1Introduction................................................................................................................................ 1-1

1.1 MICROCONTROLLER MODULE.................................................................................................1-3

1.1.1 LCD contrast adjustment................................................................................................1-4

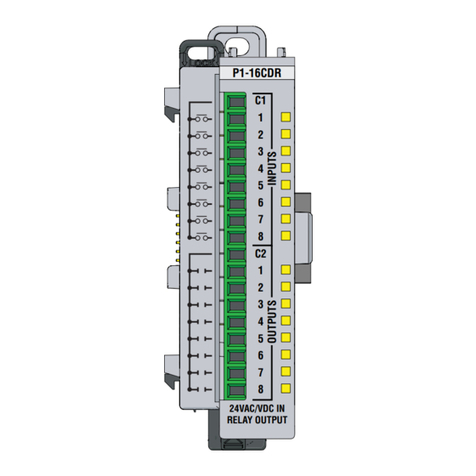

1.2 I/O CIRCUITRY ......................................................................................................................1-5

1.3 FIELD CONNECTIONS.............................................................................................................1-6

1.4 POWER SUPPLY MODULE ......................................................................................................1-7

2MCU Installation......................................................................................................................... 2-8

2.1 SITING THE MCU...................................................................................................................2-8

2.2 SYSTEM WIRING....................................................................................................................2-9

2.3 POWER SUPPLY INPUT...........................................................................................................2-9

2.3.1 A.C. Mains Connection...................................................................................................2-9

2.3.2 DC Voltage Connection..................................................................................................2-9

CABLE ROUTING...............................................................................................................................2-10

2.4 CABLE SCREENING..............................................................................................................2-10

3Gas Detector Head Installation............................................................................................... 3-11

3.1 SITING THE DETECTORS ......................................................................................................3-11

3.2 INSTALLATION IN A NON-HAZARDOUS AREA ..........................................................................3-11

3.3 INSTALLATION IN A HAZARDOUS AREAS.................................................................................3-12

3.3.1 Hazardous area installations using Safety Barriers......................................................3-13

4Input Module Configuration...................................................................................................... 4-1

4.1 INPUT CONFIGURATION..........................................................................................................4-2

4.2 STATUS SCIENTIFIC CONTROLS GAS DETECTORS...................................................................4-2

4.2.1 FGD2, FGD3, FGD4 and FGD10b O2and Toxic Detector Heads .................................4-2

4.2.2 FGD3 Infrared Gas Detector Head.................................................................................4-4

4.2.3 FGD3 Pellistor Gas Detector Head.................................................................................4-5

4.2.4 FGD4, FGD9, FGD10a, FGD10b Gas Detector Heads..................................................4-6

4.2.5 Pellistor Only Gas detectors...........................................................................................4-8

4.2.6 FGD56-IR........................................................................................................................4-9

4.2.7 External powered 4-20 mA Source...............................................................................4-10

4.3 ANALOGUE OUTPUT CONFIGURATION...................................................................................4-11

4.3.1 4-20mA Current Source................................................................................................4-11

4.3.2 4-20mA Current Sink ....................................................................................................4-12

4.3.3 1-5V Voltage Output .....................................................................................................4-13

4.4 ROUTINE SERVICING............................................................................................................4-15

4.4.1 Routine Inspection........................................................................................................4-15

5Dimension Details...................................................................................................................... 5-1

5.1 LC8 CONTROL UNIT ..............................................................................................................5-1

6Specifications............................................................................................................................. 6-2

6.1 LC8 CONTROL UNIT ..............................................................................................................6-2