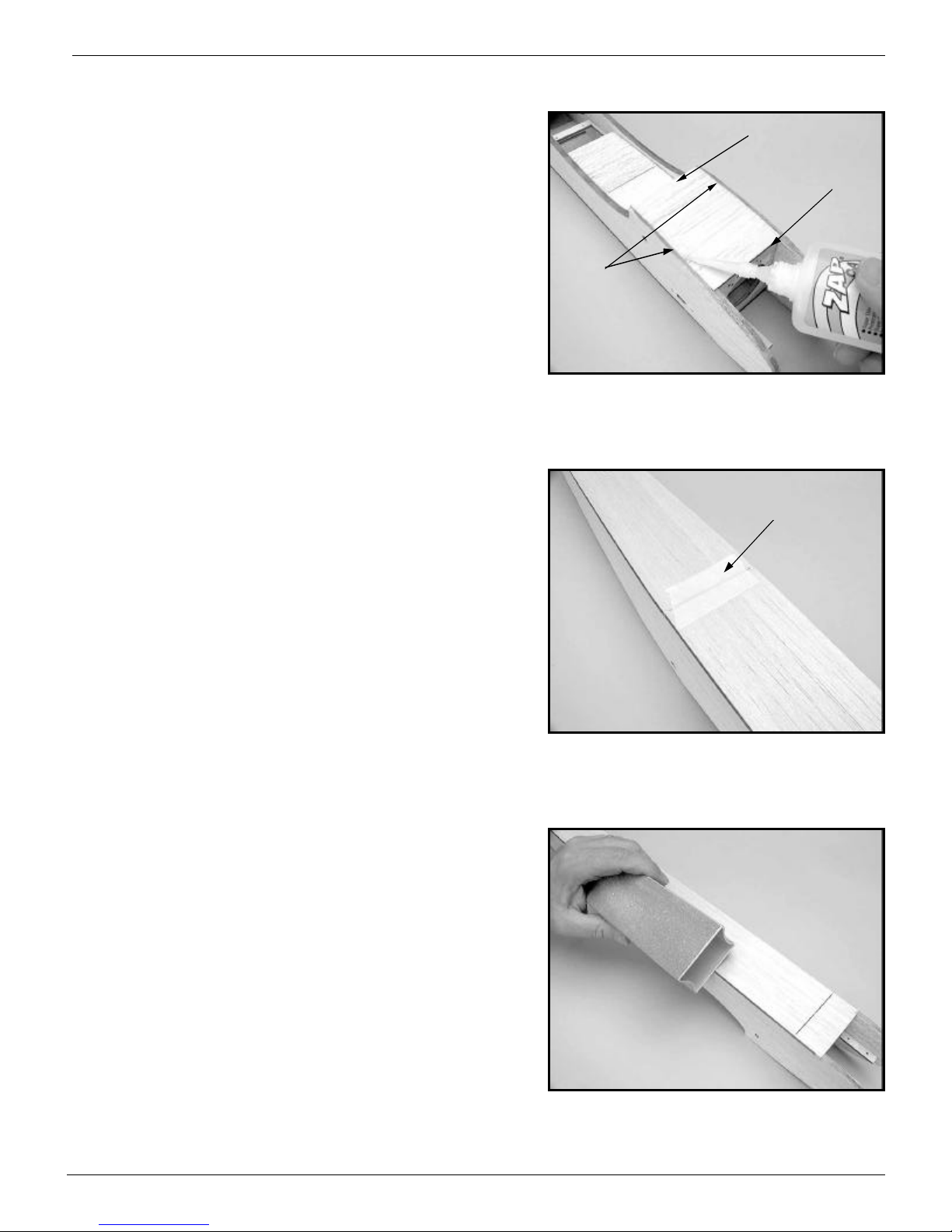

Glue the fuselage top to the sides...

Starting at the tail. Squeeze the fuselage sides together a little if

need be so that they line up with the fuselage top and glue the top to

the sides. Work on your building board so that you can be pressing

down on the fuselage top for a good fit. Continue all the way around

the fuselage top both in the front and the rear of the fuselage.

