Stealth International WSMG1 User manual

MANUAL

TRANSMISSION

Service

."anual

~L.

.,

••

1.'1

•••

Dodg_

St_lth

A/T

Turbo

,.aCk1saa

M~.ublehl

IIIIrTl

00

TlNIn

Turbo

.,_1.'1

__

Mlt.ubi.hl

30QOElT

VA4

WSMG1,W6MG1

MANUAL

TRANSMISSION

Preface

This book was translated from the original

Japanese language service manual published

by Mitsubishi Motors Corporation ofJapan.

Translation was performed by volunteers from

3000GT/Stealth International, an owners and

enthusiast group focused

on

the Mitsubishi

3000GT, Dodge Stealth and Mitsubishi GTO.

Great care has been taken to ensure the

accuracy

of

the information contained

in

this

manual, but errors may still be possible due

to the nature ofthe translation. Therefore,

this manual is presented as a guide only,

and repair procedures should not

be

undertaken by unskilled individuals who do

not posess a thorough understanding

of

the

subject material.

The authors ofthis manual will not be held

responsible for any personal injury or damage

to property incurred while performing the

procedures described within.

All tasks

in

this manual are undertaken at your

own risk.

Group

Index

c::lut;ct1

..................................

~

Manaul

Transmission

.......

~

Transfer

C::ase

Recall

.......

E33

Applicable

Models

This book covers the Getrag W5MG1 and

W6MG1 all-wheel drive manual transaxles

found

in

the following models:

1991 -1996 Dodge Stealth RlT Turbo

1991 -1999 Mitsubishi 3000GT VR4

1990 -1999 Mitsubishi GTO Twin Turbo

This book would not be possible without the

contributions

of

the following people:

Translation, and layout

JeffVanOrsdal

Additional Translation

Frank Chen, Kotaru Yamaguchi,

Corumisri

Technical Assistance

Bret Brinkmann

Jeff Lucius

Financial assistance

Many generous members of 3000GT I Stealth

International

Visit 3000GT I Stealth International on the web at www.3si.org

Introduction

Introduction

Scope

of

this

manual

This book explains the main service points

regarding the transmission itself. However,

please utilize the relevant service manual

for the car model and year

in

question

when concerns arise regarding onboard

inspection and service.

Important

points

(1) Component diagrams are published

at the beginning of each section so that

you may more easily visualize the

assembled state

of

the component or

su

b-assembly.

(2) Numbered service procedures are

displayed

in

the component diagrams

along with indications

of

non-reusable

parts and torque specifications.

(3) Main service points and maintenance

points are explained

in

detail, along with

usage and descriptions

of

special tools.

About

inspection

Descriptions are provided for procedures

to

be

taken when defective or damaged

parts are discovered during inspection.

Symbols for lubricants, sealants and adhesives

Information concerning the locations of lubricarion

and for application

of

sealants and adhesives

is

provided, by using symbols,

in

the diagram

of

component parts or

on

the page following the

component parts page.

4IiN

.................

Grease (multipurpose unless there

is

a brand or type specifed)

t

................

Brake fluid or automatic transmission

fluid

.....

.....

..

.........

..

.........

..

...........Sealant or adhesive

r,.

.............................................................

Gear oil

Removal procedures

The part designation number corresponds to the

number

in

the illustration to indicate removal

procedures.

Disassembly procedures

The part designation number corresponds to the

number

in

the illustration to indicate disassembly

procedures.

Installation procedures

Specified

in

case installation

is

impossible

in

reverse order of removal procedures. Omitted if

installation

is

possible

in

reverse order

of

removal

procedures

Reassembly procedures

Specified

in

case reassembly

is

impossible

in

reverse order of disassembly procedures. Omitted

if reassembly is possible

in

reverse order of

disassembly procedures.

Classification of major maintenance or service

points

(JAQ

: Indicates that there are essential points for

removal or disassembly.

.A,

: Indicates that there are essential points for

installation or reassembly.

I--

,-----

l-

f---

r--

-

f---

Group number and page number

21

- B

Disassembly

/

Reassembly

Introduction

Group title

~

Section title

Clutch

-

Clutch

Release

Cylinder

Torque specification 2

Jia

6 6 1

Denotes non-

reusable part

Coat

all

internal

parts

in

brake

fluid

before

reassembly

Disassembly

Procedure

1.

