SRA IST16 User manual

IST16 User manual –Version 8.0

SRA INSTRUMENTS

210 rue des Sources

69280 Marcy l'Etoile

FRANCE

SAS au capital de 150.000 €

RCS Lyon B 342 068 731

APE 4669B

SIRET: 342 068 731 00054

Code TVA FR 40342068731

p. 1 / 59

Storage Interface IST16

User manual

IST16 User manual –Version 8.0

SRA INSTRUMENTS

210 rue des Sources

69280 Marcy l'Etoile

FRANCE

SAS au capital de 150.000 €

RCS Lyon B 342 068 731

APE 4669B

SIRET: 342 068 731 00054

Code TVA FR 40342068731

p. 2 / 59

Table of contents

1. INTRODUCTION_______________________________________________________________ 5

2. SAFETY INSTRUCTIONS_________________________________________________________ 5

2.1 For your protection________________________________________________________________ 5

2.2 For experiments __________________________________________________________________ 6

3. DESCRIPTION_________________________________________________________________ 6

3.1 Presentation _____________________________________________________________________ 6

3.2 Principle of operation______________________________________________________________ 6

3.3 Fluid flow diagram ________________________________________________________________ 7

3.3.1 Storage mode _________________________________________________________________ 8

3.3.2 Injection mode ________________________________________________________________ 9

3.4 Automated control software ________________________________________________________ 9

4. INSTALLATION_______________________________________________________________ 10

4.1 Preparation for the installation _____________________________________________________ 10

4.2 Modification of the GC carrier gas system_____________________________________________ 11

4.3 Installation of the capillary on the GC injector _________________________________________ 12

4.4 Installation of the transfer line on the TGA____________________________________________ 13

4.5 Vents __________________________________________________________________________ 14

5. INSTALLATION AND CONFIGURATION OF THE IST16 SOFTWARE ______________________ 14

5.1 Software installation _____________________________________________________________ 14

5.2 Configuration of the IST16 _________________________________________________________ 14

5.3 Advanced options________________________________________________________________ 16

5.4 Commands time delay ____________________________________________________________ 16

6. OPERATE WITH THE IST16 SOFTWARE____________________________________________ 17

6.1 Washing________________________________________________________________________ 17

6.2 Temperatures ___________________________________________________________________ 18

6.3 Loops selection __________________________________________________________________ 18

6.4 Storage time ____________________________________________________________________ 19

6.5 Washing parameters______________________________________________________________ 21

6.6 Options ________________________________________________________________________ 22

IST16 User manual –Version 8.0

SRA INSTRUMENTS

210 rue des Sources

69280 Marcy l'Etoile

FRANCE

SAS au capital de 150.000 €

RCS Lyon B 342 068 731

APE 4669B

SIRET: 342 068 731 00054

Code TVA FR 40342068731

p. 3 / 59

7. GAS SAMPLING VALVE AND MULTI-INJECTION MODES ______________________________ 22

7.1 Gas sampling valve (without multi-injection) __________________________________________ 23

7.2 Multi-injection __________________________________________________________________ 24

8. DIALOG WITH THE INTERFACE __________________________________________________ 25

9. STORAGE INTERFACE _________________________________________________________ 26

9.1 Control and maintenance__________________________________________________________ 27

9.2 Changing the IP address of the interface______________________________________________ 28

9.3 Manual mode ___________________________________________________________________ 29

9.3.1 Analysis parameters ___________________________________________________________ 30

9.3.2 Storage parameters____________________________________________________________ 31

9.3.3 Washing parameters ___________________________________________________________ 31

9.3.4 Options _____________________________________________________________________ 32

9.3.5 Gas sampling parameters _______________________________________________________ 32

9.3.6 Multi-injection parameters ______________________________________________________ 32

9.4 Error and fault messages __________________________________________________________ 33

10. MAINTENANCE OPERATIONS__________________________________________________ 34

10.1 Maintenance schedule ___________________________________________________________ 34

10.1.1 After each experiment ________________________________________________________ 34

10.1.2 Every week _________________________________________________________________ 34

10.1.3 Every month ________________________________________________________________ 34

10.1.4 Every 6 months ______________________________________________________________ 35

10.2 Typical cleaning after an experiment________________________________________________ 35

10.3 Clean the valve and rotor_________________________________________________________ 36

10.3.1 Disassembly the valve _________________________________________________________ 36

10.3.2 Clean the inside of the valve body _______________________________________________ 37

10.3.3 Clean the rotor ______________________________________________________________ 37

10.3.4 Change tubing or fitting _______________________________________________________ 38

11. LOCATE THE ORIGIN OF THE PROBLEM__________________________________________ 38

11.1 Flow/pressure problem with GC ___________________________________________________ 40

11.1.1 Find the origin of the problem __________________________________________________ 40

11.1.2 There is a leak on the IST16 side_________________________________________________ 41

11.2 Problem of flow restriction _______________________________________________________ 44

