SSINVERTER SSI700 User manual

SSI700 User Manual

www.ssinverter.info

Preface

Thank you for purchasing the SSI700 series AC drive developed by SSINVERTER Co.,

Ltd.

The SSI700 series AC drive is a general-purpose current vector control AC drive. It is an

upgrade product based on SSI700 and can implement the control of asynchronous motor

It increases the user programmable function, back ground monitoring software and

communication bus function . It is used to drive various automation production equipment

involving textile, paper-making, wiredrawing, machine tool, packing, food, fan and pump.

This manual describes the correct use of the SSI700 series AC drive, including selection,

parameter setting, commissioning, maintenance & inspection. Read and understand the

manual before use and forward the manual to the end user.

Notes

• The drawings in the manual are sometimes shown without covers or protective guards.

Remember to install the covers or protective guards as specified first, and then perform

operations in accordance with the instructions.

• The drawings in the manual are shown for description only and may not match the product you

purchased.

• The instructions are subject to change, without notice, due to product upgrade, specification

modification as well as efforts to increase the accuracy and convenience of the manual.

• Contact our agents or customer service center if you have problems during the use.

Safety Information and Precautions

SSI700 User Manual

www.ssinverter.info

Introduction

Compared with SSI700, the SSI900 series AC drive incorporates the following

improvements:

1) Multiple voltage classes

It provides coverage of single-phase 220 V, three-phase 220 V, three-phase 380 V .

2) Control of asynchronous motor

It supports vector control of three-phase AC asynchronous motor.

3) Diversified control modes

It supports control modes, namely, sensorless flux vector control (SFVC) and V/F control.

4) communication protocols

It supports communication via Modbus-RTU .

5) Other new functions

The newly added functions of the SSI700 series AC drive are described as below:

Function Description

Virtual I/O It can implement various simple logic functions.

Rapid current limit It helps to avoid frequent occurrence of overcurrent faults of the

AC drive.

Function Description

Restoring user parameters It allows you to save or restore the parameters set by yourself.

Higher-accuracy AI/AO The AI/AO accuracy can reach almost 20 mv via factory

correction or on-site correction.

Customized parameter

display You can customize the parameters that need to be displayed.

Modified parameter display You can view the modified parameters.

Operation selection at fault

occurrence

You can select the reaction of the AC drive to a fault occurring,

based on the actual need. The reactions are as below:

• Coast to stop

• Decelerate to stop

• Continue to run

You can also select the frequency at which the AC drive

continues to run.

PID parameters switchover Two groups of PID parameters can be switched over via

terminals or can be automatically switched over according to

deviation.

PID feedback loss detection The PID feedback loss value can be set to realize PID

protection.

DI/DO positive or negative

logic You can set the DI/DO positive or negative logic.

DI/DO response delay You can set DI/DO response delay time.

Power dip ride through It ensures that the AC drive continues to run for a short time

when an instantaneous power failure or sudden voltage

reduction occurs.

Timing operation The AC drive supports timing operation for 6500 minutes at

maximum.

SSI700 User Manual

www.ssinverter.info

Product Checking

Upon unpacking, check:

• Whether the nameplate model and AC drive ratings are consistent with your

order. The box contains the AC drive, certificate of conformity, user manual and

warranty card.

• Whether the AC drive is damaged during transportation. If you find any

omission or damage, contact Ssinverter or your supplier immediately.

First-time Use

For the users who use this product for the first time, read the manual carefully. If in doubt

concerning some functions or performances, contact the technical support personnel of

Ssinverter to ensure correct use.

CE Mark

The CE mark on the declares that the AC drive complies with the European low voltage

directive (LVD) and EMC directive.

The SSI700 series AC drive complies with the following LVD and EMC directives and

standards:

The SSI700 series AC drive complies with the requirements of standard IEC/EN 61800-3

on the condition of correct installation and use by following the instructions in chapter 7.