Pushrod

2.

Boot

(:lAO_A. 3.

Piston

cup

(:lAO_A. 4.

Piston

5.

Conical

spring

6.

Cap

7.

Bleeder

screw

8. Release

cylinder

Disassembly

service

points

(JAc')

Removal

of

piston

cup

/

piston

TFM0494

(1) Remove the corrosion from the piston-removal port

of

the release cylinder.

(2) Remove the piston from the release cylinder using

compressed air.

Caution

1.

Cover

with

rags

to

prevent

the

piston

from

6CL035

popping

out.

~------------------------~

2.

Apply

compressed

air

slowly

to

prevent

brake

fluid

from

splashing.

21

CLUTCH

Maintenance

Standards

............................................

21-2

Torque

Specifications

................................................

21-2

Lu

brication

....................................................................

21-2

Special

Tools

.................................................................

21-3

Clutch

Assembly

..........................................................

21-4

Clutch

Release

Cylinder

.............................................

21-8

Clutch

Damper

............................................................

21-10

21

- 2

Clutch

-

Standards,

Torque

and

Lubrication

Maintenance

Standards

Item Limit Value mm

Clutch disk facing rivet sink Below 0.3

Diaphragm spring end height difference Within 0.5

Opening of release cylinder bore and piston major diameter Above 0.15

Torque

Specifications

Item Torque

Clutch damper bracket attachment bolt 6.5 tUbs / 9 Nm

Clutch damper installation bolt 14 fUbs / 19 N.m

Clutch oil tube filling nut

11

ftlbs

/15

Nm

Release fork fulcrum 26

ftlbs

/ 36 Nm

Clutch oil line bracket attachment bolt 14 tUbs / 19 N.m

3-way type connector mounting bolt 14 tUbs / 19 N.m

Clutch release cylinder mounting bolt 14 tUbs / 19 N.m

Union bolt

17

ft.lbs / 23 Nm

Clutch cover installation bolt 14

ftlbs

/ 19 N.m

Clutch release cylinder air breather 8 fUbs /11 Nm

Clutch damper air breather 6.5 ft.lbs / 9 Nm

Lubricants

Item Specified lubricant

Clutch release bearing sleeve diameter

Clutch release bearing and shift fork contact section Molykote

TA

#2

Shift fork and fulcrum contact section

Clutch release cyliner pushrod tip

Inside splines

of

clutch disk Molykote TA

#1

or #2

Clutch release cylinder piston and piston cup SAE J1703 (DOT3)

Clutch damper O-ring

Clutch

-

Special

Tool

Tool

Part Number

MD998126

Name

Clutch disk

centering guide

21

- 3

Use

Positioning the clutch disk

21

- 4

Removal/

Installation

18

4IiM

Removal

Procedure

27

fUbs

36Nm

22

4IiM

20

17

4IiM

1.

Clutch

cylinder

release

tube

2.

Clutch

cylinder

release

tube

3.

Clutch

cylinder

release

tube

4.

Clip

5.

Bracket

6.

Clutch

damper

7.

3-way

junction

block

8.

Insulator

9.

Bracket

10.

Insulator

11.

Banjo

bolt

12.

Crush

washer

23

19

c?4iM

Clutch

-

Clutch

Assembly

14

ft.lbs

19

Nm

4 5

~

~~

1

~

fI-~o

6

3---{

2

11

ft.lbs

y-----,

15

Nm

--7

14

fUbs

19

Nm

~

13

~

16

rf

~

¥

@--10

15

1~

1/

11

ft.lbs

115

Nm

1D12

117

ft.lbs

11

23 Nm

13.

Union

14. Release

cylinder

valve

15. Release

cylinder

spring

"0'

16.

Clutch

release

cylinder

..

C.

17.

Clutch

cover

..

C.

18.

Clutch

disk

ClAo

..

a;

19.

Clutch

release

fork

..

U 20.

Throw-out

bearing

21.

Boot

22. Release

fork

fulcrum

23.

