Stahlwerk MIG 200 User manual

STAHLWERK

MANUAL

MANUFACTURER: Shenzhen Stahlwerk Welding Technology Co., Ltd.

ADDRESS: 3F,Building 11, Heng Ming Zhu Science and Technology Park, Xin Qiao Tong Fu Yu

Indus rial Zone, Sha Jing S ree , Bao An Dis ric , ShenZhen Ci y

Tel:0755-23107730

·OWNER’S MANUAL· - 1 - SMC-003-A3

SAFETY WARNING

On the process of welding or cutting, there will be possibilit of injur , so please

take protection into consideration during operation. For more details please review

the Operator Safet Guide, which complies with the preventive requirements of the

manufacturer.

Electric shock——Ma lead to death !

Set the earth fitting according to app ying standard.

Forbidden to touch the bare e ectric parts and e ectrode with uncovered skin, wet g oves or

c othes.

Make sure you are insu ated from the ground and the work piece.

Make sure you are in safe position.

Gases and fumes——Ma be harmful to health!

Keep your head out of the gases and fumes.

When arc we ding, venti ators or air extractors shou d be used to avoid breathing gases.

Arc ra s——Harmful to our e es, burn our skin.

Wear suitab e protective mask, ight fi ter and protective garment to protect eyes and body.

Prepare suitab e protective mask or curtain to protect ooker-on.

Fire

We ding spark may cause fire, make sure there is no tinder stuff around the we ding area.

Noise——Excessive noises will be harmful to hearing .

Use ear protector or others means to protect ear.

Warn ooker-on that noise is harmfu to hearing.

Malfunction——When trouble happens, contact with authorized professionals

If troub e happens during insta ation and operation, p ease fo ow this manua instruction to check

up.

If you fai to fu y understand the manua , or fai to so ve the prob em with the instruction, you

shou d contact the supp iers or the service center for professiona he p.

When the se of the machine on an incline to prevent the machine overt rned.

·OWNER’S MANUAL· - 2 - SMC-003-A3

WARNING!

Creepage-protecting switch should be added when using the machine!!!

MACHINE DESCRIPTION

The we ding machine is a rectifier adopting the most advanced inverter techno ogy.

The deve opment of inverter gas-shie ded we ding equipment profits from the deve opment of the

inverter power supp y theory and components. Inverter gas-shie ded we ding power source uti izes

high-power component MOSFET to transfer 50/60Hz frequency up to 100KHz, then reduce the vo tage

and commutate, and output high-power vo tage via PWM techno ogy. Because of the great reduce of

the main transformer’s weight and vo ume; the efficiency increases by 30%. The appearance of inverter

we ding equipment is considered to be a revo ution for we ding industry.

CO2 shie ded we ding equipment adopts the most advanced inverter techno ogy by our. Inside of the

machine is equipped with e ectronic reactor circuit which can accurate y contro the process of the

e ectric short transition and b ending transition and resu t exce ent we ding characteristic. Comparing

with synergic we ding machine and other machine, it has the fo owing advantages: stab e wire speed,

compact, power saving, no e ectromagnetic noise. Continuous and stab e operation with sma current,

especia y suitab e for we ding sheet of ow-carbon stee , a oyed stee and stain ess stee . Automatic

vo tage pu sation compensation capabi ity, sma spark e, good arcing, uniform we ding poo , high duty

cyc e and so on.

The welding machine to meet the temperat re rise of 40 degrees ambient temperat re and rated

load cycle req irements.

The welding machine belongs to the CISPR11 first gro p eq ipment.

Thanks for purchasing product and hope for your precious advice. We wi dedicate to produce the best

products and offer the best service.

·OWNER’S MANUAL· - 3 - SMC-003-A3

WARNING!

The machine is mainl used in industr . It will produce radio wave, so the worker should

make full preparation for protection.

