Stahlwerk AC/DC WIG241P User manual

1

VECTOR DIGITAL

MANUAL

Digital seriers—

AC/DC WIG241P

ENG ver. 1.3 2013-03-23

2

MANUFACTURER: Shenzhen Stahlwerk Welding Technology Co., Ltd.

ADDRESS: 3F,Building 11, Heng Ming Zhu Science and Technology Park, Xin Qiao Tong Fu Yu Indus rial Zone, Sha Jing S ree , Bao An Dis ric ,

ShenZhen Ci y

Tel:0755-23107730

SWEDEN authorized distributor: Stahlwerk - SW S etsteknik AB

Postadress: Hästho sstigen 1, 296 34 ÅHUS, SWEDEN

Lager och le eranser: Boställsgatan 6, 28832 VINSLÖV, SWEDEN

Tel: 044-2531310 (mån-tor 10-17, torsdag 13-17, fre-sön 10-16, lunch normalt 12-13)

E-Mail: info@stahlwerk.se,

Internet: www.stahlwerk.se

CONTENTS

1. Contents ....................................................................... 2

2. Specifications .................................................................... 3

3. Power Source Controls Indicators And Features .... 4

4. Introduction For The Machine ....................................... 6

5. Operation ............................................................................ 8

6. uestion Of The Welding Technology ........................ 8

7. Power Souce Problems ................................................... 9

3

OPERATION AND ATTENTION

Specifications

Model

Parameters AC/ C WIG-241P

Input voltage(V,Hz) AC230±15%, 50/60

Input power capacity(KVA) 7.2

No-load loss(W) 40

uty cycle(%) 25

Power factor 0.93

Efficiency(%) 80

Insulation class F

Protection IP21

Accessories Weight(Kg) 6.5

Machine weight (Kg) 23

imension(mm) 630x380x520

Tig-welding Arc-welding

Input current(A) 20.7 32.2

Rate output current(A) 200 200

Currentadjustment range(A) 10-200 10-200

No-load voltage(V) 67 67

Work voltage(V) 18 28

Inter-diameter of burner(mm) -- --

Air compress (Mpa) -- --

Gas flow(L/min) 2-5 --

Thickness(mm) -- --

Arc polite model HFoscillate/ Touch Touch

4

OPERATION AND ATTENTION

9.01 Power Source Controls ,Indicators and Features

2 T

4 T

MM A

W IG

A C

H F

C

A

V

S H z

A C F re q ue n z S tr o mv e rl ag e ru n g

A C / D C W I G 2 1 P4

R e m o t e

%

A R C H o ts ta rt

A R C S ta rt ze it

A R C S pr h li c ht b og e nü

G a s vo r la u f

St a r ts tr o m

St r o m a n s t i e g

Sc h we i s tr o m

β

Im pu l s

Im p u l s

Im p u l s fr e q ue n z

St r o m a b s e n k u ng

Sc h l u s t r o m

β

G a s na c h la u f

st ro m

w e i te

R E S J O B

S AV E

1

2

3

4

5

6

7

8

1 0

11

12

13

14

15

16

17

18

19

2 0

21

22

2 4

23

26

25

27

28

2 9

30 3 1

3 2 3 3 3 4 3 5

1 RESET button

2 Pulse indicator

3 Pulse button

4 2T indicator

5 4T indicator

6 2T/4T Cycle choose button

7 MMA indicator

8 WIG indicator

** ******************************************

10 MMA/WIG Cycle choose button

11 Current meter

12 Voltage meter

13 Current Unit indicator

14 Time Unit indicator

15 uty cycle unit indicator

16 Frequency unit indicator

17 Power indicator

18 Over-current/Over-heat indicator

19 JOB model indicator

20 JOB model button

21 SAVE indicator

22 SAVE button

23 HF indicator

24 HF button(Only WIG)

25 AC indicator

26 C indicator

27 AC/ C botton(AC Only WIG)

28 Reduce parameter button

29 Increase parameter button

30/31 Function selection button

32 Negative output terminal

33 Torch switch socket

34 Argon/air output terminal

35 Positive output terminal

5

OPERATION AND ATTENTION

9.02 Power Source Controls ,Indicators and Features

AC Frequenz StromverlagerungRemote

ARC Hotstart

ARC Startzeit

ARC Spr hlichtbogenü

Gasvorlauf

Startstrom

Strom a nstie g

Schwei strom

β

Impuls

Impuls

Impulsfreq uenz

Strom a bsenkung

Schlu strom

β

Gasnachlauf

strom

we ite

3 7 38 39 4 1 4 3 4 4 45 4 6

42

40

5 2

5 1

50

48

47

4 9

37 Pre-flow indicator 45 End current indicator

38 Start current indicator 46 Post flow indicator

39 Up-slope indicator 47 Hot start indicator

