STATUS SCIENTIFIC CONTROLS MCU3 Instruction sheet

STATUS SCIENTIFIC CONTROLS LTD.

Hermitage Lane Industrial Estate,

Kings Mill Way,

Mansfield,

Nottinghamshire.

NG18 5ER

England

Tel

Fax

: 01623 651381

: 01623 421063

Environmental Monitoring &

Control Units Types MCU 3 & 4

Installation and Hardware

Configuration Manual

Date:

11.6.2009.

Issue:

6

STATUS SCIENTIFIC CONTROLS

MCU System Installation and Hardware Configuration Manual

The MCU3 & 4 Manuals

The MCU3 & 4 Environmental Monitoring Systems have a range of manuals covering various

aspects of their operation:

•MCU3 & 4 Installation and Hardware Configuration Manual

This manual covers all of the hardware aspects of the MCU Environmental Monitoring

Systems. Each of the component parts of the system is discussed and hardware

configuration is explained. Dimensional drawings are included.

•MCU3 & 4 Software Configuration and System Calibration Manual

The operation of the MCU system is discussed as well as the software configuration

and calibration procedures.

•‘Mentor PC’ Operators Manual

The Mentor PC software is discussed including:

Software Installation

Hardware Configuration to facilitate downloading logged data and

configuration via a PC.

Displaying, and archiving logged data.

Important

Status Scientific Controls strive to continually improve their products in line with customer’s

requirements and technological advancement. Status Scientific reserve the right to modify

the design of the system at any time.

Due to continual improvement not all of the features described within this manual may be

available on earlier models, contact Status for further details.

This manual covers all MCU Control Units containing Input Boards fitted with jumper switch

configurable options. If the configuration of the Input Boards is set by the removal or fitting

of jumpers then please refer to an Issue 2.0 manual available from Status Scientific

Controls.

STATUS SCIENTIFIC CONTROLS

MCU System Installation and Hardware Configuration Manual

1Introduction........................................................................................................................ 1-1

1.1 MICROCONTROLLER MODULE......................................................................................... 1-5

1.2 INPUT MODULE.............................................................................................................. 1-6

1.3 DISTRIBUTION BOARD.................................................................................................... 1-7

1.3.1 Field Connections ................................................................................................... 1-7

1.3.2 Distribution Board - Issues 1 & 2............................................................................ 1-8

1.3.3 Distribution Board - Issues 3 and above................................................................. 1-8

1.4 COMMON RELAY MODULE.............................................................................................. 1-9

1.5 POWER SUPPLY MODULE............................................................................................. 1-10

1.6 BATTERY BACKUP........................................................................................................ 1-11

1.6.1 Calculation Examples ........................................................................................... 1-12

1.6.2 Calculating the backup time for your system........................................................ 1-13

1.7 MCU SYSTEM COMMUNICATIONS................................................................................. 1-14

1.7.1 MCU System Configuration and Interrogation...................................................... 1-14

1.7.2 MCU System Networking...................................................................................... 1-14

2MCU Installation................................................................................................................. 2-1

2.1 SITING THE MCU........................................................................................................... 2-1

2.2 ASSEMBLING ................................................................................................................. 2-2

2.3 SYSTEM WIRING............................................................................................................ 2-2

2.4 POWER SUPPLY INPUT................................................................................................... 2-2

2.4.1 A.C. Mains Connection ........................................................................................... 2-2

2.4.2 24V DC Connection................................................................................................ 2-3

2.5 CABLE ROUTING............................................................................................................ 2-3

2.6 CABLE SCREENING........................................................................................................ 2-3

3Gas Detector Head Installation......................................................................................... 3-4

3.1 SITING THE DETECTORS................................................................................................. 3-4

3.2 INSTALLATION IN A NON-HAZARDOUS AREA .................................................................... 3-4

3.3 INSTALLATION IN A HAZARDOUS AREAS........................................................................... 3-6

3.3.1 Hazardous area installation using barrier type FGDIO........................................... 3-7

3.3.2 FGDIO Intrinsically Safe Output Module Installation .............................................. 3-9

3.3.3 Hazardous area installations using Proprietary Safety Barriers........................... 3-11

4Input Module Configuration.............................................................................................. 4-1

4.1 INPUT CONFIGURATION.................................................................................................. 4-1

4.1.1 Status Scientific Controls Gas Detectors................................................................ 4-2

4.1.2 Alternative Detector Heads..................................................................................... 4-7

4.2 ANALOGUE OUTPUT CONFIGURATION........................................................................... 4-11

4.2.1 4-20mA Current Source........................................................................................ 4-12

4.2.2 4-20mA Current Sink ............................................................................................ 4-12

4.2.3 1-5V Voltage Output ............................................................................................. 4-12

4.3 INPUT MODULE INSTALLATION ...................................................................................... 4-13

5Detector Head Operation & Calibration........................................................................... 5-1

5.1 DETECTOR HEAD VARIANTS........................................................................................... 5-1

5.2 OPERATION................................................................................................................... 5-1

5.2.1 Status Indications.................................................................................................... 5-1

5.3 INSPECTION AND MAINTENANCE ..................................................................................... 5-2

5.3.1 Calibration Intervals ................................................................................................ 5-2

5.3.2 Routine Inspection .................................................................................................. 5-2

5.4 CALIBRATION................................................................................................................. 5-2

5.5 GAS DETECTOR CONTAMINANTS.................................................................................... 5-2

5.5.1 Flammable Gas Detectors...................................................................................... 5-2

5.5.2 Oxygen Gas detectors ............................................................................................ 5-3

5.5.3 Toxic Gas Detectors ............................................................................................... 5-3

5.6 SENSOR DISPOSAL........................................................................................................ 5-4

STATUS SCIENTIFIC CONTROLS

MCU System Installation and Hardware Configuration Manual

5.6.1 Oxygen Sensors ..................................................................................................... 5-4

5.6.2 Toxic Gas Sensors.................................................................................................. 5-4

5.6.3 Flammable Gas Sensors ........................................................................................ 5-4

6Trouble Shooting ............................................................................................................... 6-1

6.1 COMMON FAULTS .......................................................................................................... 6-1

7Service ................................................................................................................................ 7-1

7.1 WARRANTY ................................................................................................................... 7-1

7.2 COMMISSIONING AND SERVICE....................................................................................... 7-1

7.3 SENSOR REPLACEMENT................................................................................................. 7-1