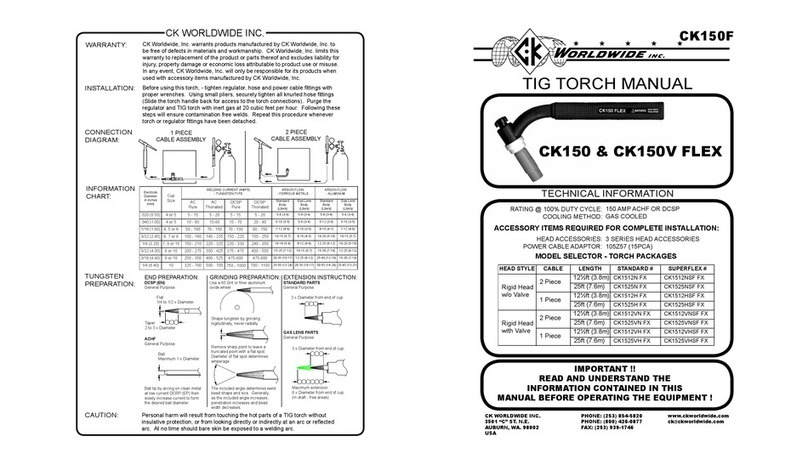

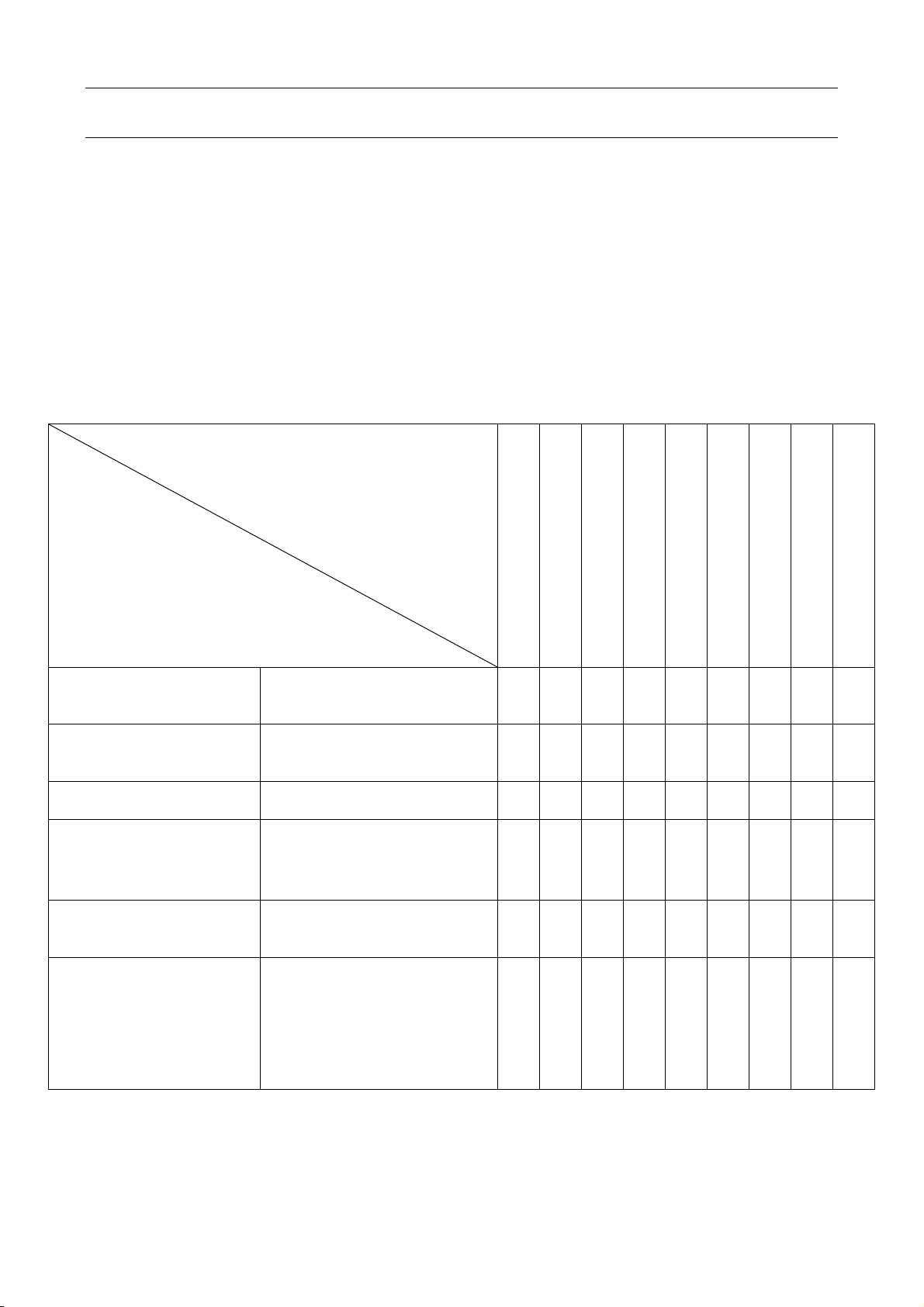

TECHNICAL PARAMETERS TABLE

Mode MIG 200

Power Vo .(V) 1 phase

AC230V±15%

Frequency(Hz) 50/60

Rated input current

(A) 37.4

Output current (A)

30-200

Output Vo . (V) 15.5-24

Duty cyc e(%) 60

Power factor 0.73

Efficiency(%) 80

Wire machine Compact

Wire speed(m /

min) 2.5-13

Post f ow (S) 1-10

wire whee diameter

(mm) 200

Wire diameter(mm)

0.6/0.8

Housing shie ding

grade IP21

Insu ation grade F

suitab e

thickness(mm) 0.8above

Weight (kg) 23.6

Dimension (mm)

610×330×540

·OWNER’S MANUAL· - 4 - SMC-003-A3

INSTALLATION INSTRUCTION

The we ding equipment is equipped with power vo tage compensation set. When power vo tage

f uctuates between±15% of rated vo tage, it sti works norma y.

