Standard Pump SP-430EX Application guide

Operation &Parts Manual

Models: SP-430EX & SP-440EX

OIPM-EXP-0818

Introduction

This manual pertains to the SP-430EX & SP-440EX Series drum pump motors. When properly installed

and operated, your Standard Pump motor and pump will provide long, trouble-free service; therefore,

please read this manual carefully before carrying out anyoperations onthe pump-motor unit. Any use

other than that described herein is considered incorrect and; consequently, Standard Pump, Inc. shall not

be held responsible for any damages to people or property.In case of doubt orinquiries,please apply to

our Technical Service department directly at the following address:

Standard Pump,Inc.

1610 Satellite Blvd, Suite D

Duluth, GA 30097 U.S.A.

Tel. 1-770-307-1003

Fax 1-770-307-1009

www.standardpump.com

info@standardpump.com

Index

Introduction.........................................................................................................................2

Safety..................................................................................................................................3

Installation...........................................................................................................................4

Operation & Specifications..................................................................................................5

Declarations........................................................................................................................7

General Terms & Conditions, Warranty..............................................................................8

OIPM-EXP-0818

2

SAFETY

1. Introduction

This manual contains allthe information needed for the correct installation, use and maintenance of your new

Standard Pump, Inc. motor. Itshould be read and understood by allthe personnel involved in installation,

operating and servicing of the pump before it isstarted.

2. Operator Qualification and Training

The personnel in charge of the installation, operation and maintenance of the pump unitwe produce must be

qualified and able to perform the operations described in this manual. Standard Pump, Inc. shall not be held

responsible for the training level of personnel and for the fact that they are not fully aware of the contents ofthis

manual.

3. Safety Instructions

FOR YOUR OWN SAFETY:

BEFORE UNDERTAKING ANY SERVICE OPERATION ON YOUR MOTOR OR PUMP, PLEASE MAKE

SURE TO WEAR THE PROPER PROTECTIVE GEAR.

GENERAL DANGER

NEVER use a plastic pump or an open, splash-proof, TEFC or non-ATEX motor when pumping or mixing

flammable or combustible material. ALWAYS use and store the pump and motor in an upright position.

DANGER: POWER SUPPLY

NEVER perform any maintenance operation on the motor while it isrunning or before it has been disconnected

from the power supply. Avoid any possible hazard that might be caused by electric power. ALWAYS check the

electrical specifications on the motor data plate and make sure they correspond to the power supply to which it

will be connected.

ALWAYS place motor in the OFF position prior to connecting the power source. NEVER immerse the

motor in liquid.

ALWAYS use an ATEX Zone 1approved plug and receptacle for ATEX motor models.

ALWAYS use a UL/CSA Class I Division 1 Group D approved plug and receptacle for Hazardous Location

motor models.

4. Noise Level

At normal operating conditions, SP-430EX and SP-440EX motors produce a sound level equal or less than 81

dBA at a distance of three feet (~one meter).

5. Modifications and Spare Parts

Any changes concerning the service of the motor as originally purchased, can be executed only after written

approval from Standard Pump, Inc. It isrecommended to use only genuine Standard Pump, Inc. spare parts

and approved accessories. The use of non-original spare parts or non-approved accessories will void warranty

and removes anyresponsibility on our behalf for any damage caused to people or things.

NEVER operate ATEX rated or Haz Loc rated motors outside their rated ambient temperature range of -20°C

to +40°C.

Warning: Explosion Hazard - Do not replace the cord on Explosion proof motor models. Replacing the cord will

invalidate the safety of the equipment. Return the motor back to the manufacturer for cord replacement. Do

not open or repair the flame-proof joints of Explosion proof motors. Contact the manufacturer for cord, fuse,

and circuit board replacement.

Static sparking can cause an explosion. Always follow NFPA 77 and CLC/TR 60079-32-1 guidelines for

control of static electricity and proper grounding methods when using ATEX and Hazardous Location motor

models. When operating in a hazardous area or pumping a hazardous fluid, the motor and entire pump system

must be grounded to prevent static discharge using appropriate grounding wires and connectors.

OIPM-EXP-0818

3

Sécurité

1. Introduction

Ce manuel donne toutes les instructions nécessaires pourassurer l’installation, l’utilisation et l’entretien

adéquats du moteur de pompe Standard Pump, Inc.Ces instructions doivent être lues et comprises par tout

le personnel participant à l’installation, à l’utilisation et à l’entretien de la pompe avant son démarrage.