Contents

Preface 1

Introduction 2

Chapter 1 Safety Information and Precautions

1.1 Safety Information

1.2 General Precautions

1

3

Chapter 2 Product Information

2.1 Designation Rules and Nameplate of the SSI700

2.2 Components of the SSI700

2.3 Technical Specifications

2.4 Peripheral Electrical Devices and System Configuration

1

1

1

3

Chapter 3 Mechanical and Electrical Installation

3.1 Mechanical Installation

3.2 Electrical Installation

1

2

Chapter 4 Operation, Display and Application Examples

4.1 Operation Panel

4.2 Viewing and Modifying Function Codes

4.3 Definition and Operation of the Multifunction Key (APP)

4.4 Viewing Status Parameters

4.5 Starting or Stopping the AC Drive

4.6 Setting the Running Frequency

4.7 Setting and Auto-tuning of Motor Parameters

4.8 Use of DI Terminals

4.9 Use of DO Terminals

4.10 Use of AI Terminals

1

2

3

3

6

11

17

19

20

20

SSI700 User Manual

www.ssinverter.info

4.11 Use of AO Terminals

4.12 Use of Serial Communication

4.13 Password Setting

4.14 Parameter Saving and Default Setting Restoring

20

21

21

22

Chapter 5 Function Code Table

5 Standard Function Parameters

1

Chapter 6 Description of Function Codes

Group P0: Basic Parameters

Group P1: Motor 1 Parameters

Group P2: Vector Control Parameters

Group P3: V/F Control Parameters

Group P4: Input Terminals

Group P5: Output Terminals

Group P6: Start/Stop Control

Group P7: Operation Panel and Display

Group P8: Auxiliary Functions

Group P9: Fault and Protection

Group 10: Process Control PID Function

Group 11: Swing Frequency, Fixed Length and Count

Group 12: Multi-Reference and Simple PLC Function

Group 13: Point-point Communication

Group 16: User Password

Group 17: Torque Control and Restricting Parameters

1

9

10

13

15

23

27

32

37

47

53

58

60

63

63

64

Chapter 7 EMC

7.1 Definition of Terms

7.2 Introduction to EMC Standard

7.3 Selection of Peripheral EMC Devices

7.4 Shielded Cable

7.5 Solutions to Common EMC Interference Problems

1

1

2

3

5

Chapter 8 Selection and Dimensions

8.1 Electrical Specifications of the SSI700

8.2 Physical Appearance and Overall Dimensions of the SSI700

8.3 Physical Dimensions of External Operation Panel

8.4 Selection of Braking Resistor

1

1

2

3

Chapter 9 Maintenance and Troubleshooting

9.1 Routine Repair and Maintenance of the SSI700

9.2 Warranty Agreement

9.3 Faults and Solutions

9.4 Common Faults and Solutions

1

2

2

5

Product Information

SSI700 User Manual Product Information

www.ssinverter.info

Chapter 2 Product Information

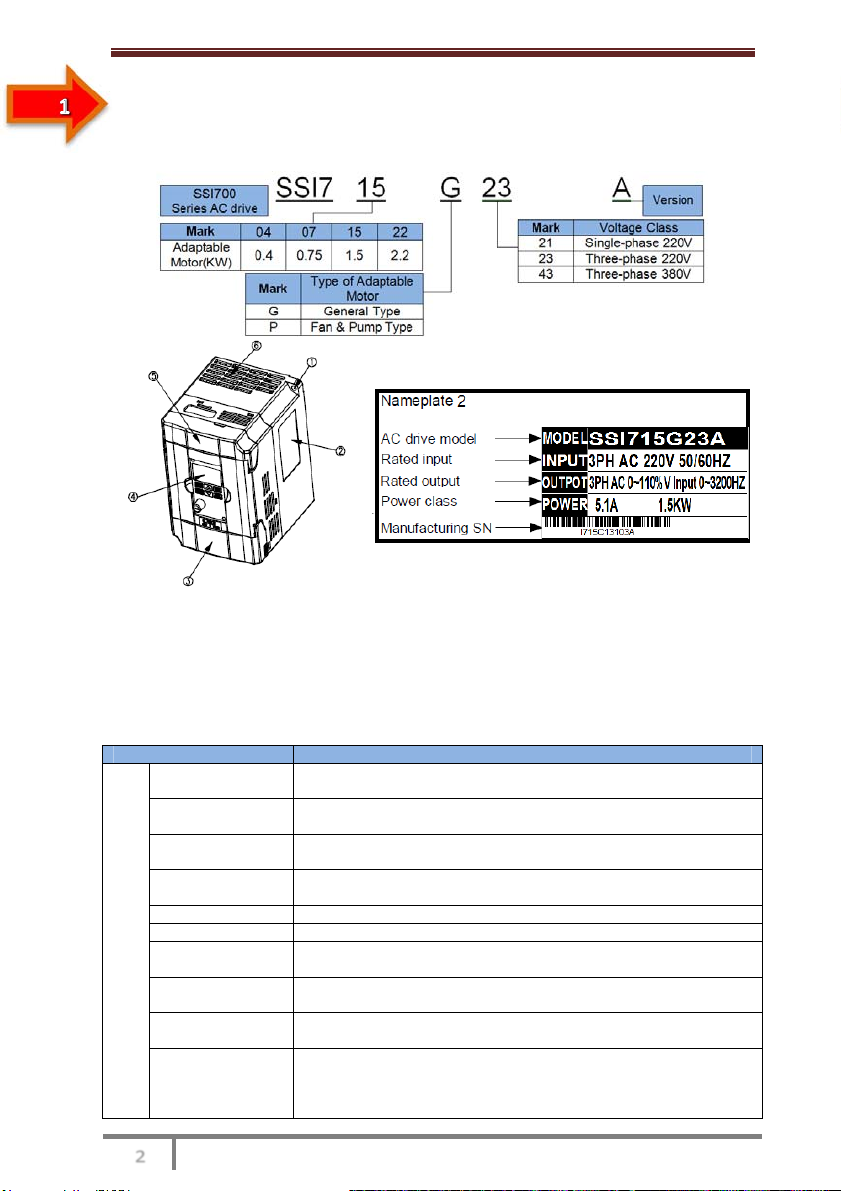

2.1 Designation Rules and Nameplate of the SSI700

Figure 2-1 Designation rules and nameplate of the SSI700

2.2 Components of the SSI700

The SSI700 series AC drives have two housing types, plastic housing according to

different voltage and power classes.