When using ong cab e, in order to minimize the reduce of vo tage, big section cab e is suggested. If the

cab e is too ong, it wi affect the performance of arcing and other system function, so stated ength is

suggested.

1. Make sure the intake of the machine is not covered or b ocked to prevent the ma function of the

coo ing system.

2. Use earth cab e that the section no ess than 6mm2 to connect the housing and earth, the method is

from the connection in the back of the machine to the earth set, or make sure the earth end of

power switch reaches the earth. Both ways can be used for better security.

MIG 200Installation:

1) Connect the gas f ask with CO2 decompression f ow meter and the CO2 mouth behind the machine

via gas cab e.

2) Insert the swift p ug of earth cab e into the swift socket in the front pane .

3) Set the wire whee with wire on the whee axis, the

whee ho e shou d be matched with the whee fixer.

4) Choose wire s ot according to wire size.

5) Loosen the screw of wire-pressing whee , pit the wire

into so t via wire- ead tube, tune the wire-pressing

whee to fix wire from g iding, but pressure shou d be

suitab e in case the wire distorts and affects wire

sending.

6) Wire ro shou d turn c ockwise rotation to et out wire,

to prevent wire from g iding, wire is usua y set to the

fixed ho e on the whee side. To prevent the bent wire

from getting stuck, p ease cut off this part of the wire.

7) Put and tighten the torch on the output socket and put

the wire into the torch by hand.

Power supp y

(1 phase~230V)

MIG 200 Installation:

·OWNER’S MANUAL· - 5 - SMC-003-A3

OPERATION INSTRUCTION

1. Put the air switch to “ON” position, open the va ve of argon cy inder and adjust the f ow.

2. Adjust the wire diameter of the wire machine to rated number according to wire diameter.

3. Choose torch oopho e span based on wire diameter.

4. Tune the vo tage and speed knob to the right position based on the thickness of the work piece and

mechanics.

5. Press the torch switch to et out the wire to the torch head and begin to work.

MIG 200Compact CO2 Welding Machine Facial Sketch:

1 Current meter

2 Abnorma indicator

3 Power indicator

4 WIG/MIG/MMA switch

5 Wire diameter se ection

6 Gasafter f ow

7 Inductance adjustment

8 Positive output termina

9 Positive output termina

10 Negative output termina

11 Gas-e ectricity system output termina

12 Torch switch socket

13 Negative output termina

14 Power switch

15 Wire feeding speed adjustment

16 We ding vo tage adjustment

·OWNER’S MANUAL· - 6 - SMC-003-A3

NOTES OR PREVENTIVE MEASURES

1. Environment

1) The machine shou d be operated in dry environments with humidity eve s of max 90%.

2) Ambient temperature shou d be between -10 to 40 degrees centigrade.

3) Avoid we ding in sunshine or drippings. Do not et water infiter the machine.

4) Avoid we ding in dust area or the environment with corrosive gas.

5) Avoid gas we ding in the environment with strong airf ow.

2. Safet norms

The we ding machine is insta ed with protection circuit of over vo tage, over current and over heat.

When vo tage, output current and temperature of machine exceed the required standard, we ding

machine wi stop working automatica y. However, overuse (such as over vo tage) wi sti resu t in

damage to the we ding machine. To avoid this, the user must pay attention to the fo owing.

1) The working area is adequatel ventilated!

The we ding machine is powerfu machine, when it is being operated, it generated by high

currents, and natura wind wi not satisfy machine coo demands. So there is a fan in

inner-machine to coo down machine. Make sure the intake is not in b ock or covered, it is 0.3

meter from we ding machine to objects of environment. User shou d make sure the working

area is adequate y venti ated. It is important for the performance and the ongevity of the

machine.

2) Do not over load!

The operator shou d remember to watch the max duty current (Response to the se ected duty

cyc e). Keep we ding current is not exceed max duty cyc e current. Over- oad current wi

damage and burn up machine.

3) No over voltage!

Power vo tage can be found in diagram of main technica data. Automatic compensation

circuit of vo tage wi assure that we ding current keeps in a owab e range. If power vo tage is

exceeding a owab e range imited, it wi damage to components of machine. The operator

shou d understand this situation and take preventive measures.

4) There is a grounding screw behind we ding machine, with a grounding marker on it. Before

operation , we ding crust must be grounded re iab e with cab e which section is over 6 square

mi imeter, in order to prevent from static e ectricity , and accidents because of e ectricity

eaking.

