TABLE OF CONTENTS

SAFETY SYMBOLS ...............................................................................................................................................................................................................4

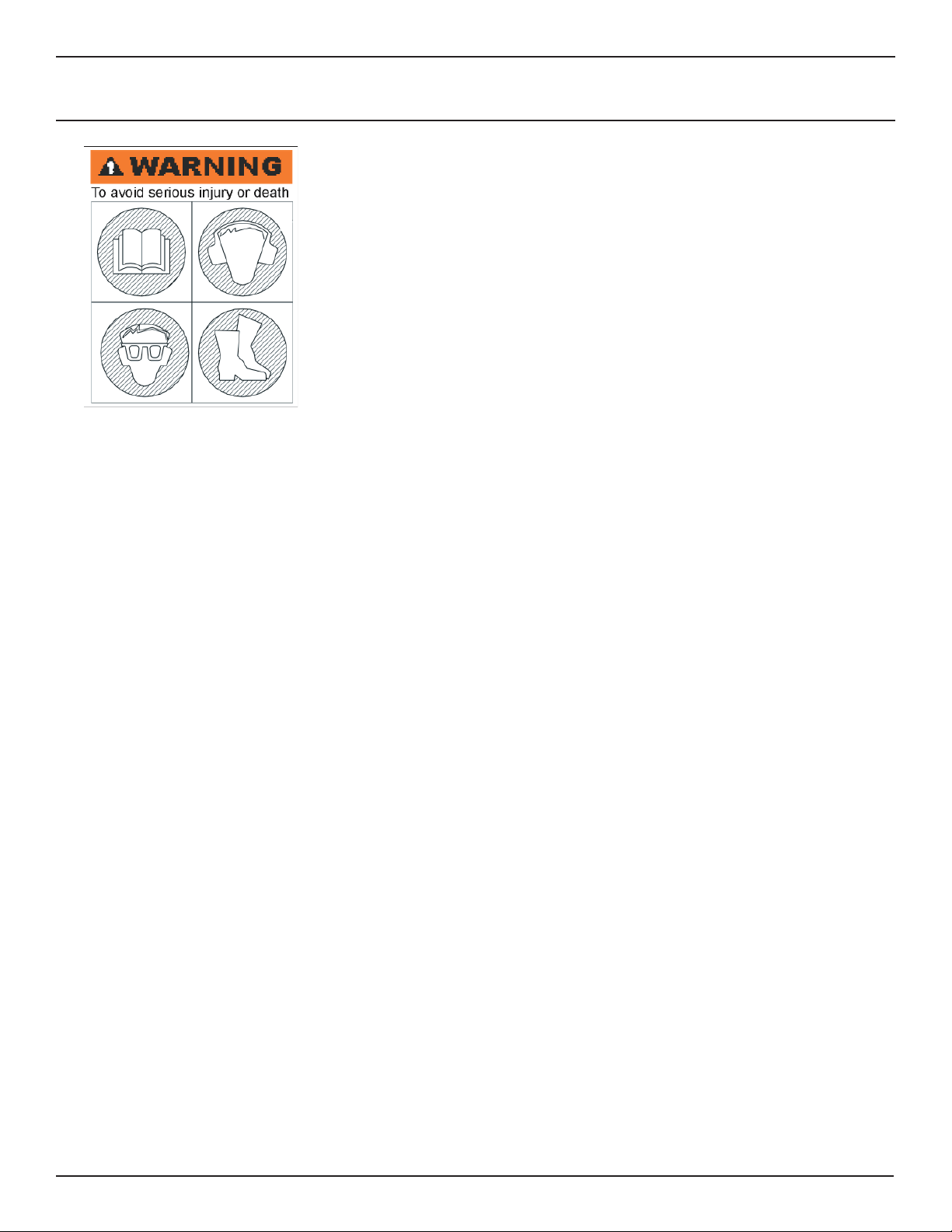

SAFETY PRECAUTIONS.......................................................................................................................................................................................................5