11.2.1 Find the problem_____________________________________________________________ 44

11.2.2 Clean the inside of the IST16____________________________________________________ 45

11.3 Problem of memory effect ________________________________________________________ 46

IST16 User manual –Version 8.0

SRA INSTRUMENTS

210 rue des Sources

69280 Marcy l'Etoile

FRANCE

SAS au capital de 150.000 €

RCS Lyon B 342 068 731

APE 4669B

SIRET: 342 068 731 00054

Code TVA FR 40342068731

p. 4 / 59

11.4 Problem of high level of air in MS __________________________________________________ 46

11.5 Problem with oven display and multi-position valve number ____________________________ 47

12. TECHNICAL DATA ___________________________________________________________ 49

12.1 Power supply __________________________________________________________________ 49

12.2 Dimensions and weights__________________________________________________________ 49

12.3 Instrument ____________________________________________________________________ 49

12.4 Utilities _______________________________________________________________________ 49

12.4.1 Carrier gases ________________________________________________________________ 50

12.4.2 Repeatability ________________________________________________________________ 50

12.5 Fuses _________________________________________________________________________ 50

12.6 Inputs/Outputs _________________________________________________________________ 50

12.7 Recycling ______________________________________________________________________ 50

13. ABOUT____________________________________________________________________ 50

14. APPENDIX I: IST16 REMOTE OUTPUTS & I/O _____________________________________ 51

15. APPENDIX II: CONNECTING THE IST16 TRANSFER LINES_____________________________ 52

16. APPENDIX III: INSTALLATION CHECKOUT SAMPLE _________________________________ 53

16.1 Sample and conditions ___________________________________________________________ 53

16.2 Instrument parameters __________________________________________________________ 53

16.2.1 TGA _______________________________________________________________________ 53

16.2.2 IST16 ______________________________________________________________________ 53

16.2.3 GC ________________________________________________________________________ 53

16.2.4 MSD_______________________________________________________________________ 53

16.3 Results________________________________________________________________________ 54

16.3.1 TGA/DSC ___________________________________________________________________ 54

16.3.2 TGA/IST16/GC-MS____________________________________________________________ 55

16.4 Conclusion_____________________________________________________________________ 56

17. APPENDIX IV: IST1 __________________________________________________________ 57

17.1 Injection parameters –Gas sampling mode __________________________________________ 58

17.2 Injection parameters –Multi-injection mode _________________________________________ 58

18. EU DECLARATION OF CONFORMITY ____________________________________________ 59

IST16 User manual –Version 8.0

SRA INSTRUMENTS

210 rue des Sources

69280 Marcy l'Etoile

FRANCE

SAS au capital de 150.000 €

RCS Lyon B 342 068 731

APE 4669B

SIRET: 342 068 731 00054

Code TVA FR 40342068731

p. 5 / 59

1. Introduction

For reasons of clarity, this manual does not contain all detailed information on all types of coupling.

In addition, it cannot describe every possible case concerning installation, use and maintenance.

If you require additional information about this device or if you encounter problems that are not addressed

in this manual, you can contact SRA Instruments for assistance.

The content of this manual is not part of any previous or existing agreement, commitment or legal status

and does not change these. All the commitments of SRA Instruments are contained in the respective sales

contracts, which also contain the only and entire applicable warranty terms. These warranty conditions in

the contract are neither extended nor limited by the content of this manual.

2. Safety instructions

Important information

This instrument is designed for use in very specific conditions. If the equipment is used in a manner not

specified by SRA Instruments, the protection provided by the equipment may be impaired.

Moreover, it is the responsibility of the customer to inform SRA Instruments after-sales service if the IST16

has been used for the analysis of hazardous samples, prior to any instrument service being performed or

when an instrument is being returned for repair.

2.1 For your protection

Warnings:

Warning: Shock hazard

Do not replace components while the power cable is plugged in. To avoid injuries, always

turn off power before touching them. Install the IST16 so that access to the power cable is

easy. Make sure that you connect the cable to an earth socket, otherwise there is a lethal

hazard.

Warning: Hot surfaces

Several parts of the IST16 work at temperatures high enough to cause severe burns.

These parts include, among others:

•the transfer lines

•the valve oven

You must be extremely careful to avoid touching these heated surfaces. Do not use the

instrument if the IST16 module is disassembled.

IST16 User manual –Version 8.0

SRA INSTRUMENTS

210 rue des Sources

69280 Marcy l'Etoile

FRANCE

SAS au capital de 150.000 €

RCS Lyon B 342 068 731

APE 4669B

SIRET: 342 068 731 00054

Code TVA FR 40342068731

p. 6 / 59

Warning: Electrostatic discharge is a threat to electronics

Electrostatic discharge (ESD) can damage the printed circuit boards of the IST16. If you

must hold an electronic card, wear a grounded wrist strap and hold it only by its edges.

Warning: Use of gases

Do not use gases that can form an explosive mixture. Do not use hydrogen as the carrier

gas or purge gas for your analyses.

2.2 For experiments

•Check that the operating voltage of the instrument is compatible with the one of your electrical

network before switching it on. Otherwise the device may be damaged.

•Have your instrument serviced by SRA Instruments or one of its distributors.