5) If we ding time is exceeded duty cyc e imited, we ding machine wi stop working for protection.

Because machine is overheated, temperature contro switch is on “ON’’ position and the

indicator ight is red. In this situation, you don’t have to pu the p ug, in order to et the fan coo

the machine. When the indicator ight is off, and the temperature goes down to the standard

range, it can we d again.

·OWNER’S MANUAL· - 7 - SMC-003-A3

QUESTIONS TO BE RUN INTO DURING WELDING

Fittings, we ding materia s, environment factor, supp y powers maybe have something to do with

we ding. User must try to improve we ding environment.

A. Arcing-striking is difficult and eas to pause:

1) Make sure the earth cab e c incher connects the work piece we .

2) Check each connecting point connected or not.

B. Output current can not reach rated volume:

That supp ied vo tage is different from the rated wi ead to unconformity of the output current and the

adjusted current. When Supp ied vo tage ower than the rated, the max output current wi be ower than

the rated.

C. Current is not stabilizing when machine is been operating.

It has something with factors as fo owing.

1) E ectric wire net vo tage has been changed.

2) There is harmfu interference from e ectric wire net or other equipment.

D. Welding gap has air hole.

1) Check the gas supp y oop eaks or not..

2) Surface of mother materia has oi , stain, rust, acquer or other impurity.

MAINTENANCE

WARNING:

Before Maintenance and checking, power must be turned off, and before opening the

housing, make sure the power plug is pulled off..

1. Remove dust by dry and c ean compressed air regu ar y, if we ding machine is operating in

environment where is po uted with smokes and po ution air, the machine need remove dust every

month.

2. Pressure of compressed air must be within the reasonab e range in order to prevent damaging to

sma components of inner-machine.

3. Check interna circuit of we ding machine regu ar y and make sure the circuit connections are

connected correct y and tight y (especia y p ug-in connector and components). If sca e and rust are

found, p ease c ean it, and connect again tight y.

4. Prevent water and steam from entering into the machine. If that happens, p ease b ow it dry and

check insu ation of machine.

5. If we ding machine wi not be used for ong time, it must be put into the packing box and stored in

dry and c ean environment.

6. When wire machine operates for every 300 hours, the e ectric carbon brush and armature recitifier

shou d be added to the turbo and bearing.

·OWNER’S MANUAL· - 8 - SMC-003-A3

TROUBLESHOOTING AND FAULT FINDING

Notes: The fo owing operations must be performed by qua ified e ectricians with va id

certifications. Before maintenance,p ease contact with us for professiona suggestion.

Fault s mptom Remed

Power indicator is not it,

fan does not work and no

we ding output

1. Make sure air switch is c osed.

2. Check if e ectric wire net is in work.

3. Some of heat-variab e resistors(four) of power pane is damaged,

when it happen, genera DC24V re ay is open or connectors are poor

contact.

4. Power pane (bottom board) is damaged, DC 537V vo tage cannot be

output.

1) Si icon bridge is broken or connector of si icon bridge poor contact.

2) Power pane has been burned up.

3) Check contact and insert cab e from air switch to power pane are

poor contact, check contact and insert cab e from power pane to

MOS board are connected re iab y.

5. Auxi iary power of contro pane is in fau t.

Power indicator is it, fan

works, no we ding output

1. Check if a kinds of cab es of inter-machine are poor contact.

2. Output connector is cut off

3. Output connector is cut off or poor contacted.

4. Contro circuit is broken.

Power indicator is it, fan

works, abnorma indicator

is it.

1. Maybe it is overheated protection, p ease turn off machine first, then

turn on the machine again after abnorma indicator is off.

2. Maybe it is overheated protection, wait for 2-3 minutes.

3. Maybe inverter circuit is in fau t, p ease pu up the supp y power p ug

of main transformer which is on MOS board (VH-07 insert which is

near the fan) then open the machine again:

1) If abnorma indicator is sti it, some of fie distor of MOS board

are damaged, find out and rep ace them with same mode .

2) If abnorma indicator is not it:

a. Maybe transformer of midd e board is damaged, measure

inductance vo ume and Q vo ume of main transformer by

inductance bridge. If vo ume is too ow, p ease rep ace it.

b. Maybe secondary rectifier tube of transformer is damaged,

find out fau ts and rep ace rectifier tube with it.

If the machine fails to work normall after maintenance and check, please contact the local

dealer or after-sale service center.