Glue from the inside too...

After you’ve finished gluing the fuselage top to the sides from

the outside, turn the fuselage over and glue the two together from the

inside too.

Cut away the hatch...

Complete the cuts we’ve started for you for the hatch and remove

the hatch. Complete these two cuts

and remove the hatch

X250tm Assembly Instructions, Page 9

All done...

This is what the bottom sheeting should look like. You’ll sand it

to final shape a little later.

Glue the bottom rear sheeting in place...

There are five pieces of bottom rear fuselage sheeting. Starting

with the widest one, line it up with the fuselage sides just after the

cutout for the trailing edge of the wing. Glue it in place pulling the

fuselage sides together a little if need be. Don’t forget to glue the

sheeting to the plywood reinforcing plate too.

Glue bottom sheeting

to plywood reinforcing

plate too

Add scrap to tail...

Continue gluing each of the pieces of bottom sheeting in place

working your way to the tail. Don’t forget to glue each piece to the

previous sheet as well as the fuselage sides. Squeeze the sides

together as you move along so that they are either flush with the

bottom sheeting or so that the bottom sheeting sticks out a little so

that it can be sanded flush with the fuselage sides at a later stage.

When you install the last sheet, you may find that you’re a little

short of the tail. If so, glue a small piece of oversized 1/16” scrap in

place to finish the job. You can trim the scrap to size after the glue

hasset.

Scrap 1/16” balsa

X250tm Assembly Instructions, Page 10

The hatch retaining plate...

Using a sanding block, round over the edges and forward corners

of the hatch retaining plate both top and bottom. Trial fit it into the

recess in the fuselage sides. It should slide in easily and sit on top of

the doublers without any part of the retaining plate sticking up above

the height of the fuselage sides. It should also slide forward easily so

that only half of the plate is exposed. You don’t want a sloppy fit, but

you also don’t want a tight fit. Adjust the plate until you’re happy

with the fit.

Leave the plate in place in its forward position and proceed to the

next step. Don’t glue anything yet.

Round over the top edges

Round the forward

corners too

The hatch retaining

plate should fit easily

into the recess in the

fuselage sides

It should also slide

forward easily too

X250tm Assembly Instructions, Page 11

Tape the hatch back in place...

Use masking tape to tape the hatch back in place. Make sure it’s

lined up perfectly with the fuselage sides and it’s centered fore and aft

in its cutout.

Tack glue the retaining plate to the hatch...

From the bottom of the fuselage, tack glue the hatch retaining

plate to the hatch. Don’t use a lot of glue or you’ll end up gluing the

hatch to the fuselage!

When the glue has set, turn the fuselage over and remove the

hatch. Note: To remove the hatch, you only have to lift it slightly at

the rear and then slide the hatch rearward. If you lift the rear of the

hatch too high, you’ll break the retaining plate free of the hatch.

Glue the retaining plate to the hatch...

Glue the retaining plate to the hatch around its entire perimeter. If

the hatch has any bow to it, (it really shouldn’t) press the hatch and

retaining plate down on your building board before you start to glue.

This will flatten out the hatch and the retaining plate will keep it flat.

Reinstall the hatch. How did it fit? Use a sanding block if need be

to adjust the retaining plate so that the hatch can be installed and

removed easily and is centered on the fuselage.

X250tm Assembly Instructions, Page 12

Sand the top sheeting and hatch...

Use a sanding block to sand the top sheeting and hatch. First,

sand the sides of the fuselage to make the curve of the top sheeting

and hatch match perfectly the curve of the fuselage sides. Then, round

over the cornersand sand the top of the fuselage. But, before you do,

see the next step!!!

Forward, bottom sheeting...

The forward, bottom fuselage sheeting will fit between the two

fuselage sides and it will rest on the edges of the doublers. It should

be flush with the face of the firewall and it should extend past the

cutout for the leading edge of the wing. Don’t trim this excess length

until after you’ve completed the wing.

