SRT SCB-PT User manual

SCB-PT Passive Pneumatic

Controller

User Manual

Version:CV1.0

Soft Robot Tech Co.,Ltd

SCB-PT

Safety notes

Before starting to use this product, please read carefully the safety

precautions and user ’s notices to prevent personal injury or property

damage to oneself and others. This product is equipped with SRT flexible

end fixture, and it should not be used for other purposes.

警告! Warning!

About working environments of the product.

Do not use in environments distributed with corrosive gases,

chemicals, seawater, water and steam.

Do not use in places distributed with explosive gases and dust.

Do not use in places prone to vibration or shock.

Do not use in places around heat sources or radiation heat sources.

If the product is used in places with water drops, oil and welding

sparks, appropriate protecting measures must be taken.

SCB-PT

Contents

1. Product introduction................................................................1

1.1 Packing list.............................................................................. 3

1.2 Panel introduction and size................................................4

1.3 Technical Parameters........................................................... 6

2. Function Description................................................................7

2.1 Display function.....................................................................7

2.2 Manual control.......................................................................8

2.3 Input-output...........................................................................9

2.4 Communication function.................................................. 15

3. Installation.................................................................................16

3.1 Installation fixed.................................................................. 16

3.2 Pneumatic connection....................................................... 16

3.3 Line connection................................................................... 18

4. Installation and use of debugging software.................19

4.1 Software interface............................................................... 19

4.2 Software installation...........................错误!未定义书签。

4.3 Software use......................................................................... 20

5. User information..................................................................... 24

SCB-PT

1

1. Product introduction

The SCB-PT series passive pneumatic controller is a special pneumatic

drive controller of the SRT flexible end fixture, which can output the

adjustable pressure of 70~100 kPa. Under the trigger of the external

equipment, the flexible end fixture is driven to perform the opening and

grasping action. The positive pressure output corresponds to the

clamping action of the fixture, and the negative pressure output

corresponds to the opening action of the fixture. The controller can be

conveniently equipped with flexible end fixture and other automation

equipment to form a flexible grasping system.

Functional characteristics:

1、Real time status display:

The SCB-PT series controller is equipped with air pressure display and

indicator lamp. The air pressure display can display the real time air

pressure value and set air pressure of the air pressure output port, and

the indicator lamp can display the current working state of the controller.

2、Accurate high speed response

SCB-PT series controllers optimize the control system of the previous

generation of controllers, which can adjust the output pressure more

accurately and quickly, and achieve the set output pressure value in a

short time to meet the requirements of certain working environments.

3、Three pressure regulating modes

SCB-PT series controllers are equipped with adjustment knobs, which

can manually adjust the set pressure of each gear grab and opening,

which is convenient, simple and saves time.

The SCB-PT series controller has eight stalls, which can store up to eight

groups of grasping and opening pressure values, and switch through I /

O signals to deal with complex working conditions.

SCB-PT

2

SCB-PT series controllers support communication voltage regulation.

After the controller connects the communication equipment through the

data line, the set pressure value can be adjusted in real time.

4、Fault alarm function

The SCB-PT controller will detect the output pressure in real time. When

there is air leakage in the end fixture, the indicator light will become red,

and the control system will output signals to facilitate the operator or the

external control system to make judgments and improve the reliability of

the production line.

