stakorr Vacu PRO Quick start guide

ENG: Installation, Use and Maintenance Instructions

Central Vacuum Unit Vacu PRO

27/04/2022 Rev:1.0.0

3

• Type: Domestic Central Vacuum Unit

• Model: Vacu Pro

• Revision 1.0.0

VACU PRO

INSTRUCTION MANUAL

1 TECHNICAL DATA 4

2 AUTHORIZED USE OF THE VACUUM CLEANER 6

3 UNAUTHORIZED USE OF THE VACUUM CLEANER 6

4 SAFETY FEATURES 7

4.1 Warning 7

4.2 Protection Degree 8

4.3 Electrical insulation degree 8

4.4 Declaration of absence of dangerous substances 8

4.5 Fixed closure guards safety 8

4.6 Movable closure guards safety 8

4.7Identicationplate 9

5 PACKAGE CONTENTS 10

6 INSTALLATION 11

6.1Preliminaryoperations 11

6.2 Place of installation 11

6.3 Fixing the vacuum cleaner to the wall 12

6.4Connectiontothepipingnetwork 13

6.5 Electrical connection 15

6.6Usingtheservicesocket 16

7 MAINTENANCE 16

7.1 Programmed routine maintenance 16

7.2 Cleaning the suction container (cylinder) 16

7.3Emptyingthedustbin 17

7.4Disposaloftheltercartridge 18

8 REPAIRS AND SPARE PARTS 18

8.1 Intervention criteria 18

8.2Recommendedspareparts 18

9 THERMAL SWITCH 18

10 TROUBLE SHOOTING 19

INDEX

Instruction manual

4

27/04/2022 Rev:1.0.0

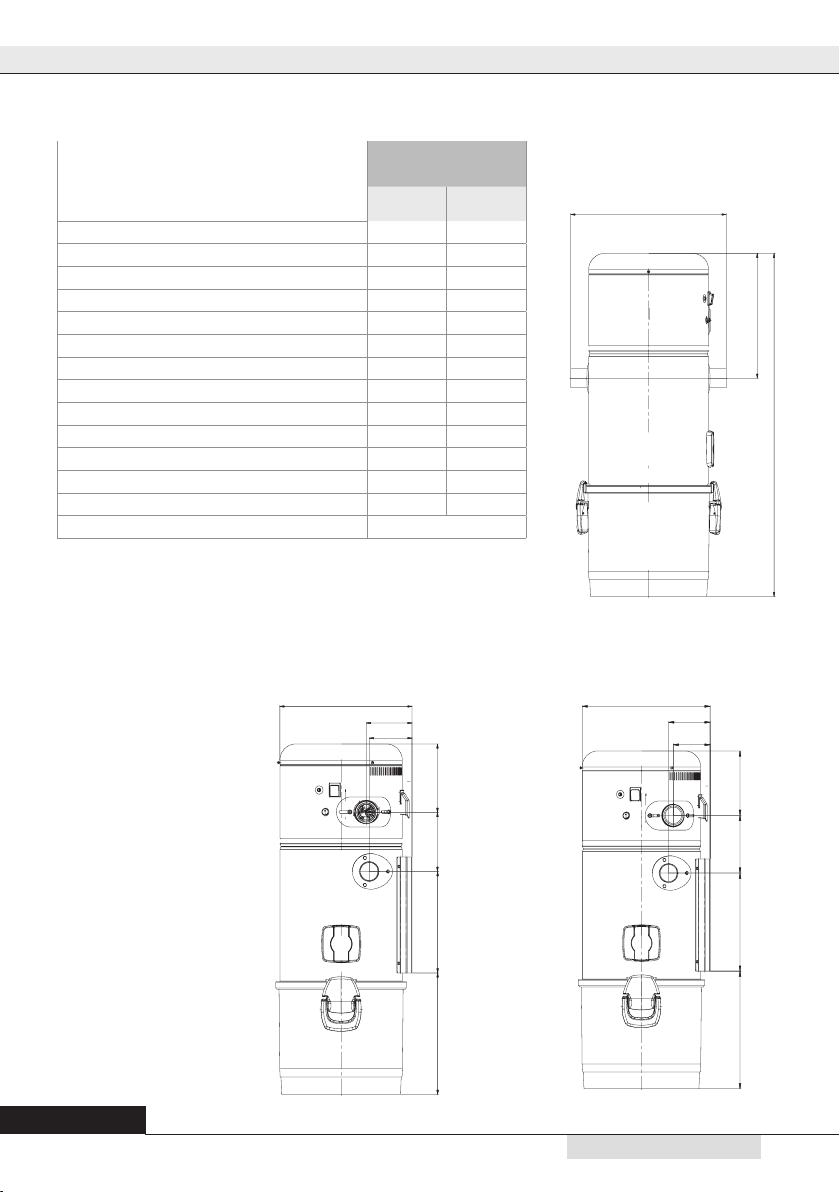

1- TECHNICAL DATA

N. B: Levels of nominal noise. The levels can vary according to the environment

where the central unit has been installed and the kind of installation

Art. 2330/2340

Art. 2330 Art. 2340

Articolo

VACU PRO

2330 2340

Suction coupling Ø mm 50 50

Air exhaust Ø mm 50 50

IP Protection Degree IP 20 20

Power supply V ac 220-230 220-230

Frequency Hz 50/60 50/60

Motor power kW 1,8 1,9

Absorption A 7,9 8,2

Socket power supply

V dc 12 12

Maximum air ow m3/h 240 257

Dust bin capacity l 25 25

Air venting YES YES

Air exhaust silencer YES YES

Weight kg 10,5 10,5

Sound level dB(A) < 70

346

120

112

177153262314

346

112

99

173154262315

415

330

907

5

2

27/04/2022 Rev:1.0.0

English

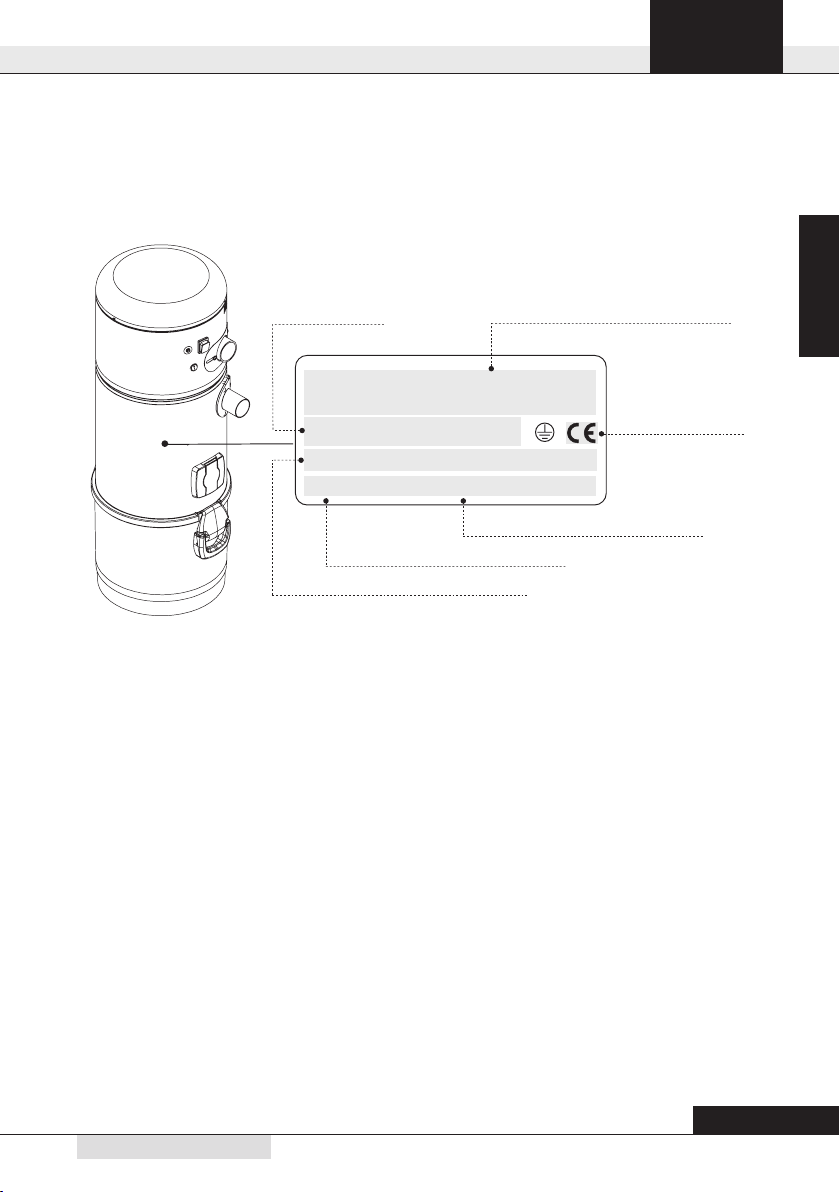

Main switch

Thermal switch

Air exhaust

ON/OFF switch

service inlet

Service vacum inlet

Closing handle and

hook

Dust bin

Dust inlet

1

2

3

4

6

7

8

5

Instruction manual

6

27/04/2022 Rev:1.0.0

2 - AUTHORIZED USE OF THE VACUUM CLEANER

The vacuum cleaner model Vacu Pro has been designed exclusively to vacuum clean house dust, very

