Handling Waste

•Do not dispose the waste fuel/oil to the sewer or river to avoid environment pollution.

•The fuel/oil drained off the machine should e kept in the container.

•Dispose of all wastes properly in accordance with local environmental regulations. This

includes fluids, filters, atteries, electrical components, etc.

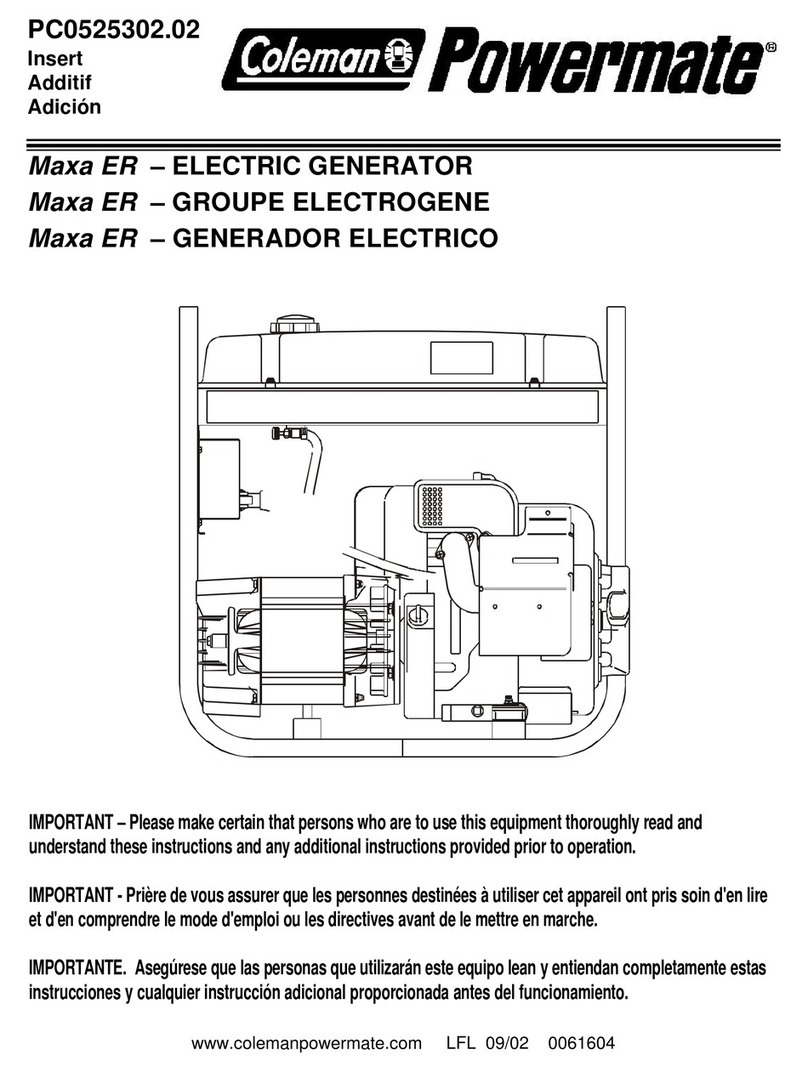

Exhaust Gases Are eadly

DANGER

•The generator emits car on monoxide, a colorless, odorless gas which can kill you y

asphyxiation. Do not reather in or come into contact with exhaust gases.

•The generator must e operated outdoors or in well ventilated areas. If the generator is

operated indoors, it must e placed in a well-designed room with proper ventilation.

•Check the exhaust system for corrosion, o struction, and leaks every time efore starting the

generator set and every eight hours when you run the unit continuously. Do not use exhaust

gases to heat a compartment. Make sure that exhaust manifolds are secured and not warped.

Moving Parts Can Cause Severe Personal Injury or eath

DANGER

•Keep hands, clothing, and jewelry away from moving parts.

•Make sure the fasteners on the generator set are secure. Tighten supports and clamps.

Generator guard doors must e completely closed and locked during running.

•Before starting work on the generator set, disconnect the attery charger from its AC source,

then turn off the attery switch. This will prevent accidental starting.

•Do not wear loose clothing or jewelry in the vicinity of moving parts or while working on

electrical equipment. Loose clothing and jewelry can ecome caught in the moving parts.

•If any adjustments must e made while the unit is running, use extreme caution around hot

manifold, moving parts, etc.

•The electric cooling fan may run a few minutes more after the unit stopped. Do inspection or

service only after the fan completely stopped.

Electric Shock and Arc Flashes Can Cause Severe Personal Injury or eath

DANGER

•Never operate the generator in wet conditions. Water will conduct electricity.

•An electric shock resulting in death can occur y touching the output terminals while generator

set is running.

•When connecting the generator to the load, the circuit reaker must e placed in the OFF

position and the generator stopped. (When in parallel operation, any other loads should e

turned off esides this unit)

•The cover of the output terminals must e closed and the screws should e tightened efore

operating the generator

•The generator produces voltage even at low speeds. Ensure the generator stopped completely

efore inspection and service.

•Touching the circuit inside the control panel will lead to electric death. Please close the control

ox and tighten the screws efore running the generator.

•Before opening the control ox, close the circuit reaker and stop the generator. The control

ox contains live current.

•The circuit reaker prevents electric shock injuries. When replacing the circuit reaker, e sure

to use the same specification one.

•The inspection of internal circuits of the control panel can only e performed after stopping the

generator unit and removing the ignition key.

Generator Wiring

CAUTION

•Connections for stand y power to a uilding's electrical system or to the mains must e made y a qualified

electrician and must comply with all applica le laws and electrical codes.

•Improper connections can allow electrical current from the generator to ack feed into the utility lines. Such

ack feed may electrocute utility company workers or others who contact the lines during a power outage, and

when utility power is restored, the generator may explode, urn, or cause fires in the uilding's electrical system.

Ver. 3/Rev. 1; Data: 03.02.2022; 31