Toro V User manual

V-ENGINE SERVICE MANUAL

Table of Contents – Page 1 of 3

ABOUT THIS MANUAL

SAFETY INFORMATION

SPECIFICATIONS

ENGINE SPECIFICATIONS

ENGINE FASTENER TORQUE REQUIREMENTS

CARBURETOR SPECIFICATIONS

SPECIAL TOOL REQUIREMENTS

SPECIAL TOOL REQUIREMENTS - REQUIRED SERVICE SUPPLIES

TORO 2-CYCLE V ENGINE TOOL REQUIREMENTS

TROUBLESHOOTING

ENGINE WILL NOT START WHEN "COLD"

ENGINE WILL START WHEN "COLD", BUT NOT WHEN "HOT"

ENGINE WILL NOT PRODUCE SPARK

ENGINE FLOODED WITH FUEL

ENGINE HAS LOW COMPRESSION

ENGINE LACKS POWER

ENGINE SURGES

ENGINE BACKFIRES

ENGINE OVERHEATS

ENGINE VIBRATES EXCESSIVELY

ENGINE CRANKSHAFT WILL NOT TURN

ENGINE PRODUCES MECHANICAL KNOCKING SOUND

ENGINE PRE-IGNITES

ENGINE SMOKES EXCESSIVELY

ENGINE STALLS

SPARK PLUG FOULED

MAINTENANCE

RECOMMENDED MAINTENANCE SCHEDULE

AIR FILTER - CLEANING

SPARK PLUG

SPARK PLUG GAP

SPARK PLUG TORQUE

EXHAUST SYSTEM - CLEANING

REASSEMBLING

PRIMER START CARBURETOR

TROUBLESHOOTING - ENGINE STARTS HARD

ENGINE RUNS RICH

ENGINE RUNS LEAN

FUEL LEAKS FROM CARBURETOR

INTRODUCTION - IDENTIFICATION

V-ENGINE SERVICE MANUAL

Table of Contents – Page 2 of 3

PRIMER START CARBURETOR - Continued

OPERATION

GOVERNOR

GOVERNOR ADJUSTMENT

SERVICING - PRELIMINARY CHECK

DISASSEMBLY

CLEANING AND INSPECTION

ASSEMBLY

INSTALLATION

PRESETTING THE GOVERNOR

SERVICING THE AIR FILTER

FUEL SYSTEM

OPERATION - FUEL TANK

FUEL CAP

SERVICE - FUEL CAP

TANK REMOVAL

CLEANING

TANK INSTALLATION

FUEL STORAGE

IGNITION SYSTEM

TROUBLESHOOTING - PROCESS

SPARK PLUG - OPERATION

SERVICE

CD PACK - ADVANTAGES

OPERATION

AIR GAP ADJUSTMENT

REMOVAL/INSTALLATION

FLYWHEEL - OPERATION

REMOVAL

INSTALLATION

REWIND STARTER

OPERATION

RECOIL ASSEMBLY REPLACEMENT

STARTER ROPE REPLACEMENT

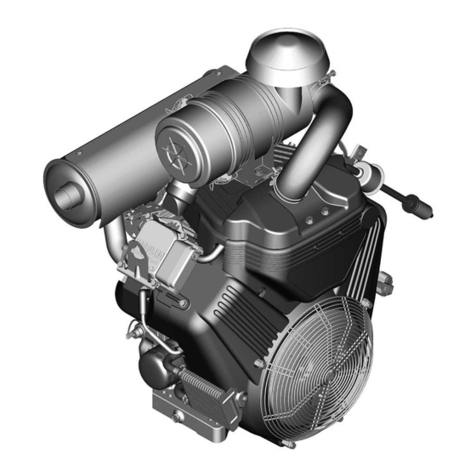

ENGINE

ADVANTAGES/DESCRIPTION

OPERATION

SERVICE TIPS - CYLINDER/CRANKCASE HALVES

OIL SEALS

CORE PLUGS

MUFFLER BAFFLE

V-ENGINE SERVICE MANUAL

Table of Contents – Page 3 of 3

ENGINE - Continued

MUFFLER PLATE SCREWS

EXHAUST PORTS

CARBURETOR GASKETS

REMOVAL

DISASSEMBLY

INSPECTION AND REPAIR

REED VALVE SERVICE

REASSEMBLY

REINSTALLING EXTERNAL COMPONENTS

PIVOTING ZONE START BRAKE SYSTEM

PIVOTING ZONE START BRAKE - INTRODUCTION

OPERATION

DISASSEMBLY

ASSEMBLY

APPENDIX

POWER HEAD - EXPLODED VIEW

IGNITION AND EXHAUST - EXPLODED VIEW

STARTER AND PRIMER START CARBURETOR - EXPLODED VIEW

PRIMER START CARBURETOR ASSEMBLY - EXPLODED VIEW

ABOUT

THIS

MANUAL

ThismanualwaswrittenexpresslyfortheTor0

V

Engine.TheTor0Companyhas

made every effortto make the informationinthis manual complete and correct.