Clutch

housing

Clutch

-

Clutch

Assembly

21

- 5

Fulcrum

Release

fork

Clip

Removal

service

points

oAQ

Release

fork

removal

(1

)Slide release fork

in

direction

of

arrow and disengage

fulcrum from clip to remove release fork.

Be

careful not to

cause damage to clip by pushing release fork

in

the direction

other than that

of

arrow and removing it with force.

L----

___________

D_C_LO-----'02

Inspection

Rivet sink

~~ifk~

6CL003

Clutch

cover

assembly

(1

)Check the diaphragm spring end for wear and uneven

height. Replace

if

wear is evident or height difference

exceeds the limit.

Limit:

0.5

mm

(.020 in.)

(2)Check the pressure plate surface for wear, cracks and

seizure.

(3)Check the strap plate rivets for looseness and replace

the clutch cover assembly if loose.

Clutch

disk

(1

)Check the facing for loose rivets, uneven contact,

deterioration due to seizure, adhesion of oil or grease,

and replace the clutch disc if defective.

(2)Measure the rivet sink and replace the clutch disc if it

is out of specification.

Limit:

0.3

mm

(.012 in.)

(3)Check for torsion spring play and damage and if defective,

replace the clutch disc.

(4)Combine the clutch disc with the input shaft and check

sliding condition and play

in

the rotating direction. If it

does not slide smoothly or the play is excessive, check

after cleaning and reassembling. Ifthe play is excessive,

replace the clutch disc and/or the input shaft.

Clutch

release

bearing

Caution

Release bearing is packed

with

grease. Therefore

do

not

wash

it

in cleaning

solvent

or

the

like.

(1

)Check bearing for seizure, damage, noise, or improper

rotation. Check also diaphragm spring contact surface

for wear.

(2)Replace bearing if its release fork contact surface is

abnormally worn.

Release

fork

(1

)Replace release fork if its bearing contact surface is

abnormally worn.

21

- 6

6C

lDI

6

3C

l

0003

Clutch

-

Clutch

Assembly

Installation

service

points

•

A.

Installation

of

clutch

release

bearing

(1) Fill the lip section with grease as illustrated

Specified grease:

Molykote TA #2

•

B.

Lubrication

of

release

fork

(1) Apply grease to release fork as illustrated

Specified grease:

Molykote TA #2

Clutch

-

Clutch

Assembly

21

- 7

Flywheel

~~7+--

Clutch disk

Clutch cover

6CL028

i

Apply 4iH

3CL0004

.C'

Installation

of

clutch

disk

cover

(1) Apply specified grease to clutch disc splines and

squeeze it

in

place with a brush.

Specified grease:

Molykote TA

#1

or #2

(2) Use the clutch disc guide to position clutch disc

on

flywheel.

(3) When installing the clutch cover, tighten the bolts

in

a diagonal pattern.

(4) Remove clutch guide tool

.0.

Installation

of

clutch

release

cylinder

(1) Apply grease to tip of release cylinder pushrod

as illustrated.

Specified grease:

Molykote

TA#2

21

- B

Disassembly

/

Reassembly

e 6

Clutch

-

Clutch

Release

Cylinder

1

2

Disassembly

Procedure

1.

Pushrod

2.

Boot

OAO.A, 3. Piston

cup

OAO.A, 4. Piston

t

Coat

all

internal

parts

in

brake

fluid

before

reassembly

5.

Conical

spring

6. Cap

7.

Bleeder

screw

8. Release

cylinder

TFM0494

Disassembly

service

points

OAt;

Removal

of

piston

cup

/

piston

(1) Remove the corrosion from the piston-removal port

of

the release cylinder.

(2) Remove the piston from the release cylinder using

compressed

air.

Caution

6CL035 1.

Cover

with

rags

to

prevent

the

piston

from

L-

________________________

~

popping

out.

2.

Apply

compressed

air

slowly

to

prevent

brake

fluid

from

splashing.

Clutch

-

Clutch

Release

Cylinder

21

- 9

.....................................................

Ii

;----++-Apply

:.:.:

..............................................

.