•Use only gases and solvents specified in the operating procedures.

•Do not open the oven if the temperature is above 100 °C.

•Do not open the electronic box.

•Eliminate from the environment of the instrument: vibrations, magnetic effects and explosive

gases.

•The IST16 must be used indoors only; it is designed for use at room temperature and under

conditions where no condensation can occur. Install the IST16 on a rigid and stable surface.

3. Description

3.1 Presentation

The IST16 is an interface for storing gases, developed by SRA Instruments. It is generally coupled to

thermogravimetric balances from different manufacturers (Mettler, Setaram, Netzsch, TA ...). Thus, the

IST16 makes it possible to recover and isolate gas fractions resulting from the thermal analysis with a

sequence defined by the user. These fractions can then be injected separately into GC-MSD for a detailed

analysis. Thanks to IST16, the duration of the analysis is no longer a limitation for the study of TGA profiles.

3.2 Principle of operation

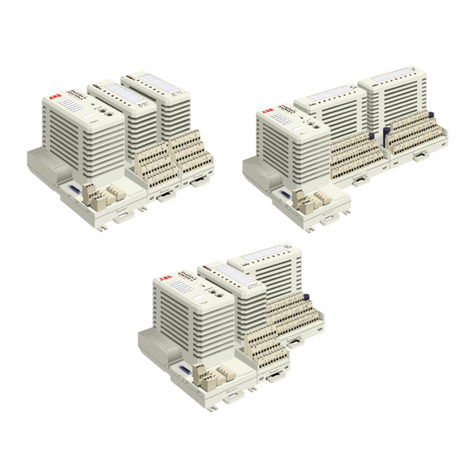

The interface consists of:

1. An upper box containing the oven integrating the 3 valves constitutive of the system

2. A lower box containing the entire electronic control unit for gas circulation

3. A 1.2m transfer line for interfacing to the TGA

4. A 1.2m transfer line for interfacing to the Split injector of the GC system

5. A touch interface

IST16 User manual –Version 8.0

SRA INSTRUMENTS

210 rue des Sources

69280 Marcy l'Etoile

FRANCE

SAS au capital de 150.000 €

RCS Lyon B 342 068 731

APE 4669B

SIRET: 342 068 731 00054

Code TVA FR 40342068731

p. 7 / 59

The IST16 provides full heating of the sample from the thermo-balance to the GC. It has 2 independent

heating zones to maintain the temperature up to 250 °C.

Each of these 2 heating zones is coupled with an independent safety device which switches off the power if

the threshold is exceeded. The alarms on the front panel are then active and it is recommended to contact

the after-sales support in this case.