Now you know why you chamfered the bottom edge of the

firewall before you glued it into the doubler. If you put the correct

angle on the bottom edge of the firewall, it will meet perfectly with

the bottom sheeting.

Glue the bottom sheeting in place.

Flush

Don’t trim

Recessed between

the fuselage sides

Secure the hatch...

Before sanding the fuselage’s top sheeting and hatch, tape the

rear of the hatch to the rear sheeting to prevent it from shifting

sideways when you’re sanding its edge. Tape rear of hatch to fuselage

top to keep it from moving

X250tm Assembly Instructions, Page 13

Don’t sand the stab mounting area...

Sand the fuselage top and hatch but don’t sand the area of the

fuselage where the horizontal stabilizer will be mounted! Don’t sand these two areas!!!

Sand the cheek cowls to shape...

Don’t be afraid to remove material with your sanding block.

There’s plenty of “meat” in the X250’s fuselage so don’t be afraid to

give the fuselage a nice curve.

Round off the cheek cowls and fair them smoothly into the

fuselage top sheeting and hatch.

Cheek cowls

X250tm Assembly Instructions, Page 14

Sand the rear bottom sheeting...

Just as you did on the top of the fuselage, first sand the sides of

the fuselage so that the bottom rear sheeting is flush with the sides of

the fuselage. Then, sand the bottom sheeting itself to remove any

excess glue on the surface of the sheeting. Finally, round over the

edges to give the fuselage a nice appearance.