SCB-PT

3

1.1 Packing list

Name

Amount

Controller

1

User manual

1

DB9 Data Line

1

DB9 Data Line

1

35mm Guide rail buckle

2

Fixed connectors

4

10mm pipe

1

SCB-PT

4

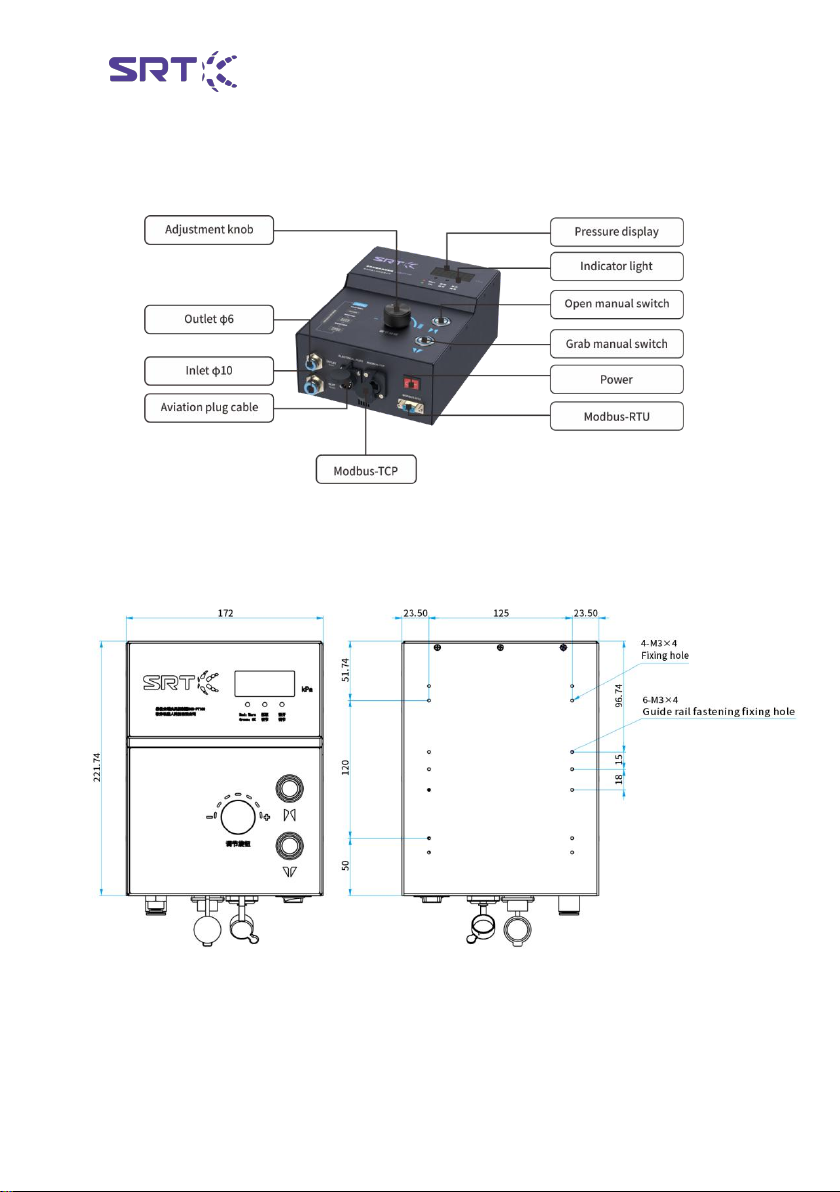

1.2 Panel introduction and size

Unit:mm

SCB-PT

5

Name

Function introduction

Power

Controller power supply switch

Pressure display

Display content

Pilot lamp

Status Display

RJ45 port

MODBUS-TCP protocol

DB9 port

MODBUS-RTU protocol

Manual switch

Manually switch the grabbing/opening state

Aviation plug in port

14 core aviation plug, controller power supply and I / O

Outlet port

Connect the end fixture via φ6 pipe

Intake port

Connect to air source through φ10 pipe

SCB-PT

6

1.3 Technical Parameters

Name

Specification

Dimensions

222*172*96mm

Net weight

3kg

Protection level

IP42

Rated voltage

DC24V±10%

Rated current

2A

Input air pressure range

0.5~0.7MPa clean air source,flow>400L/min

Output pressure range

-80~100kPa

Output positive pressure flow

285L/min

Output negative pressure flow

85L/min

Protective function

Overpressure Overflow, Leakage Alarm, Intake

Detection

Control method

Manual control, I / O signal, communication control

Pressure regulation method

Manual control, I / O signal, communication control

Cooling method

Natural cooling

Working environment

Avoid large amounts of dust, oil and corrosive gases

Ambient humidity

<85%,RH(No dew and beads)

Ambient temperature

-10~50℃(Not frozen)

SCB-PT

7

2. Function Description

2.1 Display function

Display features include pressure display and indicator light

1、Pressure display:

Display the real time output pressure value of the current air outlet;

display the set pressure during grabbing and opening debugging; alarm

information.

2、Indicator light:

Indicator lights are : completion / alarm instructions, grab adjustment

instructions and open adjustment instructions.

Complete / alarm instructions, when the end fixture completes the grab

or open action, the indicator lights green. When the controller detects

that the air inlet interface pressure does not reach the input pressure

range, or the end fixture cannot complete the operation normally, the

indicator light is red.

Grab adjustment indicator light : When the controller enters the manual

modification of the grab pressure setting value, the indicator light is

often bright, and it withdraws from the manual modification of the grab

pressure setting value, and the indicator light is extinguished.

Opening adjustment indicator light : When the controller enters the

manual modification of the opening pressure setting value, the indicator

light is often bright, and exits the manual modification of the opening

pressure setting value, the indicator light is extinguished.

SCB-PT

8

2.2 Manual control

Manual control includes manual switch and adjusting knob, as shown

below :

Manual switch :

It includes grab switch and open switch, which are used to switch the

pressure state and reset controller of the outlet interface. Press the

grab switch alone, the outlet interface will output positive pressure, drive

the end fixture to grab state. Press open switch alone, the outlet

interface will output negative pressure, drive the end fixture to open

state. At the same time press the grab switch and open switch, the

outlet interface output zero pressure, the end fixture to restore the

natural state.

At the same time press the grab switch and open switch, reset the

controller, clear the alarm state.

Adjustment knob :

The adjusting knob is used to manually set the setting pressure for each

gear to grab and open. The operation is as follows :

When the controller is in the initial state, the rotation and short button

adjustment knobs are invalid. After long pressing the adjustment knob

for 3 s, it enters the pressure adjustment state. The first is to grab the

open gear selection interface ( G0 ~ G7 ), the pressure display area shows

SCB-PT

9

the current gear, rotate the adjustment knob to find the gear that needs

to be set, and press the adjustment knob to enter the grasping pressure

setting under the gear.

When entering the grasping pressure setting, the ' grasping adjustment

indicator ' is turned on, the adjustment knob is rotated, and the grasping

pressure setting value is modified. After the setting is completed, the

adjustment knob is pressed to enter the opening pressure setting under

the gear.

When entering the opening pressure setting, the ' grasping adjustment

indicator ' is extinguished, the ' opening adjustment indicator ' is lit, the

adjustment knob is rotated, and the grasping pressure setting value is

modified. After the setting is completed, the adjustment knob is pressed

shortly, and the controller exits the pressure adjustment state.

Note : Initial state means : normal power supply, gas path seal, intake pressure to

meet the requirements, the controller without air pressure output state

2.3 Input-output

Input and output functions include inlet and outlet interface, power

interface and I / O interface.

Inlet port : INLET, suitable for external diameter of 10mm air pipe.

Outlet port : OUTLET, suitable for 6mm outside diameter air pipe.

Elctrical port : ELCTRICAL PORT, including power interface, input

SCB-PT

10

interface and output interface.