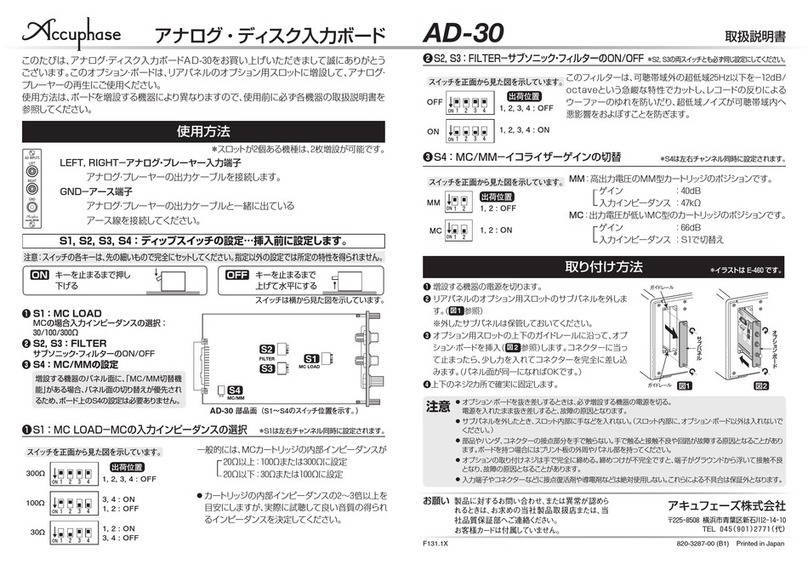

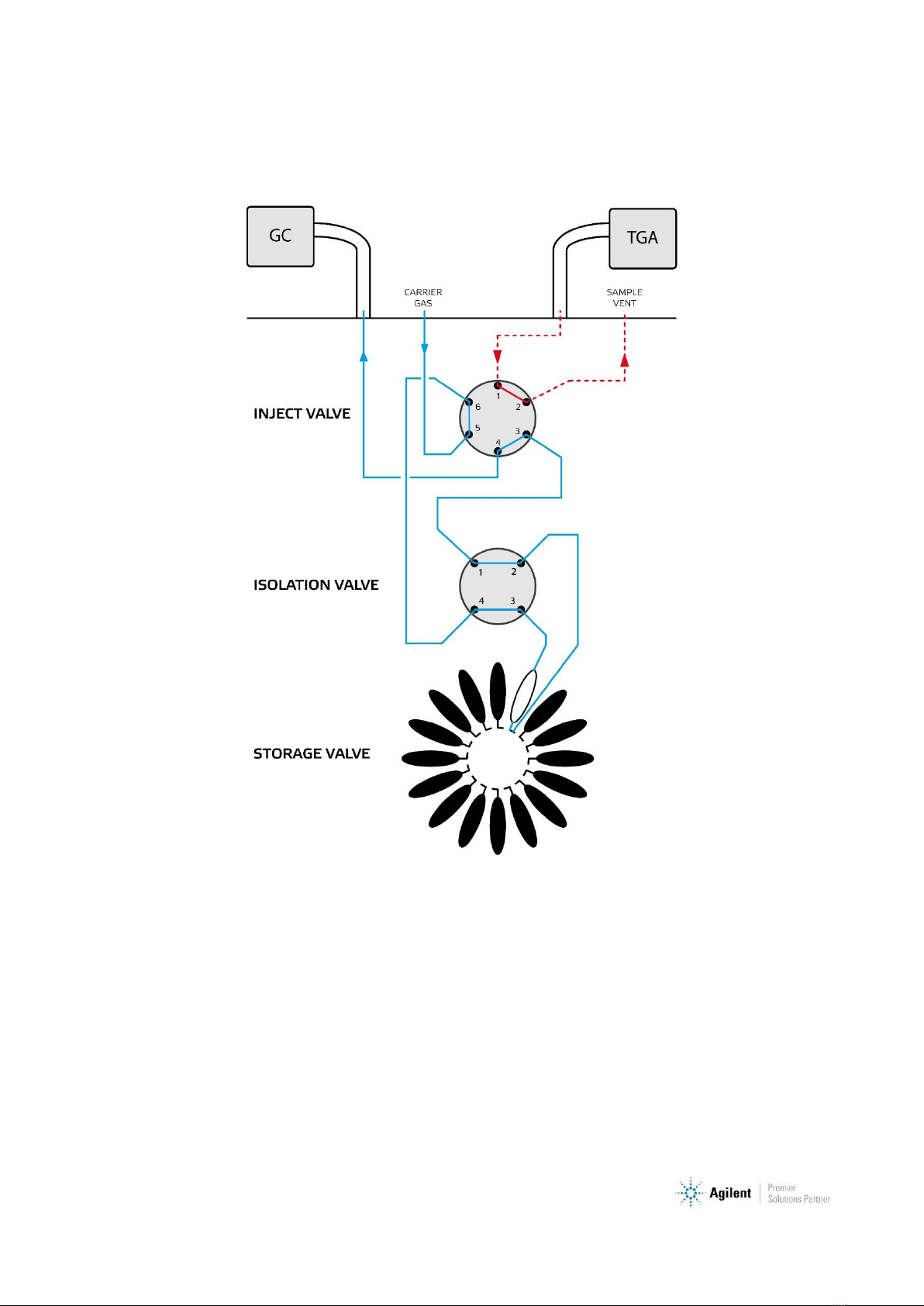

3.3 Fluid flow diagram

The IST16 is equipped with 3 high temperature switching valves. The 16 loops of the storage valve have a

default volume of 250 µL and have an external tube diameter of 1/16 inch.

The INOX used has a Sulfinert®-type treatment.

The fluid flow diagram is as follows:

3

1

4

5

2

IST16 User manual –Version 8.0

SRA INSTRUMENTS

210 rue des Sources

69280 Marcy l'Etoile

FRANCE

SAS au capital de 150.000 €

RCS Lyon B 342 068 731

APE 4669B

SIRET: 342 068 731 00054

Code TVA FR 40342068731

p. 8 / 59

3.3.1 Storage mode

This storage mode is not available on IST1. For this latter, refer to appendix IV chapter 17.

IST16 User manual –Version 8.0

SRA INSTRUMENTS

210 rue des Sources

69280 Marcy l'Etoile

FRANCE

SAS au capital de 150.000 €

RCS Lyon B 342 068 731

APE 4669B

SIRET: 342 068 731 00054

Code TVA FR 40342068731

p. 9 / 59

3.3.2 Injection mode

This injection mode is not available on IST1. For this latter, refer to appendix IV chapter 17.

3.4 Automated control software

The IST16 software has been developed to control the IST16 storage interface.

The storage sequence can trap up to 16 samples.

The injection sequence then allows injecting these samples into a chromatograph (optionally coupled to a

mass spectrometer) in an automated way.

IST16 User manual –Version 8.0

SRA INSTRUMENTS

210 rue des Sources

69280 Marcy l'Etoile

FRANCE

SAS au capital de 150.000 €

RCS Lyon B 342 068 731

APE 4669B

SIRET: 342 068 731 00054

Code TVA FR 40342068731

p. 10 / 59

This software is optimized for operation under Microsoft Windows 7 or 10.