small-size solids and dry materials. The use of the central vacuum cleaner is authorized for household

andciviluses,connectedtoaPVCwall-tracedpipingnetworkandtoastandardhomeelectricalwiring.

The vacuum cleaner can be installed in domestic dwellings with the following characteristics:

•Pipingnetworkfeaturing50-mmdiameterpipe

•220/240Vacpowersupply

• Air exhaust conveyed to the outside

•Suitableforasingle-operatoruse

•

Suitableforinstallationindomesticspacessuchasstorerooms,boilerrooms,garagesandbalconie

s.

3 - UNAUTHORIZED USE OF THE VACUUM CLEANER

It is extremely important NOT to use the system in the following circumstances which are consi-

dered to be inappropriate and dangerous:

•Neverusethemachineforunauthorizedpurposes.

• Never vacuum clean liquids.

• Do not vacuum clean fabrics, heavy materials, ashes or hot embers.

•Donotsuctioncement,ourorsimilarmaterials,includingtheconstructionsitedust(limeremains,

plasterpowderandsoon)whichmaycausethereductionofthevacuumedairwithaconsequentda-

mage of the motor.

The system has not been designed to be used in environments with risk of explosion, and the-

refore:

•itisforbiddentovacuumcleanmaterialswithhighexplosionrisk(gunpowder)ormaterialswhichare

individuallyinertbutthat,oncecollectedandmixedinthedustbin,couldprovokedangerouschemical

reactions.

•Itisabsolutelyforbiddentousethevacuumcleanerinexplosiveatmosphereoroutsidethestandard

temperature,pressureandhumiditylevels.

• Do not vacuum any material which may cause electrostatic charges in the piping system, if not

previously communicated to the constructor.

Any use of the appliance other than those specied above is forbidden.

Any change or modication made to the system in order to vacuum clean a particular type of

material must obtain the prior written approval of the manufacturer.

The use of the system for purposes other than those for which it was manufactured, represents

an irregular condition which can cause damage to the product and seriously compromise the

operator’s safety.

7

2

27/04/2022 Rev:1.0.0

English

4 - SAFETY FEATURES

WARNING: The manufacturer declines any form of responsibility or guarantee if the purchaser, or

anyoneinhisstead,makeseventheslightestmodicationoradjustmenttothepurchasedproduct.