7.4 ROUTINE SERVICING...................................................................................................... 7-2

7.4.1 Routine Inspection .................................................................................................. 7-2

8Appendix............................................................................................................................. 8-1

8.1 INSTALLATION OF SAFE AREA SOUNDERS AND BEACONS................................................. 8-1

8.2 INSTALLATION OF INTRINSICALLY SAFE SOUNDERS AND BEACONS ................................... 8-2

8.3 EXAMPLE OF CONNECTION TO A STATUS SCIENTIFIC CONTROLS TRAFFIC LIGHT UNIT ...... 8-3

8.4 MOUNTING DETAILS FOR MCU3 CONTROL UNIT............................................................. 8-4

8.5 MOUNTING DETAILS FOR MCU4 CONTROL UNIT............................................................. 8-5

8.6 MOUNTING DETAILS FOR FGD2 DETECTOR HEADS......................................................... 8-6

8.7 MOUNTING DETAILS FOR FGD3 DETECTOR HEADS......................................................... 8-7

8.8 FGD DETECTOR HEAD CALIBRATION ‘LOOK-UP’TABLE................................................... 8-8

9Specifications..................................................................................................................... 9-1

9.1 MCU3 &4CONTROL UNITS........................................................................................... 9-1

9.2 I.S. BARRIER TYPE FGDIO............................................................................................ 9-2

9.3 SPECIFICATION FOR FGD DETECTOR HEADS.................................................................. 9-3

9.3.1 FGD Flammable Heads.......................................................................................... 9-3

9.3.2 FGD O2/Toxic Heads .............................................................................................. 9-3

Please Note:

Page numbers within this manual are of the form:

Section –Page

e.g. ‘Page 2-3’ refers to Section 2, Page 3

STATUS SCIENTIFIC CONTROLS

MCU System Installation and Hardware Configuration Manual

TD06/001

Issue:

6

Change Note:

1696

Page 1-1

1 INTRODUCTION

The MCU3 & 4 are environmental Monitoring Control Units (MCU) that provide facilities to monitor

a wide variety of industry standard environmental and other sensors.

The MCU3 provides up to 8 monitoring channels.

The MCU4 provides up to 16 monitoring channels.

The MCU range has been designed primarily for environmental monitoring. However, the

versatility of the range extends its application to other aspects of industry where monitoring of

remotely connected sensors is required. The specification allows the use of any sensor that can

produce a voltage or current output within a specified range.

The versatile design allows a monitoring system to be initially installed using the minimum

number of required channels and then, as the monitoring environment changes, more channels

can be added, or alternative detector heads can be used as required.

Data logging is provided as a standard function. Data is stored within the systems’ non-volatile

memory thereby providing reliable storage without the risk of losing data in the event of total

power loss (mains and battery backup failure). Logged data can be viewed via the LCD display

situated on the front panel in either numerical or graphical form, or alternatively the data may be

transferred to a P.C. (running the Mentor PC Software) via the RS232 output. This provides the

system with an unlimited storage and data-logging medium.

Care has been taken with the design of the MCU housings and internal chassis to facilitate ease

of connection and wire termination. All on-site wiring to the system is via removable screw

terminal connectors.

A monitoring system consists of, as a minimum, an MCU3 Control Unit and 1 detector head. The

MCU Control Unit houses all of the components required to implement a sophisticated and

reliable monitoring system (battery back-up, alarm relays etc).

STATUS SCIENTIFIC CONTROLS

MCU System Installation and Hardware Configuration Manual

TD06/001

Issue:

6

Change Note:

1696

Page 1-2

•MCU3 Control Unit.

The MCU3 can monitor up to eight channels.

Channels 1-4 are located on a lower platform whilst channels 4-8 are located on a hinged

upper level. This allows easy access to all hardware configurable options whilst maintaining

its compact size.

It is supplied with interchangeable gland plates located on its upper and lower face. The

lower plate has seventeen holes suitable for 20mm compression glands, or ½” NPT Conduit

entries (other gland plate configurations are available on request), whilst the upper plate is

blank.

STATUS SCIENTIFIC CONTROLS

MCU System Installation and Hardware Configuration Manual

TD06/001

Issue:

6

Change Note:

1696

Page 1-3

•MCU4 Control Unit

The MCU4 contains two MCU3 systems giving the system the ability to monitor up to sixteen

channels.

The MCU4 is supplied with interchangeable gland plates located on its upper and lower

face. The lower plate has seventeen holes suitable for 20mm compression glands, or ½”

NPT Conduit entries (other gland plate configurations are available on request), whilst the

upper plate is blank.

STATUS SCIENTIFIC CONTROLS

MCU System Installation and Hardware Configuration Manual

TD06/001

Issue:

6

Change Note:

1696

Page 1-4

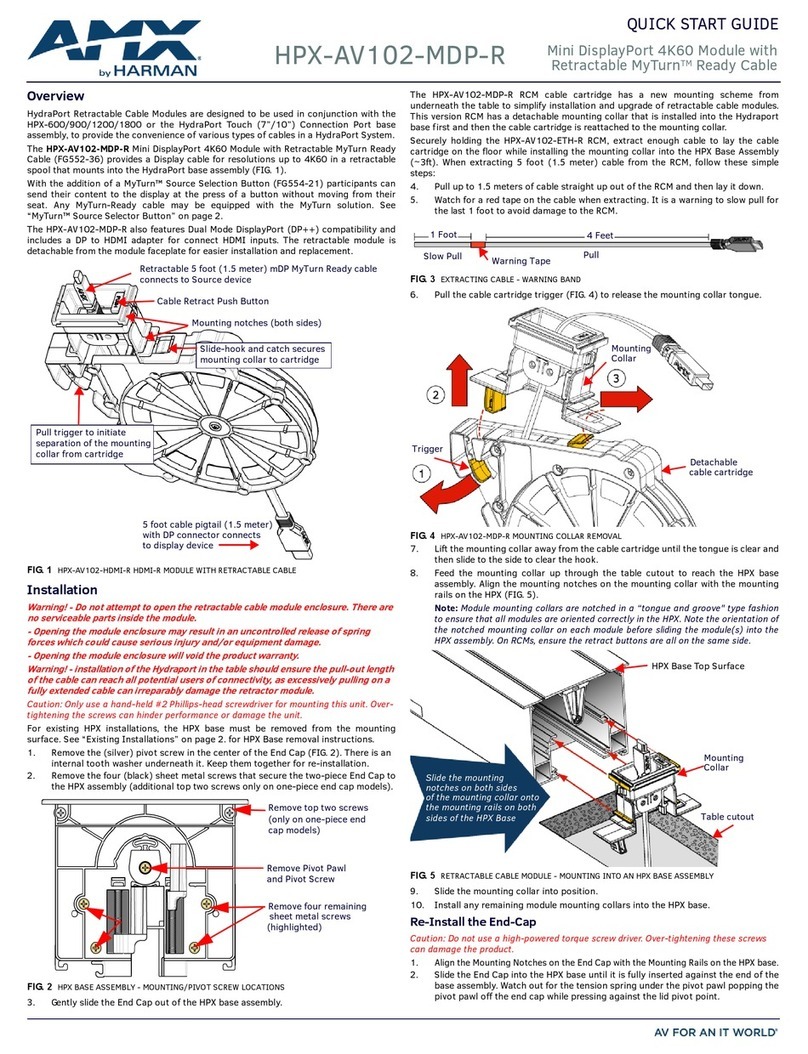

The diagram above shows a pictorial representation of the various module positions within the

MCU3 and MCU4 Control Units.

The power supply is situated beneath the main chassis and is not visible when the unit is

assembled, however the four system fuses (FS1 –4) are easily accessible. The mains input

connector and FS1 are sited beneath a cover to avoid inadvertent user contact during normal

operation. The standby batteries are also located beneath the main chassis.

Channels 5-8 are mounted on a hinged platform positioned above channels 1-4. This design

allows easy access to channel 1-4 situated below.

The microcontroller module and LCD display are not shown on the above diagram. These are

mounted on the rear of the hinged front panel of the MCU3 and MCU4 Control units.

Mains Input to PSU (situated

beneath main chassis)

Fuse FS1 (Mains Input)

RL3a RL3b RL4a RL4b

RL2b RL2a RL1b RL1a

Distribution

Board

Common Relay

Module

Fuse FS4 (int./ext. battery)

Fuse FS3 (24V for ext. outputs)

Fuse FS2 (24V)

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

Detector Head

Connections

Analogue

Output

Relay 3

Relay 2

Relay 1

CHANNEL 4

24V

24V

0V

0V

12

11

10

9

8

7

6

5

4

3

2

1

L N E

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

Detector Head

Connections

Analogue

Output

Relay 3

Relay 2

Relay 1

CHANNEL 2

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

Detector Head

Connections

Analogue

Output

Relay 3

Relay 2

Relay 1

CHANNEL 3

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

Detector Head

Connections

Analogue

Output

Relay 3

Relay 2

Relay 1

CHANNEL 1

STATUS SCIENTIFIC CONTROLS

MCU System Installation and Hardware Configuration Manual

TD06/001

Issue:

6

Change Note:

1696

Page 1-5

1.1 Microcontroller Module

Situated within the MCU Control Unit front panel is the Microcontroller Module. This module

communicates with all Input Modules connected to the system via an I2C serial bus. The

Microcontroller Module also communicates with the Distribution Board and Relay Module as well

as providing a user interface in the form of a back lit 240 x 64 dot LCD graphical display and an

eight button multifunction keypad.

Note: I2C is a trademark of Phillips Semiconductors.

Three LED indications are provided directly by the Microcontroller Module and these are visible

via MCU front panel:

➢Green LED indication of power on.

➢Red LED indication of alarm condition.

➢Yellow LED indication of fault condition.

An Audible signal is also provided by a sounder mounted within Microcontroller module. This

provides an audible intermittent tone during alarm or fault conditions.

Note:

This sounder is not intended for use as a main indication of alarm conditions. It is strongly

advised that a more substantial sounder and/or beacon be connected to this system (e.g. Status

sounder type SS367 or SS368)

The Microcontroller Module also provides the user with many configuration and interrogation

facilities via the LCD display and keypad. These facilities include:

➢Setting of the Real Time Clock.

•The system has a battery backed 24Hr clock as a standard feature.

➢Sensor Configuration.

•Allows adjustment of Sensor type and range (e.g. Flammable 100%LEL).

➢Calibration of the system.

•This allows each channel to be calibrated independently. The sensor zero point and

span can both be set via this function.

•Calibration of the retransmitted output for each channel.

➢Common Relay Configuration.

•There are four relays situated on the ‘Relay Module’. These relays can be configured

as normally energised or de-energised, and they have several triggering options

dependent on the application.

➢Input Module Relay Configuration.

•Each Input Module contains three relays. These relays can be configured normally

energised or de-energised as required. The levels at which the relays operate are

also engineer configurable.

➢Changing of display modes.

•The LCD has a variety of display modes dependent on the application or maybe the

personal preference of the engineer.

➢Interrogation of logged data.

•The data for any channel can is displayed numerically and graphically.

The microcontroller module contains all of the software required to communicate with up to eight

detecting channels. The addition of extra Input Modules therefore requires only a simple software

configuration change to monitor the additional channels.

STATUS SCIENTIFIC CONTROLS

MCU System Installation and Hardware Configuration Manual

TD06/001

Issue:

6

Change Note:

1696

Page 1-6

From the rear of the MCU front panel, access can be gained to a 9-way D-type connector labelled

‘Programming and Configuration’ (see section 1.7). With the aid of an interconnecting cable

supplied by Status Scientific the following functions can be performed:

•Programming and Configuration of the MCU system via a P.C.

•Networking of MCU Control Units.

•Downloading of logged data.

A reset button is also located on the Microcontroller Module to allow the system to be reset locally

in the event of an irretrievable fault. This will ‘reboot’ the Microcontroller but will not erase

configuration data or logged data stored within the system.

1.2 Input Module

The input module monitors the status of an externally attached sensor and interfaces the signals

that it receives to the microcontroller module.

The input module is designed to accommodate virtually all sensor configurations currently

available. It can be connected to any sensor (Environmental or otherwise) that supplies it status

signal in any of the following formats:

(a) Current Loop 4 –20mA from 24V source.

(b) Current Loop 4 –20mA to ground.

(c) 3-Wire Pellistor Systems.

(d) Voltage Input.

Note:

Option (d) requires hardware configuration that should be made at the factory prior to dispatch.

