7

OPERATION INSTRUCTIONS

1. RECOMMENDED MOTORS: Only use AEROTECH composite model

rocket motors when flying your AEROTECH rocket. See enclosed chart

for recommended motors and projected altitudes.

No warranty either expressed or implied is made regarding AEROTECH products,

except for replacement or repair, at AEROTECH’s option, of those products which are

proventobedefectiveinmanufacturewithinoneyearfromthedateoforiginalpurchase.

For repair or replacement under this warranty, please contact AEROTECH. Proof of

purchase will be required. Note: Your state may provide additional rights not covered

by this warranty.

NOTICE: AEROTECH certifies that it has exercised reasonable care in the design and

manufacture of its products. As we cannot control the storage and use of our products,

once sold we cannot assume any responsibility for product storage, transportation or

usage. AEROTECH shall not be held responsible for any personal injury or property

damageresultingfrom the handling, storage or use of our product. The buyer assumes

all risks and liabilities therefrom and accepts and uses AEROTECH products on these

conditions.

AeroTech, Inc.

Las Vegas, NV 89104

www.aerotech-rocketry.com Made in U.S.A.

©1999 AeroTech, Inc., All rights reserved.

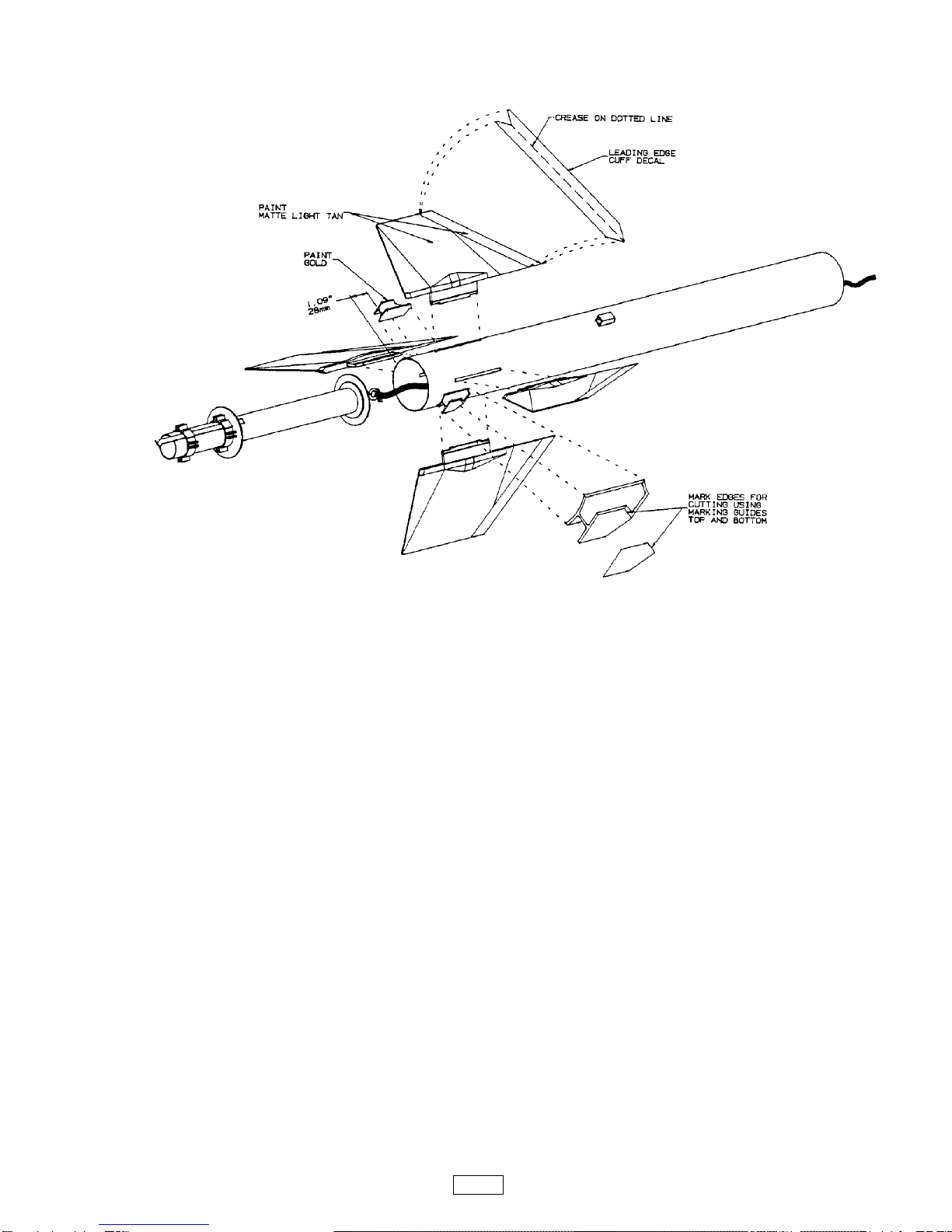

2. RECOVERY SYSTEM PREPARATION: Roll the parachute and shroud

linesfortheupperbodyassembly. Startfromthecanopypeakandrollthis

parachuteandshroudlinesintoatightcylinderthatwilleasilyslideintothe

lower body tube/fin unit. Place this parachute into the lower body tube

followed by the shock cord. Roll the parachute and shroud lines for the

lowerbodytube/finunit. Startfromthecanopypeakandrollthisparachute

and shroud lines into a loose cylinder. Pack the lower body assembly

parachute on top of the upper body parachute and shock cord previously

installed in the rocket. Pack the lower body shock cord on top of this

parachute. Insertthe remaining shock cord length into thebody tube and

insert the coupler tube for the upper body assembly. Make sure that the

parachutes, shroud lines and shock cords are not caught between the

bodytube and the shoulderof the upper bodyassembly. The upper body

unitshouldslidefreely.(NOTE: BecauseyourAEROTECHrockethasthe

LABYRINTH™ ejection gas cooling system, no recovery wadding is

required.)