40 uty cycle indicator 48 Hot start time indicator

41 Peak current indicator 49 Arc force current indicator

42 Pulse frequency indicator 50 Clean area indicator

43 Basic current indicator 51 Remote control indicator

44 own slope indicator 52 AC Frequency indicator

6

OPERATION AND ATTENTION

9.03 INTRODUCTION

AC/ C WIG241P have sticking and AC/ C wig

welding,PULSE/ C wig welding many functions,

which adopt the most advanced inverter technolo-

gy.

The development of inverter gas-shielded welding

equipment profits from the development of the

inverter power supply theory and components.

Inverter gas-shielded welding power source utilizes

high-power component MOSFET/IGBT to transfer

50/60HZ frequency up to 100KHz/40KHz, then

reduce the voltage and commutate, and output

high-power voltage via PWM technology. Because

of the great reduce of the main transformer’s

weight and volume; the efficiency increases by

30%. The appearance of inverter welding

equipment is considered to be a revolution for

welding industry.

The welding power source can offer stronger, more

concentrated and more stable arc. When stick and

work piece get short, its response will be quicker. It

means that it is easier to design into welding

machine with different dynamic characteristics, and

it even can be adjusted for specialty to make arc

softer or harder.

As sticking and arc welding ,outer characteristic of

welding machine is constant current .Welding curr

ent will not be changed with arc length and current

is stable very much .As plasma cutting ,after arc

has pressed forcedly by air which is flowing

rapidly ,temperature is rise to 10000-15000℃ and it

is up to high coinable situation then strong plasma

arc has been formed .Cutting metal rapidly with

plasma arc, heat is concentrated and energy is

used effectively and smooth cutting section can be

got.

AC/ C WIG241P can be used in welding and

cutting of mild steel, stainless steel, alloy steel,

copper and other color metal .It has lightness, high

efficiency, energy-saving, stabilizing and reliable,

The welding machine to meet the temperature rise

of 40 degrees ambient temperature and rated load

cycle requirements.

The welding machine belongs to the CISPR11 first

group equipment.

Welcome to purchase products of our company

and make suggestions, we will try our best to

perfect our products and service.

Various functional options

1. When use MMA(ARC)function.

1) Make sure the cable, holder and fastening

plug have been connected with the ground. Put the

fastening plug into the fastening socket at the

“-“ terminal and fasten it clockwise.

2) Put the fastening plug of the cable to fastening

socket of “+” terminal at the front panel,fasten it

clockwise,and the earth clamp at the of the terminal

clamps the work piece.

3) Please paty attention to the connecting

terminal , C welding machine has two connecting

ways: positive connection and negative

connection.Positive connection:holder connects with

“-”terminal ,while work piece with the “+” terminal.

Negative connection:work piece with the “-”terminal.

Choose suitable way according to working situation.If

unsuitable choice is made,it will cause unstable arc

more spatters and conglutination,If such problems

occurs,problems occur,please chang the polarity.of the

fastening plug.

2. When use TIG function.

4) Connect well the protecting gas source,Gas

supply passage includes cylinder,argon meter and gas

pipe.The joint part of the pipe should be tighten by

hoop or other things in order to prevent leakaged and

air from coming in.

5) Install the air-electricity system plug to the

socket in the panel and fix it clockwise .Air plug of the

cutting torch and arc-keepingcable should be

connected to relevant socket,and fix the screw.

6) Put the loop cable plug to the fastening

socket,and tighten clockwise ,another terminal holds

the work piece.