2. Qualifications etformation des opérateurs

Le personnel en charge de l’installation, de l’utilisation et de l’entretien de la pompe et de son moteur doit être

qualifié et capable d’effectuer les tâches décrites dans ce manuel. Standard Pump,Inc. n’est pas

responsable du niveau de formation du personnel et du fait qu’ils n’aient pas pris entièrement connaissance

du contenu de ce manuel.

3. Consignes de sécurité

POUR VOTRE SÉCURITÉ

AVANT d’utiliser ou de faire l’’entretien de votre pompe, s’assurer de porter les vêtements protecteurs

adéquats, les protections oculaires (pour les yeux) etde suivre les procédures de sécurité standard pour

manipuler les matières corrosives ou danger e uses pour la santé.

DANGERS GÉNÉRAUX

NE JAMAIS utiliser de pompe en plastique ni de moteur ouvert, étanche aux éclaboussures, de type TEFC

ou non conforme à la norme ATEX, pour pomper ou mélanger des matières inflammables ou combustibles.

TOUJOURS utiliser etremiser la pompe et le moteur enposition verticale.

DANGER : ALIMENTATION ÉLECTRIQUE

NE JAMAIS effectuer aucune tâche d’entretien sur le moteur lorsqu’il esten marche, ou avant de le

débrancher de son alimentation électrique. Éviter toute condition dangereuse en rapport avec l’alimentation

électrique.

TOUJOURS vérifier les spécifications électriques sur la plaque signalétique du moteur ets’assurer qu’elles

correspondent à l’ alimentation électrique à laquelle il estraccordé. TOUJOURS mettre le moteur en position

d’arrêt («OFF») avant de le raccorder à l’alimentation électrique.

NE JAMAIS immerger le moteur dans un liquide.

TOUJOURS utiliser une prise et une prise homologuées ATEX Zone 1 pour les modèles de moteurs ATEX.

TOUJOURS utiliser une prise et un réceptacle homologués UL/CSA Classe IDivision 1 Groupe D pour les

modèles de moteurs à emplacement dangereux.

AVERTISSMENT:Risque d'explosion - Ne remplacez pas le cordon sur les modèles de moteur

antidéflagrants. Le remplacement du cordon annulera la sécurité de l'équipement. Retournez le moteur au

manufacture pour le remplacement du cordon. Ne pas ouvrir ou réparer les joints ignifugés desmoteurs

antidéflagrants. Contacter la manufacture pourle remplacement du cordon, du fusible et du circuit imprimé.

Les étincelles statiques peuvent provoquer une explosion. Respecteztoujours les directives NFPA 77 et

CLC /TR60079-32-1 pourle contrôle de l'électricité statique et les méthodes de mise à la terre appropriées

lors de l'utilisation de modèles de moteurs ATEX etde sites dangereux. En cas de fonctionnement dans une

zone dangereuse ou de pompage d'un fluide dangereux, le moteur et l'ensemble du système de pompe

doivent être mis à la terre pour éviter une décharge statique à l'aide d'un kit de protection statique Standard

Pump.

4. Niveau de bruit

En conditions normales d’utilisation, les moteurs électriques SP-430EX et SP-440EX génèrent un niveau de

bruit égal ou inférieur à 81 dBA à une distance de 3 pieds (env. 1 mètre).

5. Modifications et pièces de rechange

Toute modification concernant l’entretien du moteur/pompe, tels qu’achetés initialement, peutêtre exécutée

seulement après en avoir obtenu l’autorisation écrite de Standard Pump,Inc. Ondemande d’utiliser

seulement les pièces de rechange originales de Standard Pump,Inc. etles accessoires approuvés. Le fait

de ne pas utiliser les pièces de rechange originales de Standard Pump, Inc. ou les accessoires approuvés

annulera la garantie et dégagera le fabricant de toute responsabilité liée aux blessures ou dommages

matériels.

OIPM-EXP-0818

4

INSTALLATION -

SP-6600, SP-7600, SP-8600 &

SP-8850 Series

Warning: Do not position the motor handle and cord over and in front of the pump discharge.

1 Unpack motor from carton. Check for shipping damage. If damage is detected, save the packaging

and notify the carrier immediately.

