manual button is pressed. Thus switching over

to manual mode. The cooking pot symbol is

illuminated steadily.

MA UAL MODE

When programming operation period or operation

stop, the timer automatically transfers into

automatic mode, being displayed by the letters

“AUTO” illuminated. The set programs being

completed, letters “AUTO” illuminated. The set

programs being completed, letters “AUTO” flash

and the time can be switched over to manual mode

by pressing the manual button. The cooking pot

symbol is illuminated steadily.

CORRECTI G OR CLEARI G PROGRAMS

Set programs can be corrected at any time by

pressing the respective button and either the plus or

minus button depending on whether the program is

to be cut short or prolonged.

Clearing is done by setting the program to “0.00”.

Clearing operation period automatically causes

clearing of operation stop and vice-versa. When

operation period or operation stop are programmed

Time-Of-Day cannot be corrected. The setting of

nonsensical programs is impossible (e.g. operation

period is programmed and operation stop is set too

early).

OTE: In the event of a short term power failure the

clock display will disappear and then turn when the

power is reinstated. If the power supply is

interrupted for a lengthy period of time the clock

display will be lost.

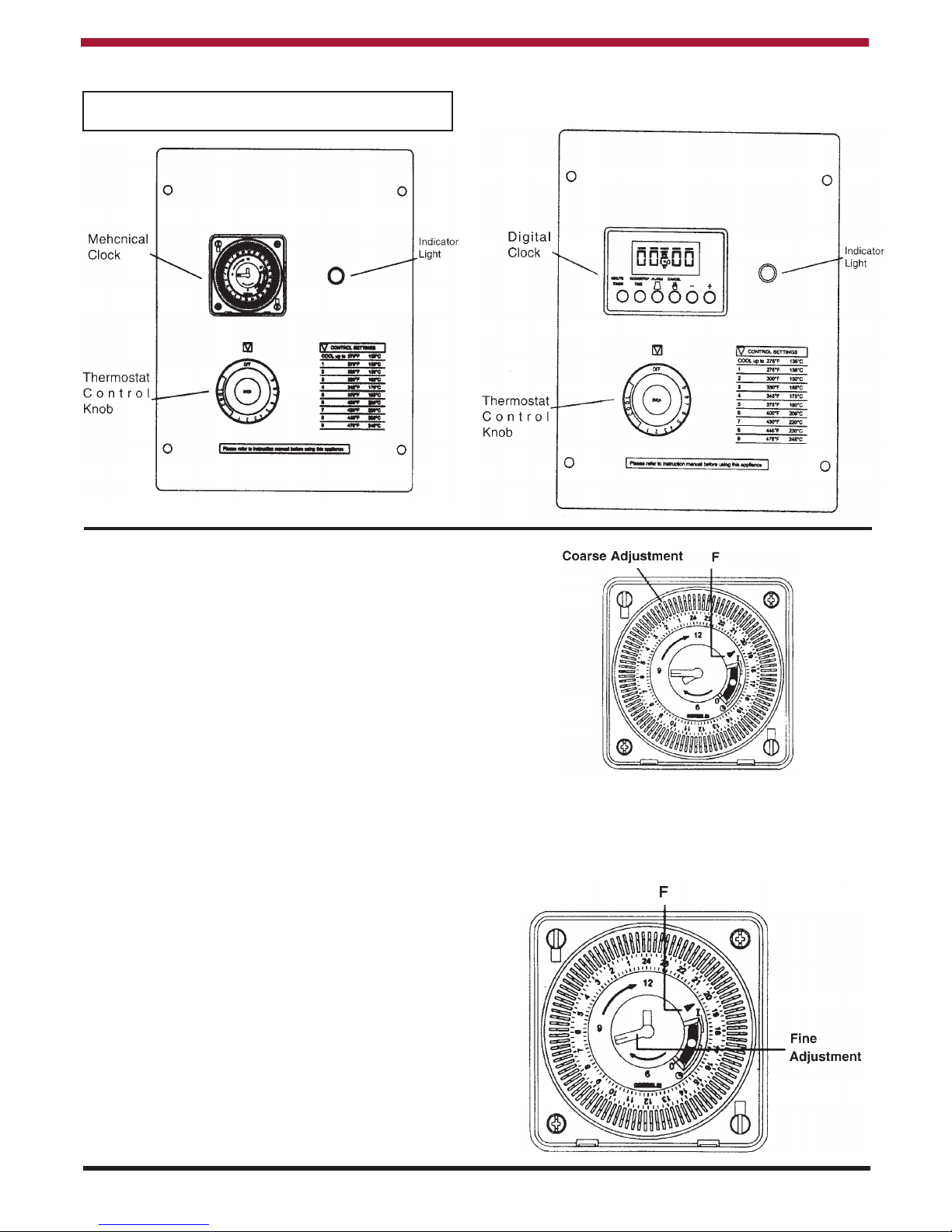

OPERATI G THE APPLIA CE

For the appliance to operate both the oven control

knob and the timer must be set correctly.

The oven control knob setting corresponds to a

temperature. The control setting and their

corresponding temperatures are shown on the

control panel to the right of the control knob. These

temperatures are a guideline to the average

temperature in the top oven.

Either time clock can be used to switch

automatically as outlined above. The mechanical

timer also has “continuous on” and continuous off”

mode on the digital time so the appliance must be

switched off using the oven control knob.

The indicator light on the control panel is illuminated

when the solenoid valve is open. It will take

approximately 8 seconds after the cooker is turned

on before the solenoid valve is opened.

OVE S

THE MAI OVE

This oven is your simmering oven, your baking oven

and your roasting oven. It is a generous size of 390

x 310 x 406 mm (15 1/4 x 12 1/4 x 16 inches) - big

enough to take a large turkey. It is of a cast-iron

construction which gives a perfect roast, sealing in

all the juices and flavours. The oven is fitted with a

thermometer which gives the average temperature

in the oven. There are two chromed steel shelves

and four shelf positions. The main oven is controlled

by the thermostat inside the top left hand door. The

top shelf will be a shade hotter than the centre of the

oven and the bottom shelf will be a shade cooler,

giving you different zones of heat in the main oven -

this allows you to cook foods that require different

temperatures in the same oven. Lifting the

insulating lids on the hotplate and cooking for any

length of time, will not affect the oven temperature.

The Stanley has hot flue gases flowing around four

faces of the main oven. The all-round heat allows

you to cook on the base of the main oven -

marvellous for browning and crisping the bases of

fruit pies and for finishing off pizzas and quiches.

You can also oven fry on the base of the oven using

metal or cast-iron cookware,and its ideal for

poaching smoked hadddock - no more tell-tale

cooking smells in the kitchen, as these pass directly

into the flue.

THE LOWER OVE

The lower oven measures 390 x 220 x 406 mm (15

1/4 x 8 3/4 x 16 inches). It has one chromed shelf

with two shelf positions. Like the main oven, it has

a cast-iron interior and gives a similarly superb finish

to dishes that need more gentle cooking.

The lower oven is heated from its top face as the

flue gases pass between the two ovens. The

temperature of this oven is approximately half that of

the main oven and the top shelf position is hotter

than the lower one.

The lower oven really comes into its own when you

are cooking a large family meal or having a baking

session - any time, in fact, when cooking foods that

need different temperatures.

HOTPLATE

The hotplate in this appliance is treated with a

protective coating, which when heated will

evaporate and will cause an odour for a short period

of time on first lighting.

6