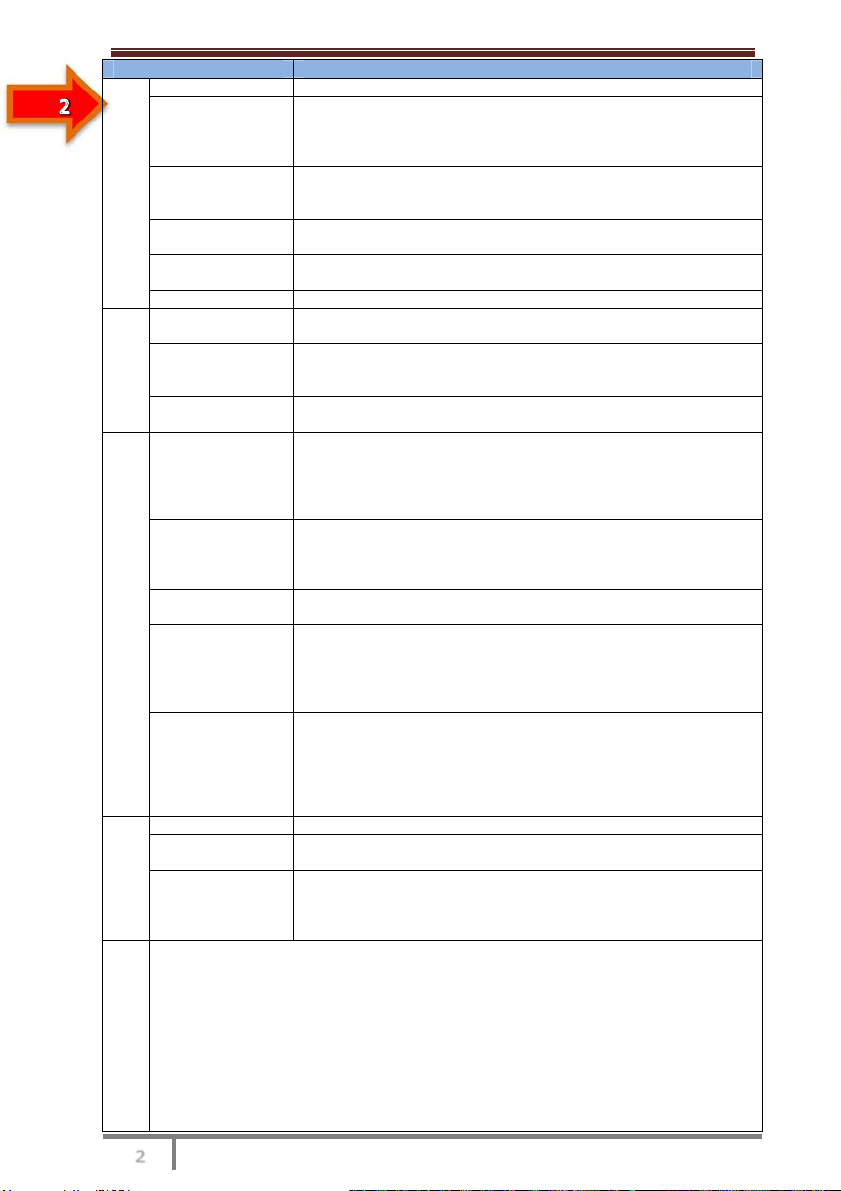

2.3 Technical Specifications

Table 2-1 Technical specifications of the SSI700

Item Specifications

Standard

functions

Maximum

frequency • Vector control: 0–320 Hz

• V/F control: 0–3200 Hz

Carrier frequency 0.5–16 kHz The carrier frequency is automatically adjusted based

on the load features.

Input frequency

resolution Digital setting: 0.01 Hz

Analog setting: maximum frequency x 0.025%

Control mode • Sensorless flux vector control (SFVC)

• Voltage/Frequency (V/F) control

Startup torque • G type: 0.5 Hz/150% (SFVC)

Speed range 1:100 (SFVC)

Speed stability

accuracy • ± 0.5% (SFVC)

Overload capacity • G type: 60s for 150% of the rated current, 3s for 180% of the

rated current

Torque boost • Fixed boost

• Customized boost 0.1%–30.0%

V/F curve

• Straight-line V/F curve

• Multi-point V/F curve

• N-power V/F curve (1.2-power, 1.4-power, 1.6-power, 1.8-power,

square)

SSI700 User Manual Product Information

www.ssinverter.info

Item Specifications

Standard

functions

V/F separation Two types: complete separation; half separation

Ramp mode

• Straight-line ramp

• S-curve ramp

Four groups of acceleration/deceleration time with the range of

0.0–6500.0s

DC braking DC braking frequency: 0.00 Hz to maximum frequency

Braking time: 0.0–36.0s

Braking action current value: 0.0%–100.0%

JOG control JOG frequency range: 0.00–50.00 Hz

JOG acceleration/deceleration time: 0.0–6500.0s

Onboard multiple

preset speeds It implements up to 16 speeds via the simple PLC function or

combination of DI terminal states.

Onboard PID It realizes process-controlled closed loop control system easily.

Individualized

functions

Auto voltage

regulation (AVR) It can keep constant output voltage automatically when the mains

voltage changes.

Overvoltage/

Overcurrent stall

control

The current and voltage are limited automatically during the

running process so as to avoid frequent tripping due to

overvoltage/overcurrent.

Torque limit and

control It can limit the torque automatically and prevent frequent over

current tripping during the running process.

RUN

Running

command source

• Operation panel

• Control terminals

• Serial communication port

You can perform switchover between these sources in various

ways.

Frequency source

There are a total of 10 frequency sources, such as digital

setting, analog voltage setting, analog current setting, pulse

setting and serial communication port setting. You can perform

switchover between these sources in various ways.

Auxiliary

frequency source There are ten auxiliary frequency sources. It can implement fine

tuning of auxiliary frequency and frequency synthesis.

Input terminal

5 digital input (DI) terminals, one of which supports up to 100 kHz

high-speed pulse input

2 analog input (AI) terminals, one of which only supports 0–10 V

voltage input and the other supports 0–10 V voltage input or 4–20

mA current input.

Output terminal

1 high-speed pulse output terminal (open-collector) that supports

0–100 kHz square wave signal output

1 digital output (DO) terminal

1 relay output terminal

1 analog output (AO) terminal that supports 0–20 mA current

output or 0–10 V voltage output

Display and

operation

LED display It displays the parameters.

Key locking and

function selection It can lock the keys partially or completely and define the

function range of some keys so as to prevent mis-function.

Protection mode

Motor short-circuit detection at power-on, output phase loss

protection, overcurrent protection, overvoltage protection,

undervoltage protection, overheat protection and overload

protection

Enironment

Installation location: Indoor, free from direct sunlight, dust, corrosive gas, combustible

gas, oil smoke, vapour, drip or salt.