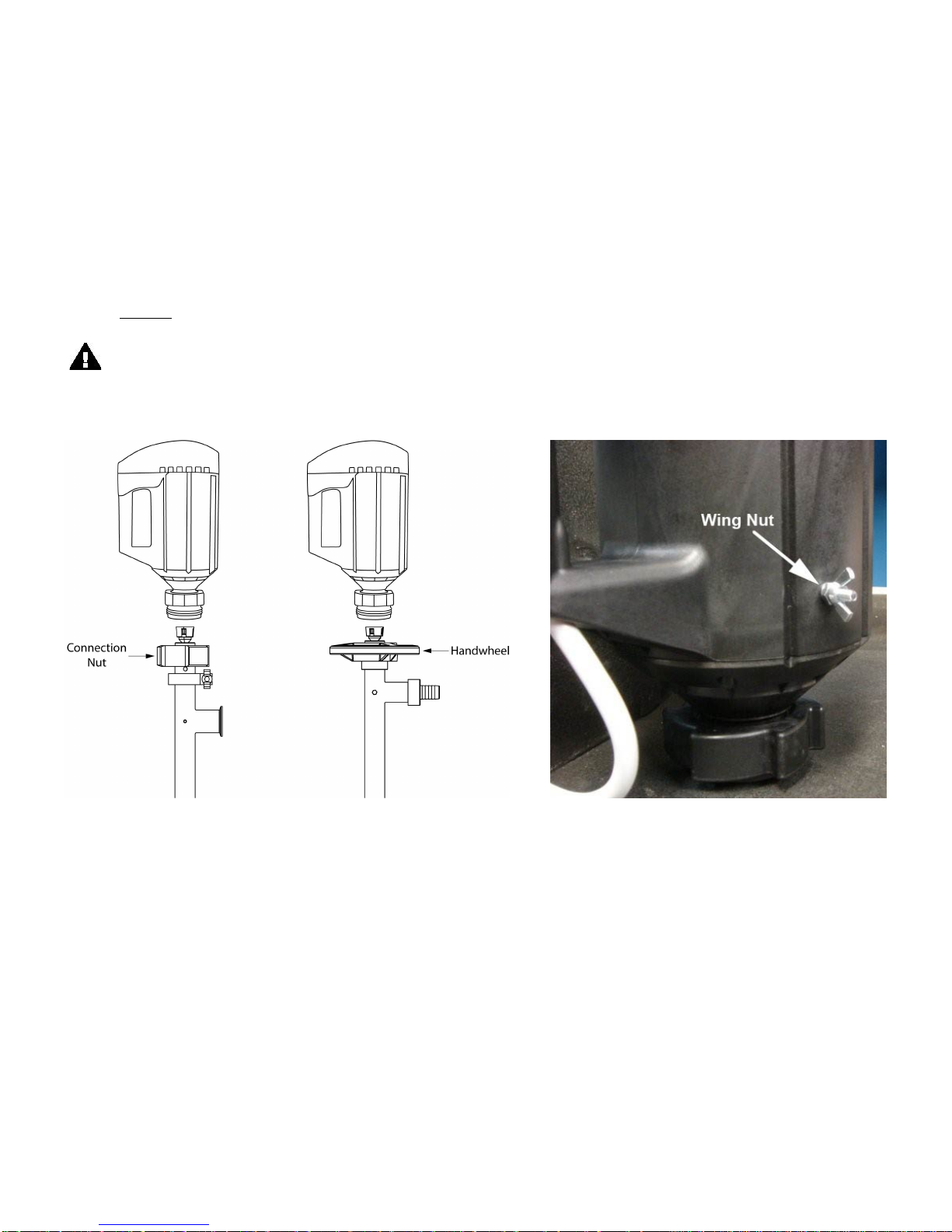

2 Couple motor to pump by maually threading handwheel or connection nut (depending on pump tube

model) onto male threads at bottom of motor until they are hand tight (see figure 1).

3 Ensure that motor is fully engaged with pump tube prior to operation.

Note: Do not use hand tools to tighten the nut as this may cause damage to the motor casing.

Figure 1

Grounding of ATEX & Haz Loc Motors

(Models SP-430EX & SP-440EX)

When operating in a hazardous area or pumping a hazardous fluid, the motor and entire pump system

must be grounded to prevent static discharge using appropriate grounding wires and connectors.

1 Unscrew the #10-32 wing nut from the side of the motor housing, and attach a grounding wire with

a #10 ring terminal. Screw the wing nut back on and tighten firmly by hand. Ground the motor, pump,

and all containers (see figure 2).