·OWNER’S MANUAL· - 9 - SMC-003-A3

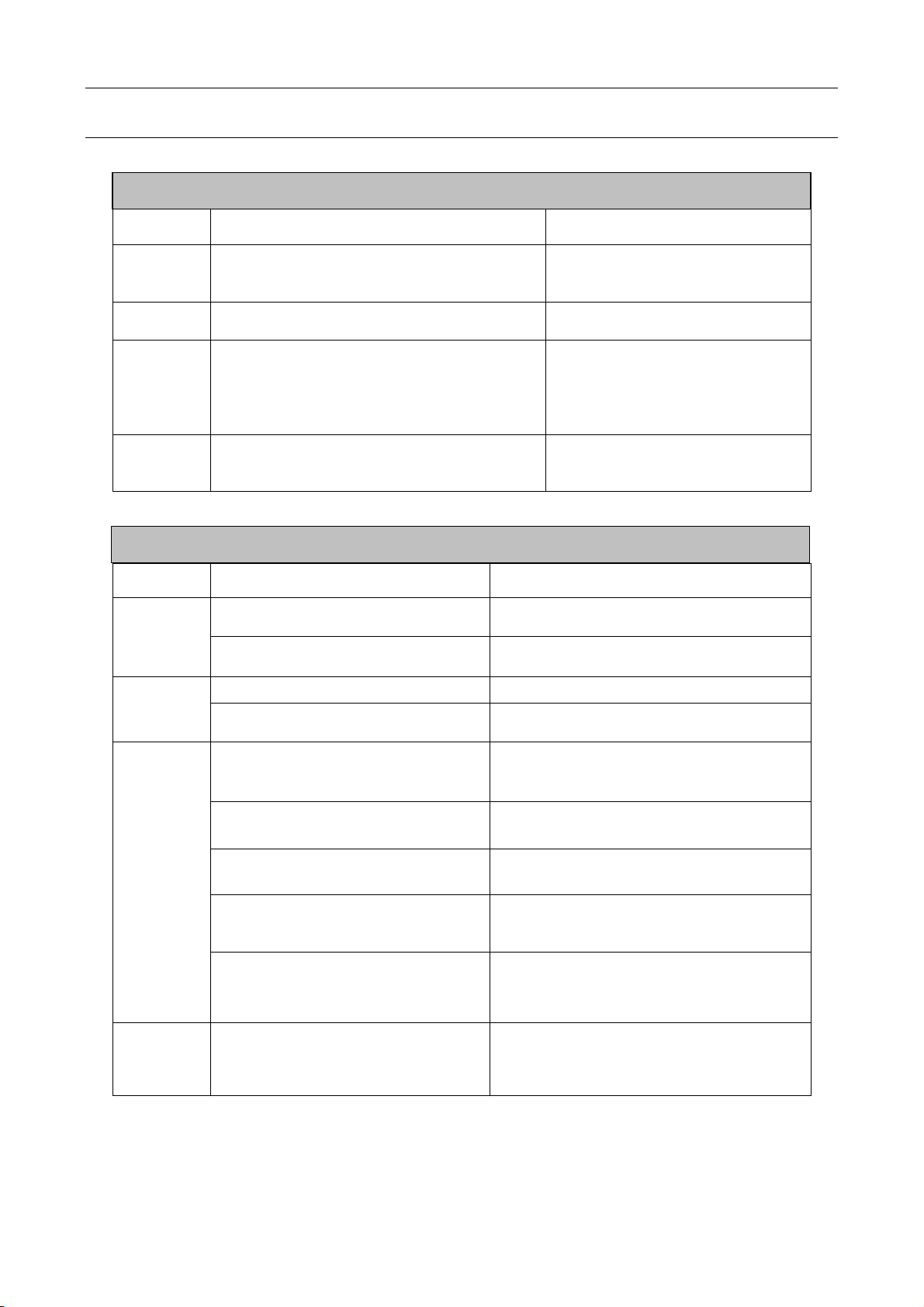

EARLIER CHECKING DIAGRAM FOR THE ABNORMAL

When abnorma situation such as fai ure of we ding, unstab e arc, poor we ding resu t, do not consider

that it must be some fau ts.

The machine may be we but just some reasons cause abnorma ity such as that some connectors are

oosened, forget to turn on the switch, wrong setting, broken cab e and gas pipe, etc. So before

maintenance, P ease check it up first, some prob em may be so ved.

The fo owing is ear ier checking diagram by this way. In the top right corner item you can find the

prob em, p ease check according to the diagram for the one with “O” mark.