Please request this option at time of ordering.

In addition the input module can re-transmit the signals for use by external equipment (e.g. chart

recorders). The transmitted signal can be configured using jumpers to provide one of three

output options:

•4 –20mA Current Source proportional to detected signal.

•4 –20mA Current Sink proportional to detected signal.

•0-5V Voltage Output proportional to detected signal.

Up to eight input modules can be located within an MCU3 Control Unit; up to sixteen can be

located within an MCU4.

Situated on each Input Module are 3 Double Pole Change-Over Relays, each relay having

contacts rated at 5A (240V AC). These relays operate at Low, Intermediate and High alarm levels

when enabled. Status Scientific Controls are able to implement modifications to the software to

meet a customer’s specific requirement. Contact Status for further information.

STATUS SCIENTIFIC CONTROLS

MCU System Installation and Hardware Configuration Manual

TD06/001

Issue:

6

Change Note:

1696

Page 1-7

1.3 Distribution Board

The Distribution Board is the distribution point for power around the system. It allows the

connection of external power supplies into the system and the use of external batteries for

backup purposes. It is located at the left-hand side of the main chassis within the MCU Control

Units beneath the Common Relay Module.

There are two main versions of the distribution board –see sections 1.3.2 & 1.3.3

Note that Issue 3 is fitted into all new equipment.

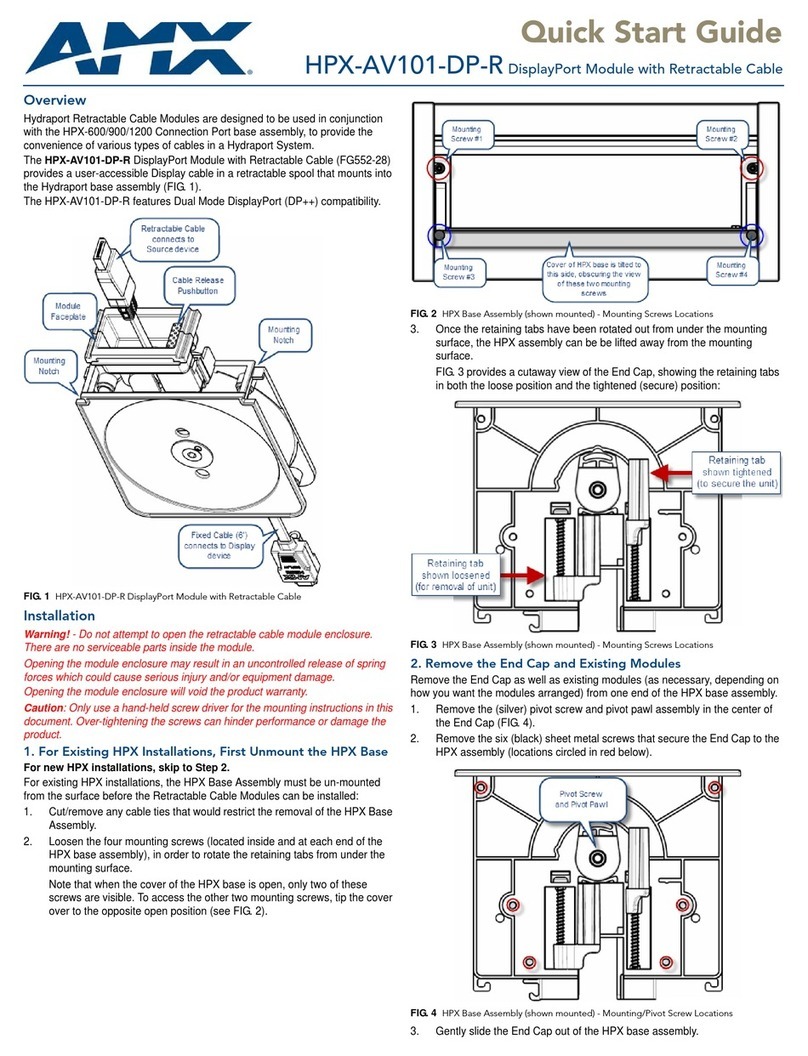

1.3.1 Field Connections

Located on the top edge of the distribution board is a 12 way connector. This is used to provide

connections for inputs, outputs and external buttons:-

Pins 7 & 8

These pins allow the connection of an external normally open switch. This switch will

allow the muting of alarms from a remote location (the control unit is the only location

from which alarm conditions can be accepted or cleared). This button can be configured

to perform other functions if required. Contact Status Scientific Control for further details.

Pins 9 & 10

External 24V batteries may be connected to the system via these pins. This is only

required if it is anticipated that the main power source will be disconnected from the

system for long periods of time, in excess of the internal battery capabilities. Note that

any external batteries must be independently charged.

Pins 11 & 12

An external 24V DC supply may be used instead of having a mains input. Refer to section

2.4.2 for further details regarding connection of an external DC supply. The internal

batteries will still maintain power in the event of the external 24V power supply failing. In

order to meet all the power supply requirements of the system, the external supply must

be rated at 24V DC @ 2A minimum.

Pins 1 to 6

The function of the remaining pins on the 12-way connector depends upon the issue of

the distribution board fitted.

Note:

The issue of the distribution board may be determined by noting the position of jumper

J1. If this not located adjacent to the 4-way connector refer to section 1.3.2. However, if

the jumper is located adjacent to the 4-way connector refer to section 1.3.3.

The jumper position on the distribution board (labelled J1) allows connection of chassis earth to

the system 0V. The fitting of J1 is not always required; section 3.2 discusses this link and

determines whether it should be fitted in a given situation.

An I.S. Earth point is also provided on the distribution board. This is discussed in section 3.3

STATUS SCIENTIFIC CONTROLS

MCU System Installation and Hardware Configuration Manual

TD06/001

Issue:

6

Change Note:

1696

Page 1-8

1.3.2 Distribution Board - Issues 1 & 2

The lower 4-way connector provides a 24V and 0V connection. The voltages are always present

at these terminals whilst FS2 is intact. The remaining two connections must not be used. The 24V

supply is designed for use by Status Scientific Controls when powering external equipment. The

amount of power available from this connector must be determined for each installation based

upon the system configuration.