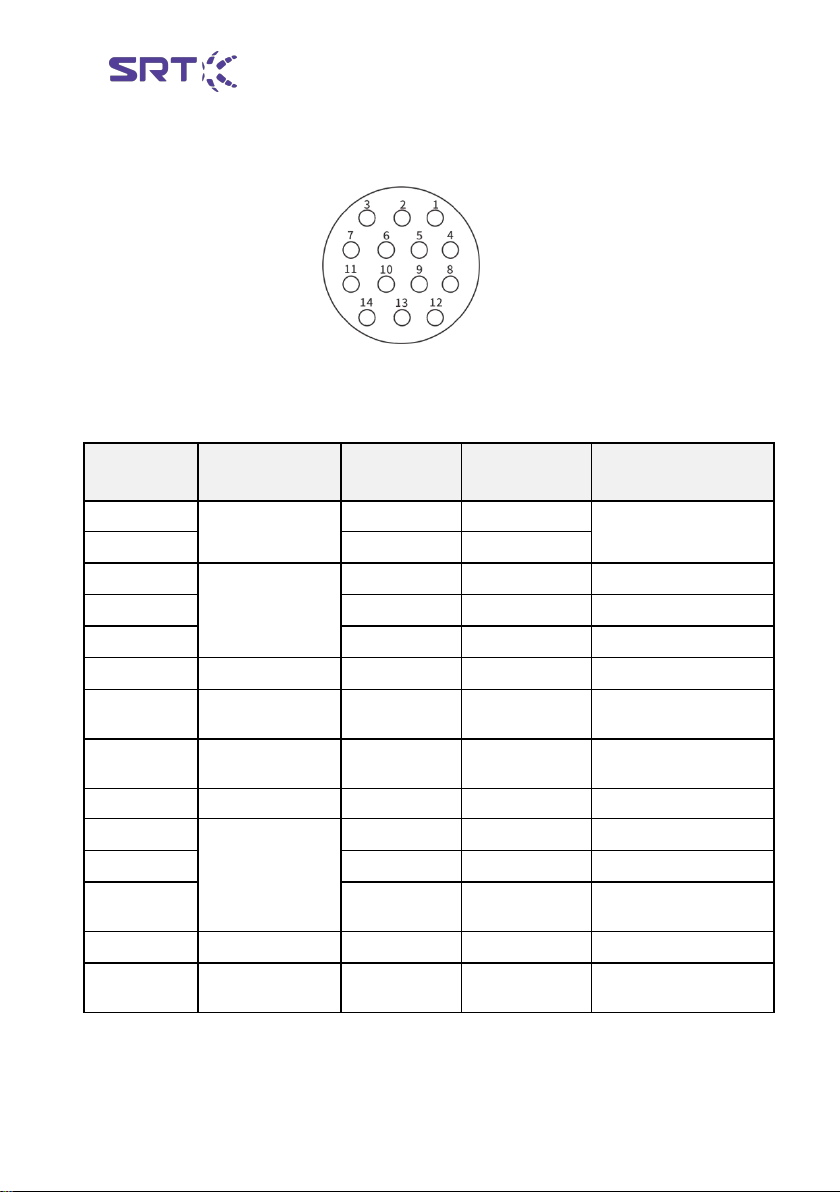

The aviation plug is 14-core cable with the label distribution as follows:

The corresponding relationship between cable and function is as

follows :

Cable color

Name

Aviation

plug cable

Name

Specifications

Red

DC power

supply port

1

24V+

DC 24V electric

support

Black

11

GND

Orange

Gear selection

port

6

IN-SW1

Gear position 1

Yellow

5

IN-SW2

Gear position 2

Brown

9

IN-SW3

Gear position 3

Cyan

Crab trigger port

13

IN-P

Grab trigger input

Green

Open the trigger

port

14

IN-N

Negative pressure

trigger input

Purple

Reset trigger

port

8

IN-RST

Reset trigger input

Grey

12

IN-COM

Input COM

Blue

Signal output

port

2

OUT-ERR

Alarm signal output

Pink

3

OUT-P

Grab complete output

Black and

white

10

OUT-N

Open finish output

White

4

OUT-COM

Output COM

Red and

white

7

NC

Normally closed port

SCB-PT

11

Function Description:

1) DC power supply port : voltage range DC24 ± 10 %, power rating

greater than 50W.

2) Gear selection port

There are eight editable stalls in the PT series controller, and eight sets of

different positive and negative pressure settings can be edited by

manual adjustment or PC software. Usage method : The IN-COM port

of the controller is connected to the output COM of the robot or PLC.

When the logical signals of SW1, SW2 and SW3 ports are 0, the first gear

is triggered. The pressure value of the clamping and opening of the end

fixture driven by the controller will be changed to the set value of the

first gear. When the logical signal of SW1 port is 1, and the logical

signals of SW2 and SW3 ports are 0, the gear 2 is triggered, and the

pressure value of grasping and opening the end fixture driven by the

controller will be changed to the set value of gear 2. File three to eight.

The trigger voltage range is DC24V ± 10 % and the current is more than

100mA. According to the working condition, the appropriate gear

position corresponding to the positive and negative pressure output

value can be selected. Compared with the table below, the I / O signal

triggering the gear position can be input, and the positive and negative

pressure trigger port can be combined to drive the end fixture to

complete the grab or open.

SCB-PT

12

Color/label

Brown/9

Yellow/5

Orange/6

Purple/8

Gear logic

signal port

IN-SW3

IN-SW2

IN-SW1

IN-COM

Gear 1

0

0

0

GND/VCC

Gear 2

0

0

1

GND/VCC

Gear 3

0

1

0

GND/VCC

Gear 4

0

1

1

GND/VCC

Gear 5

1

0

0

GND/VCC

Gear 6

1

0

1

GND/VCC

Gear 7

1

1

0

GND/VCC

Gear 8

1

1

1

GND/VCC

3) Grab, open and reset trigger ports:

The robot or PLC can output positive pressure, negative pressure,

maintenance and zero pressure by using I / O signal to control the outlet

interface of the controller through this port.

Usage : Connect the IN-COM port of the controller to the COM of the

output terminal of the control model of the robot or PLC. When the logic

signal of the IN-P port is 1, the controller performs the positive pressure

output and the end fixture is the grab state. When the IN-N logic

model is 1, the controller performs negative pressure output, and the

end fixture is open. When IN-P and IN-N are both 1, the controller

performs pressure relief action and the flexible gripper is in natural state.

When the reset port logic signal is 1, the controller is reset state, clear

alarm information, etc., and restore to the initial state.