Altitude: Lower than 1000 m

Ambient temperature: -10°C to +40°C (de-rated if the ambient temperature is between

40°C and 50°C)

Humidity: Less than 95%RH, without condensing

Vibration: Less than 5.9 m/s2 (0.6 g)

Storage temperature: -20°C to +60°C

IP level: IP20

Pollution degree: PD2

Power distribution System: TN , TT

SSI700 User Manual Product Information

www.ssinverter.info

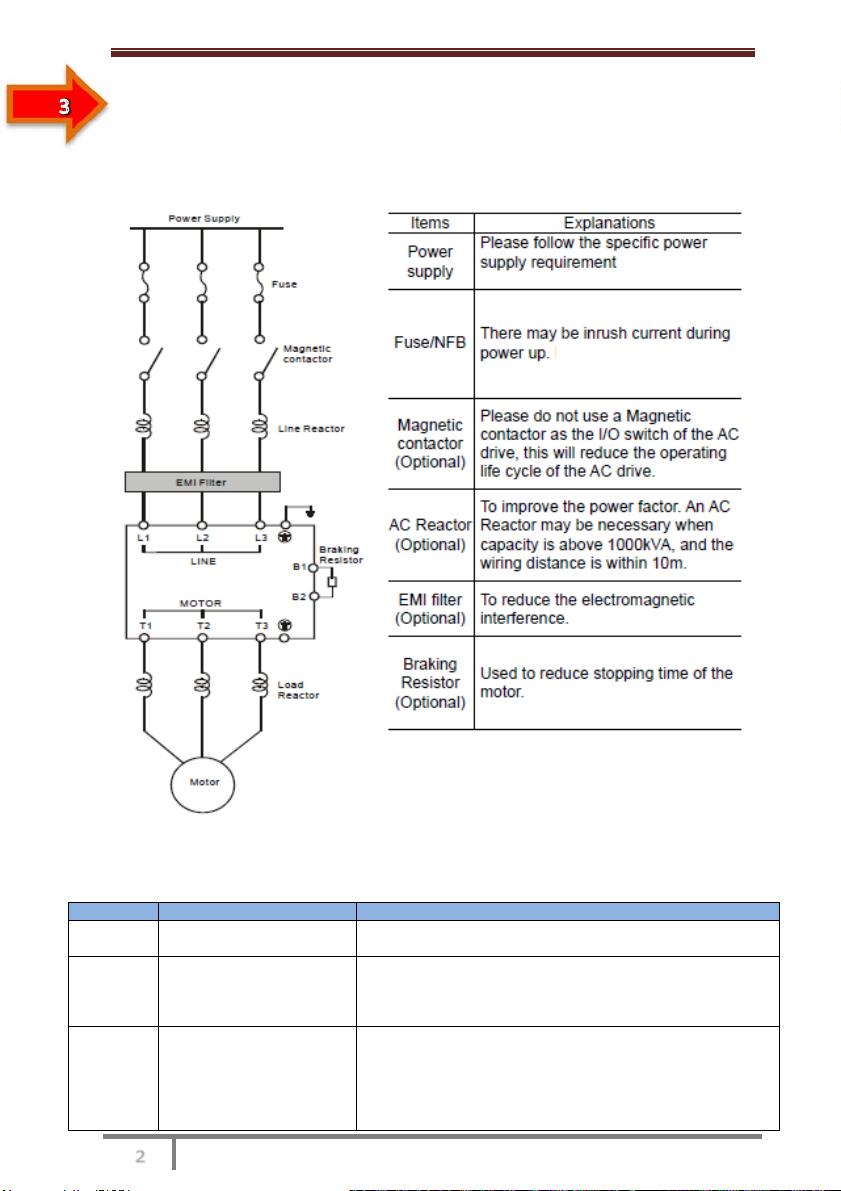

2.4 Peripheral Electrical Devices and System Configuration

When the SSI700 is used to control the synchronous or asynchronous motor, forming a

control system, it is necessary to install various electrical devices on the input and output

sides of the AC drive to ensure the system safety and stability.

Figure 2-2 System configuration of three-phase 220 V/380 V voltage class, 2.2 Kw and

above

2.4.1 Description of Peripheral Electrical Devices

Table 2-2 Description of peripheral electrical devices

Part Mounting Location Function Description

MCCB Power receiving side Interrupt the power supply when overcurrent occurs on

down stream devices

Contactor Between MCCB and

AC drive input side

Start and stop the AC drive.

Do not start and stop the AC drive frequently by switching

the contactor on and off (less than twice per minute) nor use

it to directly start the AC drive.

AC input

reactor AC drive input side

• Improve the power factor of the input side.

• Eliminate the higher harmonics of the input side effectively

and prevent other devices from being damaged due to

distortion of the voltage waveform.

• Eliminate the input current unbalance due to unbalance

between the power phases.

SSI700 User Manual Product Information

www.ssinverter.info

Part Mounting Location Function Description

EMC

Input filter AC drive input side

• Reduce the external conduction and radiation interference

of the AC drive.

• Decrease the conduction interference flowing from the

power end to the AC drive and improve the anti interference

capacity of the AC drive.

AC output

reactor

Between AC drive output

side and the motor, close

to the AC drive

The output side of the AC drive generally has much higher

harmonics. When the motor is far from the AC drive, there is

much distributed capacitance in the circuit and certain

harmonics may cause resonance in the circuit, bringing

about the following two impacts:

• Degrade the motor insulation performance and damage

the motor in the long run.

• Generate large leakage current and cause frequent AC

drive protection trips.

If the distance between the AC drive and the motor is

greater than 50 m, install an AC output reactor.

1) Do not install the capacitor or surge suppressor on the output side of the AC drive.

Otherwise, it may cause faults to the AC drive or damage to the capacitor and surge

suppressor.

2) Inputs/Outputs (main circuit) of the AC drive contain harmonics, which may interfere

with the communication device connected to the AC drive. Therefore, install an anti-

interference filter to minimize the interference.

3) For more details on peripheral devices, refer to related selection manual.

2.4.2 Description of Optional Parts

The optional parts include braking unit of different functions and external operation panel,

etc. If any optional part is required, specify it in your order.

Table 2-3 Optional parts of the SSI700

Name Model Function Remark

Internal

braking unit

AC drive

model

followed

The models of single-phase

(0.4–2.2 kW) and three-phase

(0.75–15 kW) are installed with the

internal braking unit as standard

configuration.

