Stanley SPS-750 User manual

Other Stanley Pole Saw manuals

Stanley

Stanley Fatmax SFMCPP32 User manual

Stanley

Stanley Fatmax SFMCPS620 User manual

Stanley

Stanley CS28 User manual

Stanley

Stanley Fatmax SFMCPS620 User manual

Stanley

Stanley CS25 User manual

Stanley

Stanley Fatmax SFMCPP32 User manual

Stanley

Stanley CS25 User manual

Stanley

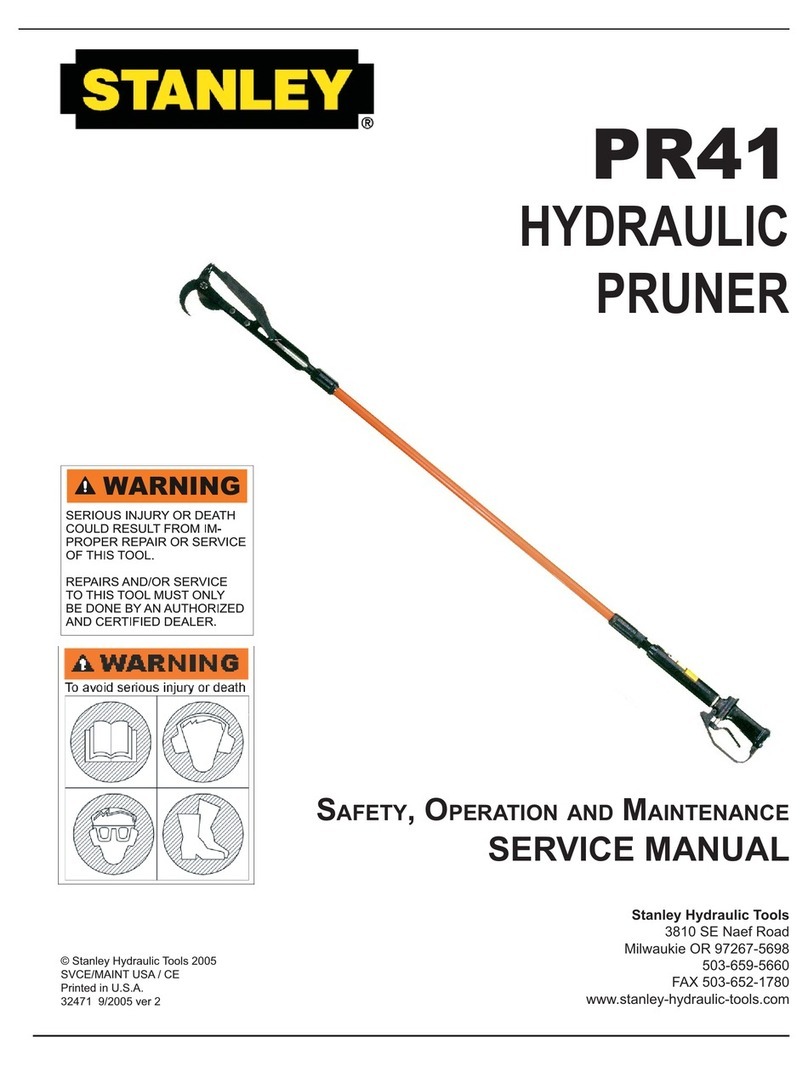

Stanley PR41 User manual

Stanley

Stanley PR41 User manual

Popular Pole Saw manuals by other brands

Poulan Pro

Poulan Pro PP258TP instruction manual

Ryobi

Ryobi RY52004A Operator's manual

Bosch

Bosch UniversalChainPole 18 Original instructions

Makita

Makita DUA301PT2 instruction manual

AL-KO

AL-KO CSA 2020 Translation of the original instructions for use

Remington

Remington BRANCH WIZARD DPS-1 owner's manual