7

OPERATION AND ATTENTION

2T

4T

MMA

W I G

PLASMA

AC

H F

C

A

V

SH z

AC F r eq u e nz S tro m v e rla g e ru n g

A C / D C P L A S M A W I G 2 5 1 P

R e m o t e

%

AR C H o t sta r t

AR C S t ar tz e it

AR C S p r hli ch tb o g e nü

Ga s v o rl a u f

Sta r tst r o m

Str o ma n s tie g

Sc h w e i s tr o m

β

Im pu l s

Im pu ls

Im pu l sfr e q ue n z

Str o ma b s en k un g

Sch l u s tr o m

β

Ga s n ac h la u f

str o m

we it e

R E S JO B

S AV E

Connect

grounding

Handle

Power supply

2 0v

3

Gas

Cylinder

earth clamp

Work piece

TIG torch

WIG/MMA installation

Electroed holder

8

OPERATION AND ATTENTION

9.04 OPERATION

1 . TIG welding function

1) Turn on the power switch at the back panel,

digital current meter is normal, fan begins to wheel.

2) Open the valve of argon cylinder , adjust the

volume of flow meter and make it is adequate to

welding .

3) Press switch of torch, electromagnetic valve

is started. Sound of HF arc striking can be heard

when HF wig state, at the same time argon is

flowing from torch burner. NOTES: When welding

is first operated, user must press switch of torch

several seconds and begin to weld until all of air is

be drained out. When welding is over, argon will

still flow out in several seconds in order to protect

welding spot before cooled down .So torch must be

kept welding place some time before arc has been

extinguished.

4)According to the workpiece need to set the

corresponding working state (AC or C,PULSE or

C)and suitable welding current and make sure

welding current is adequate to thickness of work

piece and process demand.

5)It is 1-4 mm from welding tungsten electrode

to work piece, press control knob of torch ,burn and

strike arc , sound of HF arc-striking will be

diminished .The welding machine can be operated

now.

2. MMA(ARC)function

1) Open power switch of front panel, fan begins

to work.

2) Make sure function switch of front panel is on

“down” position that is sticking. Impulse

changeover switch and knob of current down-slope

time will not work.

3) Make sure welding current is adequate to

thickness of work piece.

9.05 UESTION

Please refer to the WIG or PLASMA machine

manul.

CAUTION

Please don’t switch the function keys when the ma-

chine is in use.

9

PROBLEMS/SERVICE

9.06 Power Source Problems

NOTE

If user wants to operate machine as following, the operator must be a personnel in a specific field of electricity

and safety and hold the relevant certificate that proves there ability and knowledge. Before maintenance,

contact with our company for authorization is suggested.