Internal braking unit.

External LED

operation

panel panel It supports LED display and operations. It applies to the SSI700

series AC drives.

Mechanical and Electrical Installation

SSI700 User Manual Mechanical and Electrical Installation

www.ssinverter.info

Chapter 3 Mechanical and Electrical Installation

3.1 Mechanical Installation

3.1.1 Installation Environment Requirements

Item Requirements

Ambient temperature -10°C to +50°C

Heat dissipation

Install the AC drive on the surface of an incombustible object, and

ensure that there is sufficient space around for heat dissipation.

Install the AC drive vertically on the support using screws.

Mounting location

Free from direct sunlight, high humidity and condensation

Free from corrosive, explosive and combustible gas

Free from oil dirt, dust and metal powder

Vibration Less than 0.6 g

Far away from the punching machine or the like

Protective enclosure

The SSI700 series AC drives of plastic housing are the whole unit

built-in products operated through remote control and need to be

installed in the final system.The final system must have the required

fireproof cover, electrical protective cover and mechanical protective

cover, and satisfy the regional laws & regulations and related IEC

requirements.

3.1.2 Installation Clearance Requirements

The clearance that needs to be reserved varies with the power class of the SSI700, as

shown in the following figure.

Figure 3-1 Clearance around the SSI700 for installation

The SSI700 series AC drive dissipates heat from the bottom to the top. When multiple AC

drives are required to work together, install them side by side.

For application installing multiple AC drives, if one row of AC drives need to be installed

above another row, install an insulation guide plate to prevent AC drives in the lower row

from heating those in the upper row and causing faults.

SSI700 User Manual Mechanical and Electrical Installation

www.ssinverter.info

■ Installation Precautions

1) Reserve the installation clearances as specified in Figure 3-1 to ensure sufficient space

for heat dissipation. Take heat dissipation of other parts in the cabinet into consideration.

2) Install the AC drives upright to facilitate heat dissipation. If multiple AC drives are

installed in the cabinet, install them side by side. If one row of AC drives need to be

installed above another row, install an insulation guide plate .

3) Use incombustible hanging bracket.

3.2 Electrical Installation

3.2.1 Description of Main Circuit Terminals

■ Description of Main Circuit Terminals of Three-phase AC drive

SSI700 User Manual Mechanical and Electrical Installation

www.ssinverter.info

Table 3-1 Description of main circuit terminals of three-phase AC drive

Terminal Name Description

R, S , T Three-phase power supply

input terminals

Connect to the single-phase 220 VAC power

supply.

B1, B2 Connecting terminals of

braking resistor

Connect to the braking resistor for the AC drive of

2.2 kW and below (220 V) and 7.5 kW and below

(other voltage classes).

U, V, W AC drive output terminals Connect to a three-phase motor.

Grounding terminal Must be grounded.

3.2.2 Wiring of AC Drive Main Circuit

■ Precautions on the Wiring

1) Power input terminals R, S, T

– The cable connection on the input side of the AC drive has no phase sequence

requirement.

– The specification and installation method of external power cables must comply with the

local safety regulations and related IEC standards.

– Use copper conductors of a proper size as power cables according to the recommended

values in section 8.3.

2) Braking resistor connecting terminals B1 , B2

– The connecting terminals of the braking resistor are effective only for the AC configured

with the built-in braking unit.

– The cable length of the braking resistor shall be less than 5 m. Otherwise, it may

damage the AC drive.

3) AC drive output terminals U, V, W

– The specification and installation method of external power cables must comply with the

local safety regulations and related IEC standards.

– Use copper conductors of a proper size as power cables according to the recommended

values in section 8.3.

– The capacitor or surge absorber cannot be connected to the output side of the AC drive.

Otherwise, it may cause frequent AC drive fault or even damage the AC drive.

– If the motor cable is too long, electrical resonance will be generated due to the impact of

distributed capacitance. This will damage the motor insulation or generate higher leakage

current, causing the AC drive to trip in overcurrent protection. If the motor cable is greater

than 100 m long, an AC output reactor must be installed close to the AC drive.

4) Terminal PE

– This terminal must be reliably connected to the main earthing conductor. Otherwise, it

may cause electric shock, mal-function or even damage to the AC drive.

– Do not connect the earthing terminal to the neutral conductor of the power supply.

– The impedance of the PE conductor must be able to withstand the large shortcircuit

current that may arise when a fault occurs.

– Select the size of the PE conductor according to the following table:

Cross-sectional Area of a

Phase Conductor (S)

Min. Cross-sectional Area of

Protective Conductor (Sp)

S ≤16 mm2S

16 mm2 < S ≤35 mm216 mm2

35 mm2 < S S/2

SSI700 User Manual Mechanical and Electrical Installation

www.ssinverter.info

– You must use a yellow/green cable as the PE conductor.

5) Requirements on upstream protection device

– Install upstream protection device on the input power circuit. The protection device must

provide the protections on overcurrent, short-circuit and electrical solation.

– When selecting the protective device, you should consider the current capacity of the

power cable, system overload capacity and short-circuit capacity of the upstream power

distribution of the equipment. Generally, make selection according to the recommended

values in section 8.4.