Pins 1 & 2, pins 3 & 4 and pins 5 & 6 of the 12 Way Connector provides three external outputs

under software control. Outputs 1 and 2 are designated as Sounder and Beacon control outputs

respectively (consult section 8.1 for sounder and beacon installation details) and Output 3 is

spare. Each output is capable of switching a maximum of 200mA. Fuse protection is provided by

FS3 situated on the Power Supply (refer to section 1.5).

It should be noted that the external outputs are not switched via voltage free contacts. 24V

is always present at pins 2, 4 and 6 and the 0V line is switched via an open-collector

transistor.

Note: In certain circumstances outputs 1, 2, and 3 can be configured as Inputs. Contact Status

Scientific for further information.

1.3.3 Distribution Board - Issues 3 and above

The lower 4-way connector provides two 24V screw terminals, and two 0V screw terminals. The

voltages are always present at these terminals whilst FS3 is intact. This supply is taken from the

24V supply of the system and is used by Status Scientific Controls when powering external

equipment. The amount of power available from this connector must be determined for each

installation based upon the system configuration.

Pins 1 & 2 and pins 3 & 4 of the 12 Way Connector provides two external outputs under software

control. Output 1 is designated as the sounder output, whilst Output 2 is designated as the

Beacon output. Each output is capable of switching a maximum of 200mA. Fuse protection is

provided by FS3 situated on the Power Supply (refer to section 1.5).

J1

24V

0V

Tx

Rx

12

11

10

9

8

7

6

5

4

3

2

1

0V

External 24V DC Supply

24V

Open Collector O/P3

24V

Open Collector O/P2

24V

Open Collector O/P1

0V

Reset

0V

External Battery Supply

I.S. Earth

J1

24V

24V

0V

0V

12

11

10

9

8

7

6

5

4

3

2

1

0V

External 24V DC Supply

0V

Input 1

0V

24V O/P2

0V

24V O/P1

0V

Reset

0V

External Battery Supply

I.S. Earth

S5

S6

S7

S8

S1

S2

S3

S4

STATUS SCIENTIFIC CONTROLS

MCU System Installation and Hardware Configuration Manual

TD06/001

Issue:

6

Change Note:

1696

Page 1-9

Jumpers are located on the lower half of the distribution board. The jumpers allow the engineer to

configure the outputs for either 24V switching or 0V switching at installation.

A label appears on the PCB indicating the correct jumper settings for each option:

Input –Allows the outputs to be configured as inputs in some

circumstances. Contact Status Scientific for further details.

Output (Switch 24V) –0V always present at connector, 24V is

switched via a relay under processor control.

Output (Switch 0V) –24V always present at connector, 0V is

switched via relay under processor control.

The label shown above indicates the correct positioning of

jumpers to obtain the specified output configuration.

It should be noted that the external outputs are not switched via voltage free contacts.

Depending on the configuration, either 24V or 0V will be permanently available at the

connector with the remaining supply being switched via a relay.

Under no circumstances must mains supply voltages be connected to any of the

distribution board terminals.

Pins 5 & 6 provide connection for an external switch.

1.4 Common Relay Module

Situated on the Relay Module are 4 Double Pole Change-Over Relays, each relay having

contacts rated at 8A (240V AC). Each of the relays can be configured as normally energised or

de-energised.

The standard configuration for these relays is

Any channel incurs a low alarm, common relay 1 will operate.

Any channel incurs a medium alarm, common relay 2 will operate.

Any channel incurs a high alarm, common relay 3 will operate.

RL4 is designated as a fault alarm relay.

These relays can be configured to provide alternative features via the software if required. Status

Scientific are able to implement modifications to the software to meet a customers specific

requirements, contact Status for further information.

Input

Consult SSCL

Output

(Switch 24V)

Output

(Switch 0V)

Outputs

STATUS SCIENTIFIC CONTROLS

MCU System Installation and Hardware Configuration Manual

TD06/001

Issue:

6

Change Note:

1696

Page 1-10

1.5 Power Supply Module

The Power Supply is situated beneath the main chassis of the control unit and provides the power

for the whole system. The power supply is a standard item and does not require any

modifications regardless of the type and quantity of detector heads being used.

There are three power source options available to the system:

1. 220-240V AC Mains Supply Switch Selectable

2. 110-120V AC Mains Supply Switch Selectable

3. 24V DC Supply No switch position change required

Options 1 & 2 are easily selected via an on board switch (sited beneath a yellow protective

cover). Option 3 is provided as an alternative to an AC mains supply and allows the use of an

external 24V DC power supply (connected via the Distribution Board).

There are four fuses situated on the power supply PCB. These are:

FS1 (T1.0A) Mains Fuse

FS2 (T2.0A) Internal 24V Supply

FS3 (F1.0A) 24V to Outputs 1 –3

FS4 (F2.0A) Internal/External Battery (see Note below).

Note:

The internal batteries will supply power to the system as soon as FS4 is fitted. However, an

external power source will be selected once connected to the system and the internal batteries

will charge. The internal batteries will not provide backup if FS4 is not fitted or it has blown.

The power supply provides the charging current for the internal standby batteries such that in the

event of an external power failure, the system will continue to operate for sufficient time to allow

reconnection of the external supply. The backup time provided is dependent upon:

1. Quantity and type of Detector Heads used

2. Time since last Mains power fail and duration of power fail

3. Alarm status, and other external loads placed upon system

Refer to section 1.6 for further details.

The system will automatically select the internal batteries in the event of the external AC/DC

supply failing and will reselect the external supply on its reconnection. If it is necessary to

disconnect all power to the system, mains power should be removed followed by the removal of

fuse FS4.

Mains Fuse

L

N

E

24V

24V External O/P

INT/EXT Battery

FS1

FS2

FS3

FS4

230V

130100

Issue 2

STATUS SCIENTIFIC CONTROLS

MCU System Installation and Hardware Configuration Manual

TD06/001

Issue:

6

Change Note:

1696

Page 1-11

1.6 Battery Backup

The MCU control units are supplied with a pair of 12V 1.2Ahr maintenance free backup batteries

mounted beneath the main chassis (MCU4 contains 2 pairs of batteries). The batteries are

connected in series enabling them to provide the 24V required by the system in the event of an

external power failure. The power supply for the system provides the charging current required

maintaining the batteries in a fully charged state.

Should the main source of power fail, the system will indicate to the users that it is operating from

its batteries by flashing the green power LED, whilst lighting the yellow fault LED. The fault relay

(RL4) located within the ‘Common Relay Module’ will also operate and therefore trigger any

warning devices added to the system by the user. No audible alarm will be generated.