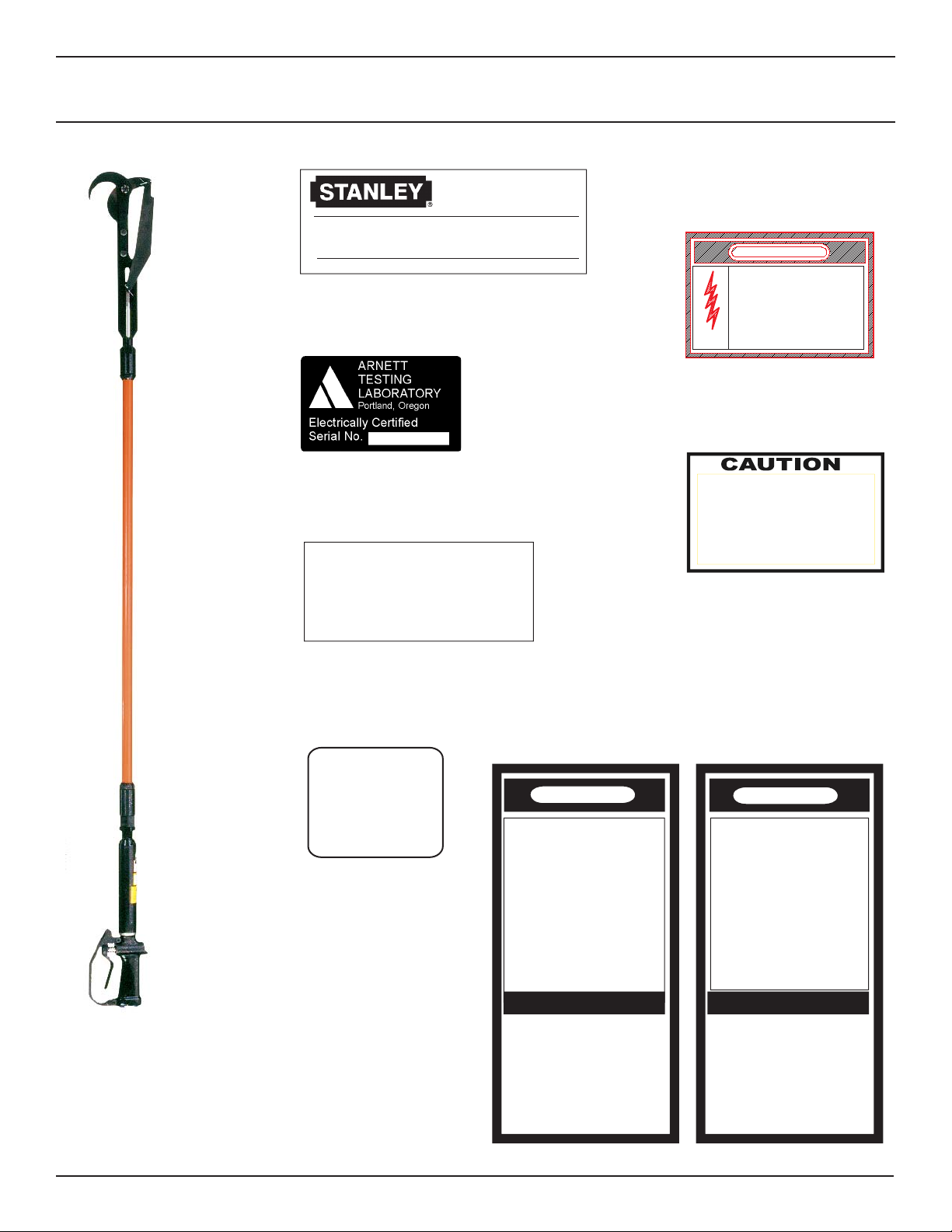

TOOL STICKERS & TAGS .....................................................................................................................................................................................................7

HYDRAULIC HOSE REQUIREMENTS..................................................................................................................................................................................8

HTMA REQUIREMENTS........................................................................................................................................................................................................9

OPERATION.........................................................................................................................................................................................................................10

PREPARATION FOR INITIAL USE ..................................................................................................................................................................................10

CHECK HYDRAULIC POWER SOURCE ........................................................................................................................................................................10

CHECK TOOL ..................................................................................................................................................................................................................10

CHECK TRIGGER MECHANISM.....................................................................................................................................................................................10

CONNECT HOSES ..........................................................................................................................................................................................................10

OPERATING PROCEDURES ..........................................................................................................................................................................................10

EQUIPMENT PROTECTION & CARE .................................................................................................................................................................................12

TROUBLESHOOTING .........................................................................................................................................................................................................13

SPECIFICATIONS................................................................................................................................................................................................................14

ACCESSORIES ...................................................................................................................................................................................................................14

SERVICE..............................................................................................................................................................................................................................15

PRIOR TO DISASSEMBLY ..............................................................................................................................................................................................15

PRUNER DISASSEMBLY ................................................................................................................................................................................................15

KNIFE BLADE, HOOK, LINK BAR & SLIDE HEAD DISASSEMBLY ..............................................................................................................................15

EXTERNAL TUBE ASSEMBLY ........................................................................................................................................................................................15

INTERNAL TUBE ASSEMBLY .........................................................................................................................................................................................15

TUBE COUPLING ............................................................................................................................................................................................................15

PISTON & PISTON ROD .................................................................................................................................................................................................15

CYLINDER & CYLINDER OIL TUBE ...............................................................................................................................................................................15

VALVE HANDLE ASSEMBLY...........................................................................................................................................................................................15

PARTS INSPECTION.......................................................................................................................................................................................................16

KNIFE BLADE, HOOK, LINK BAR & SLIDE HEAD ASSEMBLY .....................................................................................................................................16