Theunithasbeendesignedtosatisfyatbestthepresentneedsofthedomesticcentralvacuumclea-

nersmarket,bothintermsofqualityandoperatingcapacity.

AllmaterialsandcomponentsusedtomanufacturethisproductcomplywithCEsafetyregulations.

IncompliancewithsafetyregulationsdetailedintheMachineryDirective2006/42/CE(transposedinto

the Italian Legislation by Decree Law 17/10), in the Low Voltage Directive 2006/95/CE, and in the

ElectromagneticCompatibilityDirective2004/108/CE,theVacuProsystemcomplieswiththestandard

establishedforelectricalappliancesforhouseholdandsimilarpurposesEN60335-1(2008)andwiththe

RegulationCEN60335-2-2(2011),speciallyconceivedforvacuumcleanersforhouseholdandsimilar

purposeswithratedvoltagenotexceeding250V.

It is recommended to read carefully all the installation, use and maintenance instructions

detailed in this manual.

4.1 Warning

•Keepchildrenawayfromthevacuumcleanerwhilstinfunction.Childrenshouldnotplaywiththema-

chinenorwiththesuctionsockets.

•Thisequipmentshouldnotbeusedbypeople(includingchildren)withreducedpsychic,sensoryor

mentalcapacitiesorbypeoplewithnoexperiencenorknowledgeofthesystem,unlesstheyareunder

theguidanceorinstructedtousethemachinebypeopleresponsiblefortheirsafety.

•Childrenmustalwaysbesupervisedtoensuretheydonotplaywiththemachine.

•Switchoffthepowersupplyimmediatelyif:

- The electric cable is damaged or worn

-Thevacuumcleanerhasbeenexposedtorainorexcessivehumidity

-Thevacuumcleanerhasbeenknockedortheoutercoverhasbeendamagedinanyway

-Youthinkthesystemrequiresmaintenanceorrepair

•

Wearprotectiveglovesandmasktocarryoutmaintenance,toemptythedustbinorreplaceandcleanthelter.

•Onlyuseoriginalsparepartsandaccessories.

•Donotusethesystemwithoutaltercartridge.

•Donotblocktheexhaustairpipesorthemotorcoolingintakes.

•Nopartofthebodyshouldcomeintocontactwiththesuctionaccessories.

•Useonlyonesuctionsocketatatime.

•Donotleavethesystemswitchedonwhennotusingitanddisconnectitfrompowersupplywhenthe

systemisnotgoingtobeusedforalongperiodoftime.

Finally, remind that pictograms or danger and warning signals can be found on those parts of the

equipmentwhere,ifnotstrictlyfollowed,potentialriskysituationsmayoccur.

Instruction manual

8

27/04/2022 Rev:1.0.0

4.2 Protection Degree

IP44:Theappliancefeaturesaprotectionagainstsolidobjectshavingasizeexceeding

1mmandprotectionagainstsplashesofwater(splashesofwaterfromanydirectionon

thecovermustnotproducedangerouseffects).

IP20:Apparatusprotectedagainstsolidpartslargerthan12mmbutnotprotectedagainst

theinltrationofwater.

4.3 Electrical insulation degree

CLASSI:Theappliancefeaturesbasicelectricalinsulation.

Must be connected to the ground circuit through the main electric circuit.

CLASSII:Theappliancefeaturesdoubleelectricalinsulation.Theydoesn’tneedaconnetion

to the ground circuit through the main electric circuit.

4.4 Declaration of absence of dangerous substances

Themanufacturer declaresthat itsproducts andappliances havebeenmanufacturedwithmaterials

whichcomplywiththerestrictionsestablishedbythehealthandenvironmentprotectionregulationsin

forceanddonotcontainSVHC-classiedsubstances(SubstanceofVeryHighConcern)incompliance

withCEregulation1907/2006(REACH: i.e.Registration,Evaluation,AuthorizationandRestrictionof

ChemicalSubstances).Althoughthesesubstanceshavenotbeenusedduringtheprocessingcyclesof

rawmaterialsandduringthemanufacturingcyclesofourproducts,theirpresenceinp.p.m.(partsper

million)cannotbecompletelyexcludedduetomicro-pollutionofrawmaterials.

4.5 Fixed closure guards safety

ThevacuumcleanerisdeliveredtotheCustomerwithitsmainbodycompletelyassembled.Movingparts

(suctionmotor turbineblades)areprotectedbyaprotectiongriddirectlyassembled ontheinlet ofthe

suctionmotorcompartment.Thisprotectiongridcannotbeaccessedbytheoperator.Theoperatoralso

doesnothaveaccesstotheelectrically-operatedpartsoftheappliancewhichareprotectedbyacover

whichcanonlyberemovedbyunscrewingtheTorsenscrewsusedtoxthesoundproongdomeofthe

housing where the suction motors are assembled.

Everyinterventiononthecontrolboardandonthemotorsmustbecarriedoutbyqualiedpersonnelonly

afterdisconnectingtheelectricalpowersupplyandbyremovingtheelectricplugfromtheelectricsocke

4.6 Movable closure guards safety

Therearenomovableclosureguardsassembledontheappliance.Everyguardassembledisconside-

redaxedguardandisfastenedwithspecialscrews.Themanufacturerremindsyouthatitisabsolutely

forbiddentoreplacethescrewsusedforthedesignandmanufactureoftheapplianceswithscrewsthat

feature different characteristics.

Themanufacturerwillimmediatelysuspendtheproductguaranteeincaseofmachinetamperingcarried

out by the Customer.

IP20

9

2

27/04/2022 Rev:1.0.0

English

4.7 Identication plate

TheCEidenticationplateisassembledonthesideoftheconnectiontothepipingnetwork.Thisshould

not be removed or damaged.

....................................

.........................................................................