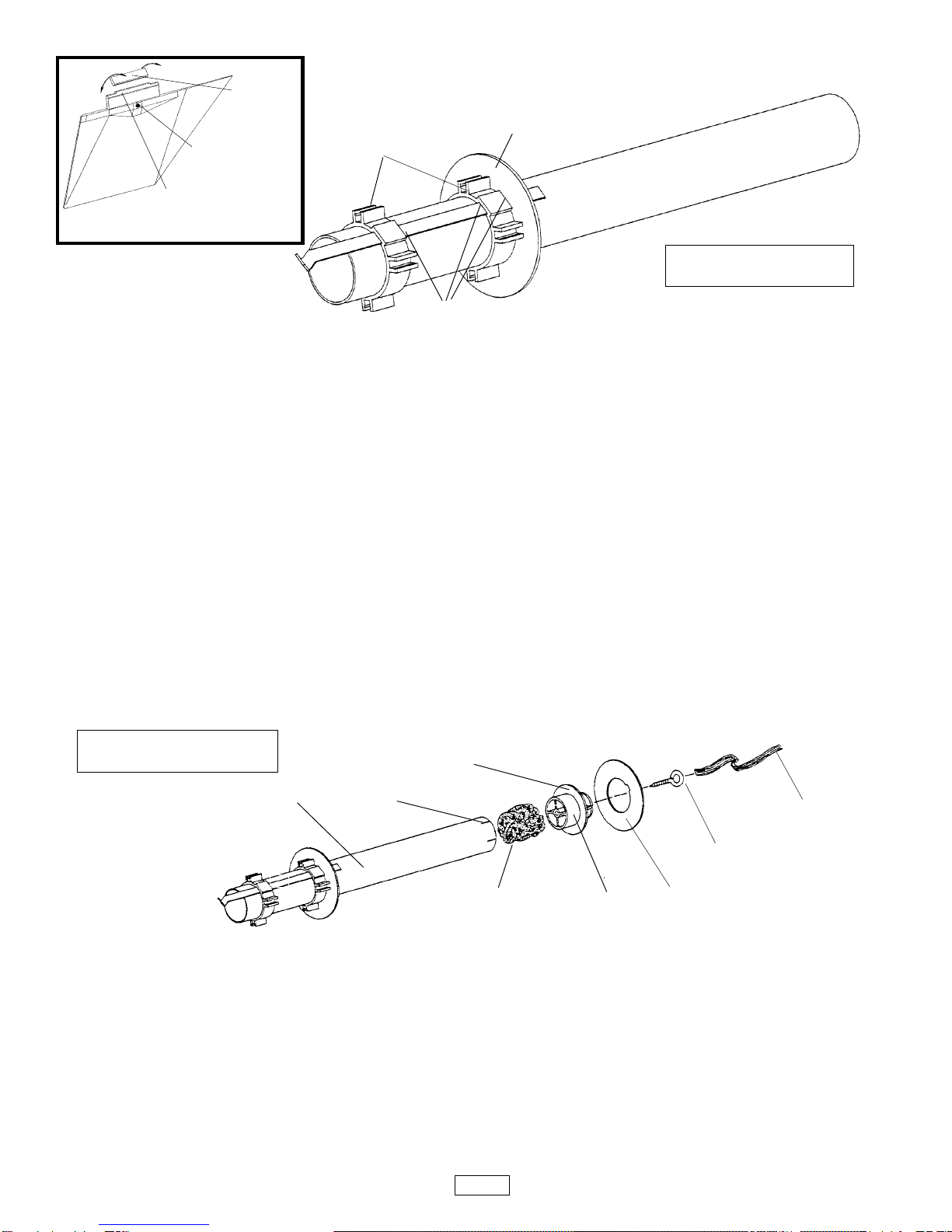

3. MOTOR PREPARATION: The motors recommended for your AERO-

TECH rocket vary in physical size as well as performance. Your rocket

comeswith a changeablemotor adaptor andspacer tubes thatpermit the

rocket to use each of the recommended motors without permanent

modification to the rocket.

Prepare your AEROTECH rocket motor according to the instructions that

come with the motor. Be sure the motor hook snaps in behind the nozzle

end of the motor and holds the motor securely in place. If the motor hook

does not hold the motor in place, bend the end of the hook until it does.

4. PRE-LAUNCH CHECKOUT: Before EVERY flight, perform a complete

pre-launch checkout of your rocket;

• Check that all fins and launch lugs are mounted securely and not

damaged.

• Examine the body tube, nose cone and payload bay to make sure

they are free of damage.

• Check that the shock cord is securely mounted to the ejection gas

baffle and nose cone (or payload bay bulkhead).

• Check that the parachute is securely tied to the shock cord.

• Check that the shock cord and parachute are free of any damage.

• See that the nose cone (or payload bay), packed parachute and

shock cord move freely. After awhile, an ejection charge residue

may build up at the top inside surface of the body tube. Wipe this

residue away with isopropyl ("rubbing") alcohol.

• With the tail of the rocket pointed down and the motor tube empty,

shake the rocket to remove any loose ejection charge debris left

from a previous flight. Periodically, fluff up the cooling mesh using

a bent wire inserted through the back end of the motor tube.

• Be certain the motor to be used is a recommended AEROTECH

model rocket motor and of a size appropriate for the launch area.

• Be sure the motor hook, motor adaptor and motor tube are not

damaged and hold the motor securely in place.

