TABLE OF CONTENTS PAGE NO.

1. Introduction ....................................................................................................................................... 3.

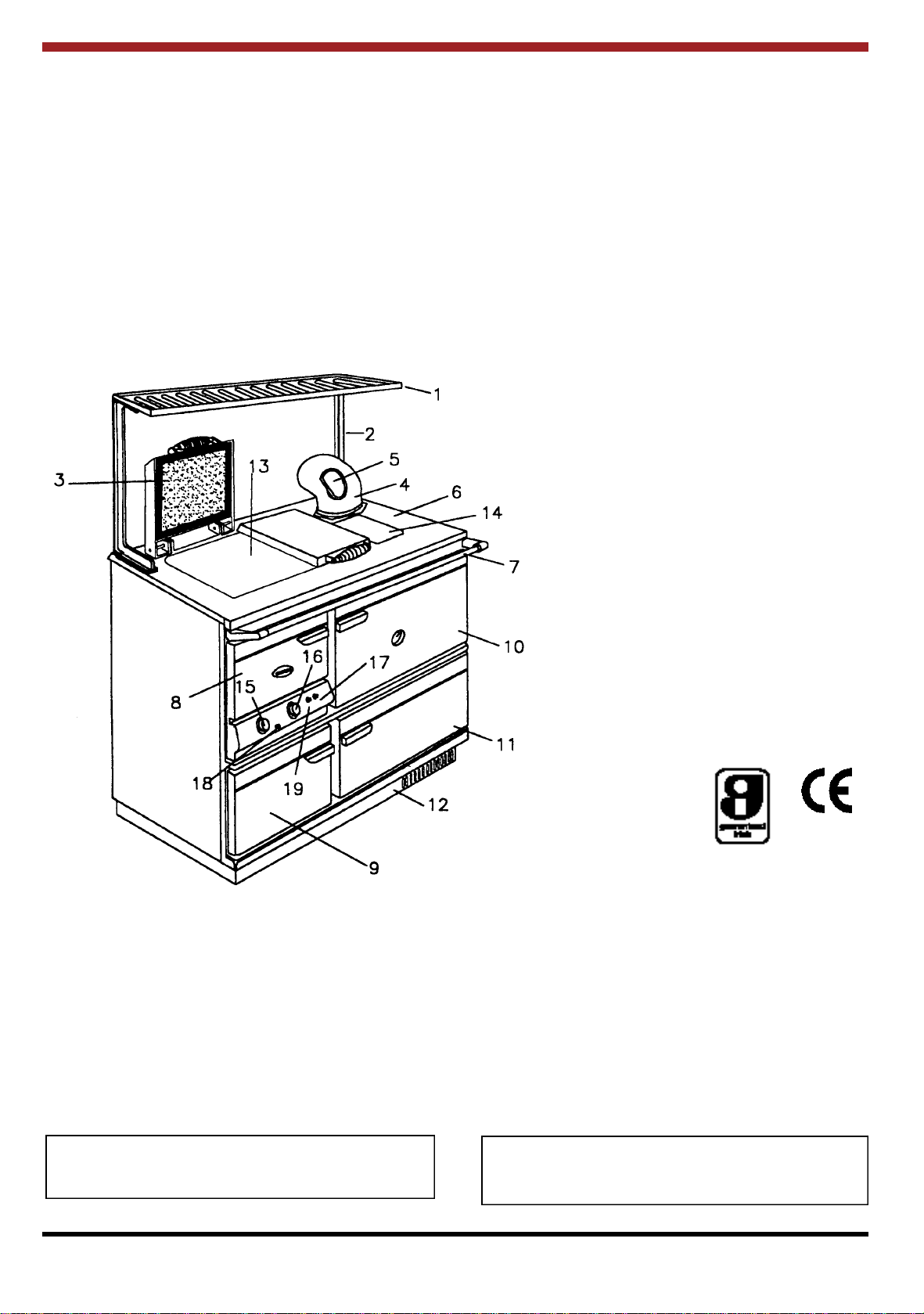

2. Specification .......................................................................................................................................4

3. Technical Data .................................................................................................................................. 5.