4. Installation

4.1 Preparation for the installation

The installation of the IST16 is performed by an SRA Instruments technician or a recognized partner. To be

able to set up the equipment in your laboratory, it is necessary to provide:

•1 power supply 237 VAC –16 A

•Approximately 40 cm wide on the right side of the GC

•Usually, the interface is placed between the analytical system and the Thermo-balance:

IST16 User manual –Version 8.0

SRA INSTRUMENTS

210 rue des Sources

69280 Marcy l'Etoile

FRANCE

SAS au capital de 150.000 €

RCS Lyon B 342 068 731

APE 4669B

SIRET: 342 068 731 00054

Code TVA FR 40342068731

p. 11 / 59

Tools:

-1 wrench 7/16'' and 2 wrenches 5/16''

-1 wrench 5 mm

-1 Torx T20 screwdriver and 1 Torx T10 screwdriver

-1 electronic leakage detector

-Allen key 9/64'' and Allen key 7/64''

-1 electronic flowmeter

The following cables are supplied with the IST16:

-TGA remote

-Ethernet

-GC remote

-Power Supply

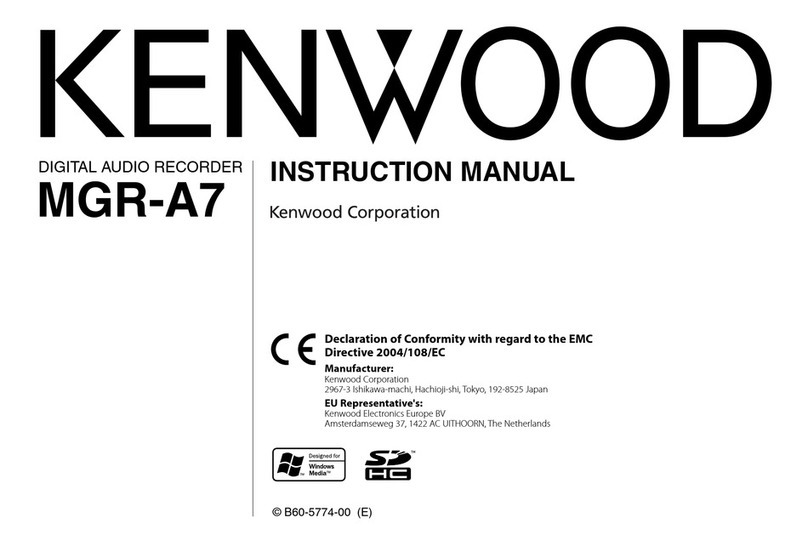

4.2 Modification of the GC carrier gas system

In order to supply the IST16 with carrier gas, a 3-way valve will be mounted on the GC. This valve allows

switching the carrier gas:

•Through the storage interface for the TGA/IST16/GC-MS mode, allowing injection with the IST16.

•Directly to the S/SL injector for standard use of the GC. It is also possible to isolate the storage

interface for maintenance.

IST16 User manual –Version 8.0

SRA INSTRUMENTS

210 rue des Sources

69280 Marcy l'Etoile

FRANCE

SAS au capital de 150.000 €

RCS Lyon B 342 068 731

APE 4669B

SIRET: 342 068 731 00054

Code TVA FR 40342068731

p. 12 / 59

The carrier gas connection to the IST16 is located on the back of the upper panel. The fitting is 1/16‘’

Swagelok type. We recommend that you use new ferrules during installation and follow the coupling

manufacturer’s recommendations for tightening to ensure the best seal. A leak control with electronic

detector is recommended periodically to check for leakage that can degrade the analysis and create

overconsumption of carrier gas.

The use of hydrogen carrier gas for IST16 is not recommended.

It is better to use helium for safety reasons.

4.3 Installation of the capillary on the GC injector

The transfer line on the Split/Splitless injector side is fixed by a bracket on top of the GC. This transfer line

contains an inert stainless-steel capillary with an outer diameter of 0.8 mm. This capillary must pass into

the injector to a depth of about 25 mm with respect to the septum nut.

2 position valve

IST16 transfer

line to GC

GC S/SL injector

GC

EPC

IST16

Swagelok 1/16" union

IST16 User manual –Version 8.0

SRA INSTRUMENTS

210 rue des Sources

69280 Marcy l'Etoile

FRANCE

SAS au capital de 150.000 €

RCS Lyon B 342 068 731

APE 4669B

SIRET: 342 068 731 00054

Code TVA FR 40342068731

p. 13 / 59

We recommend to possibly put a mark to adjust the depth once the line is in place.

4.4 Installation of the transfer line on the TGA

The transfer line is normally supplied with the connection corresponding to your TGA model. This can be a

DN16 flange (Mettler case) or a simple double ring fitting (TA, Setaram cases...).

We recommend the use of a transfer tube of 1/8" diameter.

Depending on the type of connection and type of thermo-balance, it may be desirable to mechanically

maintain the transfer line in order to not disturb the TGA or risk breaking any fragile parts composing its

oven. We can assist you in finding a support adapted to your conditions of use. Do not hesitate to contact

us for any special requests.

IST16 User manual –Version 8.0

SRA INSTRUMENTS

210 rue des Sources

69280 Marcy l'Etoile

FRANCE

SAS au capital de 150.000 €

RCS Lyon B 342 068 731

APE 4669B

SIRET: 342 068 731 00054

Code TVA FR 40342068731

p. 14 / 59

To find out how to install the IST16 transfer line on your equipment, please refer to the corresponding

appendix in the dedicated installation kit.