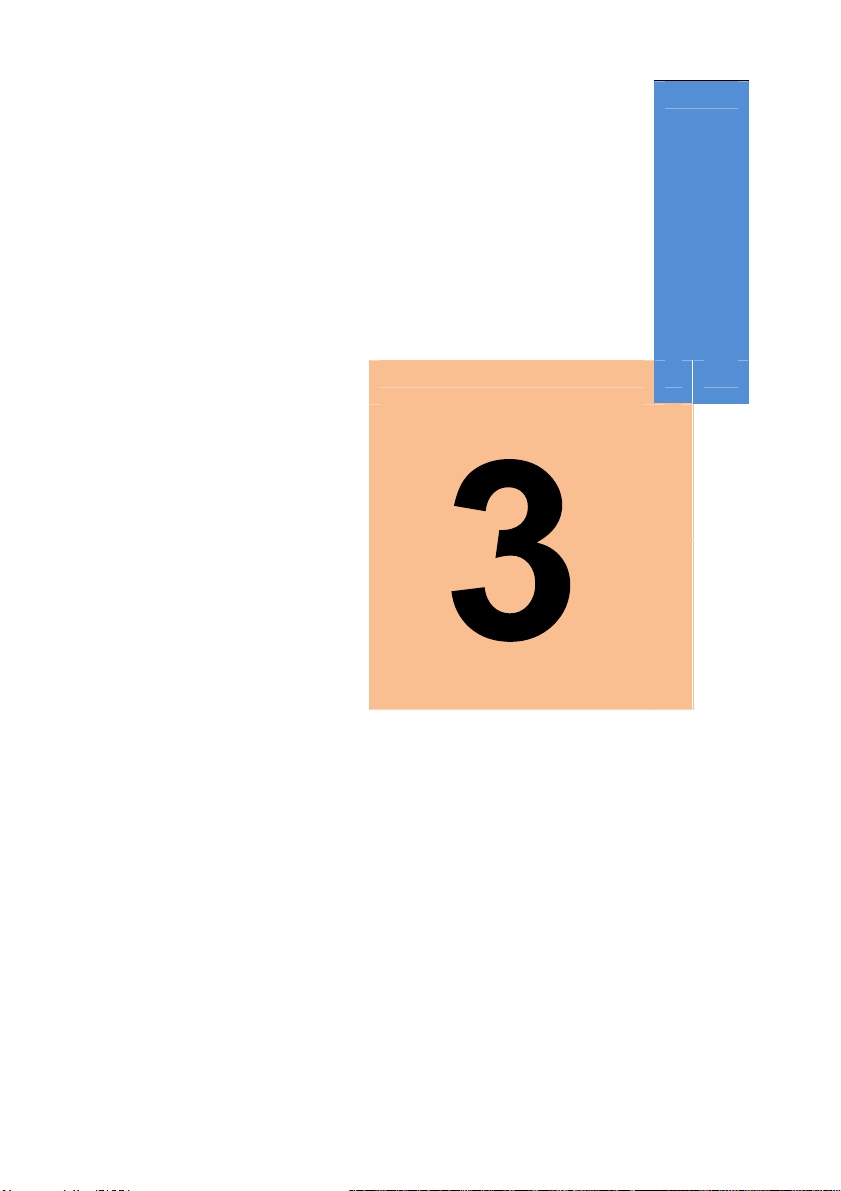

3.2.3 Description of Control Circuit Terminals

[

■ Terminal Arrangement of Control Circuit

■ Description of Control Circuit Terminals

Table 3-3 Description of control circuit terminals

Type Terminal Name Function Description

Power supply

+10V-GND External +10 V

power supply

Provide +10 V power supply to external unit.

Generally, it provides power supply to external

potentiometer with resistance range of 1–5 kΩ.

Maximum output current: 10 mA

+24V-COM External +24V

power supply

Provide +24 V power supply to external unit.

Generally, it provides power supply to DI/DO

terminals and external sensors.

Maximum output current: 20 mA

Connect to +24 V by default.

Analog

input

AI1-GND Analog input 1

Input voltage range: 0–10 VDC

Impedance: 22 kΩ

AI2-GND Analog input 2

Input range: 0–10 VDC/4–20 mA, decided by

jumper J8 on the control board Impedance:

22kΩ(voltage input), 500 Ω(current input)

Digital input

DI1 Digital input 1

Optical coupling isolation, compatible with dual

polarity input Impedance: 2.4 kΩ

Voltage range for level input: 9–30 V

DI2 Digital input 2

DI3 Digital input 3

DI4 Digital input 4

DI5 High-speed

pulse input

Besides features of DI1–DI4 and DI6, it can be

used for high-speed pulse input.

Maximum input frequency: 100 kHz

Analog

output

AO1-GND Analog output 1

Voltage or current output is decided by jumper

J5.

Output voltage range: 0–10 V

Output current range: 0–20 mA

SSI700 User Manual Mechanical and Electrical Installation

www.ssinverter.info

Type Terminal Name Function Description

Digital output

DO1-CME Digital output 1

Optical coupling isolation, dual polarity open

collector output

Output voltage range: 0–24 V

Output current range: 0–50 mA

Note that CME and COM are internally

insulated, but they are shorted by jumper

externally. In this case DO1 is driven by +24 V

by default. If you want to drive DO1 by external

power supply, remove the jumper.

FM- CME High-speed

pulse output

It is limited by P5-00 (FM terminal output mode

selection). As high-speed pulse output, the

maximum frequency hits 100 kHz.

As open-collector output, its specification is the

same as that of DO1

Relay

output

T/A-T/B NC terminal Contact driving capacity:

250 VAC, 3 A, COSø = 0.4

30 VDC, 1 A

Applying to Overvoltage Category II circuit

T/A-T/C NO terminal

COM Digital grounding Please use twisted pair cable or screening wire

3.2.4 Wiring of AC Drive Control Circuit

Figure 3-3 Wiring mode of the AC drive control circuit

Note

• All SSI700 series AC drives have the same wiring mode. The figure here shows the wiring of

Three-phase 220~380 VAC drive. ◎ indicates main circuit terminal, while ○ indicates control

circuit terminal.