7ClDDD7

IiApply

\ Apply

'"-r---",.L--,

Piston cup ,

Piston Ii

6ClDDD3

Inspection

(1) Remove any rust or corrosion from the inside

of

the release cylinder

(2) Measure the inside diameter

of

the cylinder at 3

places (bottom, middle and top) Ifthe diameter

of

the

cylinder exceeds the outside diameter

of

the piston by

more than the limit value, replace the release cylinder

assembly.

Limit value:

0.15 mm

Assembly

service

points

.A.

Installation

of

piston

/

piston

cup

(1

)Apply specified brake fluid to the release cylinder

inside and outer surface ofthe piston and piston cup

and push the piston cup assembly

in

the cylinder.

Specified brake fluid:

SAE J1703 (DOT3)

21

-

10

Disassembly

/

Reassembly

3-----1

Disassembly

Procedure

1. Cap

2.

Bleeder

screw

3.

Clutch

damper

itA"

4. O-Ring

5.

Clutch

damper

bracket

...--..-

Scratches

f"J-V''-

Scratches

TFM0292

I

~-

-

----"I

TFM0373

Clutch

-

Clutch

Damper

~f---

k2

6.5

ft.lbs

9Nm

Inspection

Clutch

damper

5

6.5

ft.lbs

9Nm

TFM0392

(1) Check that there are no scratches

on

the parts

indicated

in

the illustration.

(2) Clean completely the inside of the clutch damper and

confirm that there is no foreign material left.

Clutch

damper

bracket

(1) Check that there are no scratches of cracks

on

the part indicated

in

the drawing.

Clutch

-

Clutch

Damper

21

-

11

Assembly

service

point

.A.

Installation

of

O-ring

(1) Apply the specified brake fluid onto the O-ring, and

securely install it onto the position of the clutch damper

indicated

in

the illustration.

Specified brake fluid:

SAE J1703 (DOT3)

22

MANUAL

TRANSMISSION

Su~~ary

......................................................................

22-2

Specifications

..............................................................

22-4

Maintenance

Standards

...........................................

22-5

Sealants

........................................................................

22-5

Lu

brication

...................................................................

22-6

Adjust."ent

Spacers

.................................................

22-7

Torque

Specifications

...............................................

22-8

Special

Tools

................................................................

22-9

Transn'1ission

..............................................................

22-13

Input

Shaft

................................................................

22-34

Intern'1ediate

Shaft

..................................................

22-40

3rd-4th

Gear

Synchronizers

5th-6th

Gear

Synchronizers

<

W6MG1

>.........

22-50

<

W6MG1

>..........

22-51

Center

Differential

...................................................

22-52

Front

Output

Shaft

.................................................

22-55

Rear

Cover

.................................................................

22-57

Front

Differential

......................................................

22-62

Speedon'1eter

Gear

....................................................

22-64

Transfer

Case

............................................................