2 Follow the safety instructions for the appropriate pump.

Figure 2

OIPM-EXP-0818

5

OPERATION

The SP-430EX & SP-440EX motors utilize an electronic motor controller and membrane keypad to provide

precise speed control and superior motor protection. An electronic circuit board within the housing controls the

motor’s speed, overload protection, motor temperature, and electronics’ temperature. The keypad incorporates

two colored LED lights toprovide feedback tothe user.

Make sure the pump’s discharge hose is properly secured prior to operating the motor. When the unit is plugged

into a power outlet, the “Green” LEDwill blink indicating it isin “Standby mode”, meaning that power is

provided, but the motor is “Off”. Pressing the “Power” key will turn the motor “On” and it will begin to ramp up

to speed. The “Green” LEDwill change from blinking to solid indicating the motor is“On”. Pressing the

“Down” or “Up” keys will change the 10 available motor speeds, and can also be held in for quicker adjustment.

Pressing the “Power” Keywill switch the motor “Off” and the “Green” LEDwill again blink indicating the unitisin

“Standby” mode. When the “Power” key ispressed again, the motor will ramp up to the previously set speed.

When the unit’s power isdisconnected, the stored speed is set backto the default speed.

Keypad –Figure 2

The “Red” LED indicates a motor fault. When the motor faults, it will turn off into “Standby” mode with the

“Green” LED blinking. The blink pattern of the “Red” LED will indicate the fault type:

"Red" LED Blink Pattern Fault Type Solution

Solid RED Over Current Reduce motor speed.

Ensure fluid viscosity is within pump limits.

Allow motor to cool. Reduce motor speed.

Ensure fluid viscosity is within pump limits.

If motor is cool, brushes may have reached end of life.

Over TemperatureBlinking RED

Green LED

Power Key

Decrease Speed Key Increase Speed Key

Red LED

Press the “Power” key to reset the fault and the motor will turn “On”. The motor will not turn “On” until it has

cooled to an acceptable level.

It may be necessary to operate the pumpat a slower speed for high viscosity fluids. Contact factory for

troubleshooting tips. At slower speeds, ensure the motor isrunning toprevent itfrom overheating, of which can

reduce the motor’s life. Unplug the unit when not in use.

Depending on the application, motor brush life is approximately 200-300 hours. Models SP-430EX &

SP-440EX must be sent to Standard Pump, Inc. for factory brush replacement.