This manual was written with the service' technicianin mind. The book isdivided

into two sections, Quick Reference information (specifications, troubleshooting, etc.)

and servicing information (servicing procedures).

We hope you find this manual a valuable additionto your service shop.

If

you have

any questions or comments regarding this manual, please contact us at the

following address:

The Toro Company

Consumer Service Department

81

11

Lyndale Avenue South

Bloomington,

MN

55420-1

196

The Tor0 Company reserves the rightto change product specifications or this

manual without notice.

Copyright(R)

1995

The Tor0 Company

All

Rights

Reserved

Safety Information

This safety symbol means WARNING or PERSONAL SAFETY

INSTRUCTION

-

read the instruction becauseit has to do with your

safety. Failure to comply with the instruction may resultinpersonal

injury or even death.

This manualisintended as a service and repair manual only. The safety

instructions provided herein are for troubleshooting, service and repairof the engine

only. The Operator’s Manual will containsafetyinformation onthecomplete product

powered by theTor0

2-

Cycle

V

engine. Operator’s Manuals with complete

instructions are available through:

The Tor0Company

Publications Department

81

1

Lyndale Avenue South

Bloomington, MN

55420-1

196

U.S.A.

Avoid unexpected starting of the

engine

....

Always turn

off

the powered product and

disconnect the spark plug before attempting

cleaning, adjustment or repair.

Avoid lacerations and amputations

...

Stay clear of all moving parts when the

engine isrunning. Treat all normally

moving parts as if they were moving

whenever the engineis running or has the

potential to start.

Avoid burns

...

Do

not touch the engine whileit is running

or shortly afterithas been running.

Avoid falls

...

Do

not operate the powered product on

slippery surfaces or

if

footing is

questionable.

Avoid fires

...

Wipe up any spilled fuel or oil immediately.

Avoid asphyxiation

...

Never operate an engineina confined area

without proper ventilation.

Avoid fires and explosions

...

Use a container designed for gasoline.

Avoid spilling fuel and never smoke while

working with any type of fuel.

Avoid accidental misuseof fuel.

..

Always store fuelina properly labeled

container designed for gasoline.

Avoid injury due to inferior parts

...

Use onlyTOR0original parts to ensure that

important safety criteria are met.

Avoid injury

to

bystanders

...

Always clear the area of bystanders before

starting or testing powered equipment.

Avoid injury due to projectiles

...

Always clear the area of sticks, rocks, or

any other debris that could be picked up

and thrown by the powered equipment.

Keep all safety shieldsin place

Avoid modifications

...

Never alter or modify any part unlessit is a

factory approved procedure.

Avoid unsafe operation

...

Always test the safety systems after making

adjustments or repairs on the machine.

QUICK REFERENCE SECTION

Specifications

..............................................

SpecialToolRequirements.

...................................

Troubleshooting

............................................

Maintenance

...............................................

SERVICE SECTION

Primer Start Carburetor.

......................................

Fuelsystem

...............................................

IgnitionSystem

.............................................

~~

Rewind Starter.

.............................................

Engine

....................................................

Pivoting Zone StartBrake.

....................................

I

Appendix

..................................................

~~

ReferenceSection

1-1

Engine Specifications. 19

Engine Fastener Torque Requirements 1-4

CarburetorSpecifications1-4

1-2

Reference Section

Bolt, Blade

Nut, Flywheel

Screw, Air vane

81.6N-m)

Screw, Carburetor mounting

Screw, CD ignition pack

90

110

in

lbs(10-12N-m)

Screw,Cylindertocrankcase

105

I

115

in

lbs

(.I2

I3

N-m

Screws, Engine mounting 350-400in Ibs

(39

45 N-m)

Screw,Groundstrapstop

15

25

inIbs(1.7 2.8

Screw, Muffler cover

150

190

inIbs (I7 22 Nom)-.

Screw, Muffler plate 140 200 in

Ibs

(16

22 N-m)

Screw,Reed*

10

13inIbs(1.1-1.5

N-m)

N-m)

~-

65 75in

Ibs

(7,3-8.4N-m)

Screw, Shroud

20

25 inIbs (2.3 2.8N-m)

*Use thread-locking compound

See page

2.2

Carburetor Specifications

1-4

Reference Section

QUICK REFERENCE SECTION

Specifications

Special

Tool

Requirements.