SCB-PT

13

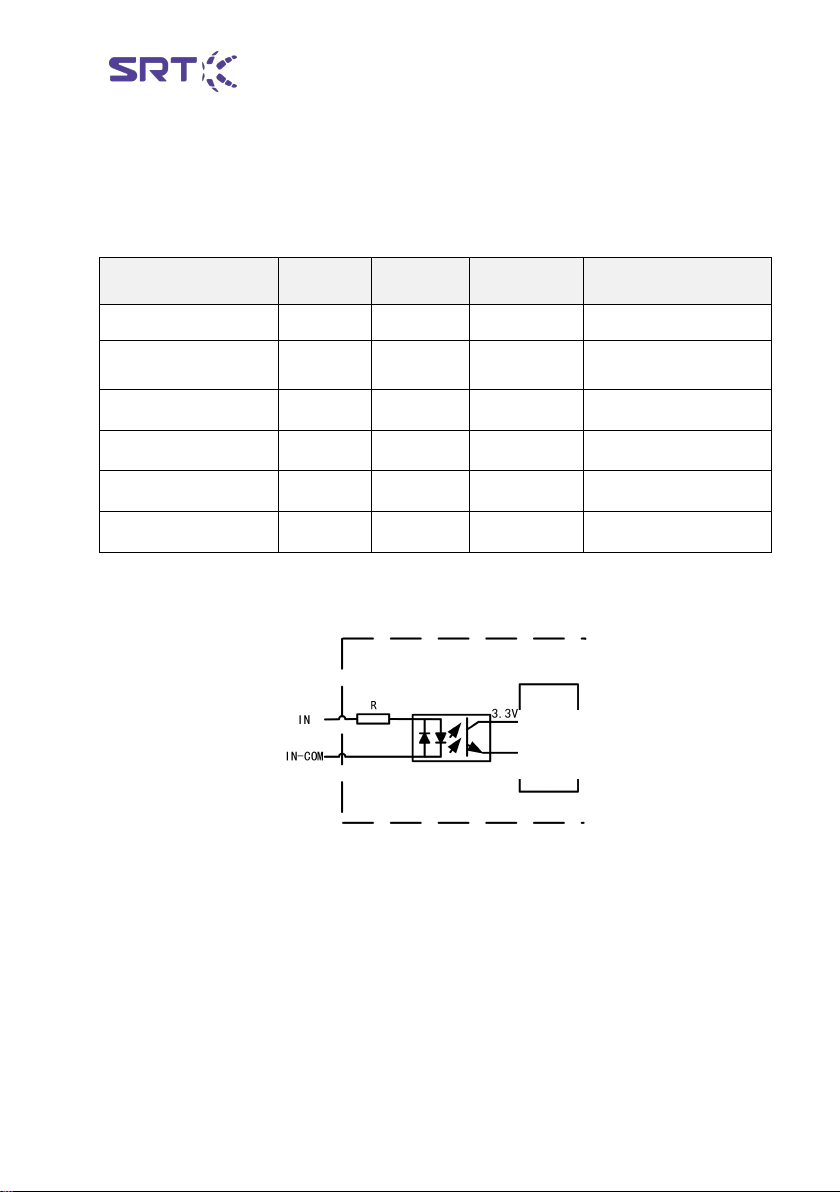

The schematic diagram of the input port is as follows :

The trigger voltage range is DC24V ± 10 % and the current is more than

100mA. The corresponding relationship between I / O signal and action

is as follows :

The schematic diagram of the input port is as follows :

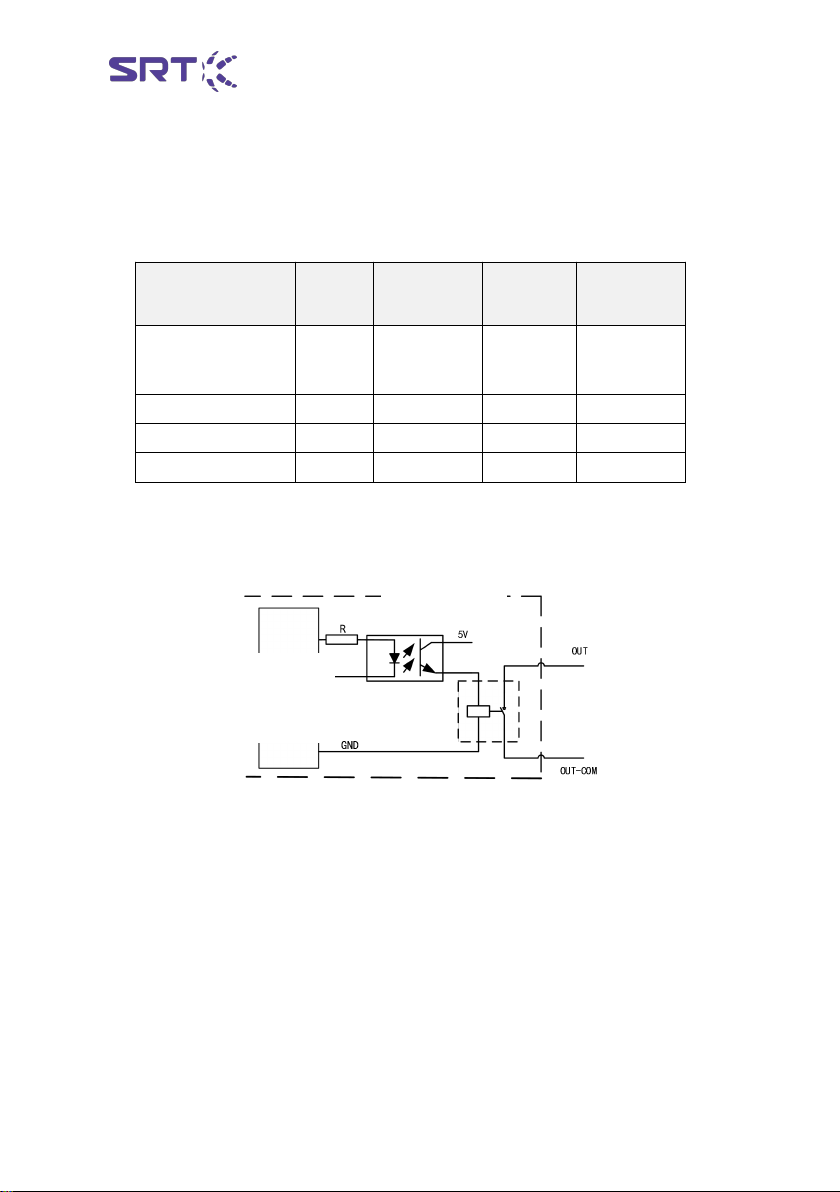

4) Signal output port:

Completed output : When the SCB-PT series controller detects that the

end fixture completes the grasping or opening action, the corresponding

port and OUT-COM will be turned on. Robot or PLC can judge whether

the end fixture completes the grasping or opening action by whether it is

turned on or not.