First, sand the edges of the

bottom sheeting to match

the sides of the fuselage

Second, sand the

sheeting smooth

Last, round over

the edges

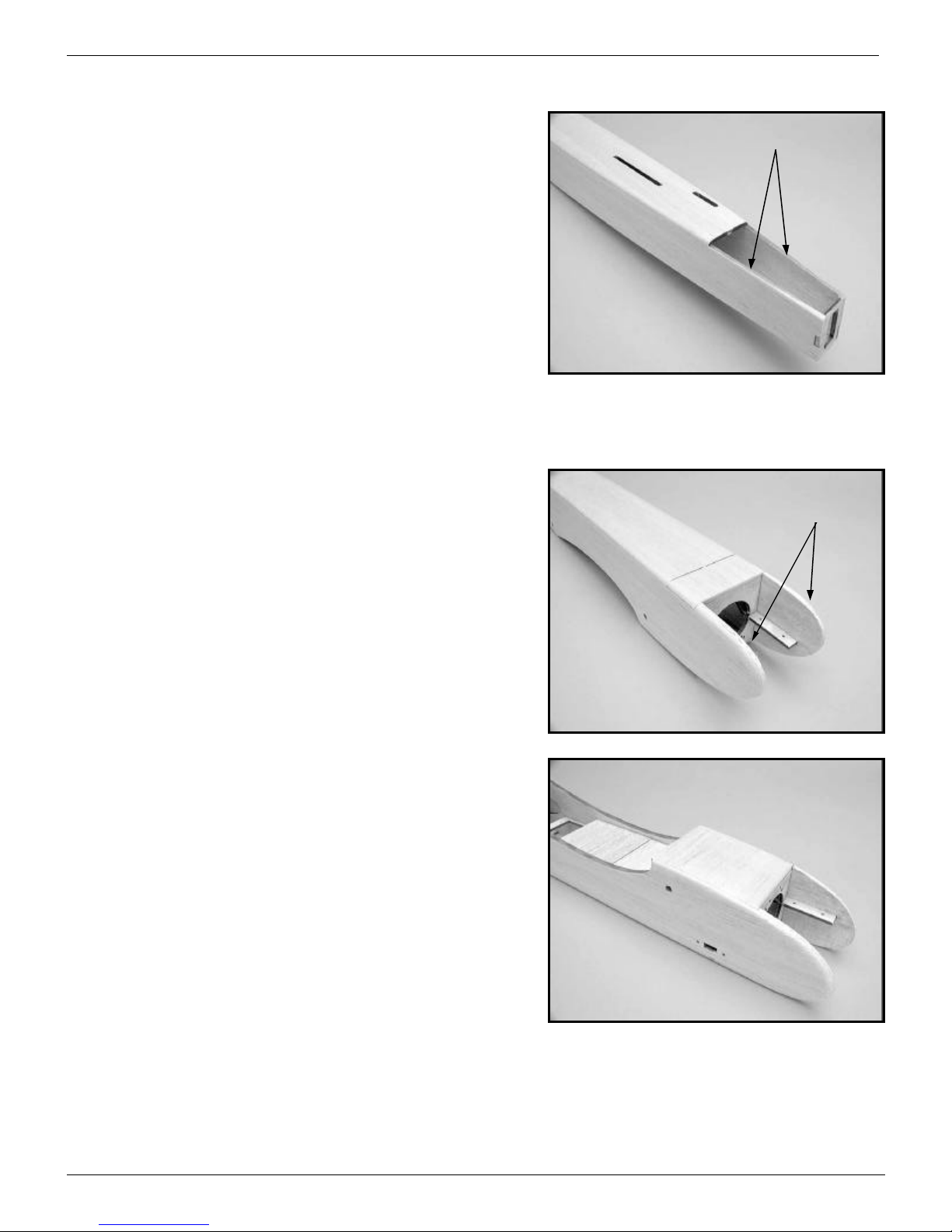

Nose gear reinforcing plates...

Line up the two nose gear reinforcing plates behind the lower

portion of the firewall. Make sure the 3 holes are on the left. Pass a

landing gear leg through the holes in the firewall and reinforcing

plates to make sure they all line up. When you’re happy with the fit

and alignment, glue the plates to each other, the firewall, the fuselage

sides, and the fuselage bottom sheeting, all at one time. In a hard

landing, we want the landing gear to bend rather than bust anything

up in the fuselage. These reinforcing plates tie everything together.

3 Holes!

Nose gear reinforcing plates

X250tm Assembly Instructions, Page 15

Horizontal and vertical stabilizers...

Laser cutting will usually leave a slight angle on the edges of

parts. For a good glue joint, you’ll want to square the edges of the

horizontal and vertical stabilizer parts where they meet each other.

Use a sanding block and only remove enough material so that the

honey color is removed from the edge of the part. This way, you’ve

sanded away any angle on the edge and made it square without

removing more material than necessary.

When you’ve finished the horizontal stabilizer, do the same for

the parts that make up the vertical stabilizer.