The backup time provided can not be stated without first considering the configuration of the

system. The backup time is dependent upon:

1.Quantity and type of detector heads used.

2.Time since last power fail and duration of power fail.

3.Alarm status.

4.Relay configuration (whether normally energised or de-energised).

5.External loads placed on the system.

The table below lists the various modules that can be connected to the MCU system and the load

that they place on the system.

Module and Condition

Current Required

Quiescent current of Microcontroller Module + Display

36mA

Display Backlight

244mA

Quiescent current of Input Module

5mA

Input Module c/w Toxic Head (Zero Gas)

8mA

Input Module c/w Toxic Head (Full Scale)

24mA

Input Module c/w Oxygen Head (20.9%)

17mA

Input Module c/w Flammable Head (Zero Gas)

41mA

Input Module c/w Flammable Head (Full Scale)

58mA

Common Relay Module with relays energised.

17mA per Relay

Input Module Relays with relays energised.

17mA per Relay

Input Module Analogue Output (Zero Gas)

4mA

Input Module Analogue Output (Full Scale)

20mA

The time for which the battery will supply power can now be calculated by taking into account the

modules fitted to the system and the configuration of alarm relays (i.e. whether normally

energised or normally de-energised)

To calculate an approximate time for battery backup we need to make several assumptions: -

1.No alarm conditions are encountered during the battery-backed time.

2.Display backlight is off.

3.The batteries are fully charged.

For instances where a longer back up time is required, Status can supply an external battery unit.

This will connect into the system at the Distribution Board and consists of its own internal charger.

Contact Status for more information.

STATUS SCIENTIFIC CONTROLS

MCU System Installation and Hardware Configuration Manual

TD06/001

Issue:

6

Change Note:

1696

Page 1-12

1.6.1 Calculation Examples

Three examples follow demonstrating how the backup time may be calculated.

Example 1 (Typical Configuration)

A 4 channel system comprising of 3 toxic channels and 1 flammable channel. All system relays

are configured as normally energised. No analogue outputs are being provided by the system.

Module and Detector Heads

Qty

Current

Controller & Display

1

x

36

=

36

mA

Input Module & Toxic Head

3

x

8

=

24

mA

Input Module & Oxygen Head

0

x

17

=

0

mA

Input Module & Flammable Head

1

x

41

=

41

mA

Common Relays (Energised)

4

x

17

=

68

mA

Input Module Relays (Energised)

12

x

17

=

204

mA

Input Module Analogue Output

0

x

4

=

0

mA

Total Current Required under normal conditions =

373

mA

Batteries are 1.2Ahr, therefore backup time is 1200/373 = 3.2 Hrs = 3 Hours 12 mins

Example 2 (Worst Case)

An eight channel system comprising of 8 flammable channels. All system relays are configured as

normally energised. All analogue outputs are providing signals to external equipment.

Module and Detector Heads

Qty

Current

Controller & Display

1

x

36

=

36

mA

Input Module & Toxic Head

0

x

0

=

0

mA

Input Module & Oxygen Head

0

x

0

=

0

mA

Input Module & Flammable

8

x

41

=

328

mA

Common Relays (Energised)

4

x

17

=

68

mA

Input Module Relays (Energised)

24

x

17

=

408

mA

Input Module Analogue Output

4

x

4

=

16

mA

Total Current Required under normal conditions =

856

mA

Batteries are 1.2Ahr, therefore backup time is 1200/856 = 1.4 Hrs = 1 Hour 24 mins

STATUS SCIENTIFIC CONTROLS

MCU System Installation and Hardware Configuration Manual

TD06/001

Issue:

6

Change Note:

1696

Page 1-13

Example 3 (Best Case)

A 4 channel system comprising of 4 toxic channels. All system relays are configured as normally

de-energised. No analogue outputs are being provided by the system.

Module and Detector Heads

Qty

Current

Controller & Display

1

x

36

=

36

mA

Input Module & Toxic Head

4

x

8

=

32

mA

Input Module & Oxygen Head

0

x

17

=

0

mA

Input Module & Flammable Head

0

x

41

=

0

mA

Common Relays (Energised)

0

x

17

=

0

mA

Input Module Relays (Energised)

0

x

17

=

0

mA

Input Module Analogue Output

0

x

4

=

0

mA

Total Current Required under normal conditions =

68

mA

Batteries are 1.2Ahr, therefore backup time is 1200/68 = 17.6 Hrs = 17 Hours 36 mins

1.6.2 Calculating the backup time for your system

Notes for Calculation

1. The Controller Module is always present on a functioning system and therefore its quiescent

current must always be included in any calculations.

2. If an external load is placed upon the system then the current that the load requires must be

added to the table prior to performing the final calculation.

Consider the system being installed, the detector heads being used and the normal status of all

relays within the system. Enter the quantities in the table below to assist in battery life

calculations.

Module and Detector Heads

Qty

Current

Controller & Display

1

x

36

=

36

mA

Input Module & Toxic Head

x

8

=

mA

Input Module & Oxygen Head

x

17

=

mA

Input Module & Flammable Head

x

41

=

mA

Common Relays (Energised)

x

17

=

mA

Input Module Relays (Energised)

x

17

=

mA

Input Module Analogue Output

x

4

=

mA

External Loads (e.g. Status Lamp)

x

=

mA

Total Current Required under normal conditions =

mA

The battery life can now be calculated by dividing 1200 by the total current required by the

system under normal conditions.

STATUS SCIENTIFIC CONTROLS

MCU System Installation and Hardware Configuration Manual

TD06/001

Issue:

6

Change Note:

1696

Page 1-14

1.7 MCU System Communications

Located at the rear of the Microcontroller Module is a 9-way D-type socket labelled ‘Programming

and Configuration’. This is the systems RS232 communications port. This provides the system

with three useful communications features:-

Note:

The PC must be running the ‘Mentor PC Software’ to perform any of communications functions.

1.7.1 MCU System Configuration and Interrogation

This provides the ability to perform all of the functions available via the Control Unit keypad (and

more) using a PC.

e.g.

•Displaying live data on the PC screen.

•MCU system configuration.

•Downloading logged data from MCU.

•View and export downloaded data (graphical or tabular format).

These features may be advantageous if the MCU Control Unit is located in a dirty environment.