Alarm output : When the SCB-PT series controller detects the leakage of

Color/label

Cyan/13

Green/14

Purple/8

Gray/12

Gear logic signal port

IN-P

IN-N

IN-RST

IN-COM

Maintain current

state

0

0

0

GND/VCC

Grab action

1

1

0

GND/VCC

Open action

0

1

0

GND/VCC

Pressure relief action

1

1

0

GND/VCC

Reset

0

0

1

GND/VCC

Controller

main circuit

SCB-PT

14

the end fixture, the OUT-ERR port and OUT-COM port will be turned on.

Robot or PLC can judge whether the end fixture has leakage by whether

it

is turned on or not. Ports and functions correspond as follows :

The circuit schematic diagram of the output port is as follows :

Color/label

Pink/3

Black and

white/10

Blue/2

White/4

Gear logic signal

port

OUT-P

OUT-N

OUT-ERR

OUT-COM

Crab complete

1

0

0

GND/VCC

Open complete

0

1

0

GND/VCC

Alarm status

0

0

1

GND/VCC

Controller

main circuit

Internal controller

SCB-PT

15

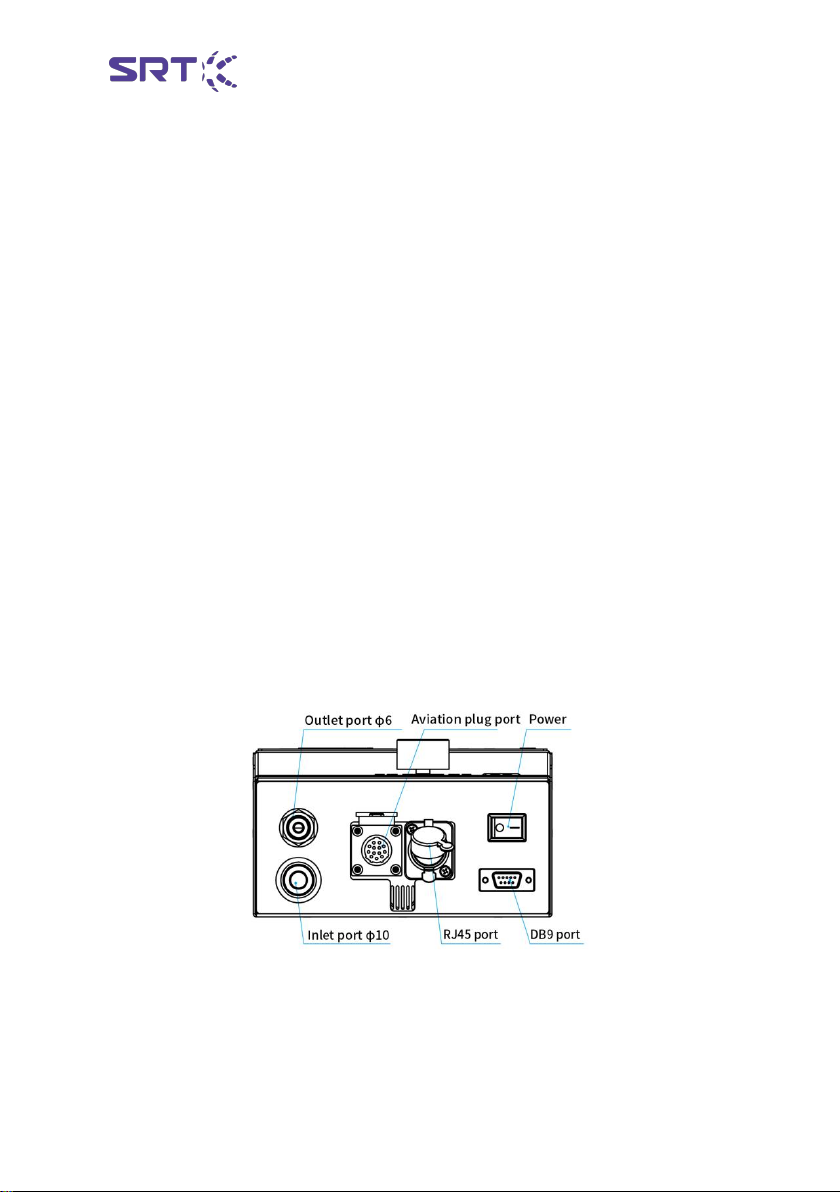

2.4 Communication function

SCB-PT series controller supports two communication interfaces : RJ45

and DB9. The location is as follows:

Among them : RJ45 interface supports MODBUS-TCP protocol. The

DB9 interface supports MODBUS-RTU protocol. Users can adjust voltage

and set editable files by connecting SRT voltage regulating software

through debugging lines, and can communicate through other control

devices. The communication protocol is referred to the 《SCB-PT series

controller communication protocol description》 document.