22-65

22

- 2

Cross-section

W5MG1

Manual

Transmission

-

Summary

Manual

Transmission

-

Summary

Cross-section

WSMG1

22

- 3

22

- 4

Manual

Transmission

-

Specifications

Transmission

types

1991

Model

Vear

Transaxle model Ratio

set

W5MG1-0-FNBR A

1992

Model

Vear

Transaxle model Ratio

set

W5MG1-1-FNCR A

1993

Model

Vear

Transaxle model Ratio

set

W5MG1-2-FNCR A

1994

+

Model

Vear

Asian

Market

Transaxle model Ratio

set

W6MG1-0-GNCR B

Speedometer Final Drive

gear ratio

27/36 3.972

Speedometer Final Drive

gear ratio

27/36 3.972

Speedometer Final Drive

gear ratio

27/36 3.972

Speedometer Final Drive

gear ratio

28/36 4.155

1994

+

Model

Vear

North

American

Market

Transaxle model Ratio Speedometer Final Drive

set gear ratio

W6MG1-0-FNBR B 28/36 3.869

Gear

ratio

sets

A

1st Gear 3.071

2nd Gear 1.739

3rd Gear 1.103

4th Gear 0.823

5th Gear 0.659

6th Gear NA

Reverse 3.076

Transfer Case 0.814

Chassis Engine type

Z15A,Z16A

6G72-DOHC TIC

Chassis Engine type

Z15A,Z16A

6G72-DOHC TIC

Chassis Engine type

Z15A,Z16A

6G72-DOHC TIC

Chassis Engine type

Z15A,Z16A

6G72-DOHC TIC

Chassis Engine type

Z15A,Z16A

6G72-DOHC TIC

B

3.266

1.904

1.241

0.918

0.733

0.589

3.153

0.958

Manual

Transmission

-

Standards

and

Sealants

22

- 5

Maintenance

Standards

Item Standard Value

in

mm Model

Input shaft bearing end play 0.02 -0.05

--

Intermediate shaft preload 0.15 -0.25 W5MG1

0.20 -0.30 W6MG1

Center differential preload 0.10 -0.20 W5MG1

0.15 -0.20 W6MG1

Front output shaft preload 0.15 -0.25 W5MG1

0.10 -0.15 W6MG1

Front differential preload 0.15 -0.25 W5MG1