INTERNAL TUBE .............................................................................................................................................................................................................16

EXTERNAL TUBE ............................................................................................................................................................................................................16

PISTON ROD & PISTON .................................................................................................................................................................................................16

VALVE SPOOL & VALVE HANDLE ..................................................................................................................................................................................16

HYDRAULIC SUPPLY......................................................................................................................................................................................................16

PRUNER ASSEMBLY ......................................................................................................................................................................................................16

VALVE HANDLE ASSEMBLY...........................................................................................................................................................................................16

CYLINDER & CYLINDER OIL TUBE ...............................................................................................................................................................................16

PISTON & PISTON ROD .................................................................................................................................................................................................16

TUBE COUPLING ............................................................................................................................................................................................................17

INTERNAL TUBE ASSEMBLY .........................................................................................................................................................................................17

EXTERNAL TUBE ASSEMBLY ........................................................................................................................................................................................17

KNIFE BLADE, HOOK, LINK BAR & SLIDE HEAD DISASSEMBLY ..............................................................................................................................17

TESTING FOR OPERATION & PERFORMANCE ...........................................................................................................................................................18

PARTS ILLUSTRATION .......................................................................................................................................................................................................19

PARTS LIST .........................................................................................................................................................................................................................20

WARRANTY .........................................................................................................................................................................................................................21

3

For the nearest authorized and certified dealer, call Stanley Hydraulic Tools at the number listed on the back of

this manual and ask for a Customer Service Representative.

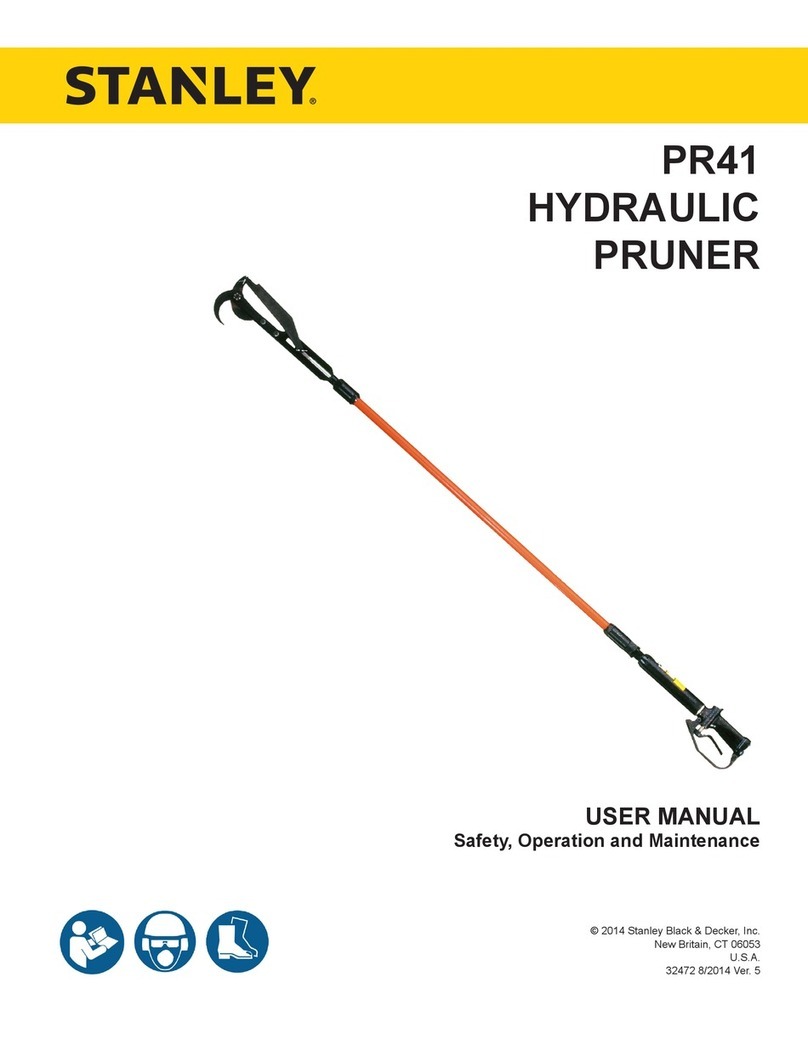

SERVICING THE STANLEY HYDRAULIC Pruner. This manual contains safety, operation, and routine maintenance

instructions. Stanley Hydraulic Tools recommends that servicing of hydraulic tools, other than routine mainte-

nance, be performed by an authorized and certified dealer. Please read the following warning.

SERIOUS INJURY OR DEATH COULD RESULT FROM THE IM-

PROPER REPAIR OR SERVICE OF THIS TOOL.

REPAIRS AND / OR SERVICE TO THIS TOOL MUST ONLY BE

DONE BY AN AUTHORIZED AND CERTIFIED DEALER.

WARNING