SCB-PT

16

3. Installation

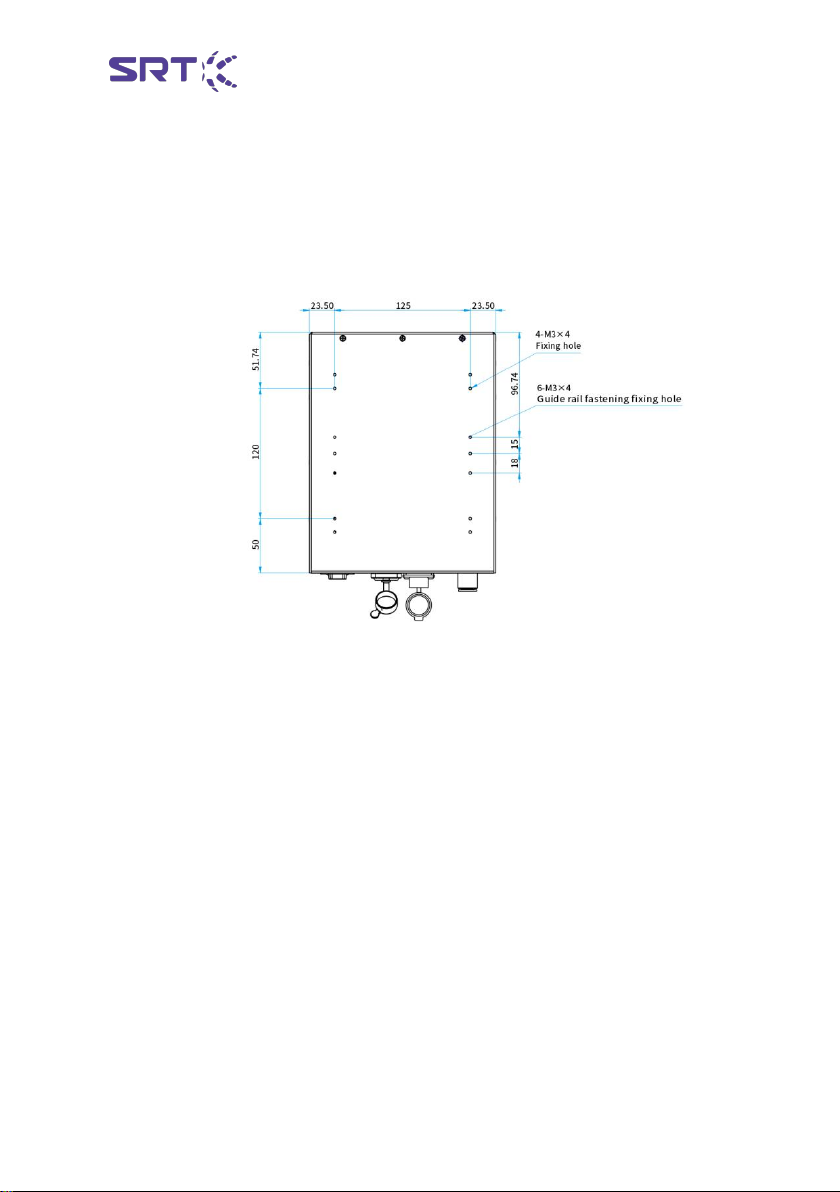

3.1 Installation fixed

The installation hole of SCB-PB series controller is located at the bottom

of the controller, and the size is as follows. Please use M3×4 bolts when

installing.

Installation Precautions :

1、 When the equipment is installed, ensure the equipment is installed

firmly.。

2、When fixing equipment, don 't squeeze equipment into or out of the

air tube or wire。

3、Please do not suspend the controller to a high position to avoid the

controller damage caused by falling.。

4、 Installation of controller grounding in special environment, such as

strong magnetic interference environment。

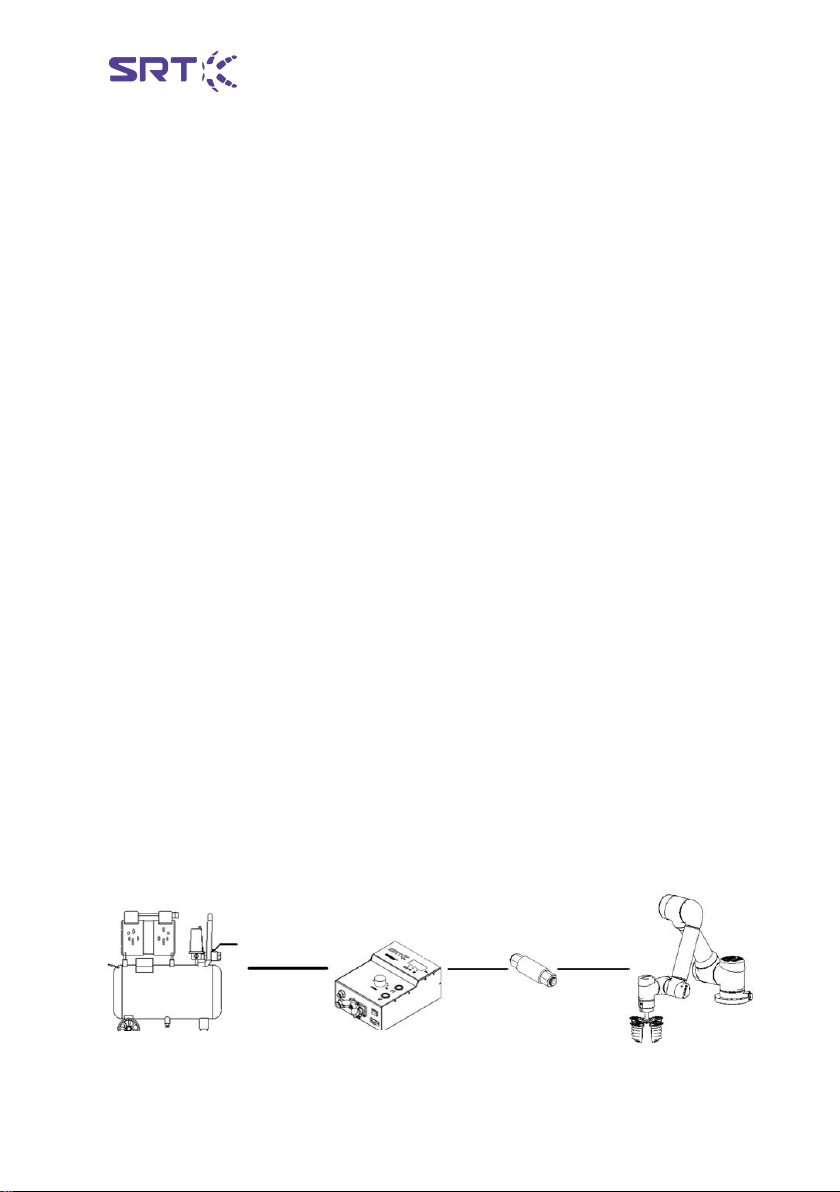

3.2 Pneumatic connection

Before pneumatic connection, SCB-PT series controller should be in a

safe position, fixed well, to prevent falling, not placed in the sealed box.