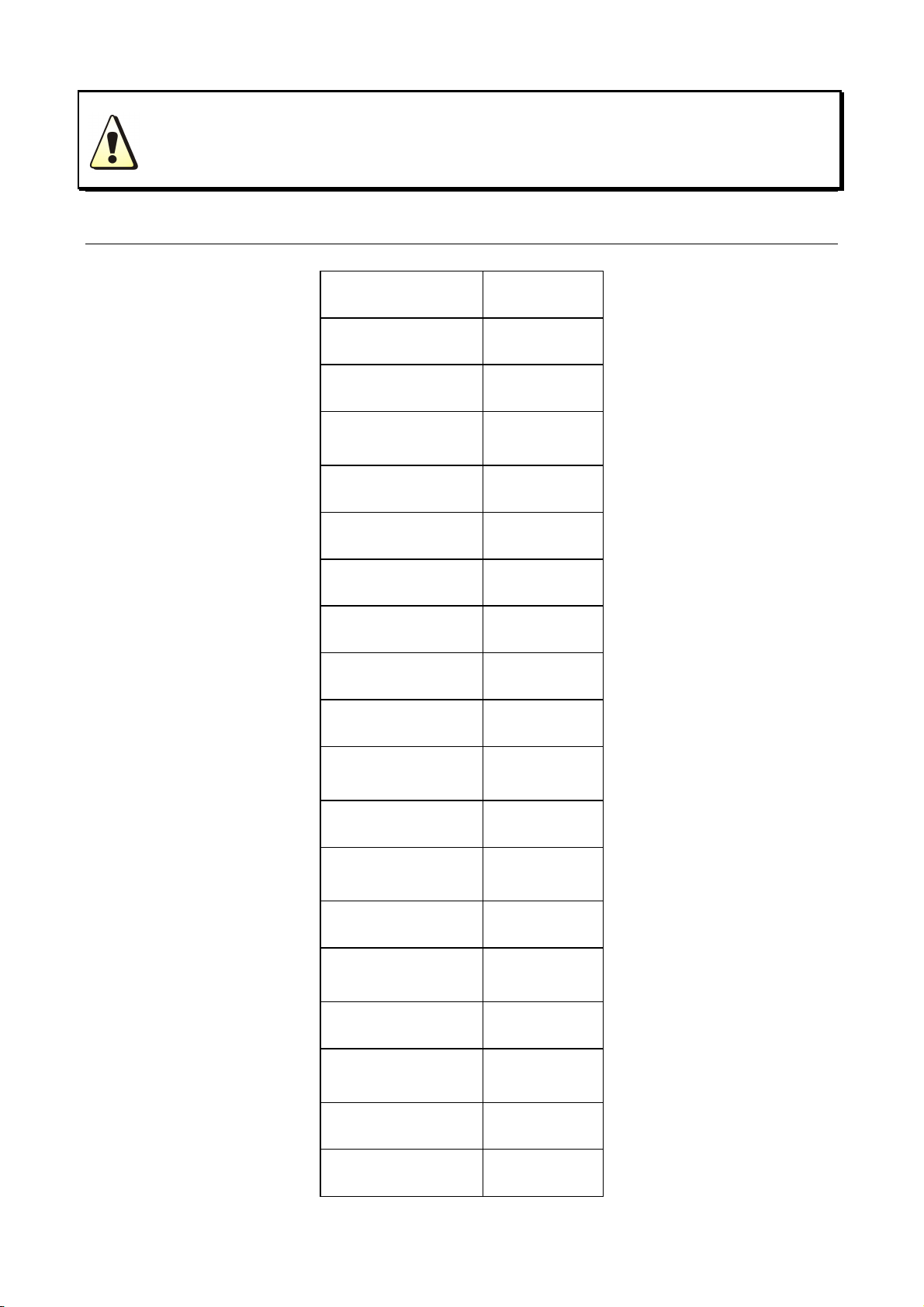

EARLIER CHECKING DIAGRAM FOR THE ABNORMAL

The abnorma

P ace and item to be checked

No arcing

No gas

Can not Send wire

wire

Poor Arcing initiation

Unstab e arc

We ding margin unc ean

Wire and Materia

cong utinated

Wire inks E ectric eading ho e

fcon cong utinated

Have air ho e

Power supp y(input

protective set )

1. Connected or not

2. Fuse broken

3. Connector oosen

〇 〇 〇 〇 〇 〇

Input cab e

1. Broken or not

2. Connector oosen

3. Overheat

〇 〇 〇 〇 〇 〇

Power 1. Switched or not

2. Lack phase 〇 〇 〇 〇 〇 〇 〇 〇

Gas cy inder & adjuster

1. Open cover

2. Remains of gas

3. F ow setting vo ume

4. Connecting point oosen

〇 〇

Gas pipe (access from the

high-pressure cy inder to

torch)