IP20

Model:

P/N: S/N:

ManufacturerIdentication

Technical data of the electric motor

Serial Number

TypeofCentralvacuumcleaner

Article

CE conformity

marking

Instruction manual

10

27/04/2022 Rev:1.0.0

5- PACKAGE CONTENTS

Thesalespackageofthecentralvacuum,inadditiontotheequipmentandthismanual,alsoincludes

theaccessorykit,consistingofthefollowingparts:

1) N°1wallmountingbracketforxingthecentralvacuumunittothewall

2) N°1rubbersleevesforconnectiontothevacuumpipenetwork

3) N°3metalclampsforxingthesleeves

4) N°1 installation, use and maintenance manual

5) N°1plasticairexhaustsilencerforairdischarge

1 2 3

45

MANUALE TECNICO

S

.l.

11

2

27/04/2022 Rev:1.0.0

English

6 - INSTALLATION

- WARNING -

THESE PROCEDURES MUST BE CARRIED OUT

BY QUALIFIED PERSONNEL

6.1 Preliminary operations

Thesuctionsystemisshippedtothecustomercompletelyassembledandpacked.

Beforeswitchingthemachineon,thefollowingchecksareadvisable:

•Checkthatthepackagingisintact.

•Checkthattheappliancehasnotbeendamagedinanywayandinparticularcheckthatallthepro-

trudingpartsareintact.

•Verifythecorrecttighteningoftheltercartridge.

•Usingtheequipmentlistandthekitandaccessorieslist,checkthattheequipmentandthekithave

beenexactlyandcompletelydelivered.

•CheckthattheGuaranteeCerticatehasbeenprovided.

Ifanydamageorirregularityisfoundorifanyaccessoryismissing,donotinstalltheapplianceand

contact your Retailer.

6.2 Place of installation

Theuseofthevacuumcleanerrequiresasuctionpipingnetworkinstalledbyqualiedpersonnelwho

has already selected the most suitable location.

Belowyouwillndthemainindicationstobefollowedforacorrectinstallation:

• Iftheappliancewillbeconnectedtoapipenetworkonmorethanoneoor,wesuggestyoutoinstall

itinthelowestpartofthebuilding.

• Installthesysteminservicerooms(e.g.garageorstorageroom)awayfrombadweather,dampness

andexcessivetemperaturevariations.

• Chooseaplacefarfromheatsourcessuchasstovesandradiators.

• Makesurethatthereissufcientspacearoundthesystemandthatthesurroundingareaiswelllitto

facilitatetheinterventionsformaintenanceandrepairs.

Whenthevacuumcleaner,forspecicinstallationneeds,isinstalledonthehighestoorsofthebu-

ildingwithregardtothelevelwherethepipenetworkishoused(attic,garretetc.),wesuggestyouto

installavacuumcleanerfeaturingapowercategoryhigherthantheoneneededtocleanthedesired

surface.

Foranyfurtherinformation,donothesitatetocontacttheManufacturer’sTechnicalService.

Instruction manual

12

27/04/2022 Rev:1.0.0

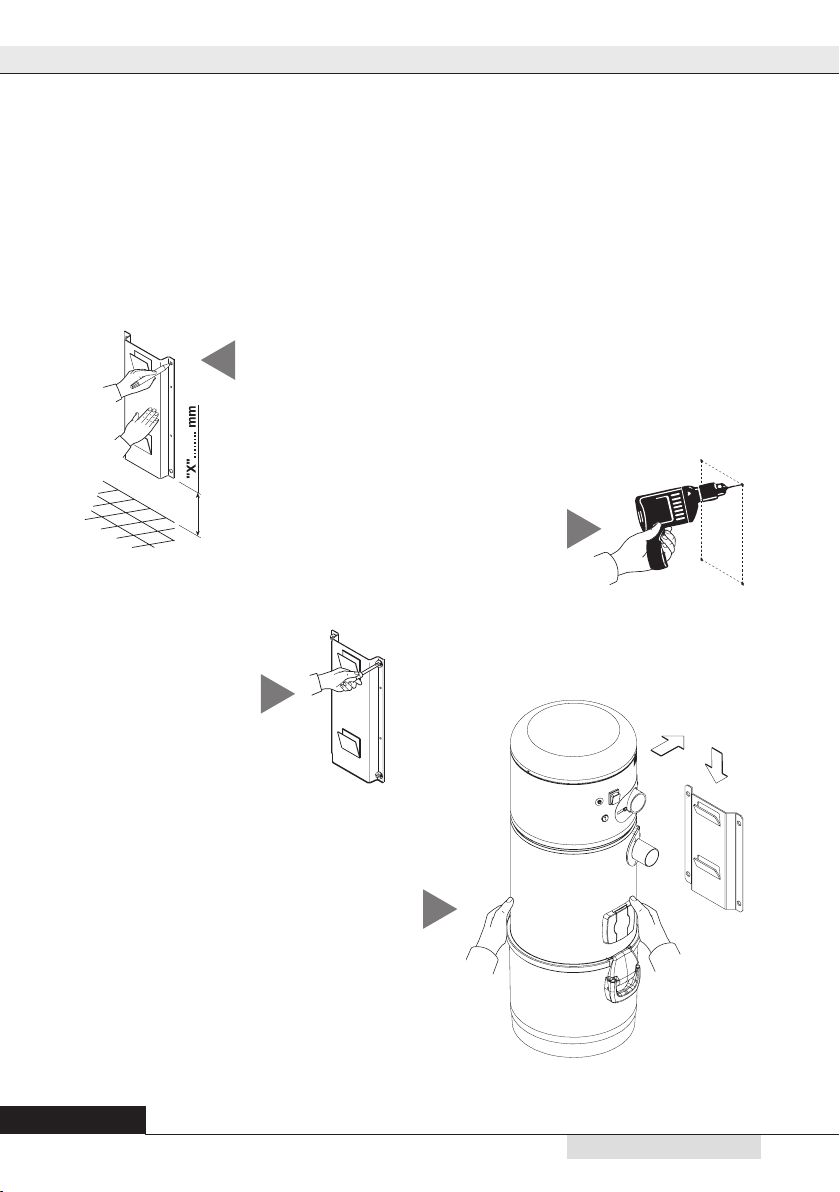

Tracethedrillingpositionusingthe

templateprovided(drillingtemplate);if

thishasalreadybeendone,proceedto

thenextstep.