0.15 -0.20 W6MG1

Sealants

Item Type

Input shaft lock bolt

Rear cover to center case installation bolt

Stopper plate installation bolt

Center case to clutch housing installation bolt

Shift shaft to clutch housing installation bolt

Shift shaft guide bolt Loc-tite #242

Select lever installation bolt

Poppet cover installation bolt

Reverse idler gear shaft bolt

Reverse shift damper

Mating surface

of

rear cover and center case Loc-tite #17430

Mating surface

of

center case and clutch housing or

Mating surface

of

clutch housing and shift shaft Mitsubishi Geunine

Sealant MD997740

Mating surface

of

poppet cover and rear cover

This manual suits for next models

1

Table of contents

Popular Automobile Part manuals by other brands

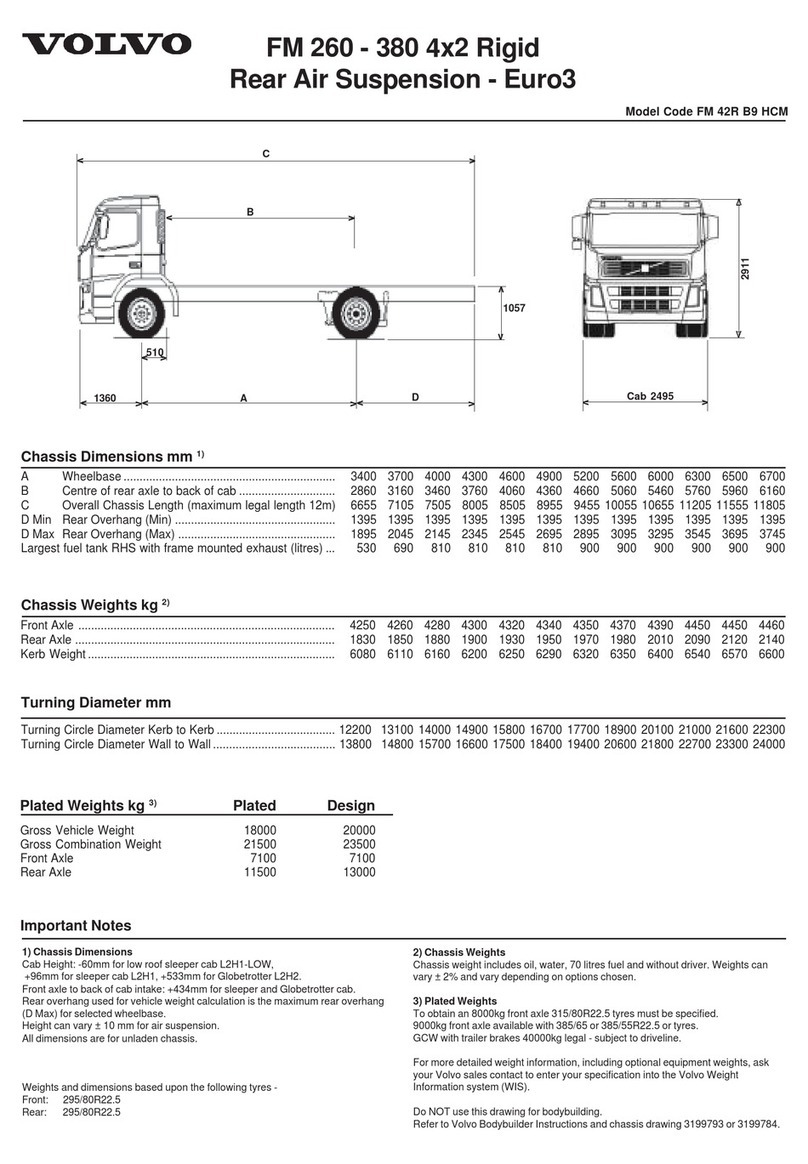

Volvo