1. Connecting point oosen

2. Pipe broken 〇

Wire sending equipment

1. Whee and eading tube

not match

2. Whee broken, s ot b ocked

or ack

3. Over pressing or oosen,

powder store up in

entrance of SUS tube

〇 〇 〇 〇 〇

·OWNER’S MANUAL· - 10 - SMC-003-A3

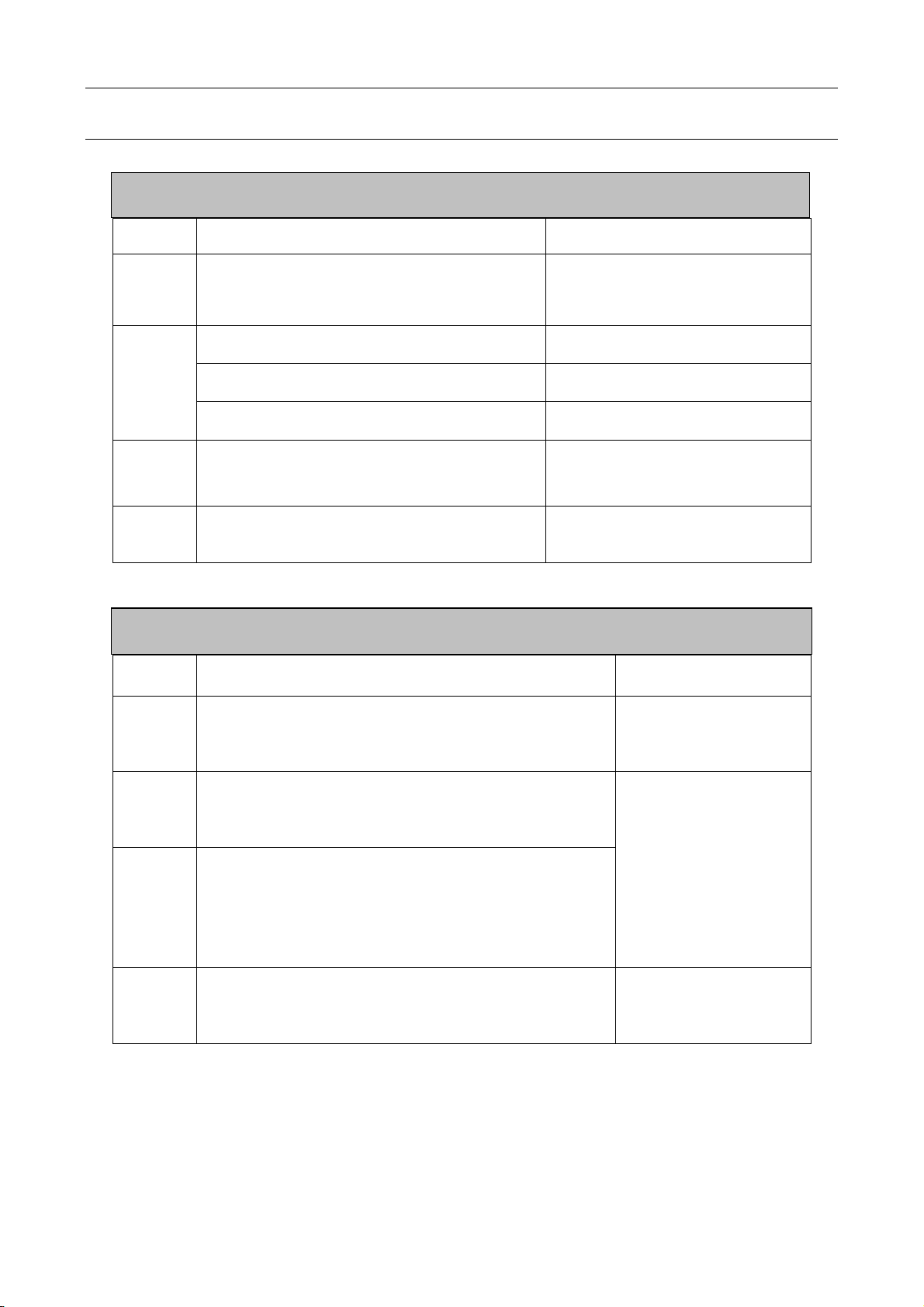

EARLIER CHECKING DIAGRAM FOR THE ABNORMAL

WARNING:If not necessar , before checking the power suppl box must be cut off to

insure securit . Violating the above principle, it will lead to serious accident

threatening life safet like electric shock and burning

EARLIER CHECKING DIAGRAM FOR THE ABNORMAL

The abnorma

P ace and item to be checked

No arcing

No gas

Can Not sending wire

Sen

d wire

Poor Arcing intiation

initiation

Unstab e arc

We ding margin unc ean

Wire and

Materia cong utinated

Wire inks

E ectric eading ho e

Have air ho e

Torch and cab e

1. Cab e over winding and over

bending

2. Adaptabi ity of e ectric ho e, wire

sending tube and the wire size

〇 〇 〇 〇

Torch body

1. E ectric ho e, oopho e, oopho e

connector oosen.