4.5 Vents

The sample vent is located on the upper back side of the instrument.

It is recommended to connect this vent to a conventional vent or a hood to prevent the emission

of toxic or odorous compounds in the immediate environment of the instrument.

In all cases, the IST16 vent must remain at atmospheric pressure in order to not disturb the

gas flow through the interface.

5. Installation and configuration of the IST16 software

5.1 Software installation

1. First, make sure that the computer is configured with Administrator rights.

2. Insert either the USB key or the CD-ROM provided and use the Windows Explorer to display the

files contained. Select the file Setup.exe, right-click on this file and select the menu Run as

Administrator.

3. A welcome window is displayed; click on Next.

4. Then accept the terms of the license agreement so that you can go on with the installation.

5. In the window “Destination location”, select the folder where the application files will be stored by

entering its name or by clicking on Browse.

6. In the window “Select start menu folder”, select the folder where the software shortcut for

launching the application will be stored by entering its name or clicking on Browse.

7. In the window displayed, check the box if you want an icon to be created on your computer

desktop.

8. Click on the Install button to complete the installation.

Before launching the entire installation of the application, you can check the data entered by

clicking on the Back button and correct any mistake.

8. In the new window, check the box “Launch IST16” to launch the application as soon as you exit the

installation.

9. Click on the “Finish” button to close the installation of the application.

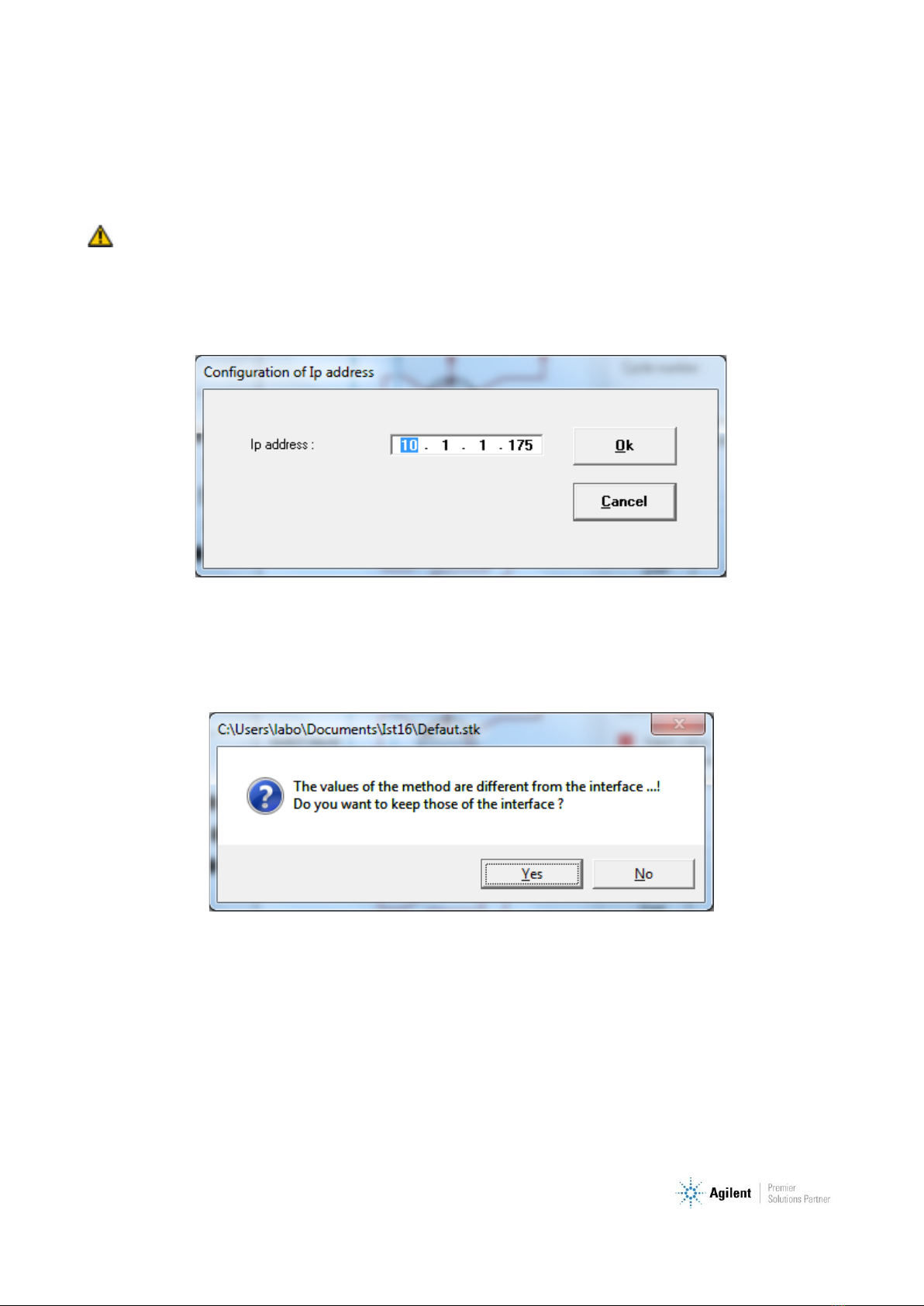

5.2 Configuration of the IST16

The dialogue with the IST16 uses an Ethernet connection and it is necessary to indicate the IP address to

the software. This configuration is accessible through the Interface\Configuration\IP Address menu.