If the pre-launch checkout reveals any damage, repair the damage

before the rocket is flown again.

7. LAUNCH AREA: Launch the rocket in a cleared outdoor area free of tall

trees,powerlines andbuildings. Theside dimensionsofthe clearedarea

should be at least one half of the projected altitude. An area for a radius

ofatleast5feet(1.5meters)fromthelaunchershouldbeclearofdrygrass

orotherflammablesubstances. ReadandfollowtheModelRocketSafety

Code of the National Association of Rocketry (NAR) and comply with all

federal, state and local laws in all activities with model rockets. A copy of

the NAR safety code is shown on the instructions that come with all

AEROTECH composite model rocket motors.

8. FLIGHT PROFILE: When the launch button of the electrical launch

controller is pressed, an electrical current causes the AEROTECH COP-

PERHEAD™ single lead igniter to ignite the composite propellant of the

AEROTECHrocketmotor. Themotorquicklybuildsupthrust andpowers

your AEROTECH rocket into the air. During powered flight the rocket

increasesinspeedandaltitude. When thepropellantburnsouttherocket

is moving at maximum velocity and a time delay material (delay grain)

inside the motor burns. While the delay grain burns the rocket coasts to

peak altitude at which point the delay grain ignites the ejection charge

within the forward part of the motor. The ignition of the ejection charge

creates a burst of hot expanding gas which is cooled by the permanent

metal mesh of the LABYRINTH™ ejection gas cooling system. The

cooled gas flows around the baffle, pressurizes the parachute bay and

ejectsthenosecone(orpayloadbay)andparachute. Theparachutethen

deploys and gently returns the rocket to the ground where the rocket can

be prepared for another flight.

9. TRANSPORT AND STORAGE: To avoid damage to your AEROTECH

rocketduringtransport,pack itinabox surroundedbysoft packing. Store

your rocket at room temperature.