OIPM-EXP-0818

6

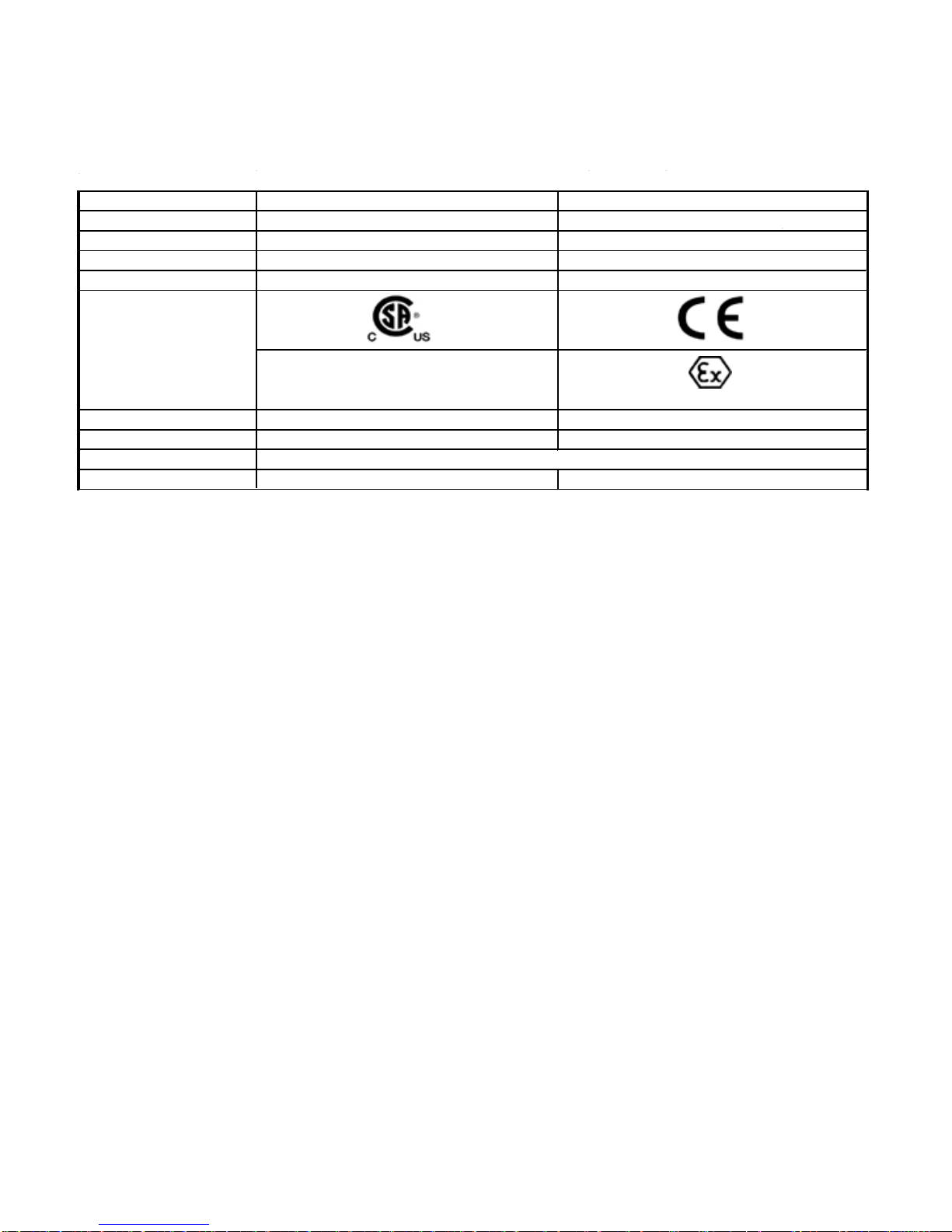

Model

Rated Voltage

Hertz

Input Watts

Output Watts

Plug Type

RPM's (Variable Speed)

Duty Cycle

Enclosure IP55 (TEFC)

3,0000-12,000 RPM

None

ContinuousDuty

230V

50/60 Hz

SP-440EX

115V

60 Hz

Haz Loc,

CLASS I, DIVISION 1,

GROUP D, T4

None

TEFC

SP-430EX

Certifications/Approvals

3,0000-12,000 RPM

680

1000

680

1000

II 2G ExdbibIIB T5Gb

MOTOR SPECIFICATIONS

OIPM-EXP-0818

7

EU Declaration of Conformity

Standard Pump, Inc. hereby declares that the following electrical equipment fully complies with the applicable health and

safety requirements as specified by the EU Directives listed. The product may not be taken into service until ithas been

established that the Drum and Container Pump complies with the provisions of allrelevant EUDirectives. The complete

product complies with the provisions of the EU Directive on machinery safety provided pumps manufactured by Standard

Pump, Inc. are used. This declaration is valid provided that the devices are fully assembled and no modifications are

made to these devices.

Type of Device:

Electric Motors for Driving Drum and Container Pumps

Models:

SP-440EX

EU Directives:

Low Voltage Equipment (2014/35/EU)

Electromagnetic Compatibility (2014/30/EU)

Applied Harmonized Standards:

EN 60335-1

EN60335-2-41 EN 60529

EN 55014-1

EN 55014-2

Manufacturer:

Standard Pump, Inc. 1610

Satellite Blvd, Suite D

Duluth, Georgia 3097 U.S.A

Signed,

James Murphy

Director of Sales and Marketing

May 1,2018

OIPM-EXP-0818

8

EU Declaration of Conformity

Standard Pump, Inc. hereby declares that the following machines fully comply with the applicable health and safety

requirements as specified bythe EU Directives listed. This declaration is valid provided that the devices are fully assembled

and no modifications are made to these machines.

Type of Device:

Electric Motors for Driving Drum and Container Pumps

Pump Motor Models:

SP-440EX

EU Directives:

Equipment and protective systems intended for use in potentially

explosive atmospheres (2014/34/EU)

EU-Type Examination:

Physical Technical Testing Institute 1026

Ostrava-Radvanice

FTZU 14 ATEX 0200X

Product Quality Assurance Notification:

Physical Technical Testing Institute 1026

Ostrava-Radanice

FTZU 08 ATEX Q003

Applicable Harmonized Standards:

EN 60079-0:2012

EN 60079-1:2014

EN 60079-11:2012

Signed,

Hans-Peder Jensen

Technical Director

May 1,2018

OIPM-EXP-0818

9

WARRANTY, GENERAL TERMS & CONDITIONS

1. The following terms and condition apply tothe sale of machinery, components and related services and

products, ofStandard Pump, Inc. (hereinafter “the products”).