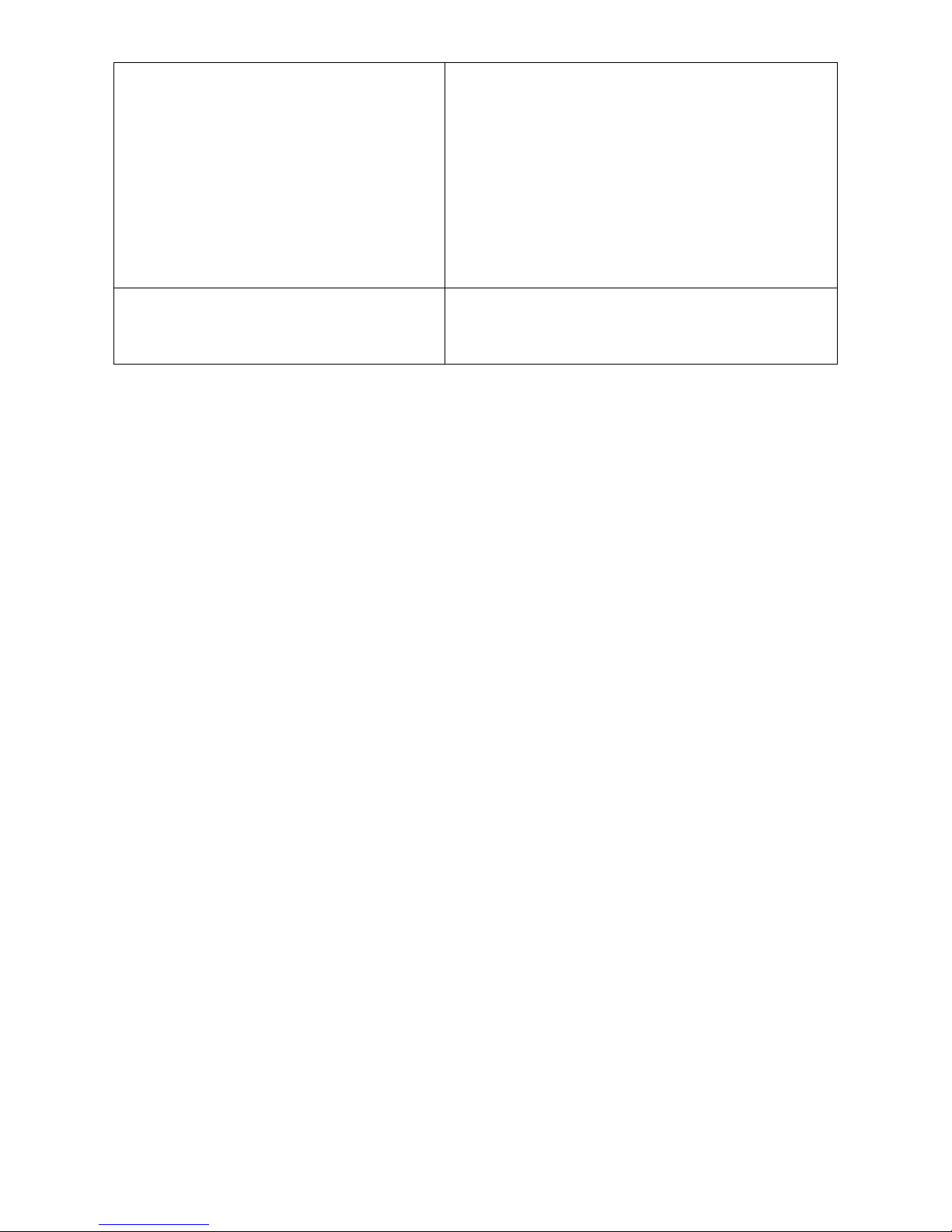

Faults Resolvable Methods

1.Power indicator is not lit,

fan is not working, there is

no welding output.

1. Power switch is damaged.

2. Make sure electrify wire net, which is connected to input cable is working.

3. Make sure if input cable is broken circuit.

2.Indicator of power switch

is lit, fan is not working or

revolves several circles

and stopped, there is no

welding output.

4. Fuse is broken.

5. Short voltage protection is starting.

6. Cable, which is from switch to power panel, is loosed, tighten it again.

7. 24Vrelay of main return circuit of power panel is not close or damaged, check

24V power and relay .If relay is damage, replace it with some model.

3.Fan is working, abnorm-

al indicator is not on, sou-

nd of HF arc striking can be

heard, wipe arc welding

cannot strike arc.

8. Measure voltage of positive and negative electrode is about C308v from power

panel to VH insert.

a) If it is broken circuit and insert cable of Silicon Bridge is poor contact.

b) If one of four high electrolytic (about 470UF/450V) of power panel is

leaking, replace it.

9. Assistant power source supply power abnormally, normal voltage is C 24V.

10. Check if all kinds of connect and insert cable is poor contact.

11. Check if there is some question in control circuit, connect with seller. If control

cable of torch is broken.

4.Abnormal indicator is not

lit, sound of HF arc striking

can be heard, wiping arc

welding can strike arc.

12. Cable of torch is broken.

13. Grounding cable is broken or is not connected to work piece.

14. Output terminal of positive electrode or there is loose between electrify output

terminal of torch and inter-machine.

5.Abnormal indicator is not

lit, sound of HF arc striking

can be heard, and there is

no welding and cutting

output.

15. Primary cable of arc-striking transformer is poor contact with power panel,

tighten it again.

16. Arc-striking tip is oxidized or distance is too far, give a good polish oxide of

burner or adjust it is 1 mm between burners.

17. Changeover switch of sticking/arc welding is damaged, replace it.

18. Some of components of HF arc striking check and replace it.

10

6.Abnormal indicator is on, there is no output.

19. Maybe it is over current protection, please close

machine first, then open the machine again after abnormal

indicator is out of work.

20. Maybe it is overheated protection, wait for 2-3 minutes

(argon-arc welding does not has overheated protection

function.) and machine can be operated normal.

21. Maybe inverter circuit is fault, Please check whether

the IGBT/FR is damaged or not.

22. Maybe feedback circuit is opened.

7. henwelding aluminum,can not break oxidized

film

23. Wrong welding value

24. Pulse duty too low

25.Twice inverter MOSFET broken

If after checking and adjustment it still can not work normally, please contact the local distributor or our service

center.

Table of contents

Other Stahlwerk Welding System manuals