The system could be remotely monitored from a ‘clean’ room.

Note:

An RS232 cable is usually only suitable for short cable runs (e.g. 10ft), however cables having

lengths of 30-40ft have been known to provide reliable communications.

1.7.2 MCU System Networking

RS485 Network Cards are available from Status Scientific Controls. These interface the RS232

signals from the MCU into a more suitable format for transmission over longer distances. This

provides the MCU system with two powerful features:

•As section 1.7.1 but with less restriction on the cable lengths between PC. and MCU

Control Unit (up to 1km possible).

•The PC can monitor more than one MCU system when utilising network cards.

All PC’s have at least one RS232 COM port to allow communications with external equipment.

The network cards supplied by Status Scientific Controls allow the PC to monitor a maximum of

32 MCU systems via one com port.

STATUS SCIENTIFIC CONTROLS

MCU System Installation and Hardware Configuration Manual

TD06/001

Issue:

6

Change Note:

1696

Page 2-1

2 MCU INSTALLATION

The MCU Control Units and FGD Gas Detectors are fully tested prior to delivery. However, after

installation we strongly recommend that full system testing and commissioning be carried out.

Status Scientific Controls Service personnel are best equipped to perform the relevant tests and

commissioning and will be able to offer advice regarding installation faults.

WARNING

Installation should be made in accordance with either British Standard BS EN60079-

14 (which supersedes BS5345) “Electrical Apparatus for Explosive Gas

Atmospheres”, or in accordance with the relevant National or Local regulations.

CAUTION

The MCU Control Units and associated modules contain no user serviceable parts. Refer all

module servicing to qualified service personnel.

2.1 Siting the MCU

THE MCU CONTROL UNIT MUST BE SITED IN A NON-HAZARDOUS LOCATION WHERE

THERE IS NO RISK OF THE PRESENCE OF POTENTIALLY EXPLOSIVE GAS.

Either a 110V-120V or a 220V-240V AC supply can be used to power the control unit;

alternatively a 24V DC supply can be used.

The site of installation should be chosen with regard to the following:

•This equipment should not be located near to known sources of heat.

•Operating personnel should be within convenient reach of the equipment and within

audible distance of alarms.

•Maximum loop lengths of cable runs and cable inductance to resistance ratios must not

exceed limits shown in the relevant loop diagrams (refer to section 3.2).

•Avoid mounting this equipment near potential sources of electrical interference e.g.

motors, switch gear, radio transmitters etc.

Mounting details for the MCU enclosures are located within the Appendix (section 8).

STATUS SCIENTIFIC CONTROLS

MCU System Installation and Hardware Configuration Manual

TD06/001

Issue:

6

Change Note:

1696

Page 2-2

2.2 Assembling

The MCU Control Units are supplied with the Standby Battery fuse (FS4) not fitted. This fuse

should be fitted once the Control Unit is mounted in position and ready for use. It should be noted

that once this fuse is fitted, power will be connected to all modules and Sensor Heads connected

to the system. All wiring tests and commissioning should therefore be performed prior to fitting

this fuse.

Note: FS4 is supplied in a plastic bag inside the MCU control unit.

It is advisable to familiarise yourself with the Control Unit and its connections before mounting. In

particular observe the mounting positions of any Input modules which have been modified to

comply with an uncommon sensor configuration. It is also a convenient time to set the jumper

switches for all the input modules according to the sensor type to be used.

Note:

Incorrect Input Module configuration can cause damage to the system.

2.3 System Wiring

All connections should be made according to the appropriate sensor or loop diagram for the

configuration required. It is advised that ‘Bootlace Ferrules’ or ‘flat blade crimps’ be used for tidy

and reliable connections of wires into the Control Unit and Detector Head connectors.

2.4 Power Supply Input

An isolating switch should be provided between the power source and the MCU control units to

allow the supply to be easily disconnected. This should incorporate over current protection or a

circuit breaker. Alternatively a fused supply would suffice. For information regarding the current

requirement of the control units, refer to the specification located in section 9.1.

2.4.1 A.C. Mains Connection

All mains voltage connectors etc. have been positioned beneath a yellow protective cover

to prevent inadvertent user contact.

The power supply board has a three pin screw terminal connector assigned for the connection of

an AC supply. This is located to the lower left-hand side of the MCU shrouded by a yellow

protective cover. The AC supply can be either 240V or 110V. The 110V mains supply can be

derived from either a 0V-110V AC power source or a 55V-0-55V AC power source. In all cases

ensure the safety earth (E) is connected.

To connect AC power to the system it is necessary to unplug the three-

terminal connector (PL1) from the power supply PCB. The screw terminals

are connected as shown

Recommendation for mains input cable:

3-Core - Conductors having cross sectional area of 0.75mm2minimum (24/0.2).