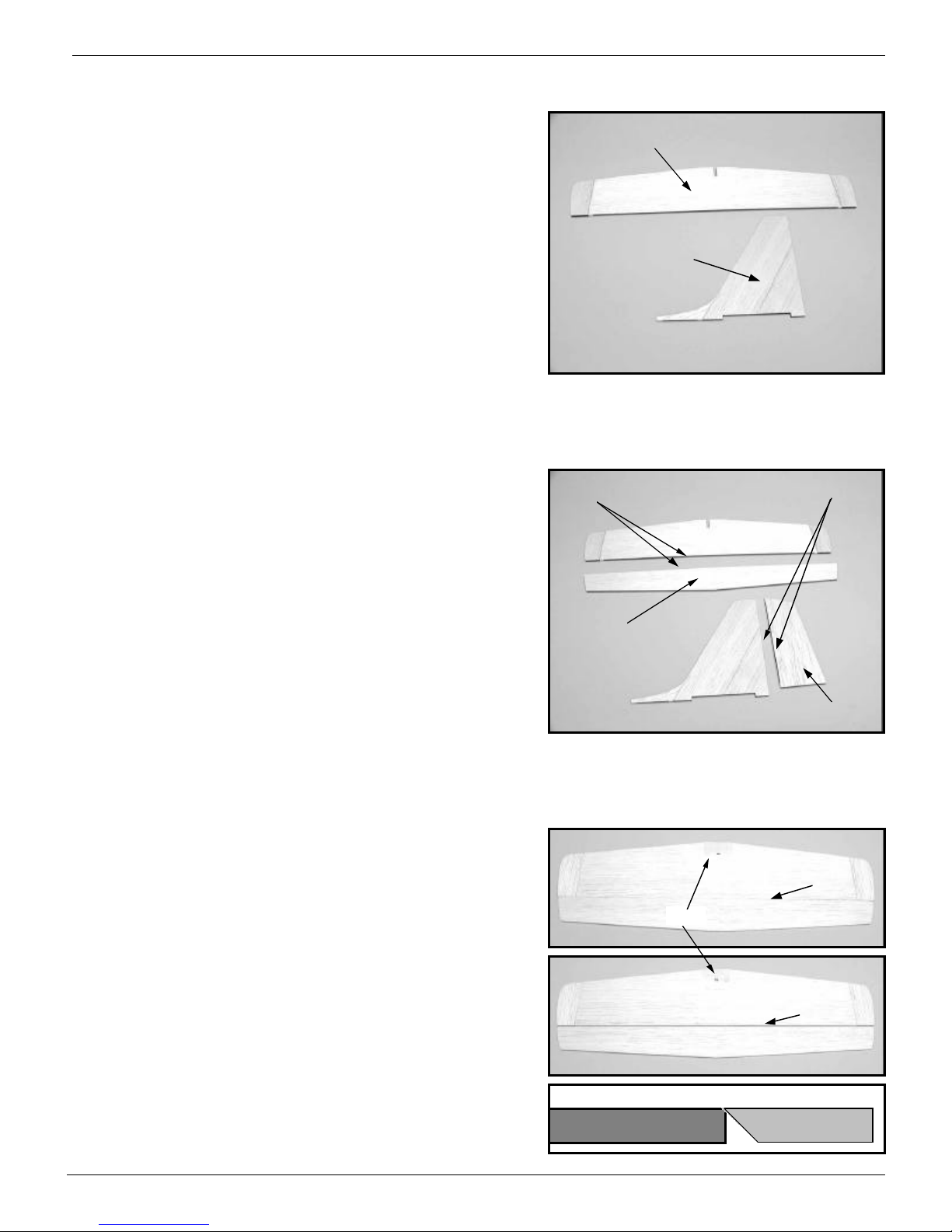

Horizontal stabilizer

Stab tip

Block sand square

Block sand square

X250tm Assembly Instructions, Page 16

Glue the parts together...

When you’re happy with the fit of the parts, glue the tips to the

horizontal stabilizer. Do the same for the three parts that make up the

vertical stabilizer. Horizontal Stabilizer

Vertical Stabilizer

Prepare the rudder and elevator...

The rudder and elevator will be shaped next. First, you’ll want to

sand the mating surfaces, where the elevator meets the horizontal

stabilizer and the rudder meets the vertical stabilizer, square with your

sanding block. Don’t sand the outer edges yet.

Sand mating surfaces square to each other

Elevator

Rudder

Horizontal stabilizer/elevator...

The rear edge of the horizontal stabilizer will be left square. The

front edge of the elevator will be sanded back at a 30° angle so that

looking at the top of the horizontal stabilizer the two are flush up

against each other. Viewed from the bottom, you can see that the

angle sanded into the leading edge of the elevator forms a “V” groove

where the two meet.

Note that you should add a piece of tape to the center of the

horizontal stabilizer’s leading edge so that this area will be left square

when the rest of the stab is sanded and its outer edges are rounded

over. The tape should be as wide as the width of the top fuselage

sheeting where it meets the horizontal stabilizer.

At this point, round off the edges of the horizontal stabilizer and

taper the elevator’s cross section so it’s only about 1/16” thick along

its trailing edge. Round off the elevator’s tips too.