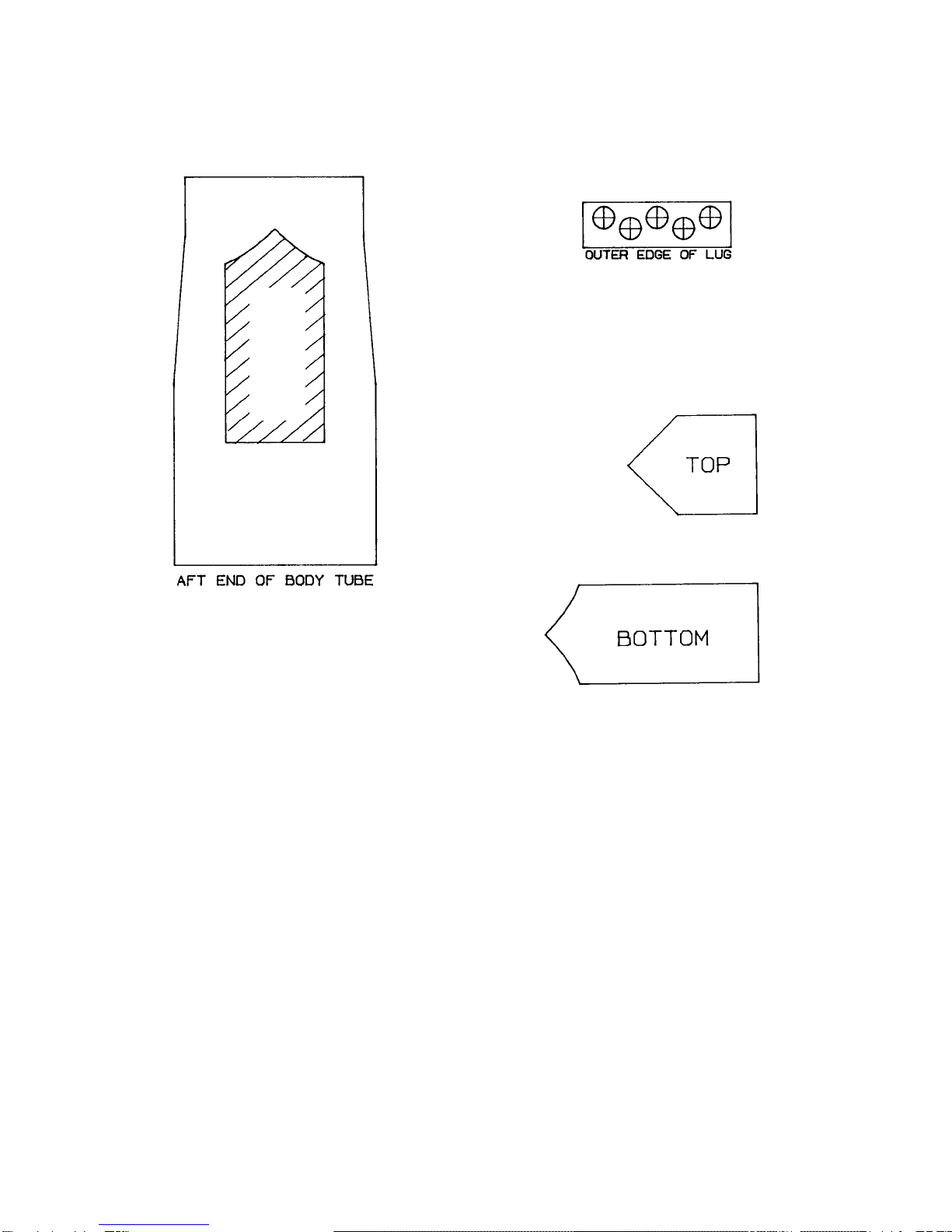

5. LAUNCHPAD: YourAEROTECHrocketmustbeflownfromalaunchpad

with a 1/4"(6.4mm) diameter metal launch rod at least 36"(0.9m) long (as

measured from the top of the blast deflector), such as the AEROTECH

MANTIS™ model rocket launch pad.

6. MOTOR IGNITION: Only launch your rocket using a remotely controlled

and electrically operated launch controller such as the AEROTECH®

INTERLOCK™ model rocket launch controller. Keep yourself and all

other people at least 30 feet (10 meters) away from the rocket during

launch.

A/D-7