6.3 Fixing the vacuum cleaner to the wall

Thevacuumcleanermustbesecurelyandpermanentlyxedtoasolidwallusingthebracketprovided

andthesuitablewallanchorsorplugstakingintoaccountthatthetotalweighttobesupportedcanbe

seven/eight times the weight of the system itself.

Thesystemshouldbepositionedhighenoughoffthegroundtoallowthedustcollectionbintobe

emptiedandtheltertobereplacedinasimpleway.

Positionthesystemsoastokeepaminimumdistanceof60cmaroundtheapplianceforextraordinary

maintenance.

Todothisfollowtheinstructionsdetailedbelow:

2

1

Drill the holes

Tighten the screws in

thewallplugsandcheck

thatthebracketiswell

anchored to the wall.

3

4

Hook the vacuum cleaner to the

anchoringbracketbyliftingit,leaning

it against the wall and allowing it to

slide down until it ts into the xing

plate.

13

2

27/04/2022 Rev:1.0.0

English

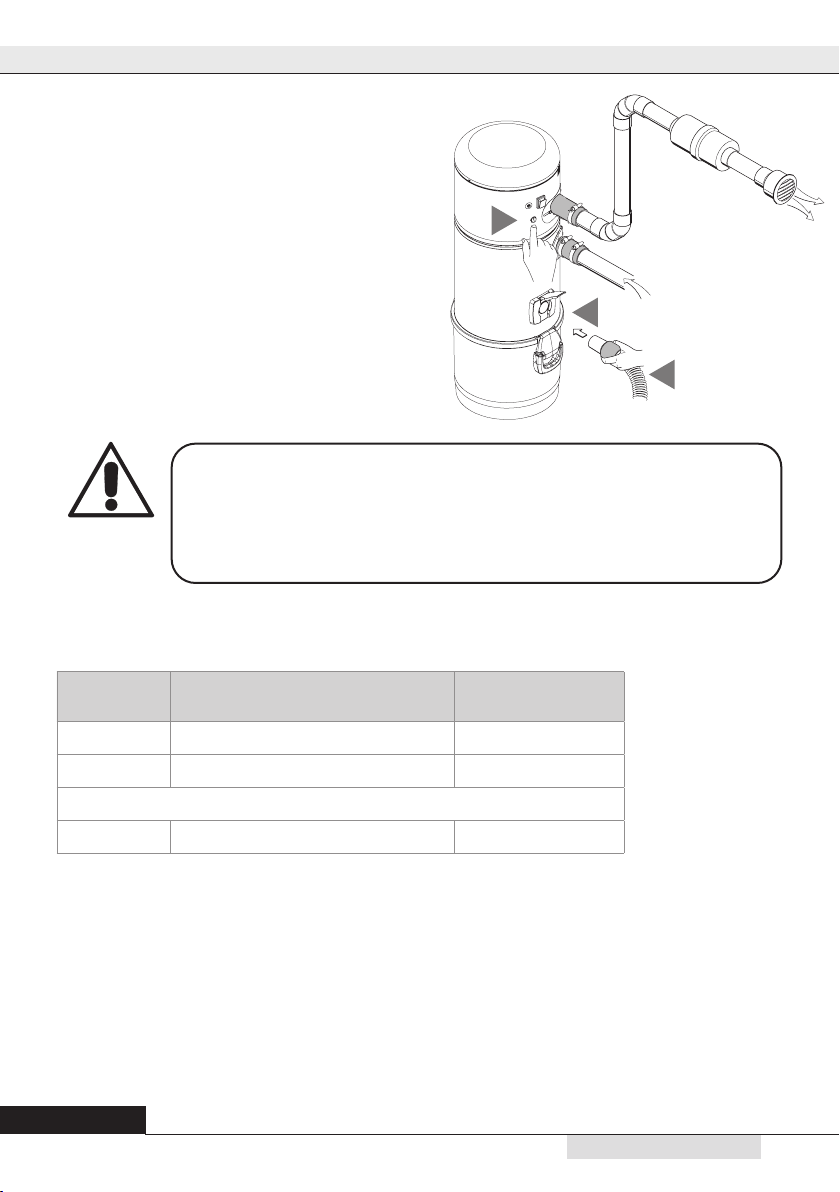

6.4 Connection to the piping network

1.Applytheclosingcap(A)ontheendoftheintakeconnectionnotusedforconnectingthepi-

pingnetwork(B),asopeningitwoulddecreasethecentralvacuumunit’svacuumpower.

A

D

E

B

C

2. Usingthesleeve,connectthedustinletcouplingofthecyclonicvacuumcleaner,identiedwith(C)

inthepicture,tothesuctionpipefromthepipingnetwork.

3. Byusingthesleeve,connecttheairoutletofthecentralvacuumunit,markedwith(D),totheair

outlet of the house.

4. Gluethesilencer(E)ontheexhaustpipeneartheexhaustairgrid.

N.B.:donotgluethepipeendofthenetworkpipetothedustinletcouplingortotheairexhaustcou-

pling:alwaysusethesleevesprovided.

Instruction manual

14

27/04/2022 Rev:1.0.0

B

C

Should it be necessary to convey the air discharge to the outside, please follow the following

instructions:

Maximum length of the discharge pipe:

N.B. Diameter of the outlet pipe for a length up to 10 m: 50 mm

Exhaust pipe diameter for lengths over 10 m: 63 mm

15

2

27/04/2022 Rev:1.0.0

English

WARNING: the electrical connection must be carried out

ONLY by qualied personnel.