L N E

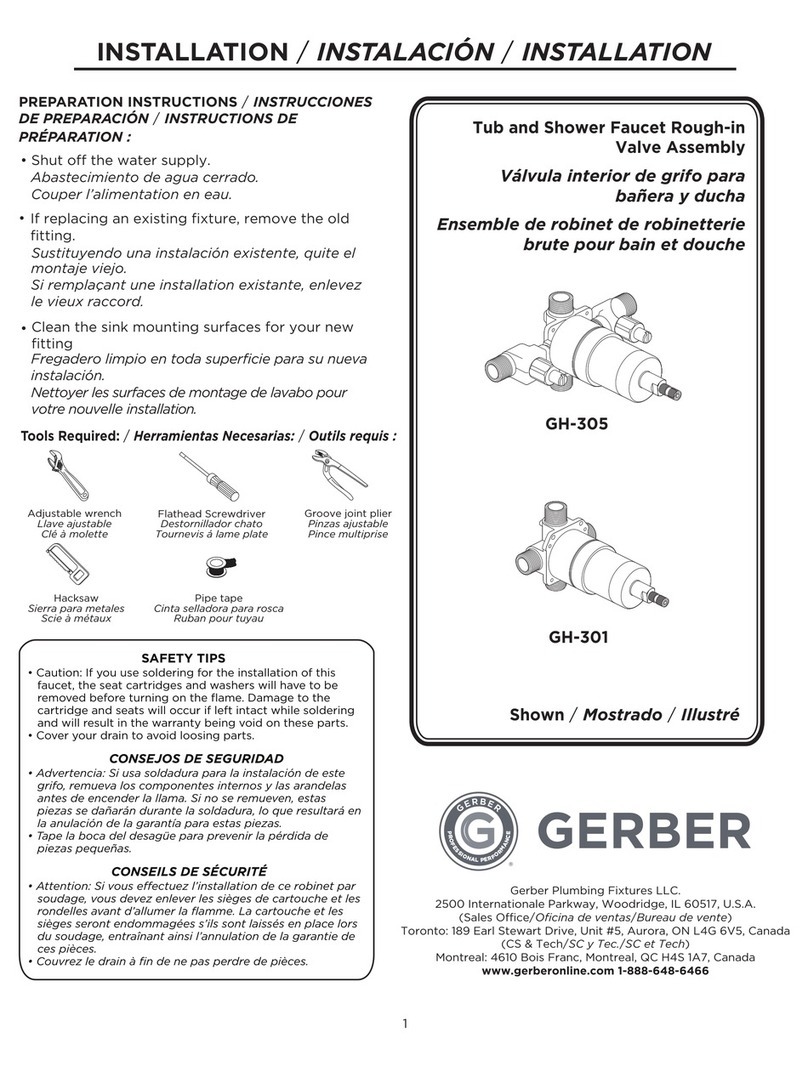

This manual suits for next models

1

Table of contents

Other STATUS SCIENTIFIC CONTROLS Control Unit manuals

Popular Control Unit manuals by other brands

Rasmussen

Rasmussen SPK3E owner's manual

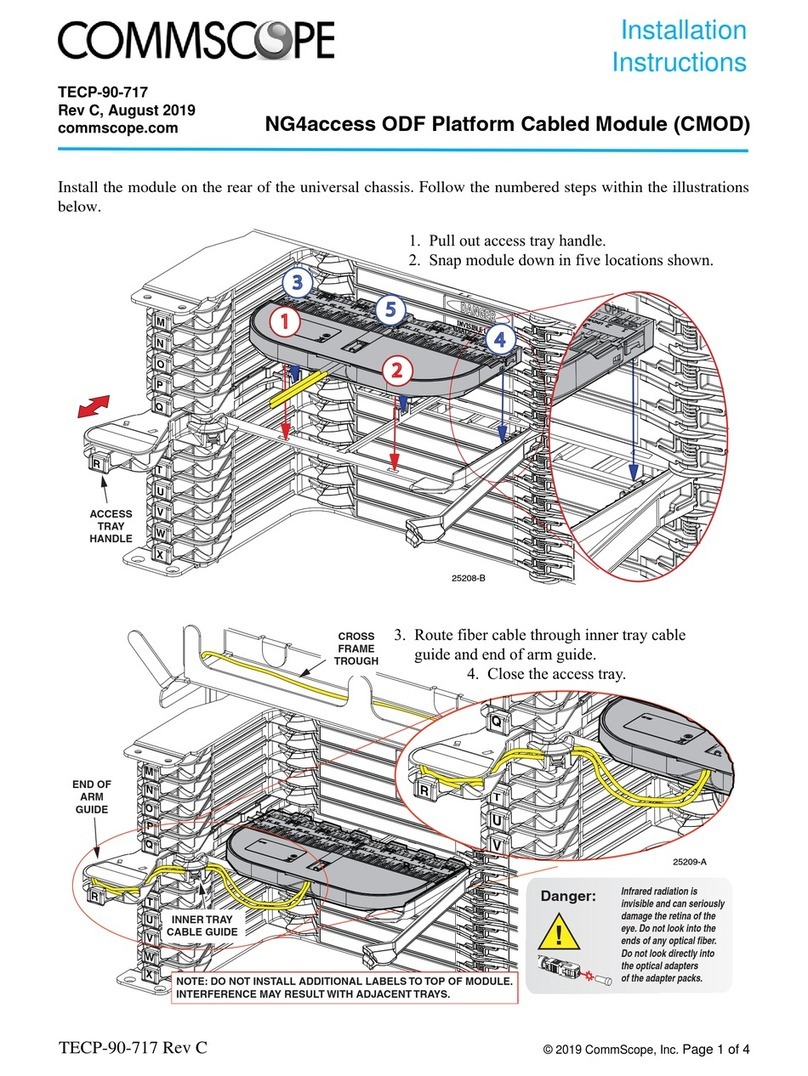

CommScope

CommScope CMOD installation instructions

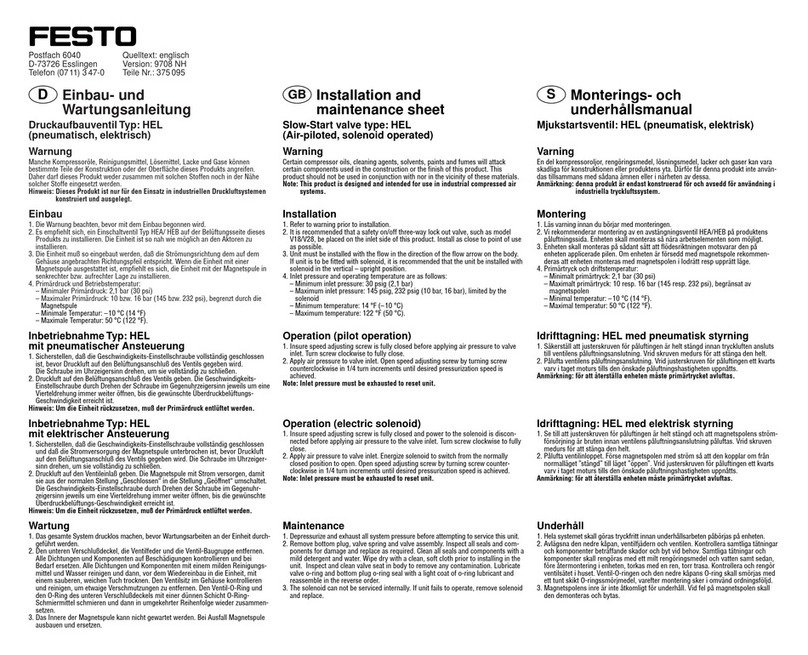

Festo

Festo HEL Series Installation and maintenance sheet

KLINGER

KLINGER INTEC K210-FS Assembly and Repair Instructions

Honeywell

Honeywell AlarmNet 7847i-E Installation and setup guide

BFT

BFT RIGEL 6 installation manual