IST16 User manual –Version 8.0

SRA INSTRUMENTS

210 rue des Sources

69280 Marcy l'Etoile

FRANCE

SAS au capital de 150.000 €

RCS Lyon B 342 068 731

APE 4669B

SIRET: 342 068 731 00054

Code TVA FR 40342068731

p. 15 / 59

If a configuration has already been carried out, this menu can be accessed with a password. In this case, the

following login and password must be entered:

Login: Config Password: ist16

The advanced configuration of the IST16 must not be used by people not trained.

When you have entered the password, select the Interface\Configuration\Ip address menu.

The following window is displayed:

Enter the IP address and validate with Ok; the software automatically tries to connect to the interface.

When connecting to the IST16 and if a method has already been loaded, the following message may be

displayed:

This message means that the parameter values of the IST16 method are different from those of the method

loaded in the application.

If you click Yes, the application method parameters will be cleared and replaced by the IST16 method

parameters.

If you click No, the application method will not be changed.

IST16 User manual –Version 8.0

SRA INSTRUMENTS

210 rue des Sources

69280 Marcy l'Etoile

FRANCE

SAS au capital de 150.000 €

RCS Lyon B 342 068 731

APE 4669B

SIRET: 342 068 731 00054

Code TVA FR 40342068731

p. 16 / 59

5.3 Advanced options

There are three ways to use the interface.

These modes are selected through the Interface\Configuration\Advanced Options menu.

!This menu is accessible only if the software is connected to the interface.

The following page is displayed:

By default, the interface is used in Storage mode. You can also use the Gas sampling valve or Multi-

injection modes which will be described in chapter 7.

When the 'Manual mode' checkbox is checked, the user can work manually with the IST16 and has access

to the method parameters. For more information on the manual mode, please refer to chapter 9.3.

The 'Automatic wash' checkbox allows the user to activate the request for washing after analysis.

5.4 Commands time delay

Several commands must remain active for a given time. The default values are suitable for most

configurations, but you can modify these times if necessary by using the Interface\Configuration\Times

menu.

! This menu is accessible only if the software is connected to the interface.

The following page is displayed:

IST16 User manual –Version 8.0

SRA INSTRUMENTS

210 rue des Sources

69280 Marcy l'Etoile

FRANCE

SAS au capital de 150.000 €

RCS Lyon B 342 068 731

APE 4669B

SIRET: 342 068 731 00054

Code TVA FR 40342068731

p. 17 / 59

Delay configuration

6. Operate with the IST16 software

The IST16 typical sequence is as following:

1. First step: storage of the sample in different loops at programmed time.

2. Second step: loops are injected and analyzed one after the other.

3. Third step: loops are cleaned with the flowing gas coming from the TGA at the end of the GC

analysis sequence.

The storage sequence can only be started when the interface oven temperature is steady. Before each

injection of a loop, the software checks that the gas chromatograph is in a ready state (green color). The

GC cycle time must correspond to the GC analysis time. It is used to adjust the delay between two injection

loops.

6.1 Washing

The washing sequence can be started when the IST16 is idle by checking the Washing option and clicking on

the Start button.

IST16 User manual –Version 8.0

SRA INSTRUMENTS

210 rue des Sources

69280 Marcy l'Etoile

FRANCE

SAS au capital de 150.000 €

RCS Lyon B 342 068 731

APE 4669B

SIRET: 342 068 731 00054

Code TVA FR 40342068731

p. 18 / 59

If the 'Automatic wash' option has been checked, it can be started as soon as the injection cycle has been

completed on all loops. Depending on the method, there may be several washing sequences.

6.2 Temperatures

The temperature of the transfer lines is self-regulated at 250 °C and therefore cannot be changed.

The valves oven temperature can be changed in the Method\Temperatures menu.

The following window appears:

The temperature can be set between 150 and 250 °C. Click on "Apply" to send values to the storage

interface, then click on "Ok" and save in the IST16 method.

Note that when the temperature from 150 to 250 °C is applied, the storage interface will start its own

heating procedure and will automatically trigger the switch valves during the temperature raise. This

operation is done to preserve the system from mechanical problems with the rotary valves.

6.3 Loops selection

For some experiments, it is not necessary to use all the 16 storage loops. In this case, you can disable the

loops which will not be used from the Interface\Select loops menu.

It is strongly recommended to work only with consecutive loops to keep the performance in terms of

reproducibility of results.