2. P ug of torch not fixed

〇 〇

Torch power cab e and

switch contro cab e

1. Broken (over bending)

2. Damaged by heavy stuff 〇 〇 〇 〇 〇

Main materia

surface

1. Oi , stain, rust, acquer fi m

2. Wire come out too ong 〇 〇 〇 〇 〇

Output cab e

1. Cab e section is not big enough

2. (+)、(-)connecting points of

output cab e oosen

3. Poor e ectric eading abi ity of

main materia .

〇 〇 〇

Lengthened cab e

1. Cab e section is not big

enough

2. Winding and bending

〇 〇 〇 〇

We ding operation

condition

Confirm the we ding current, vo tage,

torch ang e, we ding speed, and

extended wire ength

〇 〇 〇 〇 〇

·OWNER’S MANUAL· - 11 - SMC-003-A3

DAILY CHECKING

Position Checking keys Remarks

Contro

pane

1. Switch condition of operation, transfer

and insta ation.

2. Test the power indicator.

Coo ing

fan

1. Check if there is wind and the sound

norma or not.

If abnorma noise and no wind, to

check the inner.

Power part

1. When e ectrified, abnorma sme or not.

2. When e ectrified, abnorma vibration and

buzz or not.

3. Co or changing and heating or not in

appearance.

Periphery

1. Gas pipe broken, oosen or not.

2. Housing and other fixed parts oosen or

not.

Position Checking keys Remarks

Loopho e

1. If insta ment fixed, the front

distorted Reason for air ho e.

2. Attach sp ash or not. Reason for burning the torch.

(can use sp ash-proof materia )

E ectric

ho e

1. If insta ment fixed Reason of torch screw thread damage

2. Damage of its head and ho e

b ocked nor not Reason of unstab e arc and broken arc

Wire

sending

tube

1. Check the extended size of the

pipe

Have to be changed when ess than 6mm,

when the extended part too sma , the arc

wi be unstab e.

2. Wire diameter and the tube inner

diameter match or not

Reason of unstab e arc, p ease use the

suitab e tube.

3. Partia winding and extended Reason of poor wires sending and

unstab e arc, p ease change.

4. B ock caused by dirt in the tube,

and the remains of the wire

p ating ay.

Reason of poor wire sending and

unstab e arc, (use kerosene to wipe or

change new one.)

5. Wire sending tube broken O

circ e wear out

1.Pyrocondensation tube broken, change

new tube

2.Change new O circ e

Gas

bypass

Forget to insert or the ho e b ocked,

or different factory component.

May ead to vice (sp ash) because of poor

gas shie d, torch body get burned (arc in

the torch), p ease hand e.

WELDING TORCH

WELDING POWER SUPPLY

·OWNER’S MANUAL· - 12 - SMC-003-A3

DAILY CHECKING

Position Checking keys Remarks

Pressing

arm

1. If put the arm to the suitab e indicating

eve .(notes:not to damage wire ess than

Ф1.2mm )

Lead to unstab e arc and wire

sending.

Wire

ead

tube

1. If powder or residue store up in the mouth

of the tube.

C ean the residue and check the

reason and so ve it.

2. Wire diameter and the tube inner diameter

match or not

If not match, ead to unstab e arc

and residue.

3. If the tube mouth center matches the wire

whee s ot center or not.

If unmatched, ead to unstab e arc

and residue.

Wire

whee

1. Wire diameter matches the whee ’s

requirement

2. If the whee s ot b ocked.

1. Lead to unstab e arc and

residue, and b ock wire tube.

2. Change new one of necessary.

Pressure

whee

Check the stabi ity of its move, and

wearing-out of pressed wire, the narrowing of

its contact surface

Lead to unstab e arc and wire

sending.

Position Checking keys Remarks

Torch

cab e

1. If torch cab e over bended.

2. If the meta connecting point of mobi e p ug oosen.

1. Cause poor wire

sending.

2. Unstab e arc if cab e

over bended.

Output

cab e

1. Wearing-out of the cab e insu ated materia .

2. Cab e connecting head naked(insu ation damage),or

oosen(the end of power supp y, and cab e of main

materia connecting point.)

For ife security and

stab e we ding, adopt

suitab e method to

check according to

working p ace.

Simp e check dai y

Carefu and

in-depth check on

fixed period

Input

cab e

1. If the connect of power supp y input, protective

equipment input and the output end fixed or not.

2. If the security equipment cab e re iab y connected.

3. If the power input end cab e fixed.

4. If the input cab e is worn out and bares the

conductor.

Earth

cab e

1. If the earth cab e that connects the power supp y is

broken and connect tight y.

2. If the earth cab e that connects the main part is

broken and connects tight y.

To prevent creep age

and insure security,

p ease make dai y

check.

CABLE

WIRE SENDING MACHINE

Table of contents

Other Stahlwerk Welding System manuals