MicroLine/Suctionsocket

12V

PowersupplyAC230V

6.5 Electrical connection

Beforeconnectingthesystemtotheelectricalpowersupplycheckthatthesupplyvoltagecorresponds

totheonerequiredbythevacuumcleaner(seetheidenticationplate).

Themanufacturerdeclinesanyresponsibilityfordamagestopeopleand/orobjectsduetotheconnec-

tiontoanon-complyingelectricwiring.

Followtheinstructions(seepicture)detailedbelowtocarryouttheoperation:

• Connecttheinputsignalcable(MICROLINE)tothesuctionsockets.

• Inserttheplugofthepowersupplycablefromthecentralsystemintheelectricsocket.

• Checkthattheelectricalwiringofthehousehasbeensetupincompliancewiththeelectricalregula-

tions in force.

• Donotpowerthesystemwithsupplyvoltagefromprovisionalortemporaryswitchboards(forexample

constructionsitesswitchboards)toavoidpossibledamagetotheelectronicparts.

Instruction manual

16

27/04/2022 Rev:1.0.0

7 - MAINTENANCE

7.1 Programmed routine maintenance

Maintenance should be carried out according to the effective running time of the system to ensure

efcientperformanceandtoavoidseriousmechanicaldamages.

7.2 Cleaning the suction container (cylinder)

Periodicallycleantheoutsidecasingofthevacuumcleanerwithasoftdampclothwithwaterandneutralsoap.

Important: only use water or neutral soap and water to clean the vacuum cleaner. The use of other

solvents or alcohol can entail damages. Ensure the system’ s surface is completely dry before

switching it back on.

Alwaysuseasuitablemasktoprotectagainstairbornedustandwearlatexglovestoprotectyourhand

skin.

BEFORE CARRYING OUT ANY MAINTENANCE

OPERATION, IT IS MANDATORY TO UNPLUG THE POWER

SUPPLY CABLE FROM THE POWER SUPPLY INLET.

PROTECTIVE MASK AND GLOVES MUST

ABSOLUTELY BE WORN

Working time

(h)

Maintenance Executor

6 Filter cleaning User

6 Emptying the dust container User

every 4 years Substitution of lter cartridge User

6.6 Using the service socket

1. Insert the hose (A) directly in the service outlet (B

- see the drawing), after lifting the cover.

2.Press the switch (C) on the frontal panel of the

machinetostartandstopsuction.

A

B

C

17

2

27/04/2022 Rev:1.0.0

English

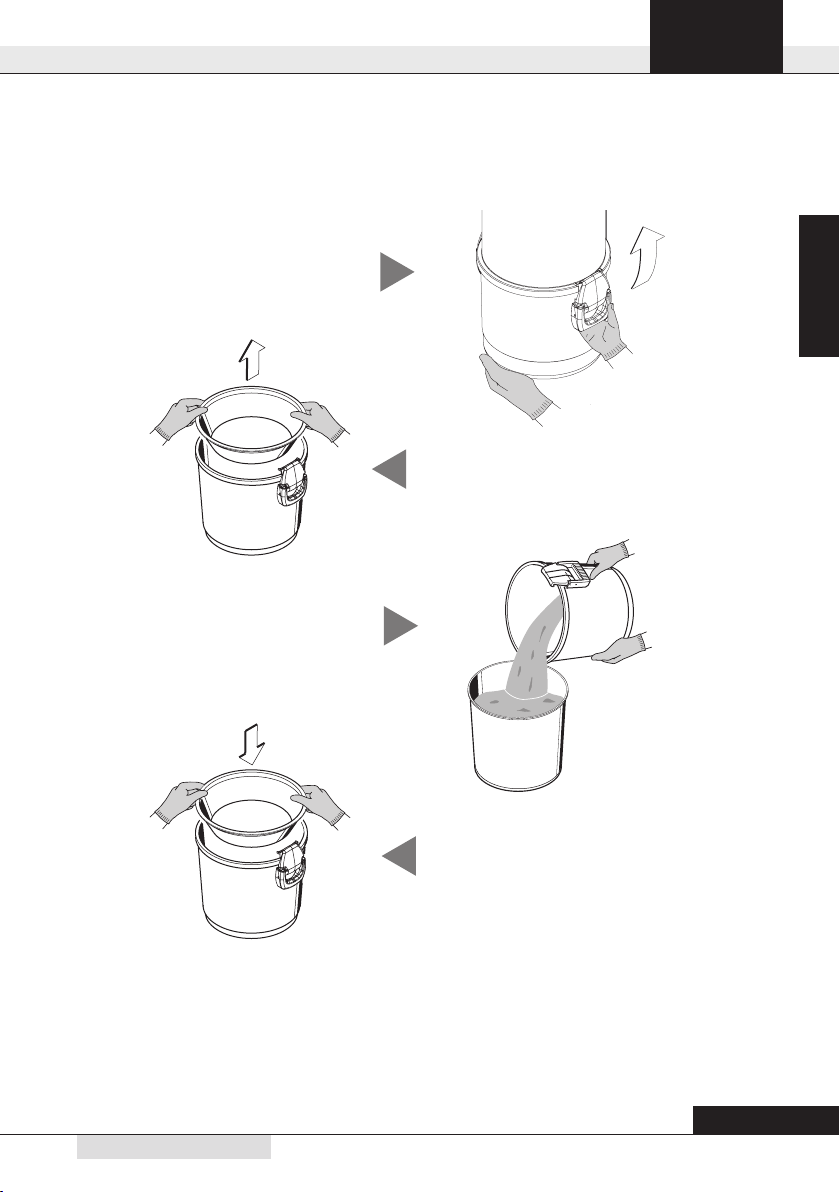

7.3 Emptying the dust bin

SwitchthesuctionsystemoffbypressingtheON/OFFswitch.