2. Standard Pump, Inc. (the manufacturer) warrants onlythat:

a.) its products are free ofdefects in material, design and workmanship at the time oforiginal purchase

b.) its products will function in accordance with Standard Pump, Inc. operation manuals;

Standard Pump, Inc. does not guarantee that the product will meet the precise needs of

the customer, except for those purposes set out in any invitation to render documents or

other documents specifically made available to Standard Pump,Inc. before entering into

this agreement

c.) high quality materials are used in the construction of the pumps and that machining and assembly are

carried out to the highest standards. Except as expressly stated above, Standard Pump,Inc.

makes no warranties, express orimplied, concerning the products, including all warranties of

fitness for a particular purpose.

3. This warranty shall not be applicable in circumstances other than defects in material, design, and

workmanship. In particular, this warranty shall not cover the following:

a.) Periodic checks, maintenance, repair and replacement of parts due to normal wear and tear;

b.) Damage to the product resulting from:

i. tampering with, abuse or misuse, including butnot limited tofailure touse the product for its

normal purposes as stated at the time ofpurchase or in accordance with Standard Pump,Inc.

instructions for use and maintenance ofthe product, orthe installation or improper ventilation or

use of the product in a manner inconsistent with the technical orsafety standard in force

ii. repairs performed by non-authorized service workshop, or opening of the unitby non-

authorized personnel, oruse of non-genuine Standard Pump,Inc. parts

iii. accidents, acts ofGod or any cause beyond the control ofStandard Pump,Inc., including but

not limited tolightning, water, fire, earthquake, and public disturbances, etc.

4. This warranty shall cover the replacement or repair ofany part(s), which is documented to be faulty due to

construction or assembling, with a new or repaired part(s) free ofcharges delivered by Standard Pump,

Inc. Part(s)subjected to normal tear and wear shall not be covered by thewarranty. Standard Pump,Inc.

shall decide as to whether the defective or faulty part shall be replaced orrepaired. Transportation charge is

prepaid to Standard Pump, Inc.

5. The warranty ofthe products shall be valid for a period of 36 months from the date ofdelivery, under the

condition that notice of the alleged defect to the product(s) orpart(s) thereof be given to Standard Pump,

Inc. in writing within the term of8 days from the discovery.

6. Repair or replacement under the terms ofthe warranty shall not give a right to an extension to, ora new

commencement of, the period of warranty. Repair or replacement under the terms ofthis warranty may be

fulfilled with functionally equivalent, reconditioned units. Standard Pump, Inc. qualified personnel shall be

solely entitled to carry outrepair or replacement offaulty parts after careful examination of the motor. Faulty

parts orcomponents when replaced by Standard Pump, Inc. will become the property ofStandard Pump,

Inc. If this warranty doesnot apply, the purchaser shall bear allcost for labor, material and transportation.

7. Standard Pump, Inc. will not be liable on any claim, whether in contact, tort, orotherwise, for any indirect,

special, incidental, orconsequential damages, caused to the customer orto third parties, including loss of

profits, process down time, transportation costs, costs associated with replacement orsubstitution products,

labor costs, installation or removal costs. In any and all events, manufacturer’s liability shall not exceed the

purchase price of the product and/or accessories.

8. Return Policy. Should you have any problems with this product, please contact the distributor in your area.

The distributor will determine if a return to the factory isnecessary and will contact the factory for a Return

Authorization Number. Otherwise, contact ourTechnical Service Department (1-866-558-8611)or email

[email protected].com ifyou have any questions regarding product operation or repair.

OIPM-EXP-0818

10

This manual suits for next models

1

Table of contents

Popular Engine manuals by other brands

Siemens

Siemens Simotics M-1FE1 Series Hardware installation manual

Rockwell Automation

Rockwell Automation Allen-Bradley MP-Series installation instructions

Briggs & Stratton

Briggs & Stratton 194700 Series Operating & maintenance instructions

Volvo Penta

Volvo Penta AD31L Instruction book

ABB

ABB UEMC 40 K6 Series Installation and operating guide

Siemens

Siemens SIMOTICS XP 1LA5 Compact operating instructions