2

Troubleshooting

Maintenance

SERVICE SECTION

Primer Start Carburetor.

Fuelsystem

Ignition System

Rewind Starter.

Engine

Pivoting Zone StartBrake.

Appendix

Reference

Section

2-1

QUICKREFERENCESECTION

Specifications

Special

Tool

Requirements.

Troubleshooting

3

Maintenance

SERVICE SECTION

Primer Start Carburetor.

Fuelsystem

Ignition System

Rewind Starter.

Engine

Pivoting Zone StartBrake.

Appendix

Reference Section

3-1

ENGINEWILLNOTSTARTWHEN“COLD”

Remedies

Fillwith

clean,fresh,

properlymixed, unleaded fuel

Drain and flush tank andfloat bowl,

fill

tank with

clean fresh unleaded, properly mixed fuel

Clean and backflush fuel tank. Replace fuel tank

if

necessary

Wash and re-oil air cleaner element

Replace

thespark

plug

See “ENGINE WILL NOT PRODUCE

SPARK

table

Check for loose blade

See “ENGINEHASLOW COMPRESSIONtable

See“ENGINE

FLOODED”

WITHFUEL”table

Check

ENGINE WILL START WHEN “COLD”, BUT NOT WHEN “HOT”

I

See‘ENGINE-FLOODEDWITHFUEL”table

fuelUse nomorethan

10%

ethanolblend

See: ENGINE OVERHEATStable

Clean bowl vent

Reference Section

3-3

ENGINE FLOODED WITH FUEL

ENGINE HAS LOW COMPRESSION

Remedies

severaltimes.. Reinstall plug. Try again.

Let unit sit, retry, or, remove spark plug, pull rope

Adjust

throttle

cable

Wash and re-oil cleaner element

Replacespark

plug

Clean carburetor, replace failedparts

Clean

Clean

Dirty plugged main fuel and/or

airbleedcircuits

Remedies

Clean main fuel circuit andall air bleed circuits

Check sealing surfaces, oil

plugs

Checkfiltersandfuel line

3-4

Reference Section

ReferenceSection

3-5

ENGINEPRODUCESMECHANICALKNOCKINGSOUND

Remedies

Inspectand tightenflwheel nutto correct torque

See

“ENG!NE

PRE-IGNITES’table

Inspectand repair and tighten-nuts to correct torque

Tightenbolts

Inspect and tighten bladebolt tocorrect torque

ENGINE SMOKES EXCESSIVELY

ENGINE STALLS

Remedies

Refill with fresh fuel-of the correct mixture

Unloadengineand-restart

See “SPARK PLUG FOULED-table

Replace fuel cap

Inspect and repairto removeunwantedground

Clear ventof obstruction

Clear debris from fins or causeof overheating

Refill-with fresh, and

properly

mixed,fuel

3-6

Reference Section

SPARK

PLUG

FOULED

possible

Causes

Carburetor running too rich

Clogged air cleaner element

Weakignition

syslem

Worn rings and/or cylinder

Useof leaded fuel

Fuel/oilmixture too rich

Wrong oil

Incorrect spark plug

~-

Usecorrectsparkplug

Clean-!rebuildcarburetor

Clean and re-oil element

or

replace

Rebuild engine or

short block

Drain fuel tank and replace with fresh, unleaded

Drain fuel tank and

fill

with fuelof correct mixture

Use Tor0 2-Cycle,or

NMMA

certified ashlessoil

Replace CD ignition pack

regular fuel, having the correct oil mixture

(32:

1

)

ReferenceSection

3-7

QUICK REFERENCE SECTION

Specifications

Special Tool Requirements.

Troubleshooting

Maintenance

e

SERVICE SECTION

Primer Start Carburetor.

Fuelsystem

Ignition System

Rewind Starter.

Engine

Pivoting Zone StartBrake.

Appendix

Reference Section

4-1

Table of contents

Other Toro Engine manuals

Toro

Toro 138-2139 User manual

Toro

Toro GTS 150 User manual

Toro

Toro GREENSMASTER 3100 User manual

Toro

Toro GTS 120 User manual

Toro

Toro 1P65F-2 User manual

Toro

Toro 303447 Operating instructions

Toro

Toro 139-5636 User manual

Toro

Toro Z Master 500 Series User manual

Toro

Toro GTS 200 User manual

Toro

Toro Power Plus P216V User manual