SSI700 User Manual Mechanical and Electrical Installation

www.ssinverter.info

■ Description of Wiring of Signal Terminals

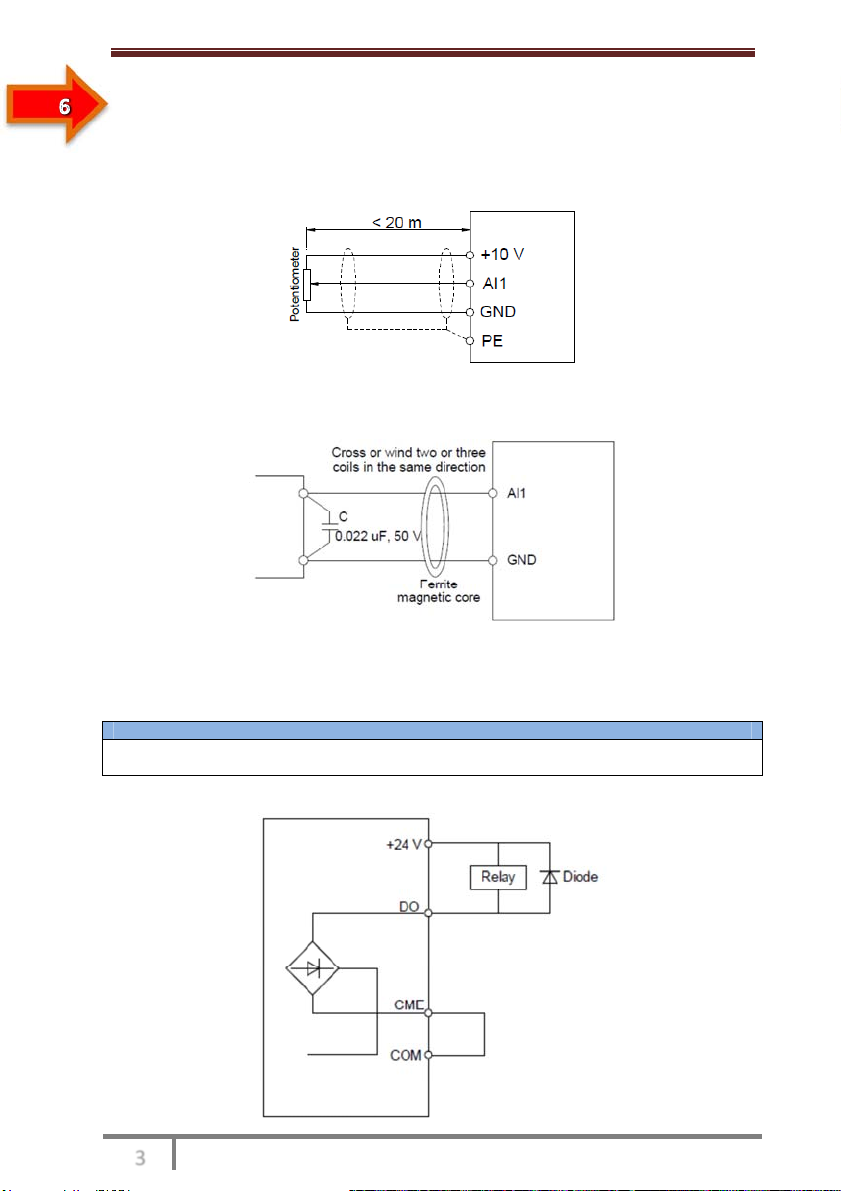

1) Wiring of AI terminals

Weak analog voltage signals are easy to suffer external interference, and therefore the

shielded cable must be used and the cable length must be less than 20 m, as shown in

following figure.

Figure 3-4 Wiring mode of AI terminals

In applications where the analog signal suffers severe interference, install filter capacitor

or ferrite magnetic core at the analog signal source.