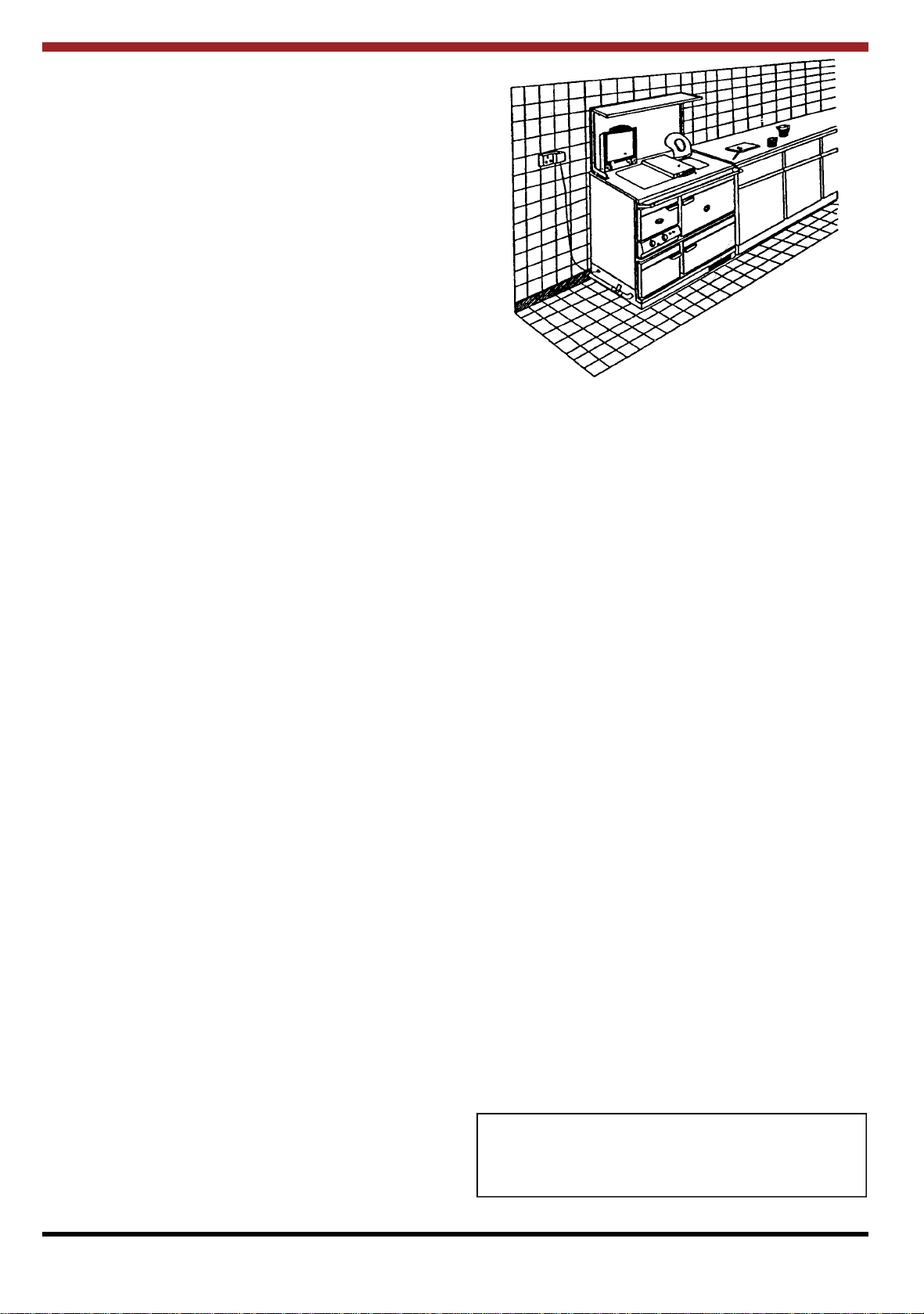

4. Location ............................................................................................................................................ 6.

5. Electrical Supply ............................................................................................................................... 6.

6. Gas Pipes & Fittings ......................................................................................................................... 6.

7. Meters ............................................................................................................................................... 6.

8. Gas Pipe Size .................................................................................................................................... 6.

9. Hearth Construction .......................................................................................................................... 7.

10. Installation ......................................................................................................................................... 7.