IST16 User manual –Version 8.0

SRA INSTRUMENTS

210 rue des Sources

69280 Marcy l'Etoile

FRANCE

SAS au capital de 150.000 €

RCS Lyon B 342 068 731

APE 4669B

SIRET: 342 068 731 00054

Code TVA FR 40342068731

p. 19 / 59

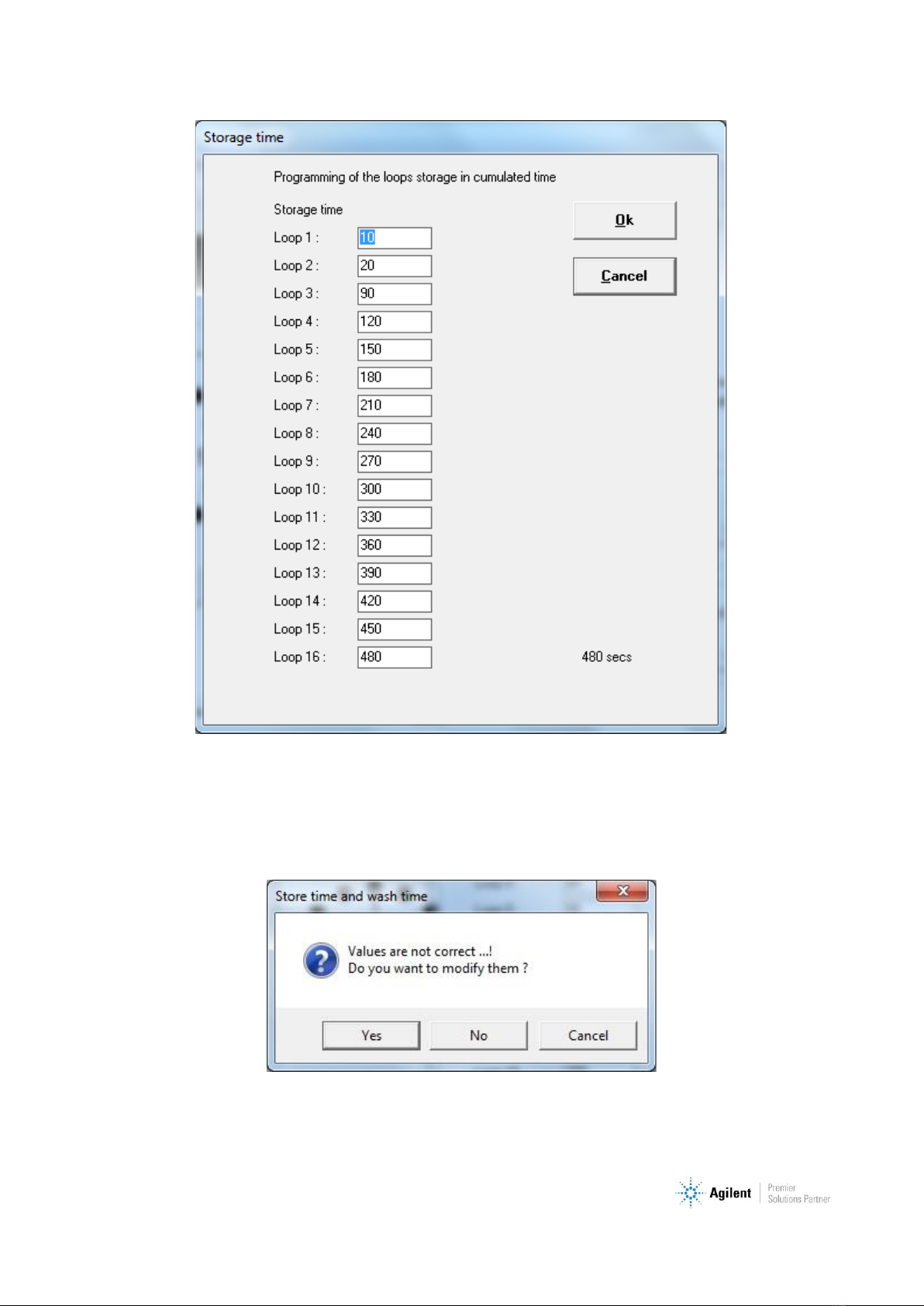

6.4 Storage time

During the storage sequence of an experiment, the multi-position valve allows each loop to be flushed with

the emitted gas for a period of time. This time is defined in the window below accessible from the

Method\Storage Time menu. A fraction of the emitted gas (typically 250 μL) will be stored in one of the 16

loops at the end.

IST16 User manual –Version 8.0

SRA INSTRUMENTS

210 rue des Sources

69280 Marcy l'Etoile

FRANCE

SAS au capital de 150.000 €

RCS Lyon B 342 068 731

APE 4669B

SIRET: 342 068 731 00054

Code TVA FR 40342068731

p. 20 / 59

Note that if a set time is not correct, the input value is displayed in red.

When all changes are made, click on the “OK” button to confirm. The software checks the values and if

there is an error, it reports it with the message:

•If you click on the “Yes” button, the software corrects the values and displays again the window.

•If you click on the “Cancel” button, it displays again the window without making any changes.

Table of contents