Volvo FM 42R B9 HCM Specification sheet

Eibach

Eibach 2021.312 installation instructions

Edelbrock

Edelbrock 70003 installation manual

Edelbrock

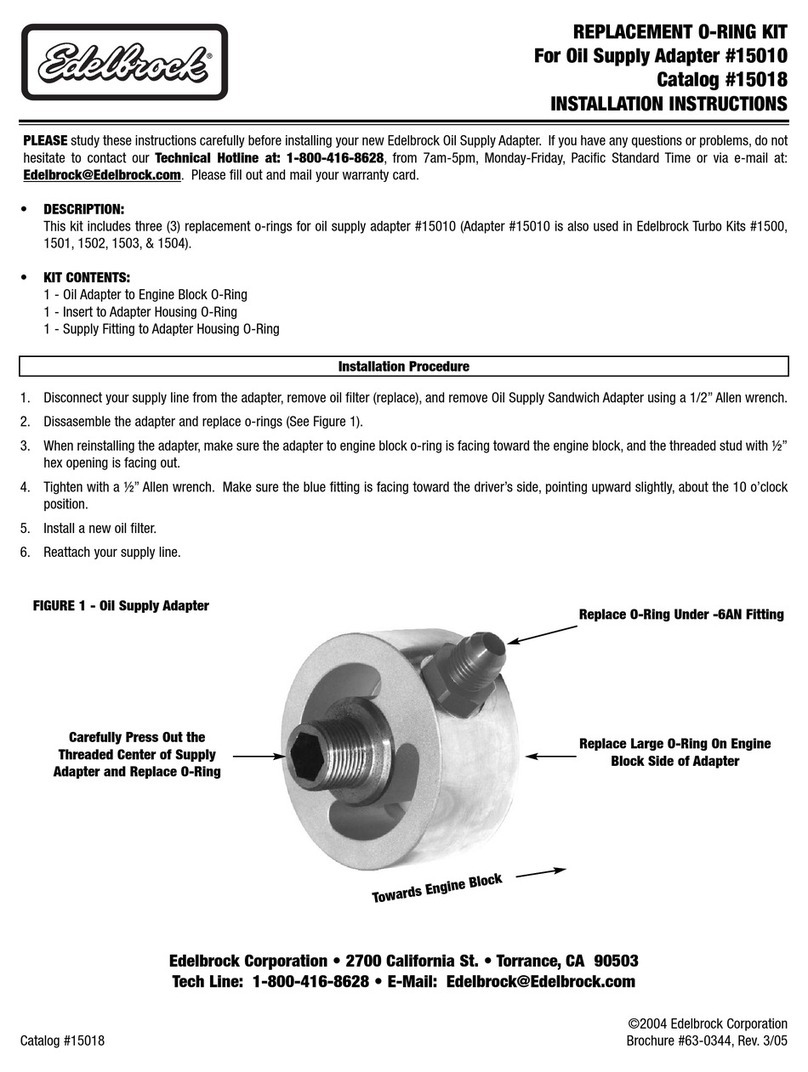

Edelbrock 15018 installation instructions

Edelbrock

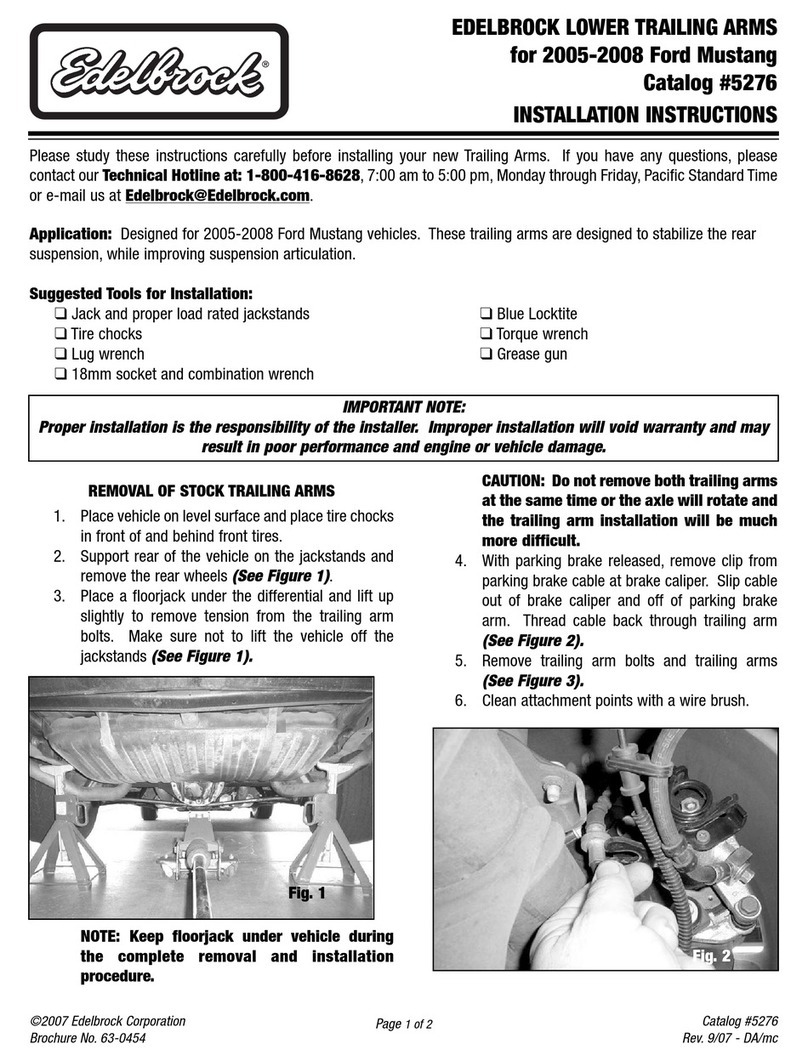

Edelbrock 5276 installation instructions

Lambo Doors Canada

Lambo Doors Canada Chevrolet Camaro 1993 instructions

Go Rhino

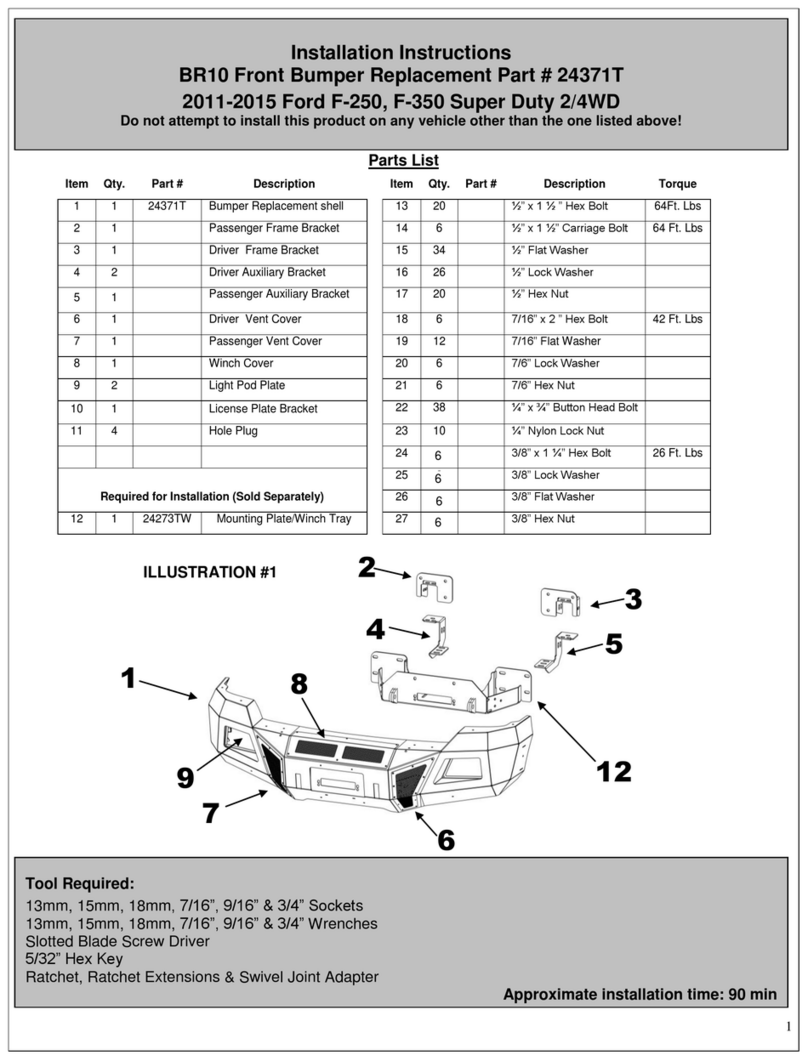

Go Rhino 24371T installation instructions

Edelbrock

Edelbrock 5266 installation instructions

Axxess

Axxess CHTO-013 installation instructions

Ingersoll-Rand

Ingersoll-Rand AUTOMOBILE PARTS LM2350E-X Operator's manual

Edelbrock

Edelbrock 61409 installation instructions

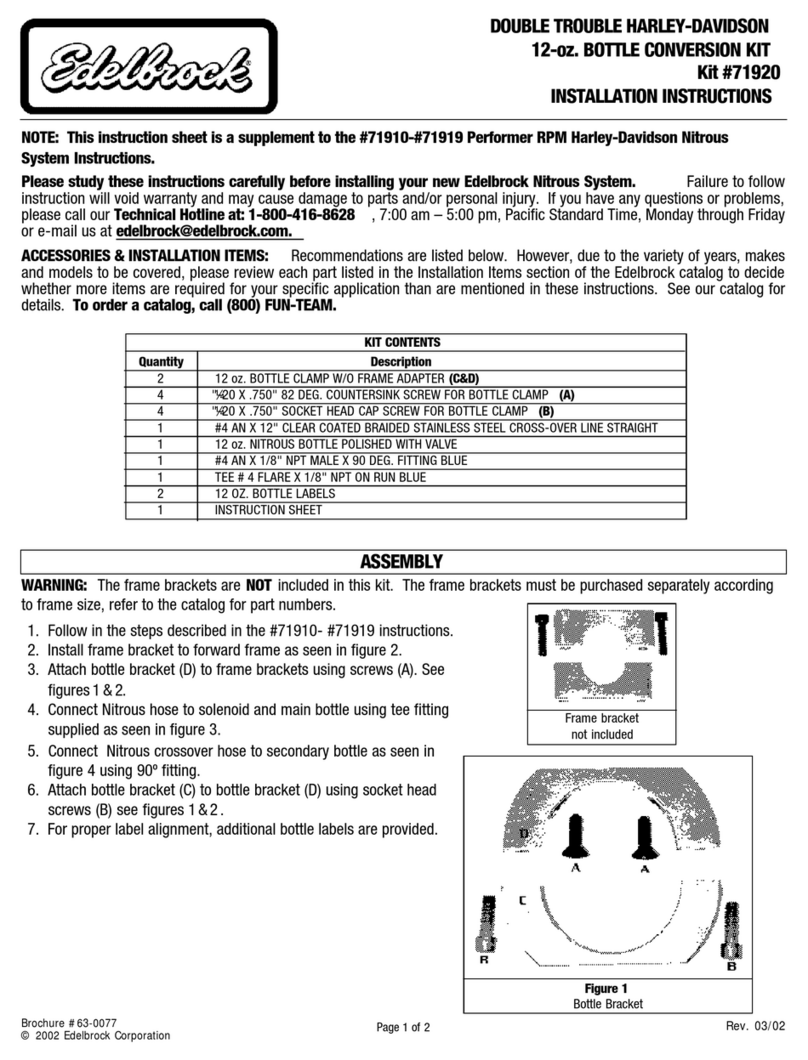

Edelbrock

Edelbrock 71920 installation instructions