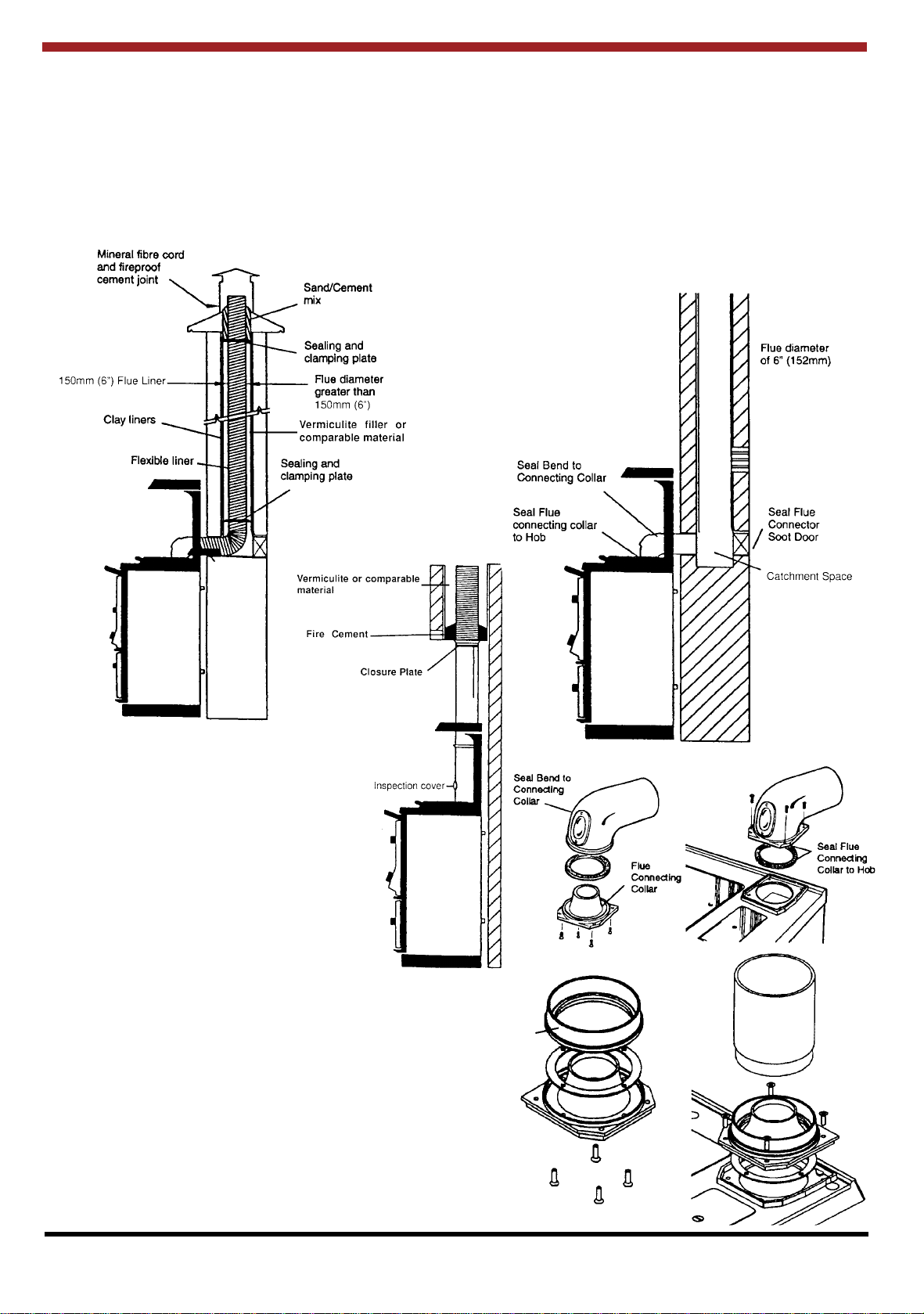

11. Chimney’s .......................................................................................................................................... 7.

12. Pre-Installation Check........................................................................................................................ 7.

13. Sealing............................................................................................................................................... 7.

14. Flue Height..........................................................................................................................................8

15. Flues ................................................................................................................................................. 8.

16. Suitable Material ............................................................................................................................... 8.

17. Connections ...................................................................................................................................... 8.

18. Draught Requirements....................................................................................................................... 8.

19. Flue Cleaning..................................................................................................................................... 8.

20. Down Draughts ................................................................................................................................. 9.

21. Use of Existing Chimneys and Flues ................................................................................................ 9.

22 Factory Made Insulated Chimneys ................................................................................................... 9.

23. Flue Liner .......................................................................................................................................... 9.

24. Ventilation and Combustion Air Requirements ................................................................................ 10.

25. Outside Air Connection..................................................................................................................... 10.

26. Clearance to Combustibles .............................................................................................................. 11.

27. Gas Connection.................................................................................................................................12.

28. Heating .............................................................................................................................................12.

29 Water Pipe Fittings ............................................................................................................................13.

30. Plumbing Drawings............................................................................................................................13.

31. Safety Valve.......................................................................................................................................14.

32. S Plan Wiring Diagram......................................................................................................................14.

33. By Pass Loop ....................................................................................................................................15.

34. Airing Cupboard Layout.....................................................................................................................15.

35. Provision for Filling Sealed Systems.................................................................................................16.

36. Water Circuit Temperature.................................................................................................................16.

37. Pipe Thermostats ..............................................................................................................................16.

38. Care for your Central Heating System..............................................................................................16.

39. General Maintenance ........................................................................................................................17.

40. Servicing............................................................................................................................................17.

41. Draining..............................................................................................................................................17

42. Indirect Domestic Cylinder ................................................................................................................17.

43. Commissioning Procedures and Checks ..........................................................................................17.

44. Operation...........................................................................................................................................18.

45. Ovens................................................................................................................................................19.

46. Cental Heating...................................................................................................................................19.

47. Summer Setting.................................................................................................................................19.

48. Hotplate.............................................................................................................................................19.

49. Hotplate Insulating Covers ................................................................................................................19.

50. Cooking Utensils................................................................................................................................19.

51. Heating System Controls...................................................................................................................19.

52. Opening Cooker Door .......................................................................................................................20.

53. Cleaning ............................................................................................................................................20.

54. Mild Steel...........................................................................................................................................21.

55. External Automatic Time Switch........................................................................................................21.

1