Remove the conveyor cone

2

Remove the dust bin 1

Emptythedustbin 3

Puttheconveyorconebackinposition

4

Reassemblethedustbininsideitshousingunderthesuctionsystemandlocktheclosinghandles.

SwitchthesuctionsystemonbypressingtheON/OFFswitch.

Remember to be careful when emptying the bin: if there is a big quantity of dust, make sure you

do not throw away the conveyor cone. Always check that the conveyor cone is still in place and

correctly assembled in its housing inside the bin.

Instruction manual

18

27/04/2022 Rev:1.0.0

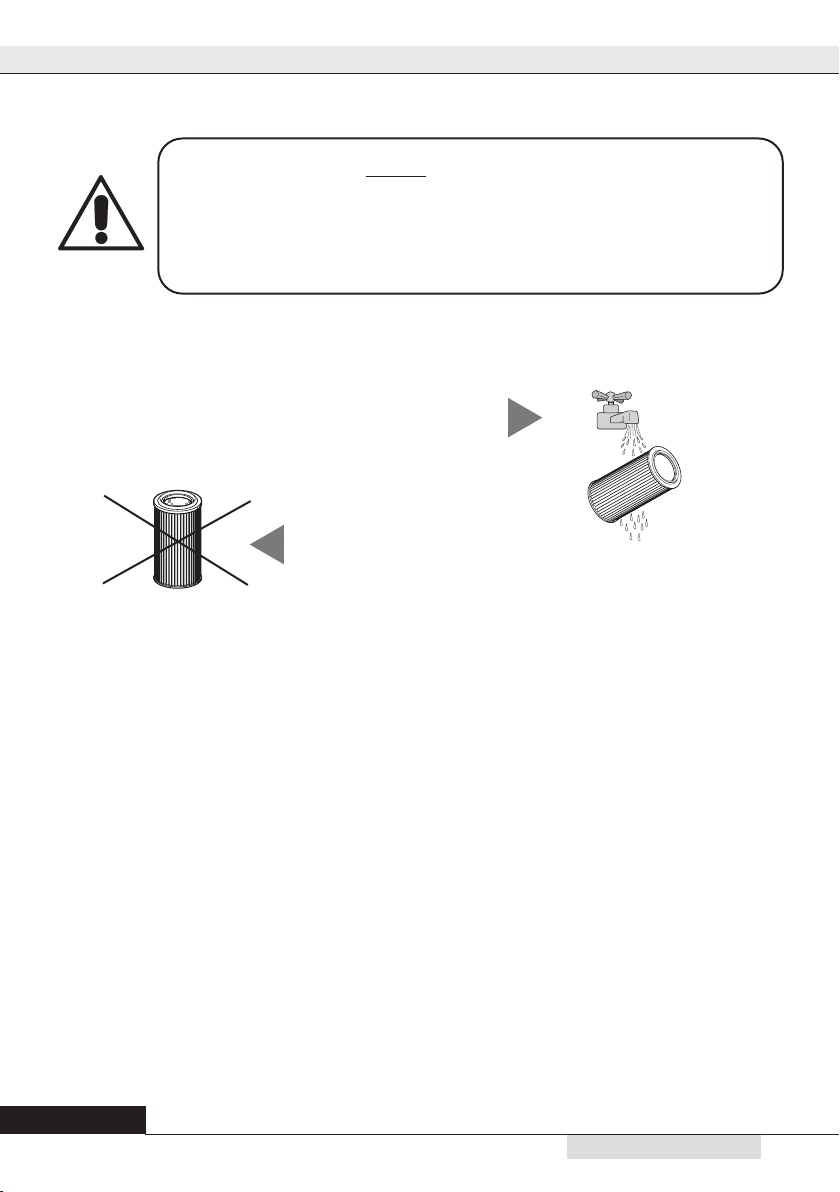

7.4 Disposal of the lter cartridge

Theltercartridgecanbereusedafterwashingitunderrunningwater.

ATTENTION: before replacing the lter cartridge back in the system after washing, ensure it has

completely dried. DO NOT reassemble the lter cartridge if the surface is still wet or damp

Check that the lter surface is not

cut. If this is the case, the cartridge

should not be used again and

shouldbedenitelyreplaced.

2

Before washing the cartridge it is always recommended to

vacuum clean the dirty surface with an auxiliary suction cleaner

orwiththeutility/serviceinlet,rememberingtoinsertaspare

cartridge in the system before use.

1

ATTENTION

YOU SHALL ALWAYS CHECK THE RIGHT POSITIONING AND TIGHTENING

OF THE FILTER CARTRIDGE. A WRONG POSITIONING MAY CAUSE

A SERIOUS DAMAGE OF THE PRODUCT.

DO NOT USE THE VACUUM CLEANER WITHOUT THE FILTER CARTRIDGE.

ENSURE YOU HAVE REPLACED A SPARE FILTER CARTRIDGE BEFORE

CARRYING OUT THIS OPERATION.

8 - REPAIRS AND SPARE PARTS

8.1 Intervention criteria

Anyinterventiononthevacuumcleanerforrepairsand/ormaintenancewhicharenotexpresslyauthorized

in this manual is absolutely forbidden.

AnyrepairforbreakageormalfunctioningmustbecarriedoutbyqualiedTechnicalAssistancepersonnel.

Anyinterventionofnon-authorizedpersonnelwillresultintheinvalidationofanyguaranteeoftheproduct

andthemanufacturerwillnotbeheldresponsibleforanyeventualdamagetopersonsand/orobjectsdue

to such interventions.

8.2 Recommended spare parts

Itisadvisabletoorderintimethosesparepartswhichneedtobechangedmoreoften.