SCB-PT

17

Ensure φ 10mm inlet length is sufficient to reach the controller inlet

interface. The φ 6 mm outlet pipe should be connected to the end

fixture after the filter, and the total length is in the range of 3-5 m.

When the gas path is connected, it is ensured that the trachea is

completely inserted into the fast insertion joint. In the insertion process,

there is a clear sense of sudden frustration to prove that the gas path is

connected correctly. After opening the industrial gas source, twisting the

debugging switch, and running three to five times, it is ensured that the

gas path is connected well. If air leakage is found, the gas source and

power supply switch are shut down immediately, and after the air

leakage is eliminated, it can be continued to use.

Notes on Airway Connection:

1、Fully blow or wash the end, oil and dust of the pipe before piping.

2 、 When the controller is connected to the trachea, the bending and

blockage of the trachea are avoided as far as possible, otherwise it is

easy to cause the instability of the pneumatic system of the controller.

3、Do not make mistakes in product inlet and outlet.

4 、 Ensure the air tightness of the product outlet to the end actuator

trachea.

5、Series filter can ensure the service life of the end fixture and pneumatic

controller, and the filter should be between the controller and the end

fixture.

The following diagram is the schematic diagram of gas path connection

for SCB-PT series controllers:

Soft

φ10 pipe

SCB-PB Passive

pneumatic controller

Φ6 pipe

Φ6 pipe

Filter

Clean industrial

gas source

Table of contents

Popular Controllers manuals by other brands

Linak

Linak TD4 user manual

STA-RITE

STA-RITE SR6000S Installation & operation guide

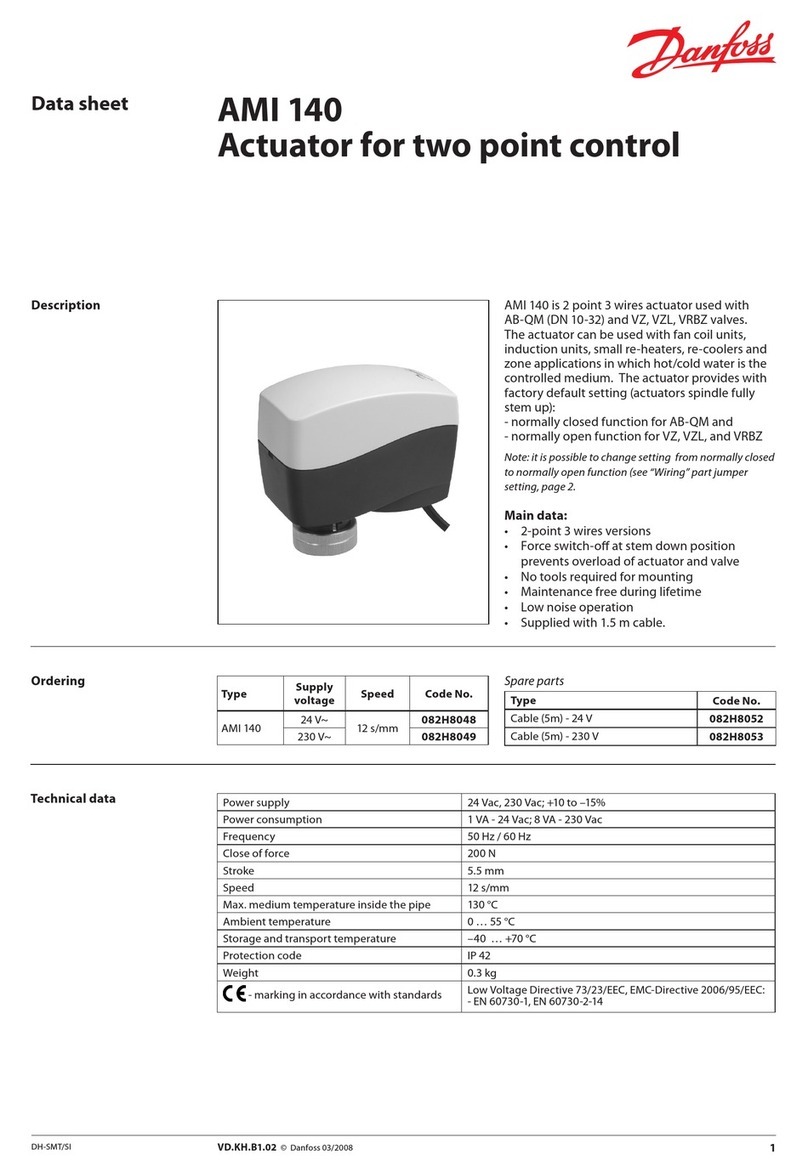

Danfoss

Danfoss AMI 140 Series datasheet

Carrier

Carrier 42EL Aqualia Installation, operation and maintenance instructions

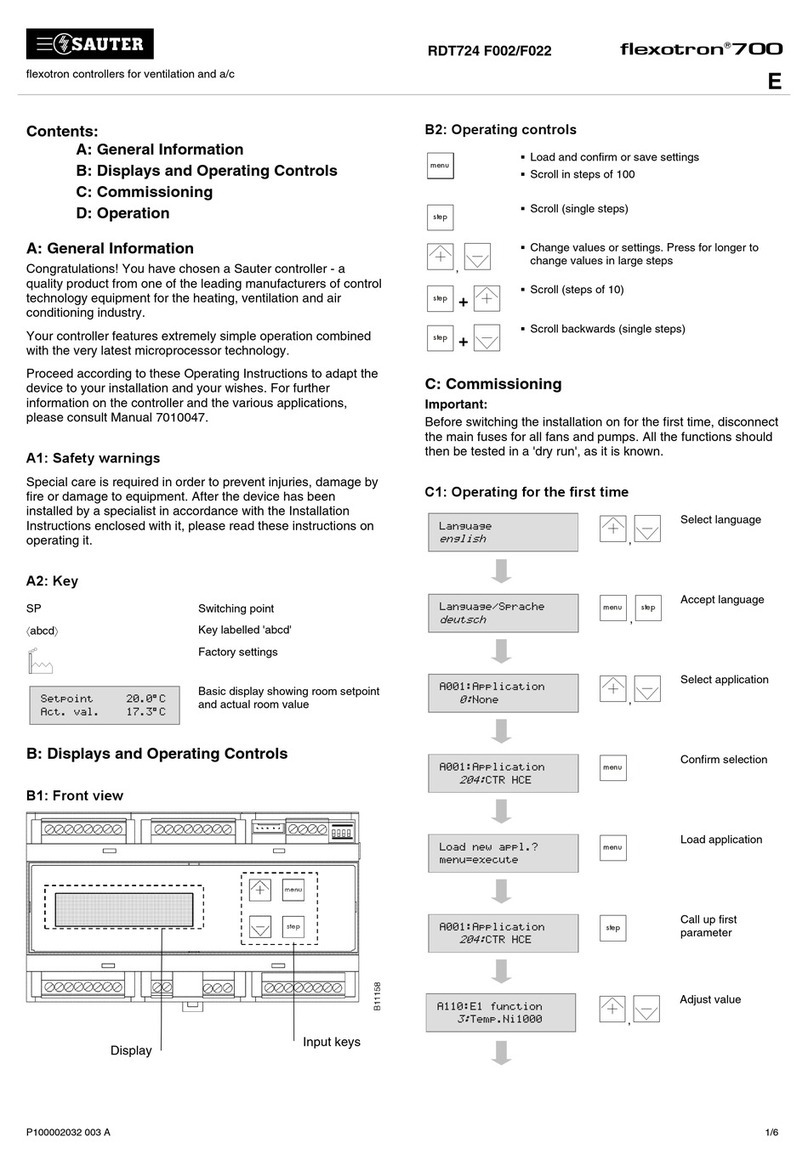

sauter

sauter flexotron 700 user manual

Keating Of Chicago

Keating Of Chicago 8 Product Cooking Controller IM-2000 Operating & programming manual

Valco Cincinnati

Valco Cincinnati MCP-25 user manual

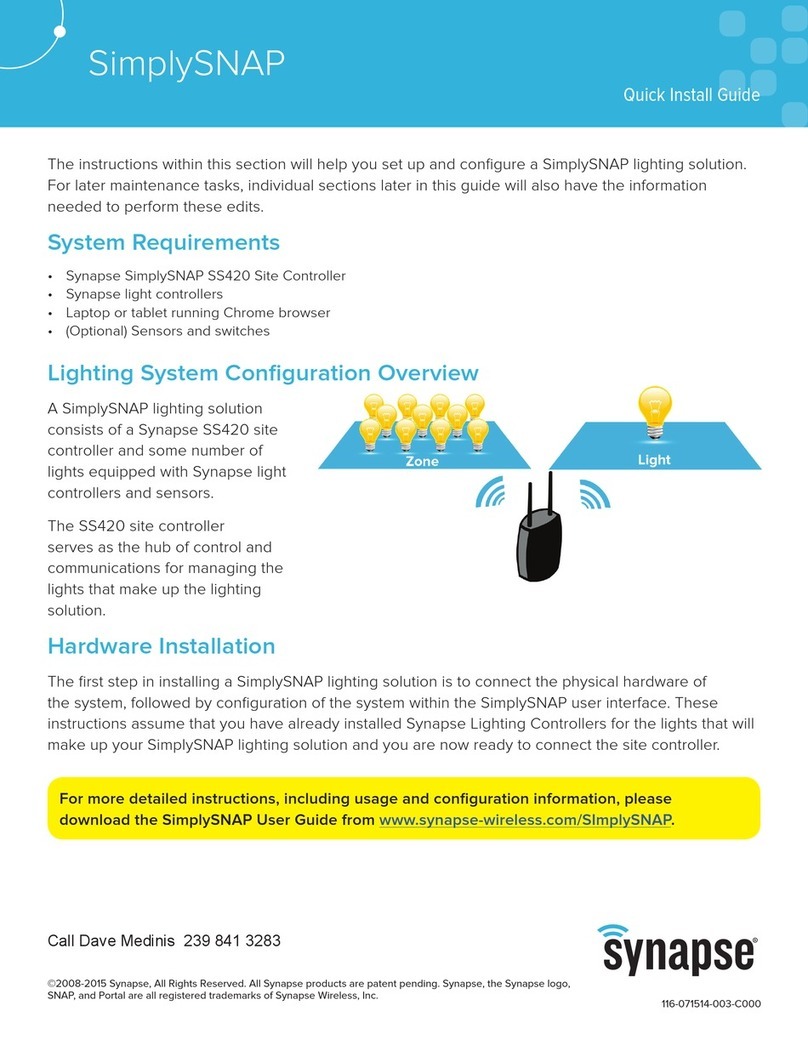

Synapse

Synapse SimplySNAP SS420 Quick install guide

LED Lights Canada

LED Lights Canada SP105E manual

Contrec

Contrec 515 BR03 Operation manual

Hanna Instruments

Hanna Instruments mV 602 Series instruction manual

Sturtevant Richmont

Sturtevant Richmont Global 400mp user manual