Figure 3-5 Install filter capacitor or ferrite magnetic core

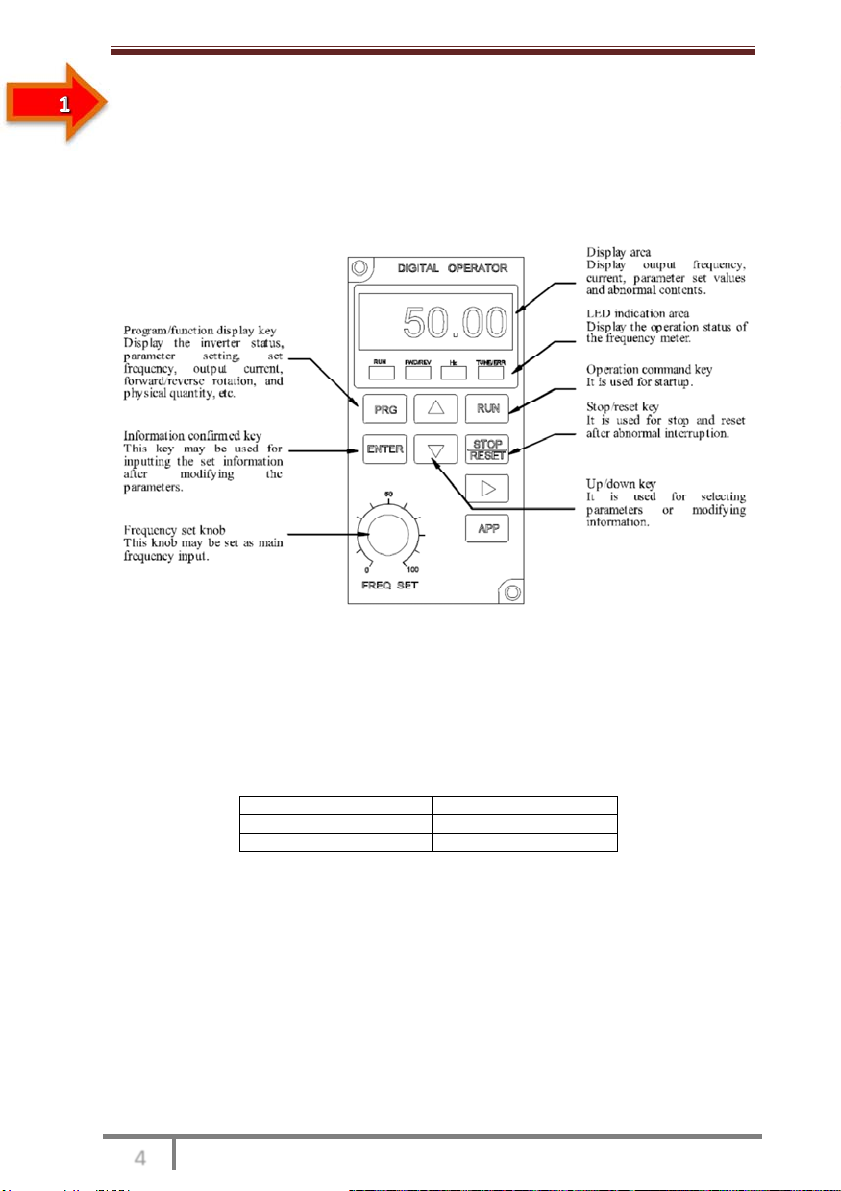

2) Wiring of DO terminal

When the digital output terminal needs to drive the relay, an absorption diode shall be

installed between two sides of the relay coil. Otherwise, it may cause damage to the

24 VDC power supply. The driving capacity is not more than 50 mA.

Note

Do not reverse the polarity of the absorption diode during installation, as shown in Figure 3-3.

Otherwise, the 24 VDC power supply will be damaged immediately once there is digital output.

Figure 3-6 DO terminal wiring diagram

Operation, Display and

Application Examples

SSI700 User Manual Operation, Display and Application Example

www.ssinverter.info

Chapter 4 Operation, Display and Application Examples

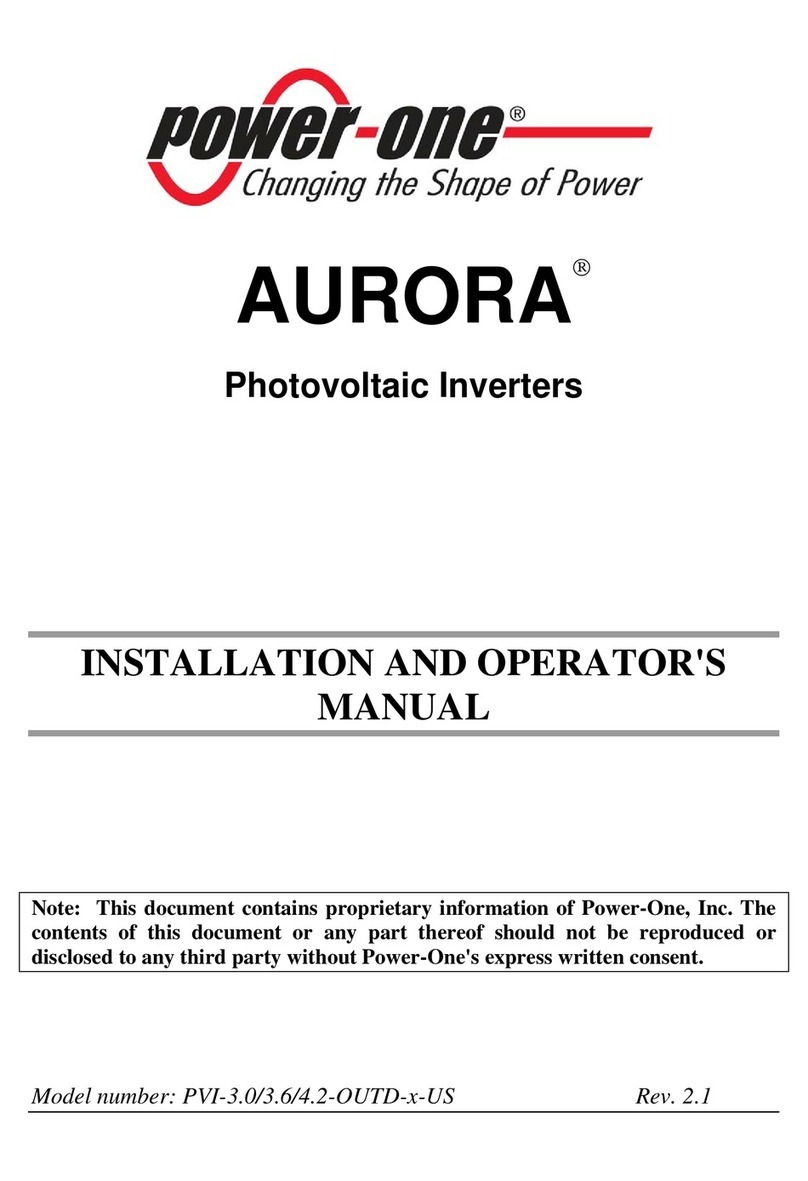

4.1 Operation Panel

You can modify the parameters, monitor the working status and start or stop the SSI700

by operating the operation panel, as shown in the following figure.

Figure 4-1 Diagram of the operation panel

4.1.1 Description of Indicators

• RUN

ON indicates that the AC drive is in the running state, and OFF indicates that the AC drive

is in the stop state.

• LOCAL/REMOT

It indicates whether the AC drive is operated by means of operation panel, terminals or

communication.

LOCAL/REMOT: OFF Operation panel control

LOCAL/REMOT: ON Terminal control

LOCAL/REMOT: blinking Communication control

• FWD/REV

ON indicates reverse rotation, and OFF indicates forward rotation.

• TUNE/TC

When the indicator is ON, it indicates torque control mode. When the indicator is blinking

slowly, it indicates the auto-tuning state. When the indicator is blinking quickly, it indicates

the fault state.

• Unit Indicators

This manual suits for next models

1

Table of contents

Popular Inverter manuals by other brands

XihaBabe

XihaBabe PS-150 instruction manual

Kostal

Kostal PIKO 36 EPC operating manual

Power One

Power One AURORA PVI-OUTD-US Series Installation and operator's manual

AWE

AWE Corona Discharge CD10 Installation and owner's manual

Firman

Firman W03083 owner's manual

Toshiba

Toshiba TOSVERT VF-S15 series instruction manual