Inordertoguaranteetheoptimalandlongworkinglifeofthevacuumcleaneritisrecommendedtouse

onlyoriginalspareparts

9 THERMAL SWITCH

Thethermalswitchpreventsdamagestotheelectricandelectronicpartsfrompoweroverloadsandfrom

short-circuits. The switch button is located inside its lodging during the regular functioning of the machine,

whileincaseofactivatedprotectionitwillbeoutofitslodging.Thereactivationoftheswitchmustbedone

manuallybypushingthebuttonbackintoitslodging.Thisoperationwillbeeffectiveonlyifthecauseof

theblockinghasbeenxed.Iftheblockingoccursregularly,itisadvisabletoletaspecializedtechnician

verify the correct functioning of the machine.

19

2

27/04/2022 Rev:1.0.0

English

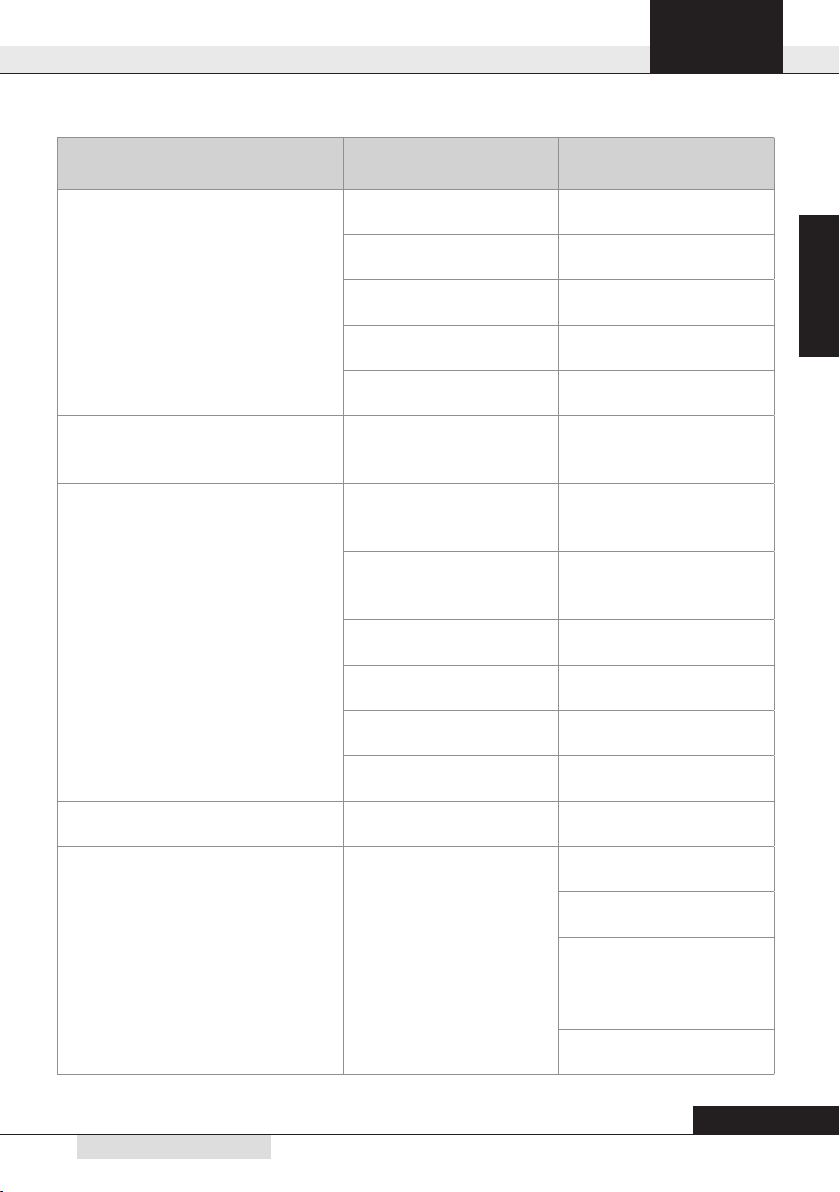

10 - TROUBLE SHOOTING

PROBLEM CAUSE SOLUTION

There is no suction from any of the

suctionsockets

Thepowercableisunplugged Connectthepowercable

The start button is on OFF

position Press the Start button

The micro line cable is not

connected

Connect the activation cable

(sensor)

Thethermalprotectionofthe

motor has intervened

Allowafewminutesstopfor

the motor to cool down

The thermal switch has

intervened

Press the restart button on the

thermail switch

Thereisnoairsuctionfromjustone

suctionsocket

Theelectriccontactsareinterruptedorthe

micro-switchofthesuctionsocketisout

of order

Call the Technical Service

Theairsuctionisweak

Morethanonesuctionsocketisbeingusedat

thesametimeand/ortheservicesuctionsocket

isworking

Use only one suction inlet at

a time

Theexiblehoseorthe

cleaning accessories are

broken

Checktheexiblehoseandtheaccessories

are not damaged (change them if

necessary)

Theltercartridgeisdirty Cleantheltercartridge

Thesealinggasketofthedust

bin is damaged

Checksealinggasket

integrity

There is a clogging in the suction

pipesofthepipe

network

Call the Technical Service

The air exhaust outlet is

blocked Call the Technical Service

Thevacuumcleanerstillworkseven

when the suction inlets are closed

Fault of the electronic board Call the Technical Service

Thesuctionworksintermittentlywiththe

hose inserted in the inlet.

Thethermalprotectionofthe

motor has intervened

Checkforapossibleclogging

inthepipingnetwork

Checkforapossibleclogging

intheairdischargepipe

Remove the hose from the

suctioninletandwaitacouple

of minutes to let the motor

cool down

Call the Technical Service

F0920620

36031 Dueville (VI) ITALIA - Via Prati, 11

Tel. + 39 0444 1803418 - info@stakorr.it

Table of contents