Top View

Bottom View

Flush

“V” Groove

Tape

Horizontal Stabilizer Elevator

X250tm Assembly Instructions, Page 17

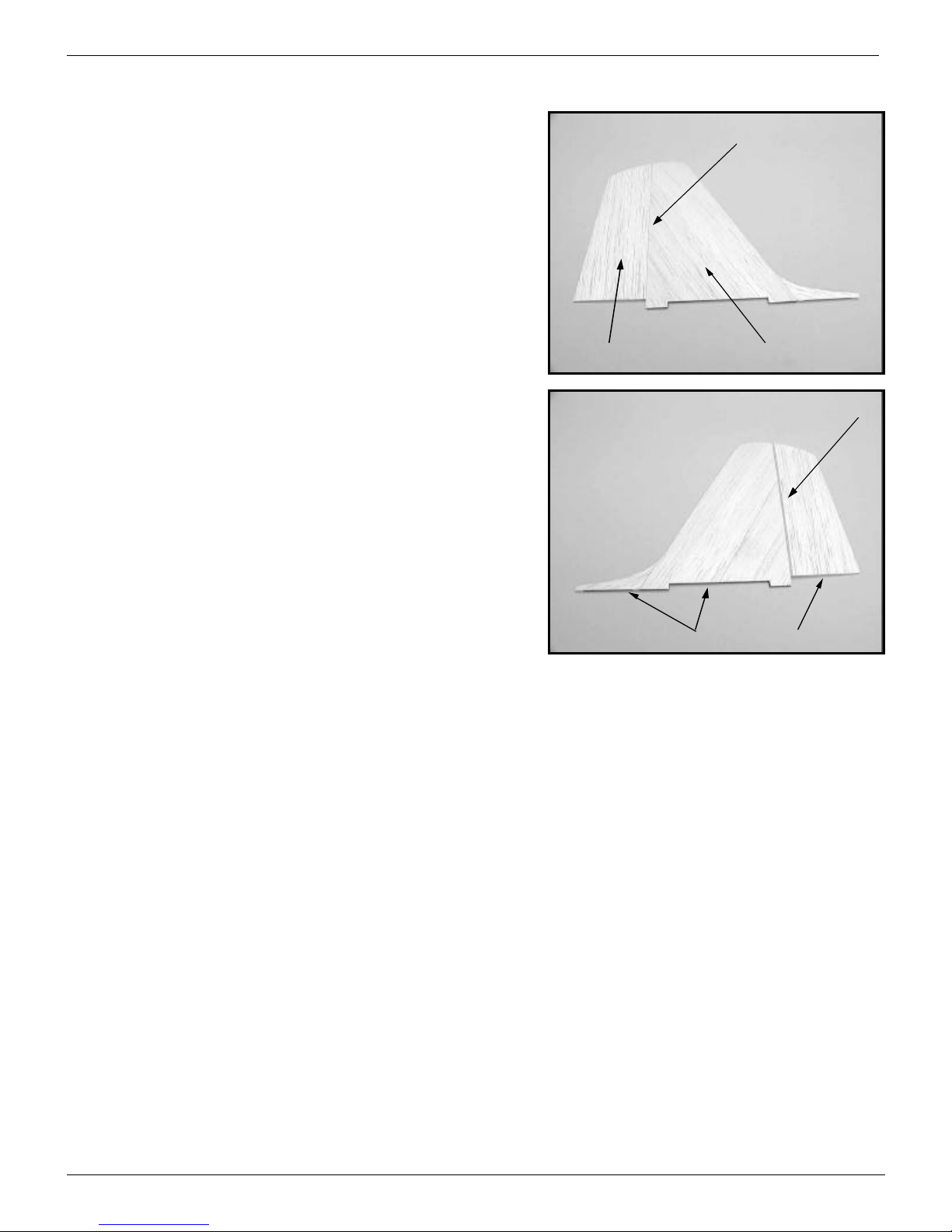

Vertical stabilizer/rudder...

Next, you’ll do the same thing to the vertical stabilizer as you did

the horizontal stabilizer. In this case, the two will meet flush on the

right side of the vertical stabilizer and there will be a groove on the

left side ofthe rudder.

Taper the rudder as you did the elevator and don’t round off the

bottom edges of the vertical stabilizer or rudder.

Don’t glue the horizontal stabilizer or vertical stabilizer to the

fuselage until after the fuselage is covered.

Right side, no groove

The left side of the rudder has the groove

Rudder Vertical Stabilizer

Don’t round off

Table of contents